6

IV. INSTALLATION

1. UNPACKING INFORMATION

After removing the trolley from the shipping carton/crate, carefully inspect the external

condition of the cord, electric housing, gear reducer, motor for damage that may have

occurred during shipment and handling. Check to make sure all parts are furnished. i.e. trolley

side frame with electric housing, side frame with reducing gear motor, position tube, spacer

washer, stay-bolts, nuts and load plate for hoist top hook. Also, before attempting to install

the trolley, make sure that the power supply indicated on the labels attached to the motor

housing is the same as the power supply on which the unit is to operate.

Generally, the hoist and trolley are packed separately. Except when the order indicates the

requirement of 4-way control for the hoist with trolley, then the hoist will be packed with

trolley together in one wooden crate.

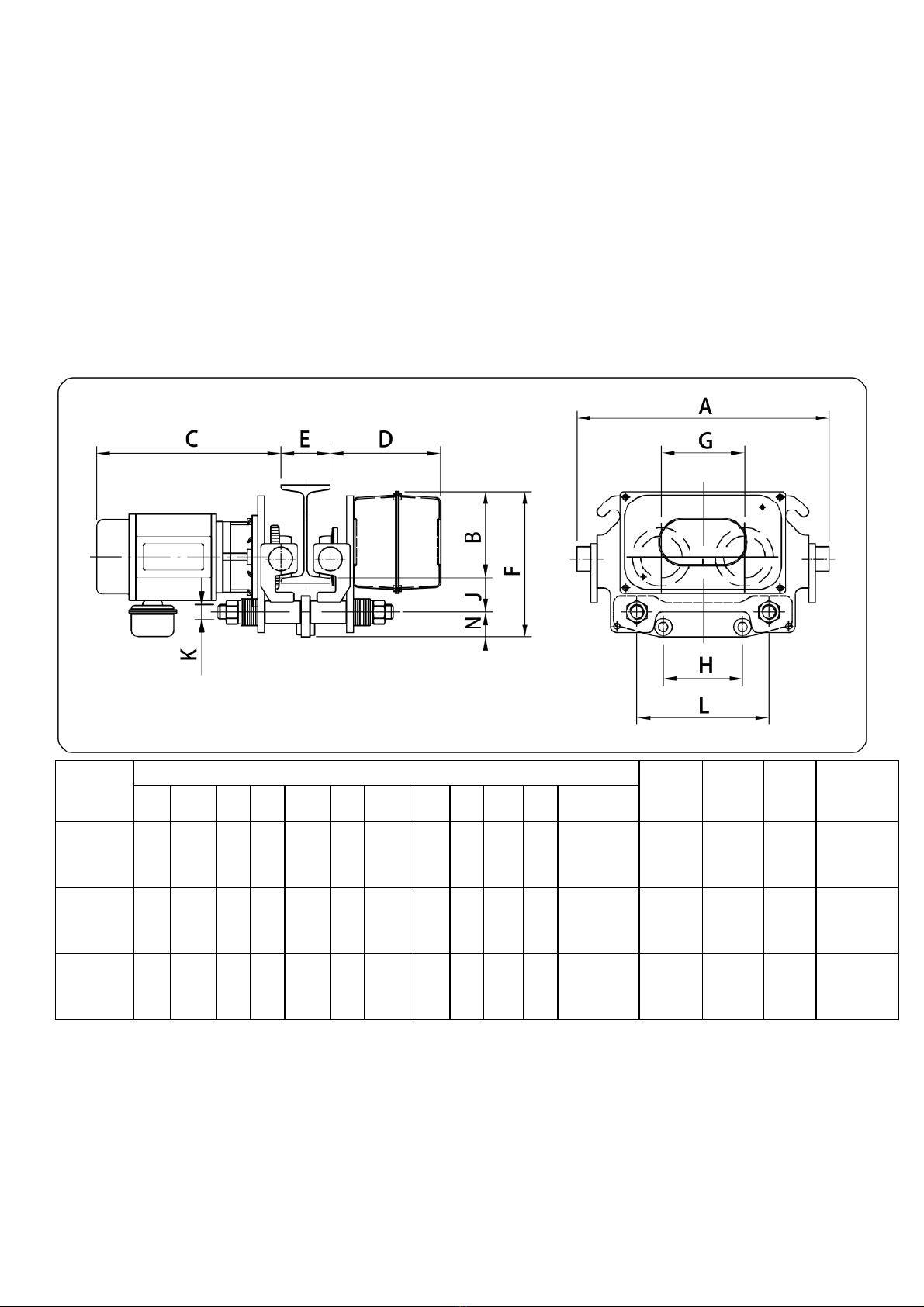

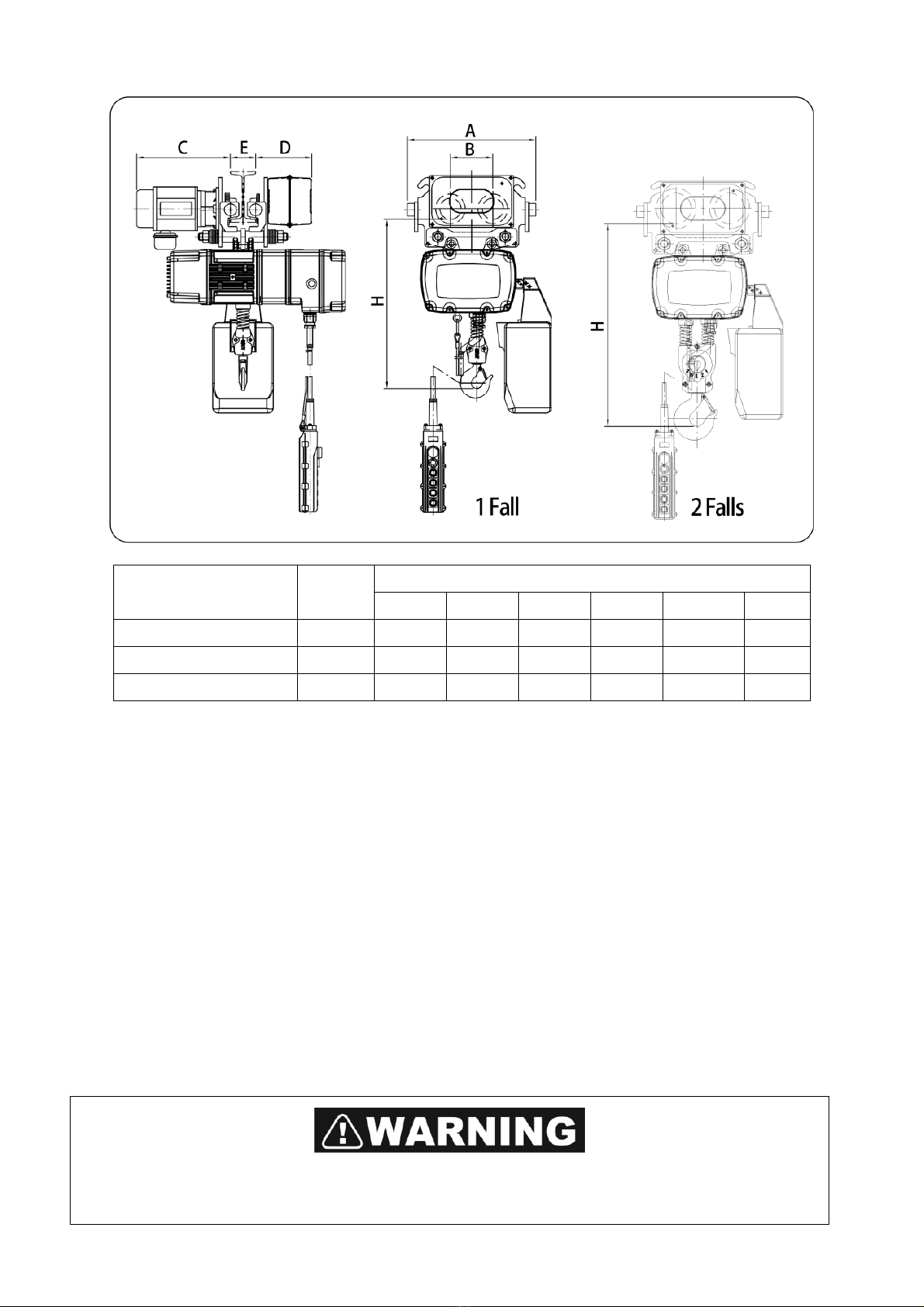

2. TROLLEY TO BEAM

It is recommended that the trolley be mounted on the beam prior to attaching the hoist to

the trolley. Before attempting to mount the trolley on the beam, measure the actual width of

the beam flange on which the trolley is to operate. Using this measurement determine the

arrangement of spacer washers between the two trolley side frames. First loosely assemble

the side frames, position tubes, spacer washers and nuts on the stay bolts.

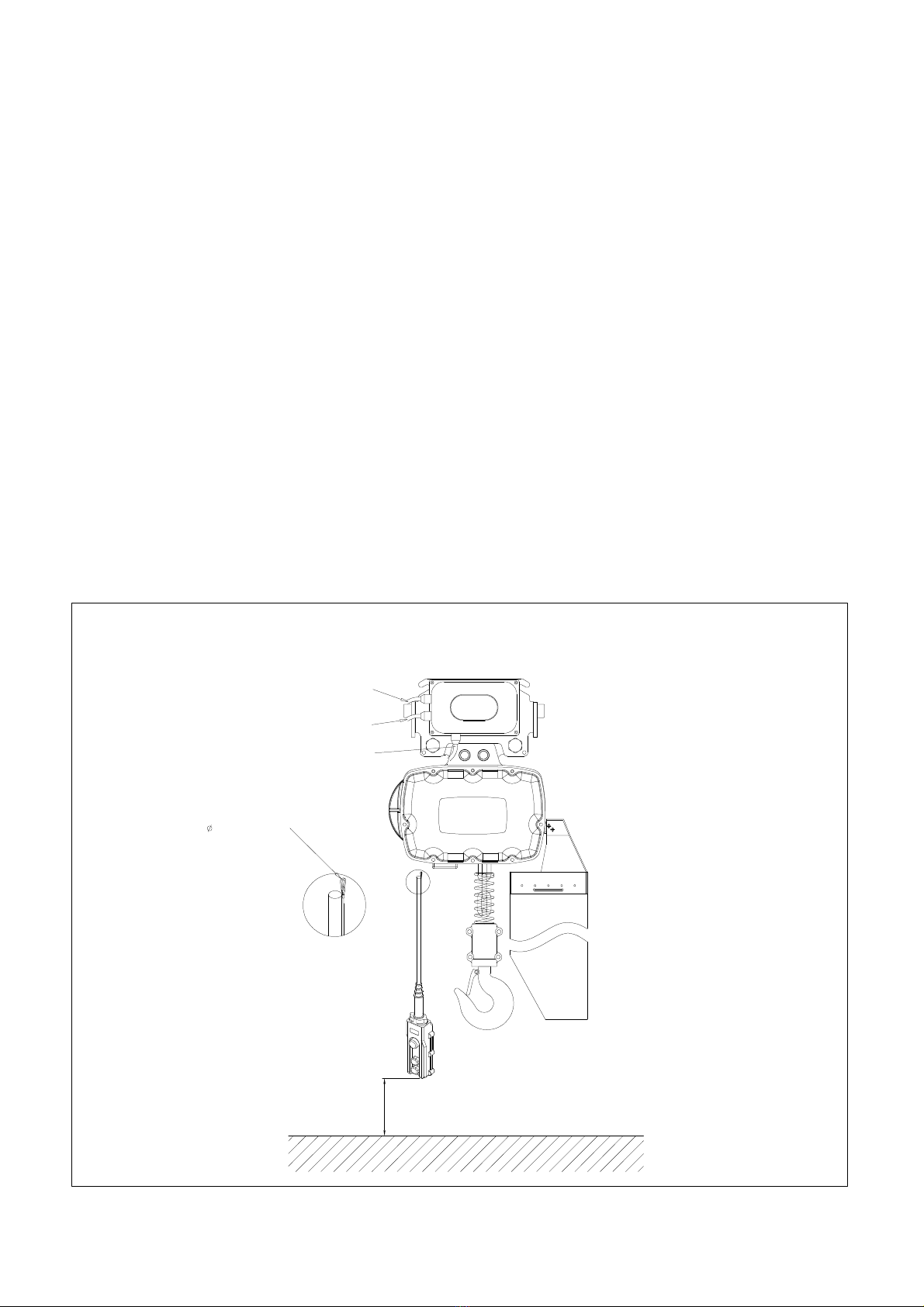

For all trolley suspended hoist rail stops must be installed at each end of

the rail. Failure to install rail stops will allow the hoist and trolley to fall off

the end of the rail and thus cause an accident that may result in injury

and/or property damage. The stops must be positioned as to not exert

impact force on the hoist frame or trolley wheels. They must contact the

ends of the trolley side frames.

The trolley and beam should be inspected periodically to assure their

continued operations. Operating a malfunctioning trolley and/or operation

the trolley on a beam with an excessively worn flange may allow the trolley

to fall from the beam causing an accident that may result in injury and/or

property damage.