TMB ProFan User manual

Other manuals for ProFan

1

Table of contents

Other TMB Fan manuals

Popular Fan manuals by other brands

Hunter

Hunter 21322 owner's manual

cecotec

cecotec ENERGYSILENCE 600 WOODDESK instruction manual

Trox Technik

Trox Technik UL series installation manual

NuAire

NuAire Genie Plus GPE-100 Series Installation and Maintenance

S&P

S&P CK-25 Series manual

Xpelair

Xpelair XIL100 Installation and operaing instructions

NuAire

NuAire MRXBOXAB-ECO2-1ZSW installation manual

Hyundai

Hyundai H-SF16-F1602 instruction manual

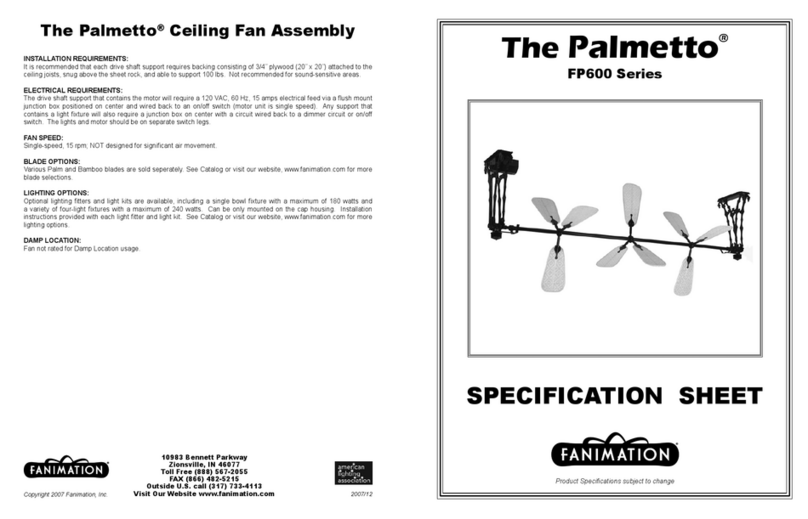

Fanimation

Fanimation Palmetto FP600 Series Specification sheet

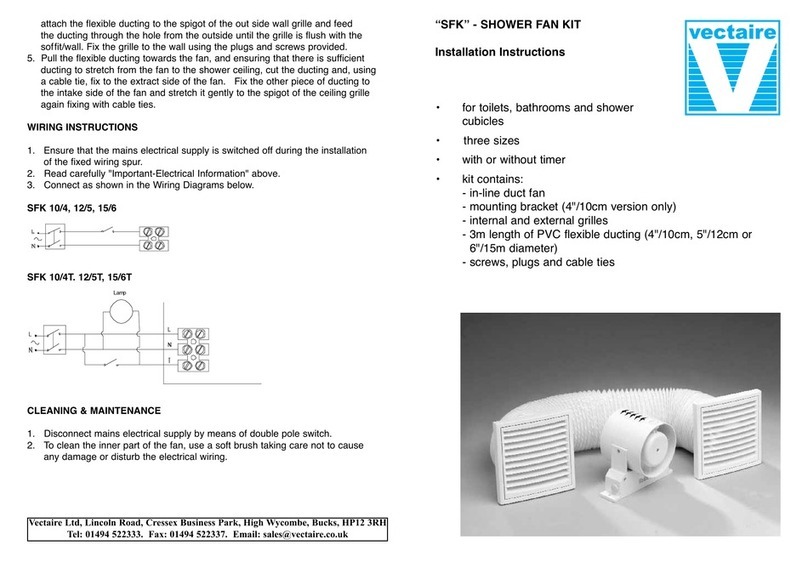

Vectaire

Vectaire eSmile Installation and operating instruction

Vectaire

Vectaire SFK10/4 installation instructions

Bionaire

Bionaire BSF1613MW instruction manual

NuAire

NuAire Ecosmart ESTCP Installation and Maintenance

LUCCI Air

LUCCI Air OSPREY 216170 Installation operation & maintenance

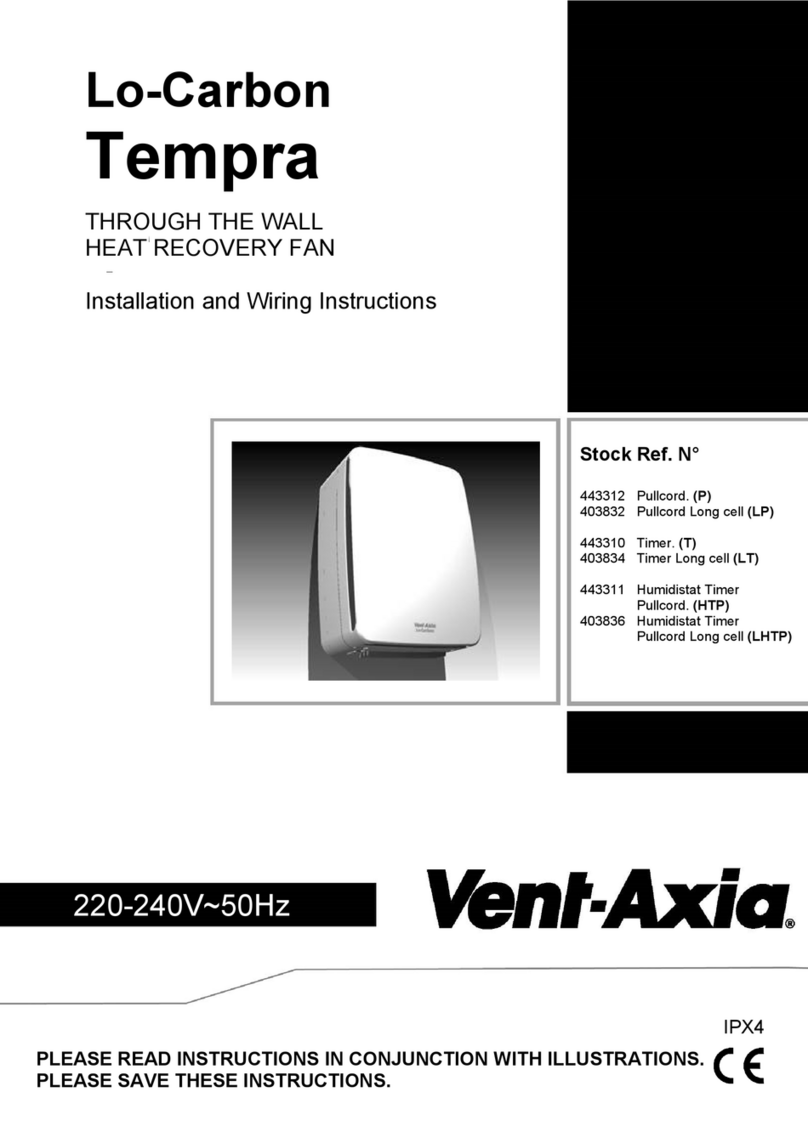

Vent-Axia

Vent-Axia Lo-Carbon Tempra P Installation and wiring instructions

Hunter

Hunter 20531 Owner's guide and installation manual

Radic8

Radic8 VK Link manual

Dyson

Dyson AM 08 operating manual