TMB ProFan User manual

Revised: 24 August 2011

Operating Manual

ProFan Operating Manual

2

TABLE OF CONTENTS

1. BEFORE YOU BEGIN....................................................... 3

ProFan Overview 3

Unpacking Instructions 3

Exploded Views 4

2. SAFETY INSTRUCTIONS................................................. 5

3. MOUNTING....................................................................... 6

Mounting Options 6

Attaching the Yoke Assembly 7

Overhead Rigging 8

Support Stand 8

4. REMOTE CONTROL........................................................ 9

Basics of DMX Control 9

DMX Data Cable 9

Cable Connectors 10

DMX Termination 10

3-Pin to 5-Pin Conversion 11

5. OPERATING INSTRUCTIONS......................................... 12

Back Pack Overview 12

Connecting the Back Pack Controller 13

DMX Mode 15

Manual Mode 16

Master/Slave Operation 17

Using ProFan with a Smoke Machine 18

6. TROUBLESHOOTING AND MAINTENANCE................. 19

Troubleshooting 19

Replacing the Fuse 20

Cleaning 20

7. APPENDIX....................................................................... 21

Limited Warranty 21

Technical Specifications 22

Contact Information 23

ProFan Operating Manual

3

1. BEFORE YOU BEGIN

ProFan Overview

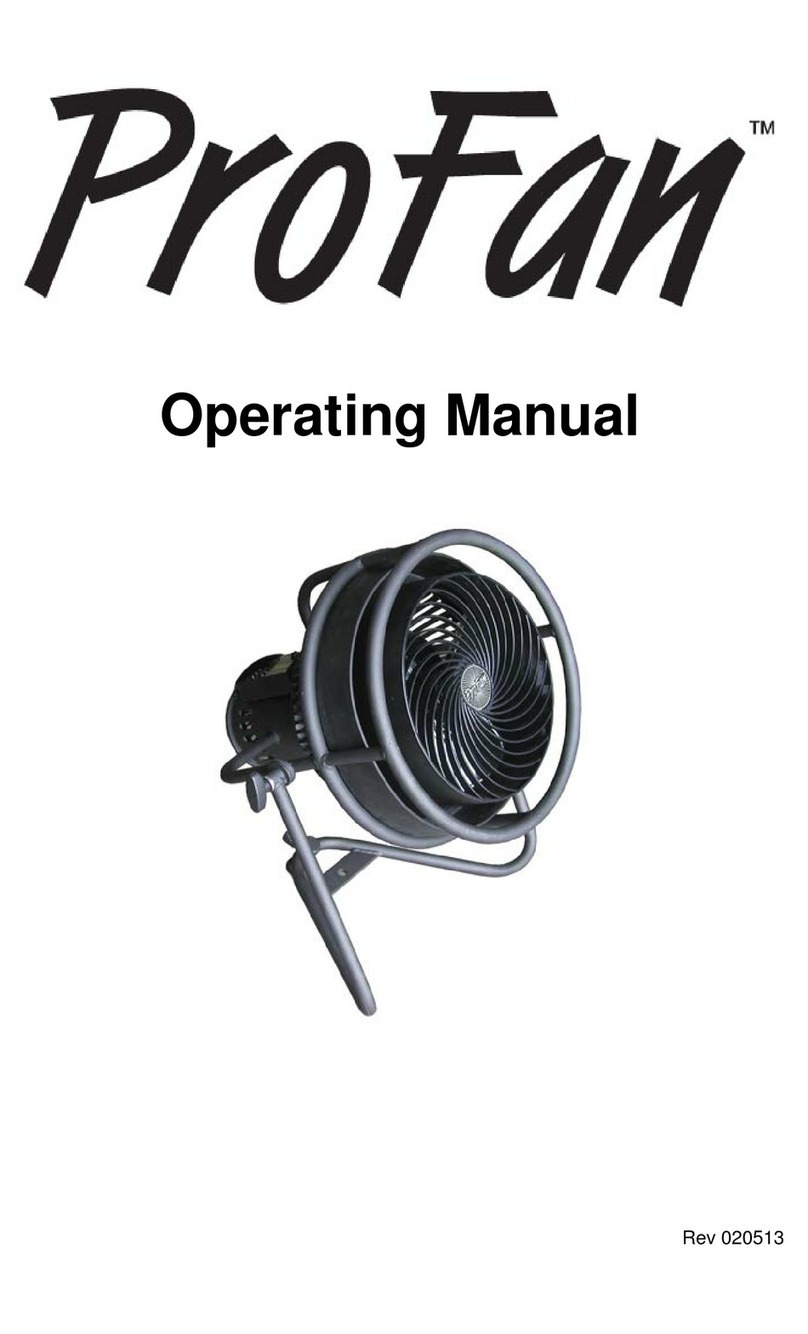

ProFan is a professional DMX-controlled fan capable of producing

high velocity air current. It can operate from 100 to 240VAC.

Multiple ProFans can also slave together to increase air flow or to

achieve complex flow patterns for special effects. The ProFan is

designed to mount upon a stand or (using ProBurger Accessory

clamps or couplers) suspend from a truss or other suitable support.

The external Back Pack controller allows DMX or manual control.

Manual control, using the onboard slide fader, adjusts fan speed

from zero to full.

The ProFan housing is molded lightweight polymer; the venting

area is protected with rugged tubular steel. The 11" one-piece

three-blade vane and spiral front grille creates a focused wind

effect.

ProFan applications range from general wind effects to blowing

smoke, haze, bubbles and confetti with programmable effect and

distance. Additionally, air circulation, ventilation and ambient

cooling can be equally controlled with repeatable characteristics

and effects.

Unpacking Instructions

Immediately upon receiving the fixture, carefully unpack the carton

and check the contents to ensure that all parts are present (see

exploded view) and have been received in good condition. Notify

the shipper immediately and retain packing material for inspection

if any parts appear damaged from shipping or the carton itself

shows signs of mishandling.

ProFan Operating Manual

4

Back Pack Controller

Power

Supply

Motor

Grille

Body

Yoke

Back Panel Detail

Knob

Blade

Knob

ProFan Operating Manual

5

2. SAFETY INSTRUCTIONS

Preventing Fire and Electric Shock

Always ground (earth) the machine electrically.

ProFan has a built-in speed control. Do not connect ProFan to

any external solid-state speed control device or dimmer circuit.

Disconnect the machine from power before removing any

components or servicing, and when not in use.

Moisture can cause dangerous electrical faults. Do not aim fog

output at electrical connections or devices.

Do not expose this machine to excess moisture. ProFan is

NOT waterproof.

Do not spill fluid over the machine. In the event of a fluid spill,

disconnect the machine from power and clean with a damp

cloth. If fluid is spilled onto electrical components, contact TMB.

Do not dismantle or attempt to repair a faulty machine. Refer

all service to TMB.

Do not operate the machine if the power cable or connector is

damaged. A damaged cable or connector must be replaced

with a new item, available from TMB.

Do not operate the machine with damaged, deformed or

missing parts.

Preventing Injuries

Never allow any object or part of the body to enter the path of

the fan blades. Ensure that clothing, cables or other items

cannot be sucked into the fan.

Disconnect power before removing cover or grille. Do not

operate unless all covers and grilles are installed and securely

fastened.

ProFan is designed to be used by professionals,

and is NOT intended for household use. Improper

use can cause severe injury due to electrical or

mechanical hazards.

ProFan Operating Manual

6

Ensure that any supporting structure or surface can hold at

least 10 times the weight of all installed devices.

Use approved secondary attachment when possible, such as a

safety cable.

3. MOUNTING

Mounting Options

ProFan may be suspended, mounted on a suitable stand, or stood

alone on its own steel yoke.

As delivered, the ProFan is ready for stand alone use. Included

with the ProFan is a yoke assembly for mating the unit to a floor

stand or suspension clamp. The yoke assembly easily attaches to

the ProFan using the provided fasteners and wrench.

A1 Small head, short

shank, T-Handle Knob

B1 Large Head, long

shank, T-Handle Knob

B2 Thrust Washer

B3

B4 Flat Washer

B5 Aluminum Bushing

C1 Allen Bolt

C2 Split Washer

C3 Allen Wrench

B1 A1 C1

C2

C3

B2 B3 B4

B5

ProFan Operating Manual

7

Attaching the Yoke Assembly

1. Place the ProFan face down upon its front grille with the hinge

barrel side on the left and the hinge flat side on the right.

2. Place Item B3 flat washer upon the shank of Item B1 T-Handle,

followed by Item B2 thrust washer and Item B4 flat washer.

3. Place the yoke bracket into position. Insert the shank of Item

B1 T-Handle through the flat face hinge until the shank just

protrudes from the flat face.

4. Insert Item B5 aluminum bushing between the ProFan

housing’s tubular bracket and the yoke assembly hinge’s flat

face.

5. Rotate the T-Handle clockwise until the T-Handle has

threaded into the ProFan tubular housing bracket. Do not

tighten completely at this point.

6. Place Item C2 split washer onto Item C1 Allen bolt. Place the

Allen bolt through the barrel portion of the ProFan hinge and

rotate the bolt until it threads into place.

7. Tighten the Allen bolt and the T-Handle until the yoke

assembly is fixed and not easily moved.

8. At this point the ProFan is ready for mating with a stand or

clamp. Grip the fan by its tubular housing brackets when lifting

or mounting to avoid pinching hands or fingers.

B1

A1

C1

C2 B2

B3

B4

B5

ProFan Operating Manual

8

Overhead Rigging

Recommended ProBurger rigging clamps:

1. PRBHC3/8 or PRBHC1/2 Half Couplers

2. PRBSNC1/2 Snap Coupler.

It is recommended that any structure used to support the unit can

support at least 10 times the total weight of all installed fixtures,

clamps, auxiliary equipment, etc.

1. Check that all rigging clamps are undamaged and can support

at least 10 times the weight of the unit.

2. Clamp the fan to truss or similar support.

3. Loosen the swivel locks and tilt the fan to the desired angle.

Turn the swivel locks clockwise to tighten. Make sure that fan,

hardware, and safety attachment are secure before applying

power.

Support Stand

A professional stand, rated to support a weight greater than the

unit, must be used to support the ProFan. TMB ProStands,

supplied with a PRXTVMP adapter, provide a reliable floor-

standing solution

ProFan Operating Manual

9

4. REMOTE CONTROL

Basics of DMX Control

There are 512 channels in a DMX-512 connection. Channels may

be assigned in any manner. A fixture capable of receiving DMX-

512 will require one or a number of sequential channels. The user

must assign a starting address on the fixture that indicates the first

channel reserved in the lighting console. There are many different

types of DMX controllable fixtures and they all may vary in the

total number of channels required. Choosing a start address

should be planned in advance. Channels should never overlap. If

they do, this will result in erratic operation of the fixtures whose

starting addresses are set incorrectly. You can however, control

multiple fixtures of the same type using the same starting address

as long as the intended result is that of unison movement or

operation. In other words, the fixtures will be slaved together and

all will respond in the same way.

DMX fixtures are often designed to receive and transmit data

through a DMX daisy-chain. A DMX daisy-chain is where the DMX

THRU of one fixture connects to the DMX IN of the next fixture.

The order in which the fixtures are connected is not important and

has no effect on how a lighting console communicates to each

fixture. Use an order that provides for the easiest and most direct

cabling. Connect fixtures using shielded two-conductor twisted

pair cable with 5-pin XLR male to female connectors. The

shield/ground is pin 1, while pin 2 is Data Negative (D-) and pin 3

is Data positive (D+). Pins 4 and 5 are not used according to the

DMX-512 standard.

DMX Data Cable

Use a ProPlex®PC222P, PC224P, or equivalent cable which

meets the specifications for EIA RS-485 applications. Standard

microphone cables cannot transmit DMX data reliably over long

distances. The cable should have the following characteristics:

ProFan Operating Manual

10

Minimum 2-conductor twisted pair plus a shield

Maximum capacitance between conductors – 22 pF/ft.

Maximum capacitance between conductor and shield – 41 pF/ft.

Maximum resistance of 14.5 ohms / 1000 ft.

Characteristic impedance of 80 – 110 ohms

Cable Connectors

Cabling must have a male XLR connector on one end and a

female XLR connector on the other end.

DMX connector configuration

The maximum recommended DMX data link distance between

fixtures is 300 meters (984 ft.)

DMX Termination

Use of a DMX terminator is strongly recommended for the last

fixture in a DMX chain. Comprised of a 120Ωresistor across XLR

pins 2 and 3, a terminator prevents electrical reflections from

traveling back down the signal chain and corrupting the DMX data

stream. External XLR terminators such as the ProPlex “Arnold”

are available for such use.

ProFan Operating Manual

11

CAUTION: Another consideration to prevent the corruption

of DMX data is to not allow contact between the common (pin

1) of a DMX cable and the fixture’s chassis ground.

Grounding the common can cause a ground loop, and your

fixture may perform erratically.

Test cables and terminators with a continuity tester to verify

correct polarity and to make sure the pins are not grounded

or shorted to the shield or each other.

3-Pin to 5-Pin Conversion Chart

If you use a console with a 3-pin DMX output connector, you will

need to use a 3-pin to 5-pin adapter. The chart below details a

proper conversion:

3-Pin Male

(Input) 5-Pin Male

(Output) Purpose

Pin 1 Pin 1 Ground / Shield

Pin 2 Pin 2 Data ( - ) signal

Pin 3 Pin 3 Data ( + ) signal

Pin 4 Not Used

Pin 5 Not Used

ProFan Operating Manual

12

5. OPERATING INSTRUCTIONS

Back Pack Overview

XLR 3-pin male

connector to ProFan DMX/MANUAL

Mode switch LCD Display

Button:

1. Hold down and slide

fader to set DMX

address in DMX

Mode

2. Press to bump to full

speed in Manual

Mode

Slide Fader Control:

1. Fan Speed Control in

Manual Mode

2. DMX Address Setting in

DMX Mode

DMX512 input &

output XLR 5-pin

connectors

Input Output

ProFan Operating Manual

13

Connecting the Back Pack Controller

With rear fan power switch in OFF position:

Connect the integral male XLR on the Back Pack directly to the

integral female XLR on the fan body. If desired, the Back Pack

can be removed and connected using a standard 3-pin XLR

microphone cable up to 60 ft / 20 m in length.

Attaching the Back Pack to the Fan Housing

The Back Pack is secured to the fan housing by: 1) two snap-in

clips; 2) an internal magnet; 3) the XLR connection.

Prior to connecting the Back Pack to the integral female XLR on

the fan body, notice that two flat slots exist on the top and bottom

of the Back Pack housing. These flat slots mate with the mounting

bracket fixed to the top of the fan housing.

ProFan Operating Manual

14

Place the Back Pack with the sliding fader to the left. Push the

Back Pack forward to mate with the integral female XLR while

gently pressing the Back Pack against the fan body. While

inserting the Back Pack onto the integral female XLR, ensure it

aligns with the slot in top face of the Back Pack. Once fully

connected to the integral female XLR, the bottom edge of the

mounting bracket will snap into place fixing the bottom of the Back

Pack by locating into the bottom housing slot.

CAUTION: Double-check that the Back Pack is securely fixed

to the fan housing prior to use.

Note: Ensure the ProFan is pointed in a direction where

considerable wind will not cause a disturbance or any safety

issues.

Turn ProFan on using rear Power switch.

ProFan Operating Manual

15

DMX Mode

When the recessed switch on the Back Pack is switched to "DMX",

the display will indicate that the unit is in DMX Mode and will

display the current address of the ProFan. If no incoming DMX

signal is detected, the display will then read "No DMX Found".

To change the address of the unit, press and hold the Full Speed

button while adjusting the fader. With the fader moved all the way

up, the address will change to 512. With the fader moved all the

way down, the address will change to 1. Anywhere in between will

change the address proportionally between those values. To store

the new address, simply release the button.

ProFan Operating Manual

16

Manual Mode

When the recessed switch on the Back Pack is switched to

"MANUAL", the display will indicate that the unit is in Manual

Mode. The display will also indicate the current speed of the fan,

based on the position of the fader and whether the Full Speed

button is depressed.

In this mode, a Back Pack controller also acts as a master

controller for up to nine ProFans slaved to it via the DMX OUT

connector. See Master/Slave Operation for details.

ProFan Operating Manual

17

Master/Slave Operation

Up to nine ProFans can be locally controlled by one Back Pack

using a DMX data link. To link multiple ProFans, use 5-pin XLR

DMX cables between each pair of fans, as well as female and

male ProPlex "Arnold" DMX terminators on the first and last

ProFans in the chain respectively. Arnolds are wired per the ESTA

DMX512A specification and are available pre-wired from TMB.

Connect each controller to each fan via the XLR 3-pin line female

connector. Connect the 5-pin female Arnold to the 5-pin XLR male

connector on the "master" (i.e. first) ProFan Back Back controller.

Use 5-pin XLR cables to connect the master ProFan output to the

next "slave" ProFan input. Continue connecting ProFans output to

input as needed, up to nine units total. Connect the 5-pin male

DMX terminator to the DMX output of the last ProFan in the chain

Set the mode switch of the master controller to "MANUAL", and

set all the slave controllers to "DMX" at address 001.

ProFan Operating Manual

18

Using ProFan with a Smoke Machine

When using ProFan with smoke, fog or hazer machines, place the

fan behind the machines as illustrated below. Do not place the fan

in front of the machine. This will cause residue build-up on the fan

blades and degrade the quality of the smoke, fog, or haze.

.

Correct ProFan placement

behind or to the side of

fogger/hazer

Incorrect ProFan placement

in front of fogger/hazer

ProFan Operating Manual

19

6. TROUBLESHOOTING AND MAINTENANCE

Troubleshooting

Problem Symptom/Cause Suggested Remedy

Display says "No

DMX Found" Connect DMX

Incorrect DMX

address

Press button and move

fader until correct

address appears

Power is

supplied, but fan

does not operate

via DMX

In Manual Mode Switch control switch to

DMX mode

No Power Check power supply and

connection

Fuse blown Replace fuse with one of

same type and rating

Back Pack

display is blank

Back Pack not

connected Check connection

Reduced airflow Low voltage supply Check AC supply

ProFan Operating Manual

20

Cleaning

Clean the outside of the fan with a damp cloth only. Do not use

solvents. Periodic cleaning of the fan blades and grilles is

necessary to maintain peak performance. Cleaning frequency

depends on the operating environment. Inspect the fan regularly

for dust and smoke residue buildup. Clean as soon as there is

significant dirt buildup on fan blades or if airflow through grilles

becomes restricted. Use a soft brush and vacuum to clean grilles

and fan blades.

Cleaning Steps:

1. Disconnect power

2. Remove the screws to clean the housing and blades

3. After cleaning, make sure that screws are securely tightened

Replacing the Fuse

The fuse can be replaced if necessary.

1. Turn the fuse knob counter-clockwise

2. Replace fuse

3. Turn fuse knob clockwise

Other manuals for ProFan

1

Table of contents

Other TMB Fan manuals