TOC AVIATION 35% Yak 54 User manual

TOC AVIATION

35% Yak 54

W;’’’kllingspWingspaFlying Weight: 30lbs

Specification:

Wingspan :107”

Length: 95”

Flying weight:30 lbs

Wing area: 2223 sq. inches

Engine: 100 gas engine

1. Servo installation:

Locate the servo bay holes and cut the

covering back. Take your covering iron

and tack the covering around the edges.

2. Servo installation:

Use the fishing line to feed your servo

lead through the wing ribs out to the roo

t

of the wing.

3.Servo Installation:

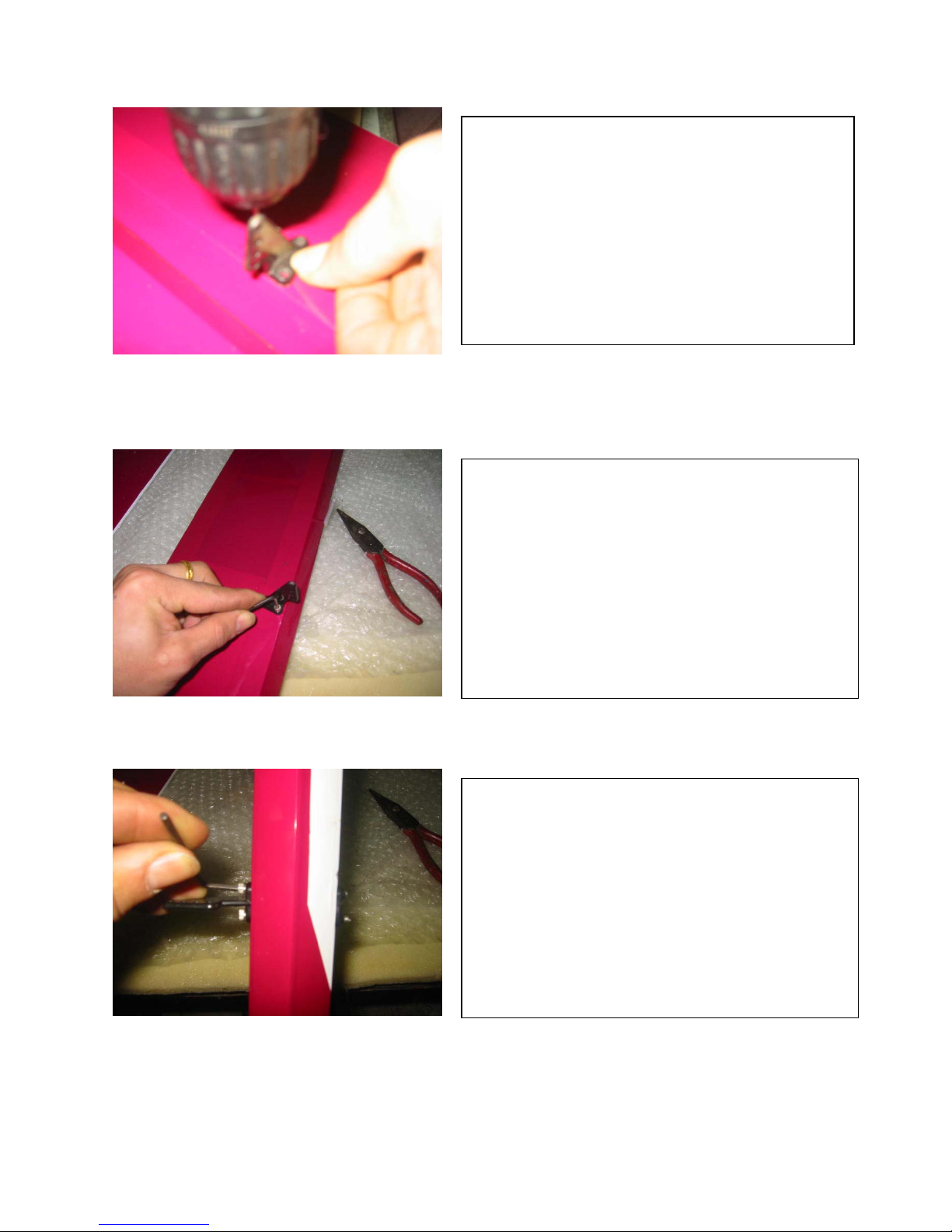

After placing the servo into the bay, drill the

servo mounts and then use the servo

mounting screws that are provided with

your servo.

4. Once the servo is mounted, it shoul

d

look like the picture provided. Fo

r

finial assembly you may want to add

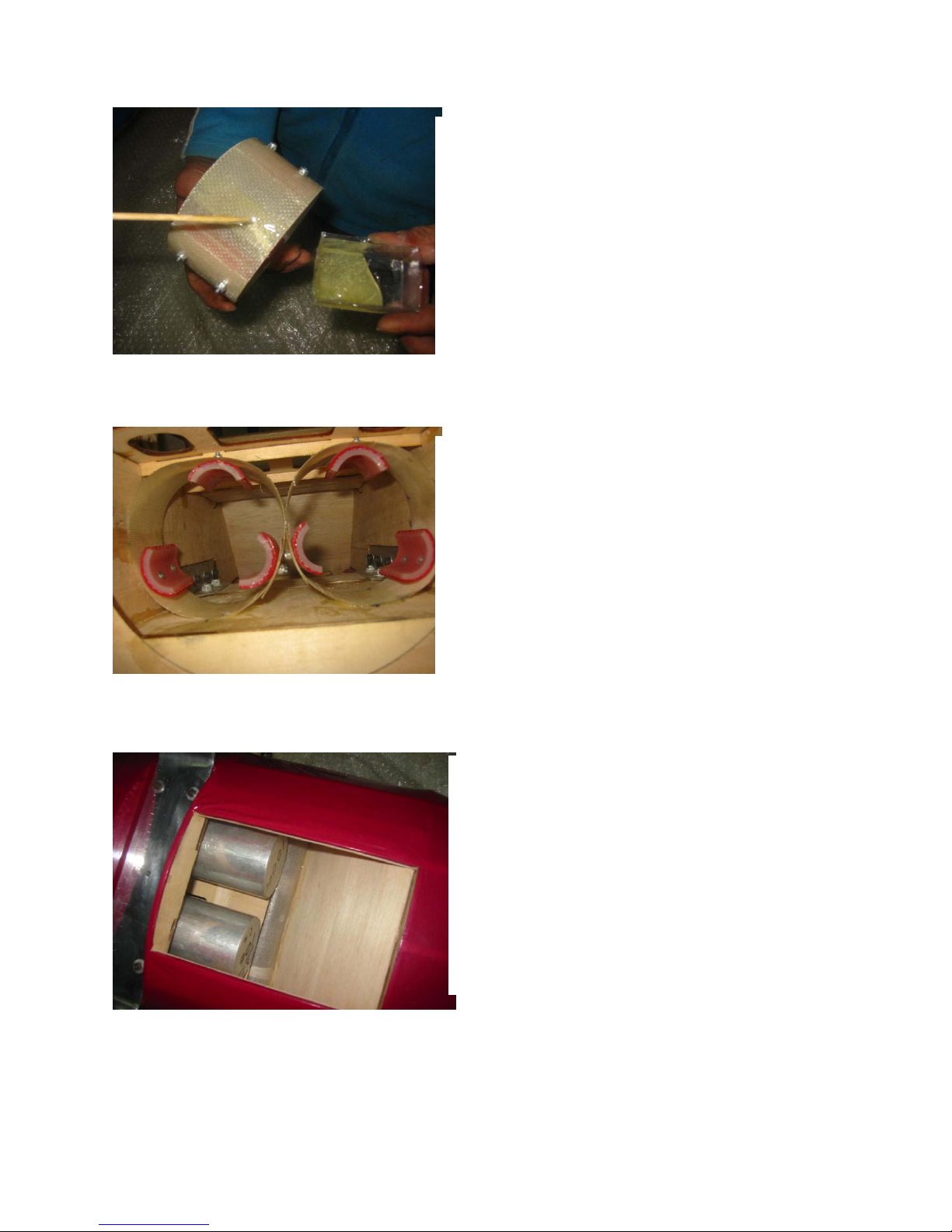

a

drip of thin CA to the screw holes an

d

re-drill. This will provide a secure

mount.

5. Once the servo is installed measure

the length of the push rod.

6. Make sure your control horn is place

d

5mm toward the root of the wing. This

measurment is taken from the edge o

f

the servo.

7. Center the aileron and position the control horn as close to

the leading edge as possible. Pre-drill the holes and use the

allen screws provided to mount the control horn. Make

sure to use a drip of thin CA in the hole to provide a stronge

r

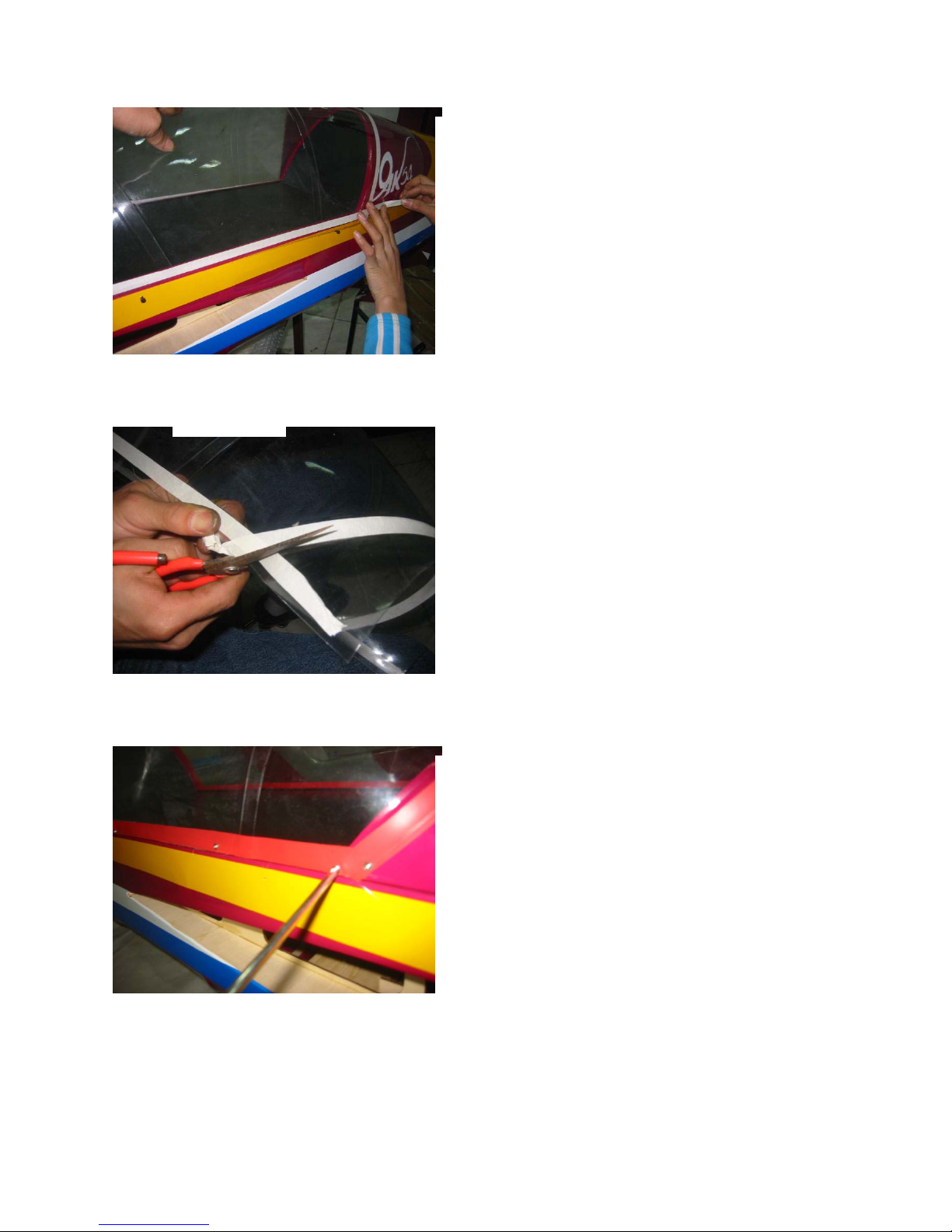

mount.

8. Tighten the allen screws, once complete the control hor

n

should look like the picture provided.

9. Make sure that the allen bolt goes through the entire

aileron and into the mounting back plate.

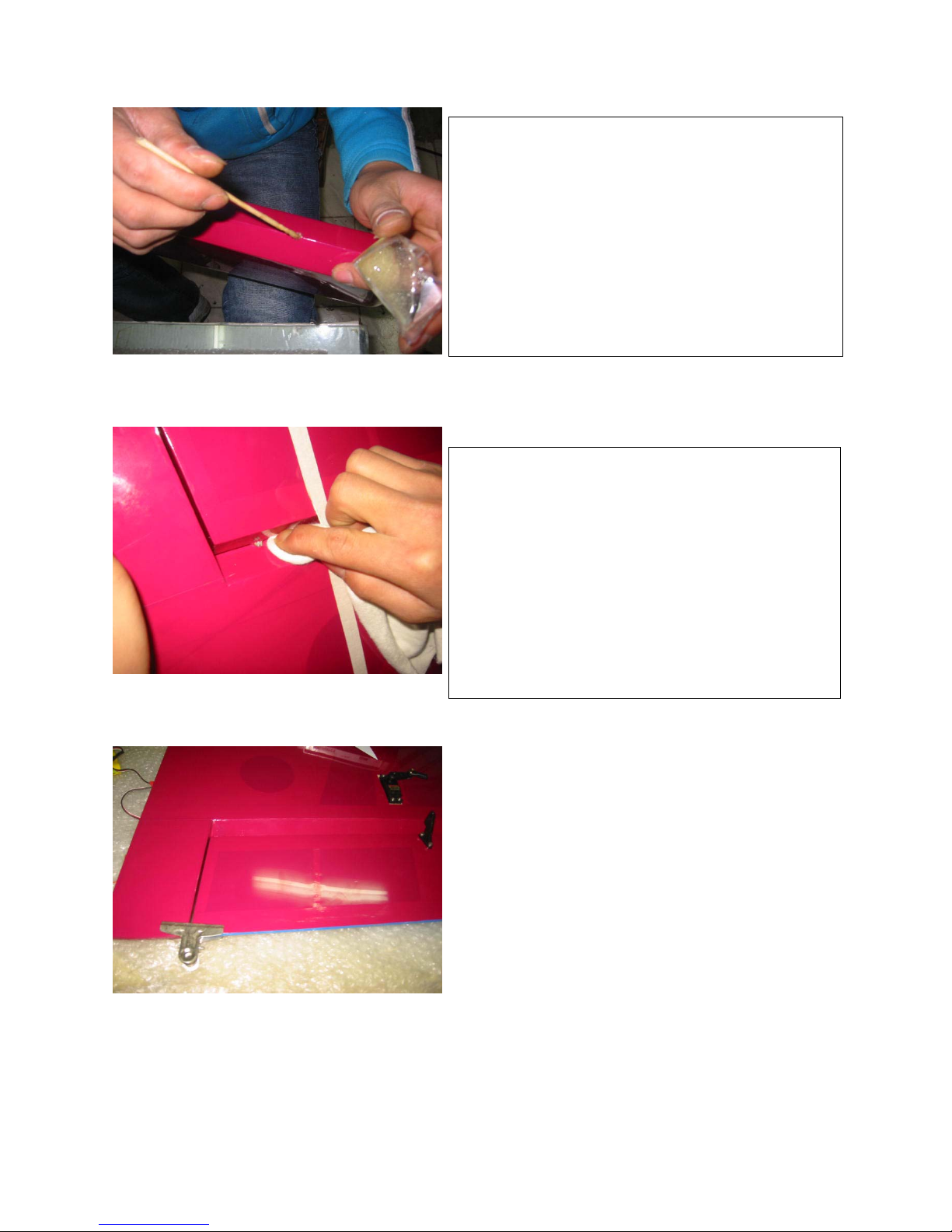

10. Hinge installation

Mix the proper amount of epoxy and coat the hinge

hole.(This is a very important step so make sure you have

p

lenty of epoxy in the hole).

Fig.10

11. Wipe the excess glue away from the hinge and off of the

covering once the surfaces are taped together.

12.Installing pushrods:

Use some type of clamp to help center the

aileron.

13.Measure the length of the pushrod and mark.

Make sure you have plenty of threads left tha

t

will be able to screw into the ball link an

d

control horn (provided).

14. Once you have the proper length, cut the

p

ushrod and install.

15.Place the servo arm back onto the servo an

d

tighten the screw. Make sure the arm is at a

90-degree angle to servo with the control

surface at center.

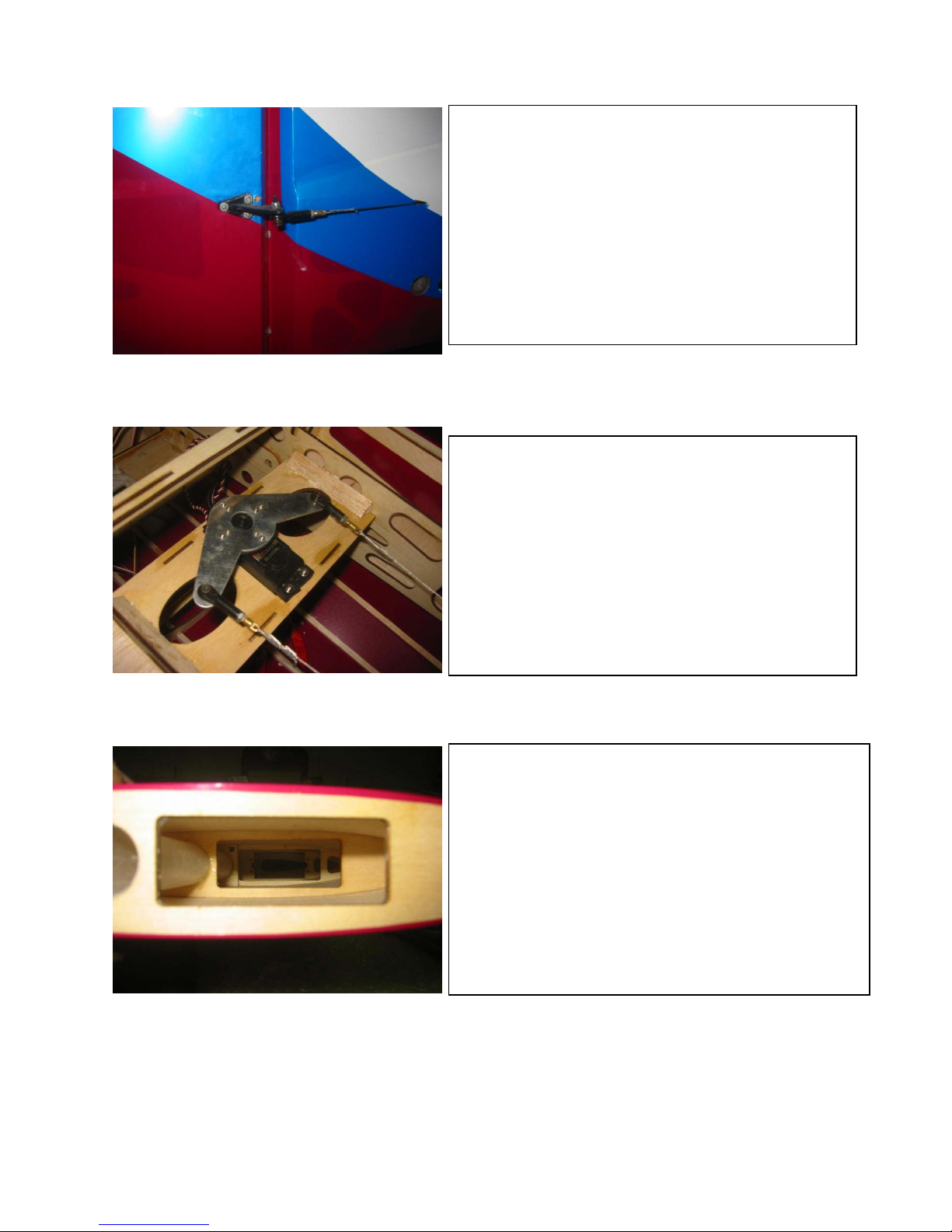

16.Main Landing Gear Installation:

Use the four 1/4×20 bolts provided to mount the

gear to the gear plate. Back the bolts from the

inside with the four lock nuts. Once the locknuts

are tight you may move to the next step.

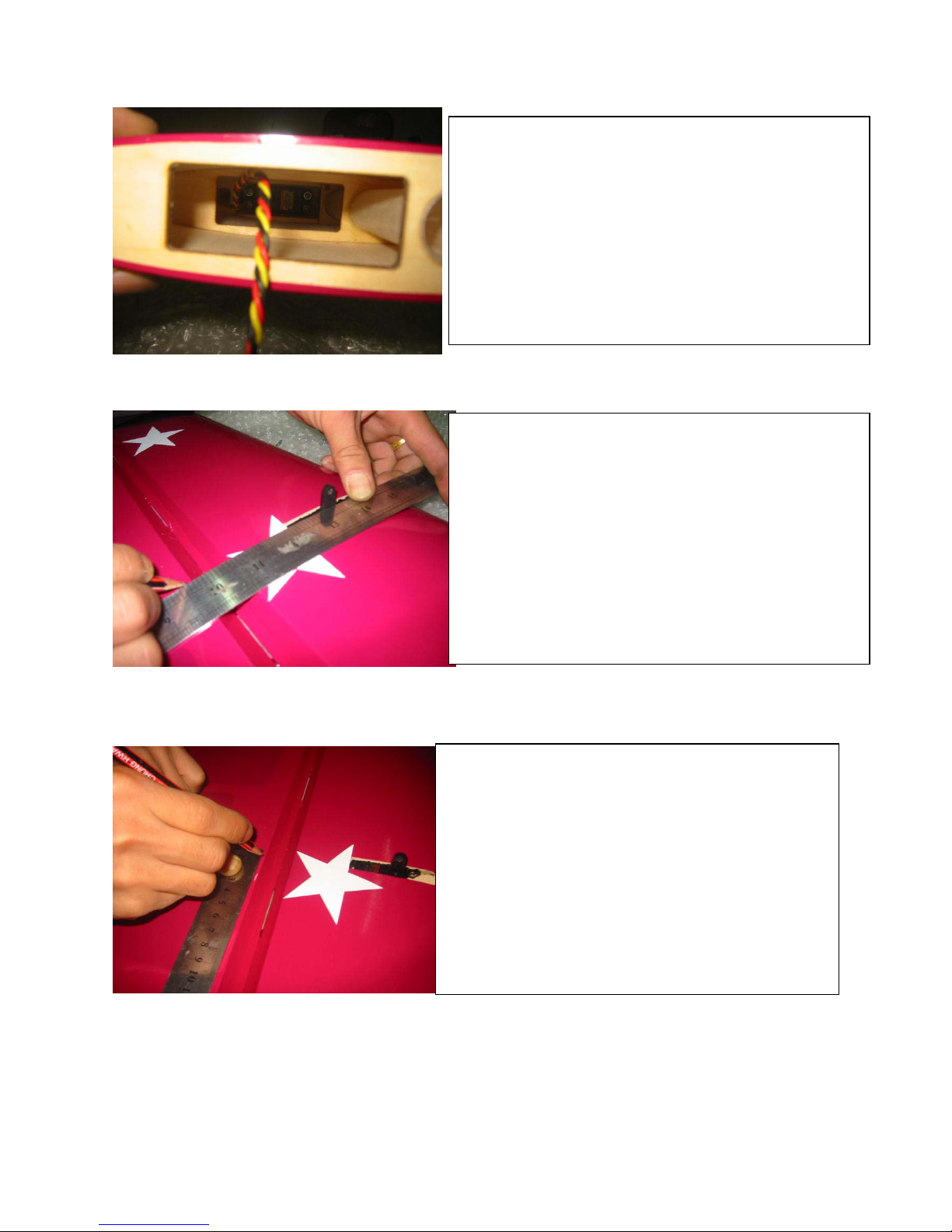

17.Tail Wheel Installation:

Install your preferred tail wheel to the hard woo

d

at the rear section of the fuselage. Here is an

example of our installation.

18. Install the blind-nuts needed for the tail wheel

through the acess hatch in the rear portion of the

fuse.

19. Here is a picture of a proper installation o

f

the tail wheel blind-nuts.

20.Here is another example of the tail wheel

installation.

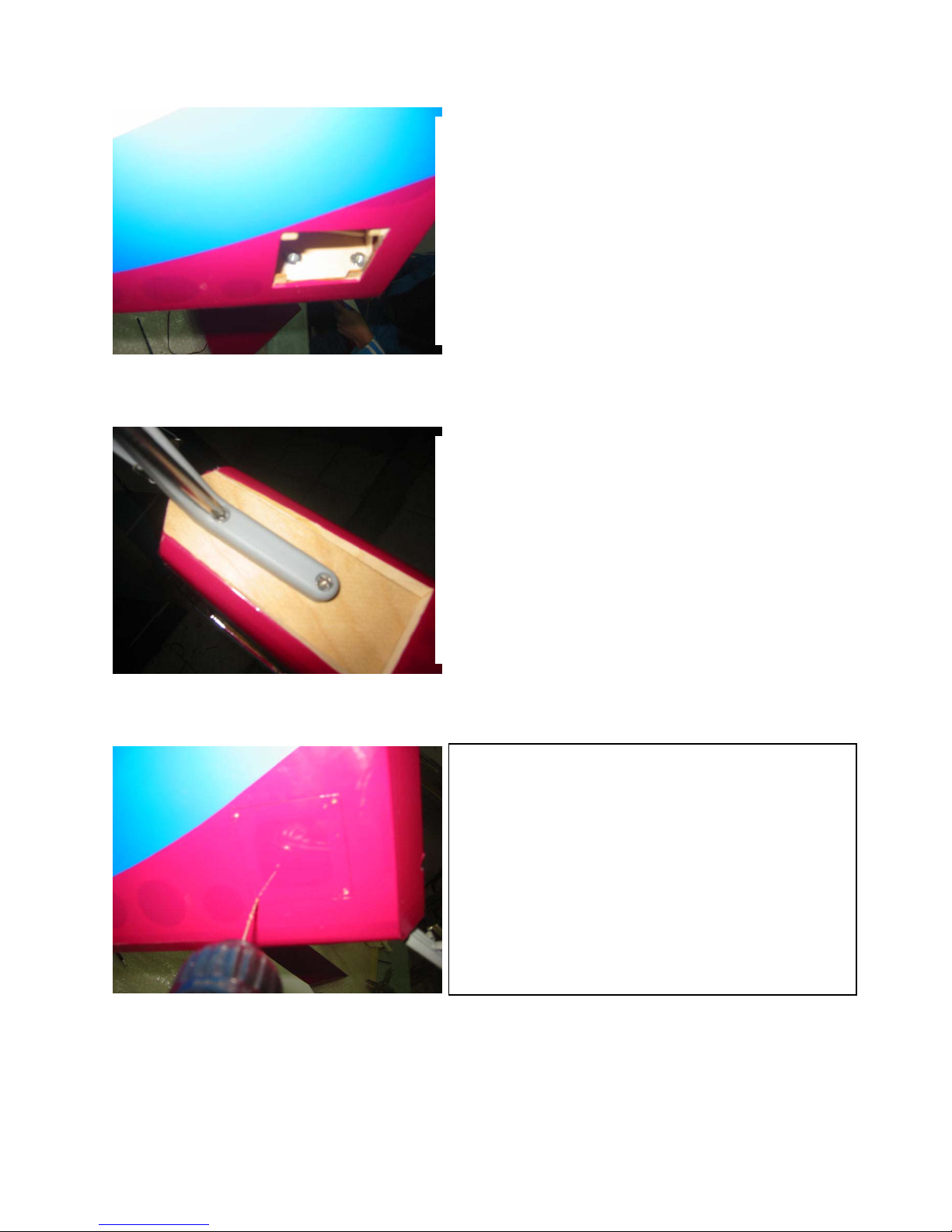

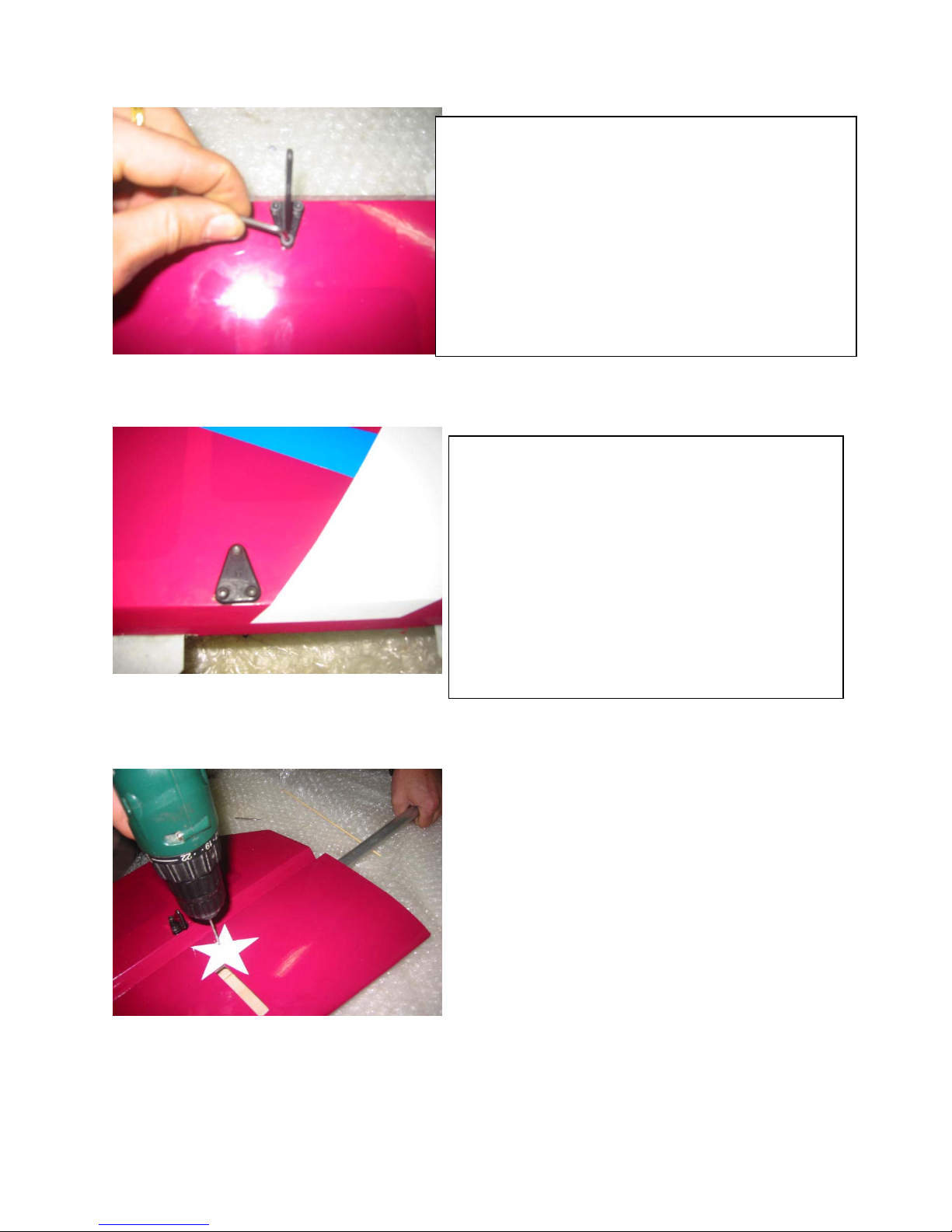

21. Installing the acess hatch.

Use a 1.5mm drill bit to drill the four holes into

the hatch at each corner. Make sure to hit the

mounting block behind the hatch.

22. Use four machine screws 3x6mm to

secure the hatch plate.

23. Using a soldering iron, open the hole in the

rear for the stab tube.

24.Rudder control horn:

Drill through the hard point in the rudde

r

making sure that the control horn will clea

r

the elevators at full up deflection.

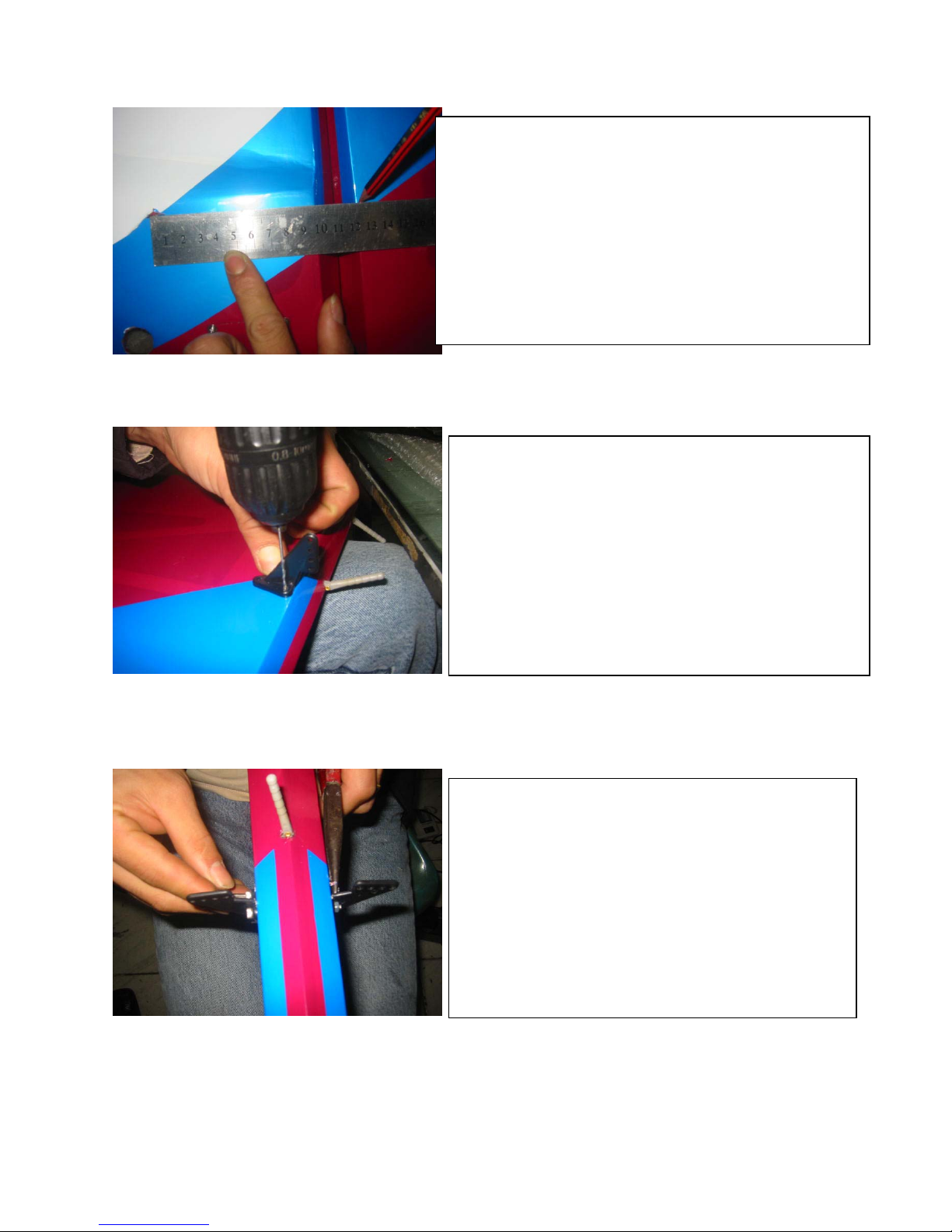

25. Rudder Cable

Take a straight edge and mark where the rudder cable will touch the

turtle deck.

You are looking for a straight shot all the way up to your rudde

r

servos.

Make sure you have clearance between the cable and your elevato

r

at full travel.

26.Using the rudder horn provided and place it as marked.

Use a 3mm drill bit to drill through the hard point. Use the

3mm allen bolts to secure the rudder horns together. Back the

allen bolts with lock nuts and move to the next step.

27. Pictures showing the correct position of the rudder horns.

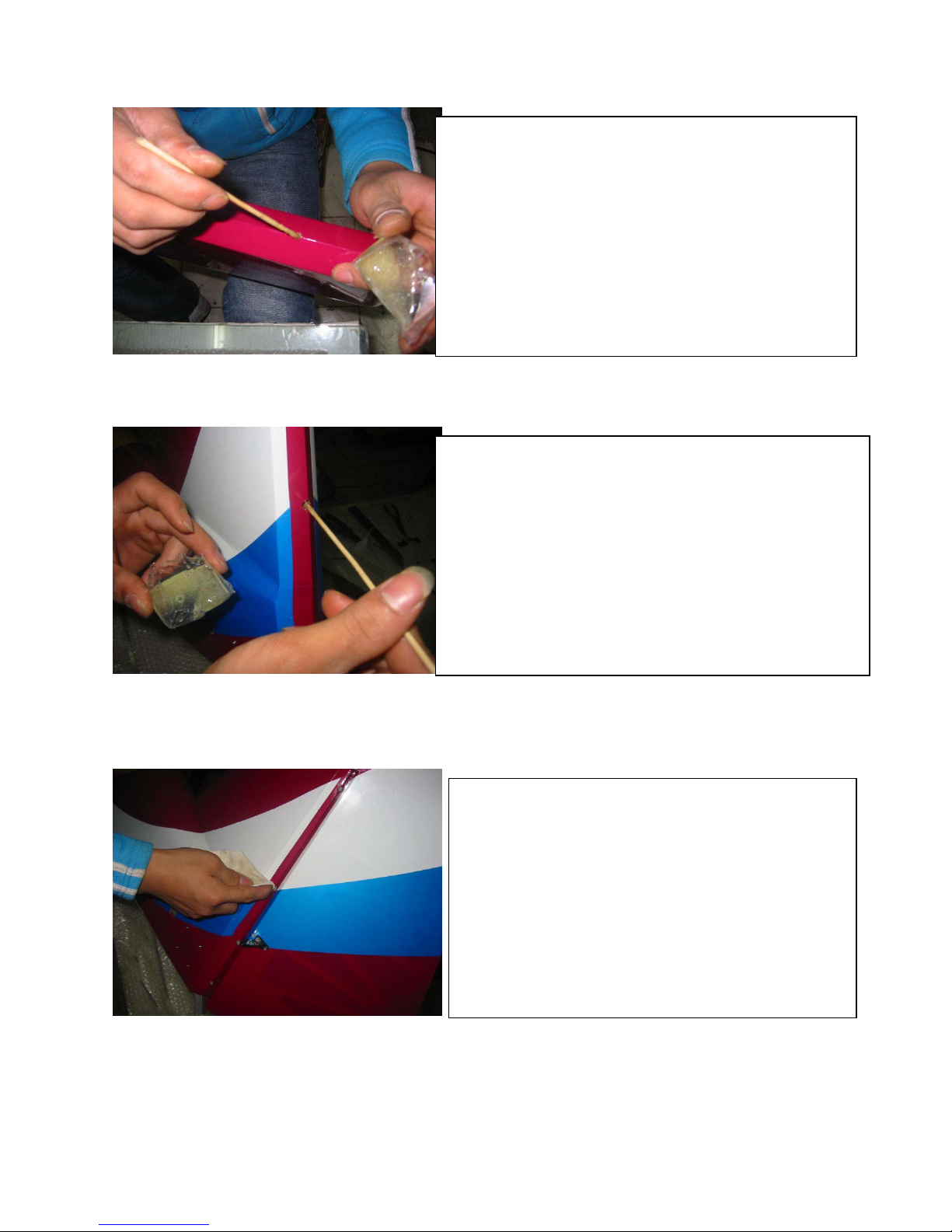

28. Hinge installation

Mix the proper amount of epoxy and coat the hinge hole.(This is

a very important step so make sure you have plenty of epoxy i

n

the hole).

29. Fill the holes with epoxy using a long sharp stick.

30. Make sure all hinge gaps are 1/16 or less. You shoul

d

not be able to see any type of gab in the hinge line if done right.

Once all hinging is done we recommend sealing the gaps wit

h

clear covering. This will prevent any type of flutter problems.

32. Rudder horn installation is completed.

33. Rudder servo installation

The torque of your servos will determine how many servos yo

u

will need to run.

Here is one example of the set up.

34. Stab installation

35. Mount the servo inside of the stab to the stab rib. Use the

fishing line to guide your servo lead out of the root.

36. Locate the servo horn exit hole. Once locate

d

cut open the hole and install your servo horn to

the servo. Locate the center point for your control horn.

Fig.33

37. Move 2mm towards the root rib or fuselage for the cente

r

of the control horn.

38. Use the same method as the aileron to mount your elevato

r

control horns.

39. Make sure all the allen bolts come through the bac

k

p

lane of the control horn. You can cut the bolts flush with

a

cut off wheel.

40.Stab Tube Installation:

The next step is to drill and tap the tail tube.

Insert the tail tube into one side of the stab an

d

then locate the predrilled hole in the stab. Yo

u

will need to drill the tube to accept a 6/32 tap.

41. Now proceed with tapping the tail tube

using a 6/32 tap.

42. Secure the stab tubes using a 6/32 allen bolt.

43. Next step is to slide the stab and stab tube

through the fuselage. Now slide the opposite stab

onto the stab tube and make sure both sides are

p

ressed tight against the fuse. Now follow the

same drill and ta

pp

in

g

ste

p

s as the first stab

Fig.43

44. wheel pant installation:

Install the wheel pant to the landing gear using two

6-32×3/4″allen bolts.

Make sure you have a small 1/16” thick bloc

k

glued to the inside of the pant.

N

ow you can take two of the supplied 6/32 blin

d

nuts and back the bolt.

Once the blind nuts are pulled tight into the wood,

p

lace a small drop of CA or epoxy to the blind nuts

to kee

p

it from fallin

g

out.

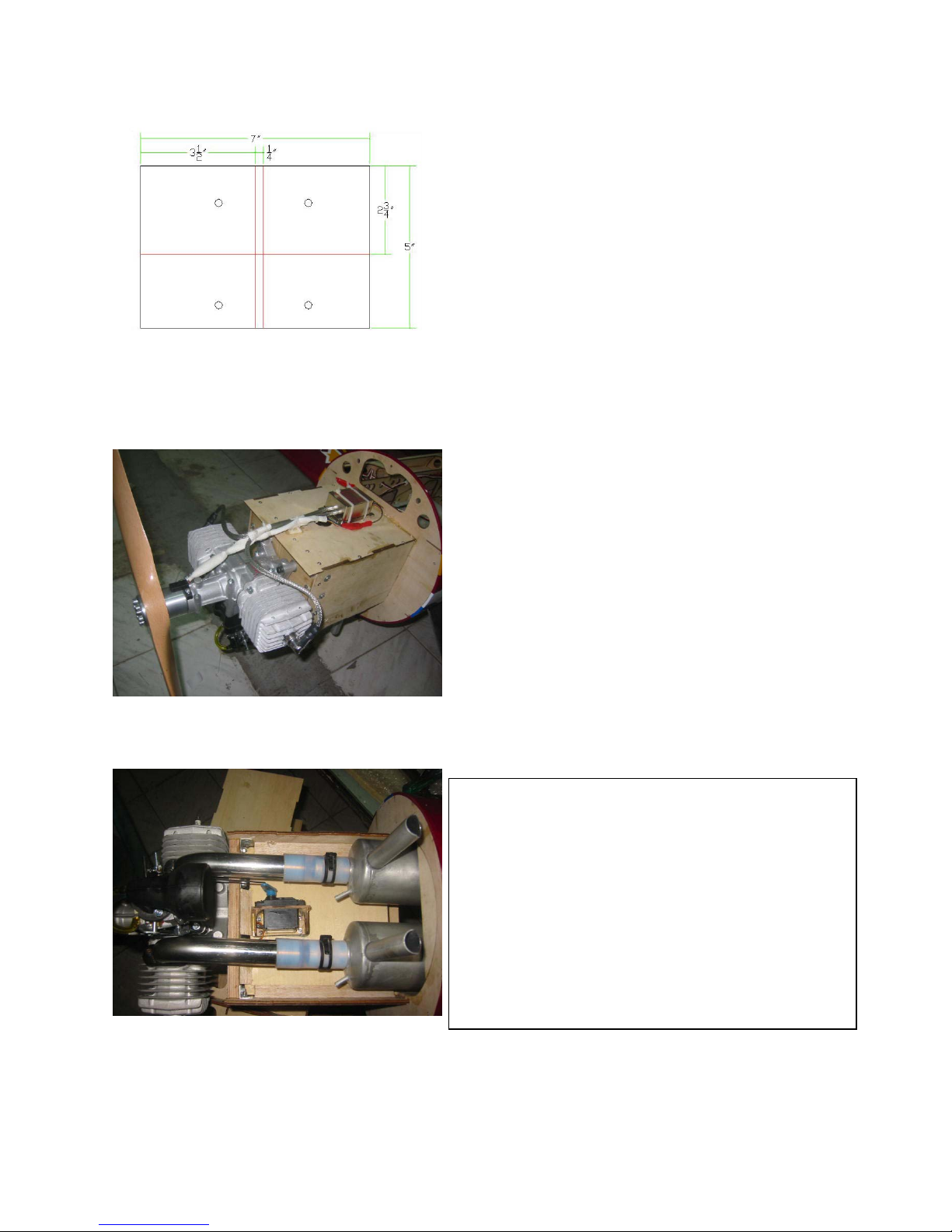

45. Engine installation:

N

ext step is to mark the center of the box. Yo

u

will need to offset then engine to center the

crank. Here is an example of what the firewall

should look like when mounting a 3w106

engine.

46. Here is a picture of a 3W 106 bolted to

the firewall.

47. Canister Installation:

This aircraft is ready to accept canister mufflers. If yo

u

choose to use canisters follow the next few steps.\

Here is a picture of the 3w 106 and PeFa canisters installed.

.

48. Add a small bit of epoxy glue on the

muffler mounting rings. These rings shown

here are 3w Cannister rings.

49. Measure the fixed position of the mufflers

before installing it inside of the fuselage. Once

you have your mounting point finish glueing

the canister mounts to the pipe tunnel.

50. Here is a picture of the canisters installed.

51. Another view of the canister installation.

N

otice the throttle servo mounted below the

engine box.

.

52.Cowling installation:

Using 5 6-32 ×3/4allen head bolts

(provided) attach the cowling to the fuse

using the pre-installed cowl ring.

53. Fuel tank installation.

Mount the fuel tank as close as possible to

the cg of the aircraft. Make sure to

mount the tank on foam to prevent the fuel

from foaming.

54.Canopy Mounting:

Cut the canopy to fit onto the canopy hatch.

Make sure to take a little off at a time or yo

u

might take to much off.

55. Trim the canopy.

56 .Canopy installations:

Trim the canopy to fit the canopy hatch. Once you

are happy with the fit, glue the canopy to the canopy

hatch with your favorite canopy glue. You may also

install eight small self-tapping screws for adde

d

strength

Table of contents

Popular Toy manuals by other brands

Reely

Reely R222 operating instructions

The World Models Manufacturing

The World Models Manufacturing PIPER J-3 CUB 48S instruction manual

VTech Baby

VTech Baby Sort and Learn Car user manual

Matchbox

Matchbox WOLF MOUNTAIN instructions

Makeblock

Makeblock mBot manual

Athearn

Athearn Genesis SD45-2 user manual