8. Care after use

•Never leave or store the lever hoist with the brake system locked. Loosen the brake system by operating the lever hoist as if

lowering a load.

•Always service and repair the lever hoist after use. Thoroughly clean the dust or if used in the rain, wipe off the dirt and

moisture. Lubricate all moving parts of the hoist after use, especially the load chain, to prevent rust.

•Inspect the hooks and load chain for bends and any other type of defects. Also check to see if the hooks freely rotate. If any

defect is found, replace the defective component before using the lever hoist again.

1. INSPECTION PRECAUTIONS

• All new, altered or modified equipment should be inspected and tested by personnel trained in the safety, operation and

maintenance of this equipment to ensure safe operation at rated specifications before placing equipment in service.

• Frequent and Periodic inspections should be performed on equipment in regular service.

• Frequent inspections are visual examinations performed by operators or service personnel and include observations made

during routine equipment operation.

• Periodic inspections are thorough inspections conducted by personnel trained in the safety, operation and maintenance of

this equipment.

• ASME B30.21 states inspection intervals depend up the nature of the critical components of the equipment and severity of

usage.

• Deficiencies revealed through inspection or operation must be reported to designated personnel trained in safety, operation

and maintenance of this equipment. Any corrective action must be completed and documented by written report before

placing the equipment in service.

2. RECORDS AND REPORTS

• Inspection records should be maintained for all load bearing equipment requiring periodic inspection.

• Written reports should be made on the condition of the critical parts as a method of documenting periodic inspection.

These reports should be dated, signed by the person who performed the inspection, and kept on file where they are readily

available for review.

3. FREQUENT INSPECTION

• The Manual Lever Hoist should be inspected at the beginning of each shift. Visual inspections should also be conducted

during regular service for any damage or evidence of malfunction which appears between regular inspections.

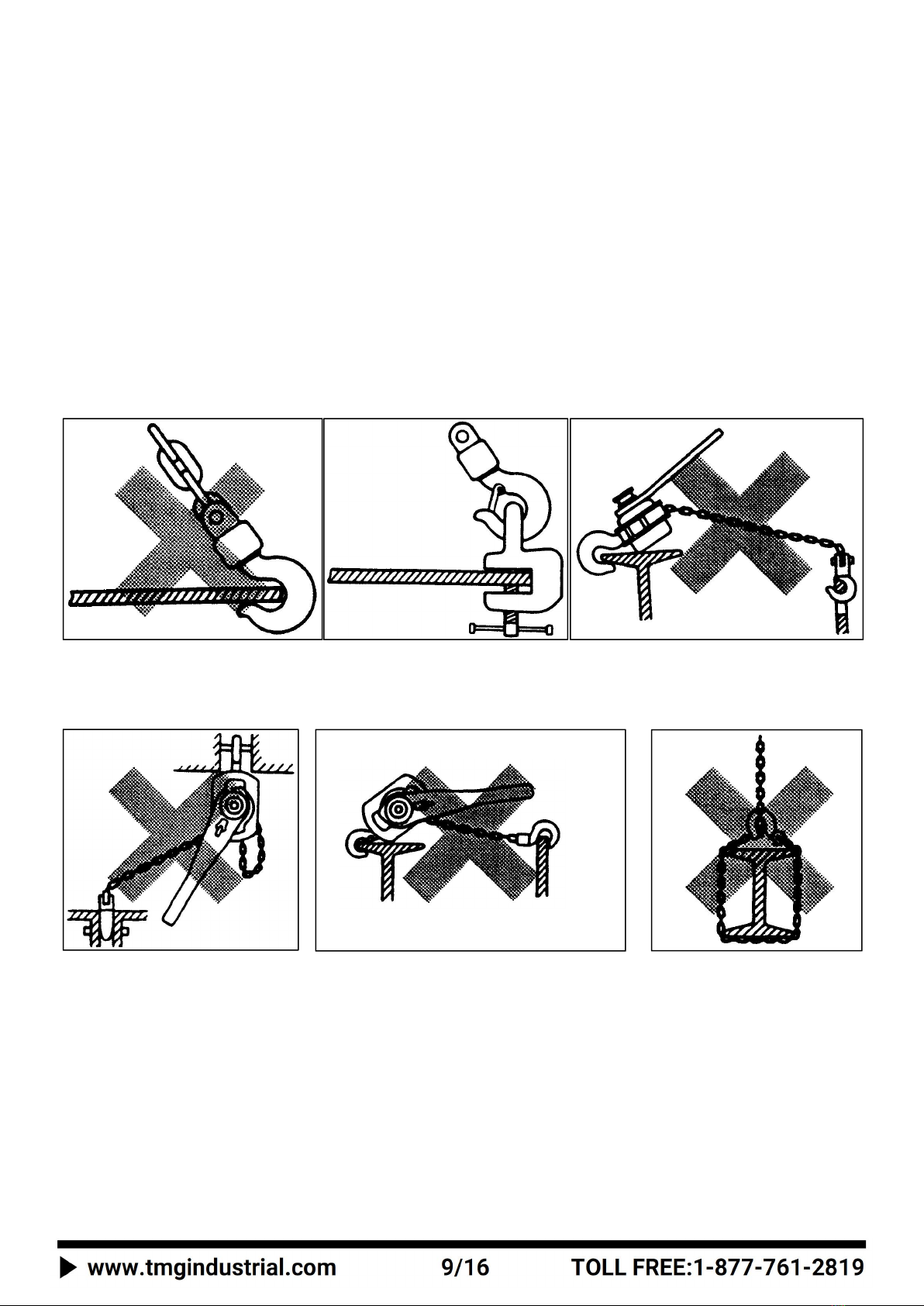

»»OPERATION: Check for visual signs or abnormal noises which could indicate a potential problem. Do not operate a hoist

unless the chain feeds through the hoist and hook block smoothly. If the chain binds, jumps or is excessively noisy, clean

and lubricate the chain. Do not operate the hoist until all problems have been corrected. The bottom hook should stop

moving when the hand chain stops moving.

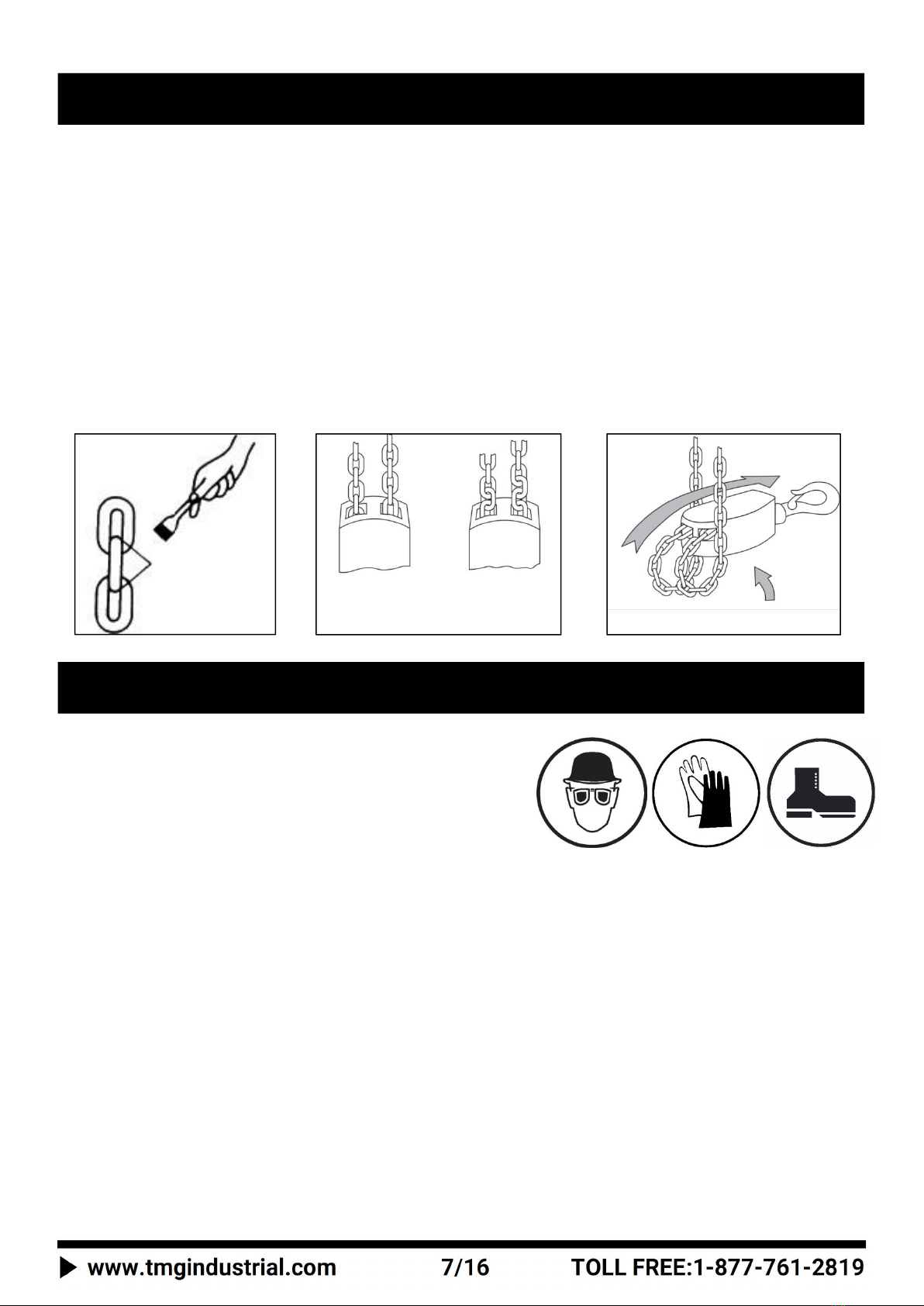

»»HOOKS: Check for wear and damage monthly. This includes: cracks, twists, latch engagement and latch operation (See

Figure 12). Replace hooks that exceed the throat opening discard width. If the hook latch snaps past the tip of the hook, the

hook has been overloaded and must be replaced. Check the hook support bearings for lubrication and damage. Check that

hooks swivel easily and smoothly. Repair or lubricate as needed.

»»HOOK LATCHES: Check operation of hook latches. Replace if broken or missing. Ensure they catch the tip of hook.

»»CHAIN: Examine each link for bending, cracks in weld areas or shoulders, transverse nicks and gouges, weld spatter,

corrosion pits, striation (minute parallel lines) and chain wear, including bearing surfaces between chain links (See Figure 13).

Replace a chain that fails any of these inspections. Check lubrication and lubricate if necessary.

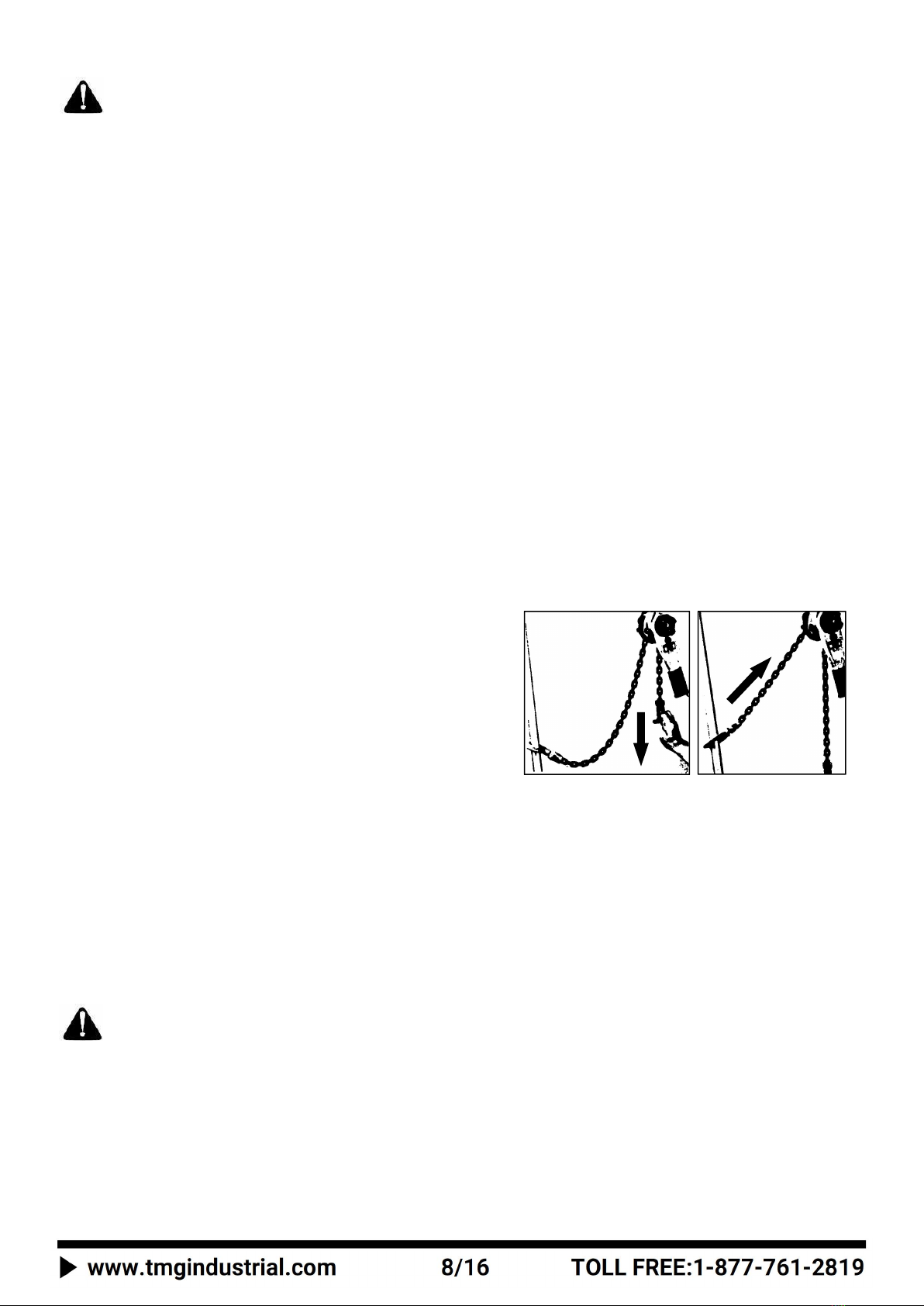

»»LOAD CHAIN REEVING: Make sure welds on standing links are away from the load sheave. Reinstall chain if necessary (See

Figure 14). Make sure chain is not capsized, twisted or kinked (See Figure 2 & 3). Adjust as required.

»» HAND LEVER: Check for cracks, bending and other damage. Replace if necessary.