EQUIPMENT PROTECTION QUICK FACTS...............................................................................2

TABLE OF CONTENTS................................................................................................................3

ABOUT YOUR AIR COMPRESSOR.............................................................................................5

SPECIFICATIONS.........................................................................................................................6

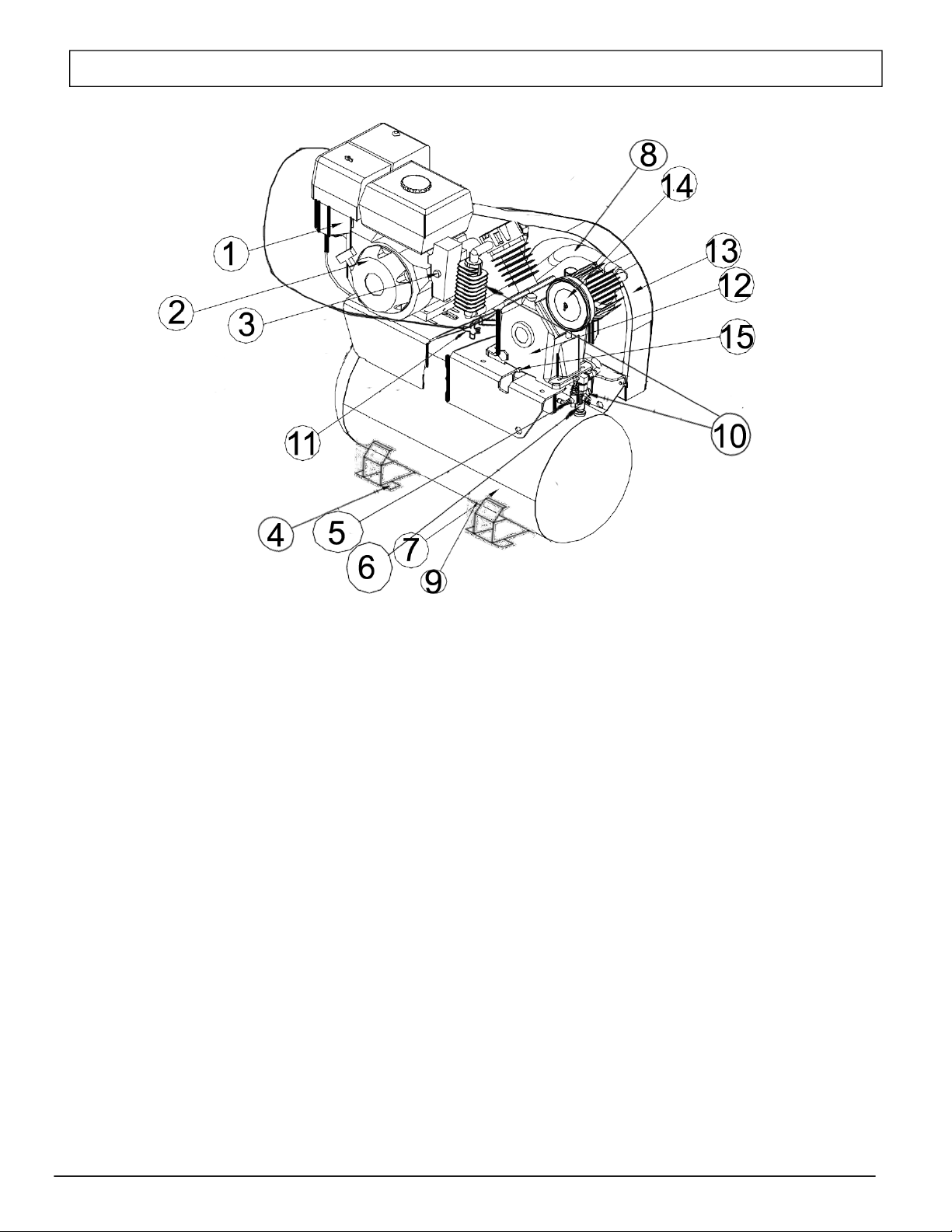

COMPONENT IDENTIFICATION..................................................................................................7

SAFETY.........................................................................................................................................8

Hazard Signal Word Definitions........................................................................................................8

SAFETY LABELING......................................................................................................................9

Safety Decal Locations.....................................................................................................................9

Safety Decals..............................................................................................................................................10

INITIAL SET-UP...........................................................................................................................11

Step 1. Inspect & Unpack....................................................................................................................11

Step 2. Select Suitable Location.........................................................................................................11

Outdoor Use Only...........................................................................................................................11

Step 3. Mounting..................................................................................................................................12

Mounting on Service Vehicle..........................................................................................................12

Installing Discharge Piping..............................................................................................................12

Step 4. Electrical Starting: Battery Procedure..................................................................................12

Battery Connection.........................................................................................................................12

Battery Disconnection.....................................................................................................................13

Install Spark Arrestor(if Required)...................................................................................................13

OPERATION................................................................................................................................14

Follow Safety Rules for Operation.....................................................................................................14

Preparing for Operation.......................................................................................................................14

Check/Add Oil to the Engine and Pump..........................................................................................14

Check and Fill Gasoline Tank.........................................................................................................15

Inspect Fuel System/Check for Leaks.............................................................................................15

Start-Up Procedures............................................................................................................................15

Air Hose and Tool Use.........................................................................................................................16

Attaching Air Hose and Tools.........................................................................................................16

Using Compressor for Spraying.........................................................................................................17

Moisture in Compressed Air............................................................................................................17

Shutdown Procedures.........................................................................................................................17

STORAGE....................................................................................................................................18

Between-Use Storage..........................................................................................................................18

WWW.TMGINDUSTRIAL.COM P03/27 Toll Free:1-877-761-2819