TOELLNER TOE 9261 User manual

22.11.2017

TOELLNER Electronic Instrumente GmbH

Instruction Manual

Electronic Switch

TOE 9261

9261E-Manual-Rev05.doc

R

TOELLNER ELECTRONIC INSTRUMENTE GMBH

Gahlenfeldstraße 31, 58313 Herdecke, Germany

+49 (0) 23 30 - 97 91 91 • Fax +49 (0) 23 30 - 97 91 97

E-Mail: info@toellner.de • Web: www.toellner.de

Subject to technical changes

Contents Page

TOELLNER Electronic Instrumente GmbH

2

1. Introduction.............................................................................................................4

1.1 Features................................................................................................................................4

1.1.1 General feature set.............................................................................................................4

1.1.2 Overview of features...........................................................................................................5

1.2 Model overview .....................................................................................................................5

1.3 Schematic diagram for TOE 9261 .........................................................................................5

2. Operation.................................................................................................................6

2.1 Startup...................................................................................................................................6

2.1.1 Installation and ventilation ..................................................................................................6

2.1.2 Preparations.......................................................................................................................6

2.2 Description of the controls.....................................................................................................7

2.2.1 Front panel controls............................................................................................................7

2.2.2 Rear panel controls.............................................................................................................9

2.3 General operation features....................................................................................................9

2.4 Power switch operation .........................................................................................................9

2.4.1 Connection of the input voltage source...............................................................................9

2.4.2 Insertion of artificial networks .............................................................................................9

2.4.3 Application of the internal input buffer capacitor.................................................................9

2.4.4 Connection of the consumer for switching the positive supply line...................................10

2.4.5 Connection of the consumer for switching a ground line (minus) .....................................10

2.4.6 Connection of the control signal .......................................................................................10

2.4.7 Control of switching paths and operation of the consumer...............................................10

2.4.8 Display of the switching states..........................................................................................11

2.4.9 Use of the branch path .....................................................................................................11

2.4.10 High-impedance base load...............................................................................................12

2.4.11 PWM operation of a consumer .........................................................................................12

2.5 Operation of the signal line switches...................................................................................13

2.5.1 Connection .......................................................................................................................13

2.5.2 Control..............................................................................................................................13

2.6 Protection............................................................................................................................14

2.6.1 Overcurrent and short-circuit protection of the switching paths........................................14

2.6.2 Input overcurrent protection..............................................................................................14

2.6.3 Protection against exceeding of the maximum switching frequency.................................14

2.6.4 Excessive temperature protection ....................................................................................15

3. Configuring for 19" rack mount ..........................................................................16

3.1 19" adapter set (2 HU) for 1x TOE 9261 (option) ................................................................16

3.2 19" adapter set (2 HU) for two Toellner Instruments ½ 19" (option)....................................17

4. Technical data.......................................................................................................18

4.1 Technical data TOE 9261....................................................................................................18

4.2 General data........................................................................................................................20

4.3 Specification of the high-current connectors........................................................................20

5. Views......................................................................................................................21

TOELLNER Electronic Instrumente GmbH

3

Warning

This device has been constructed and inspected in conformity with DIN EN61010-1,

"Safety requirements for electrical equipment for measurement, control and laboratory

use", and left the plant in perfect condition with respect to safety technology and meets

Safety Class I. To maintain this condition and ensure hazard-free operation, the user must

observe the instructions and warnings contained in this manual.

When operating electronic equipment certain parts in these devices are necessarily

under dangerous voltage. Non-observance of the warnings may therefore result in

severe bodily injury or damage to the equipment.

Only suitably qualified personnel should perform work on these devices or in their vicinity.

Flawless and safe operation of these devices presumes correct transport, proper storage,

assembly as well as careful operation and maintenance.

Qualified personnel according to this manual are persons who are familiar with the

assembly, startup and operation of the devices and who possess the corresponding

qualifications for their work activity.

Section 1 –Introduction

TOELLNER Electronic Instrumente GmbH

4

1. Introduction

The electronic switches of the TOE 9261 series are used for time-specific switching on and

off of load and signal currents. These devices use an electronic, unidirectional power switch

as well as four electronic bidirectional signal line switches. The power switch can be used

either to switch a positive supply line or to switch the return line, e.g. for ground interruption

tests. When using the switch in the positive supply line, a branch path parallel to the load can

be additionally connected for specific discharging of buffered loads.

A digital input signal can be used to generate on and off durations of any length down to the

microsecond range for both the power switch and the signal line switches.

Series TOE 9261 switches are therefore ideal for use in test systems or any other

applications where current paths from consumers or control devices need to be closed or

interrupted for defined time intervals.

1.1 Features

1.1.1 General feature set

An essential feature of the series TOE 9261 electronic switches is the electronic power

switch, which is constructed of a longitudinal path and a branch path. Both paths can be

used unidirectional, i.e. with a fixed, specified current direction.

In order to switch a positive supply line, the longitudinal path represents the actual switching

path via which the energy flow takes place from a feeding source to the connected

consumer.

The branch path in this case is arranged parallel to the consumer and can be optionally

connected via a DIL switch. It serves as needed to selectively discharge a buffered

consumer or a buffered load during the turn-off phase of the longitudinal path. It is possible

to select either a direct parallel connection to the consumer or a parallel connection via a

0.1 Ωseries resistor.

DIL switches are used to continually switch resistances of 10 kΩ or 100 kΩ to the output as

high-impedance base loads, i.e. parallel to the consumer.

If the return line of the load is switched, the switch otherwise used as branch path carries the

load current. Base load impedances parallel to the consumer are not available in this

configuration.

The switching states of the power switch as well as the states of the selectable elements for

the load circuit are displayed by LEDs.

Another feature of the series TOE 9261electronic switches are the four electronic

bidirectional signal line switches, which can be operated selectively in any direction. These

signal line switches are used to switch low currents such as occur on control or signal lines.

Control of the switching states of as well as the power and signal line switches is

accomplished as desired using a front panel or rear BNC input. A DIL switch can be used to

internally invert the control signal.

A further DIL switch can be used to connect a pull-up resistor to the BNC input, thus making

possible control using an open collector or open drain switch.

The BNC inputs are compatible with TTL levels as well as CMOS 5 V and LVCMOS 3.3 V.

Section 1 –Introduction

TOELLNER Electronic Instrumente GmbH

5

1.1.2 Overview of features

Basic functions

- Electronic power switch consisting of longitudinal and branch path, both paths

unidirectional for specified current flow direction

- Branch path selectable inactive, active without series resistor or active with series

resistor 0.1 Ω

- High-impedance loads of 10 kΩ or 100 kΩ can be continually applied

- Applicability of branch path for switching ground lines or return lines

- Capacitive buffering of input can be applied

- Four electronic bidirectional signal line switches

- BNC control inputs at front and rear

- Control signal can be internally inverted

- Pull-up resistor can be connected to the control inputs

- Control inputs compatible with TTL, CMOS 5 V, and LVCMOS 3.3 V

- Permissible switching frequency DC up to 100 kHz

- Protected against overcurrent / short-circuit, excessive temperature, excessive switching

frequency

1.2 Model overview

Series TOE 9261devices are available in models for various rated currents. The rated

current of the power switch is indicated by a hyphenated number added to the basic part

number.

The rated currents for the signal line switches as well as the rated voltages are shown in the

following table.

Series TOE 9261 electronic switches

Model

Power switch

Signal line switches

Current

Voltage

Current

Voltage

TOE 9261-50

0 - 50 A

0 - 60 V

0 - 2 A

0 - 60 V

TOE 9261-100

0 - 100 A

0 - 60 V

0 - 2 A

0 - 60 V

1.3 Schematic diagram for TOE 9261

S1

S2

0.1 Ω

OUT

IN

−

+

−

+

Control

Logic

&

Driver

S3

S4

S5

S6

S1: Unidirectional electronic

power switch,

longitudinal path

S2: Unidirectional electronic

power switch, branch

path

S3…S6: Four electronic

bidirectional signal line

switches

Section 2 –Operation

TOELLNER Electronic Instrumente GmbH

6

2. Operation

2.1 Startup

Warning

Safe operation of these devices presumes that they have been placed in service properly

by qualified personnel in compliance with the warnings in this manual.

In particular the general installation and safety regulations (e.g. DIN/EN and VDE) must be

observed. Non-observance may result in death, serious personal injury or major damage

to equipment.

These devices meet Protection Class I (protective earth connection) according to DIN

EN61010-1. Before powering up, be sure that the mains voltage agrees with the

permissible operating voltage of the device (4.1 Technical data TOE 9261 and the

rating plate). Except in areas with special protection measures, the mains plug must only

be inserted in a socket having a PE contact. The protection effect must never be defeated

through use of an extension cable not having a protective earth. The mains plug must be

inserted in the socket before the device is turned on and the measuring and control circuits

connected. Any interruption in the protective earth inside or outside the unit or removal of

the protective earth connection may result in a hazardous condition for the device. No

intentional interruption of the protective earth connection is permitted. Observe local

regulations for earthing.

Ensure that only fuses of the specified type and specified current are used as

replacements (4.1 Technical data TOE 9261 and the rating plate). The use of repaired

fuses or short circuiting the fuse holder is not permitted.

If it is apparent that non-hazardous operation is no longer possible, the devices must be

taken out of service and secured against unintended operation.

2.1.1 Installation and ventilation

There are no problems associated with installation of these devices.

The devices include a thermostatically controlled fan which brings in air from the sides and

below and blows it out to the rear. Provide sufficient ventilation distance so that the rear fan

can work effectively. Otherwise it can happen that under high load conditions the unit will

heat up to a point where it is automatically shut off (2.6.4 Excessive temperature

protection).

Series TOE 9261devices are designed so that they can be used either as tabletop units or

in 19" rack systems. Appropriate adapters for 19" rack use are available as an option.

2.1.2 Preparations

OFF

ON

After connecting the mains supply and pressing the POWER switch the device is ready. This

is indicated by the green power LED above the mains switch.

Section 2 –Operation

TOELLNER Electronic Instrumente GmbH

7

2.2 Description of the controls

At the end of the manual you will find the various operating and display elements for the

series TOE 9261 numbered with front panel and rear views. In the following the individual

operating elements are explained in detail.

2.2.1 Front panel controls

[1]

Mains switch for turning the power to the device on and off. When the unit is ON the

green POWER LED will be illuminated.

[2]

8x DIL switch. Assignments from top to bottom (Nos. 1 to 8):

1. INPUT C: Apply input buffer capacitor to input socket pair Plus –Minus. Indication

by green LED.

2. R = 10 kΩ: Apply high-impedance base load 10 kΩ parallel to output socket pair

OUT –Minus. Indication by green LED.

3. R = 100 kΩ: Apply high-impedance base load 100 kΩ parallel to output socket

pair OUT –Minus. Indication by green LED.

4. S2 + 0.1 Ω: Apply branch path switch S2 with 0.1 Ω series resistor. Indication by

green LED (2.4.9 Use of the branch path).

5. S2 + 0 Ω: Apply branch path switch S2 without series resistor: Internal resistance

0 Ω. Indication by green LED (2.4.9 Use of the branch path).

6. S1 ENABLE: Activation / deactivation of switch S1 in order to carry out ground

interruptions using switch S2 (2.4.5 Connection of the consumer for switching a

ground line)

7. CONTROL: Inversion of the control signal present at front panel or rear

CONTROL input

8. PULL-UP: Apply pull-up resistor of approx. 22 kΩ to the front panel or rear

CONTROL input

[3]

Front panel BNC input CONTROL for controlling the switching state both for the power

switch and the signal line switches (2.4.7 Control of switching paths and operation

of the consumer, 2.5.2 Control).

[4]

Selectable input buffer capacitor. This appears parallel to the input socket pair Plus –

Minus. The selection is indicated by the green LED next to the switch symbol.

[5]

Input sockets Plus –Minus of power switch. The input voltage should preferably be

connected to the right-hand Plus socket and to the Minus socket. The left-hand Plus

socket is used to connect the input voltage for carrying out ground interruptions.

An appropriate voltage source should be used to provide the input voltage. The

polarity and magnitude of the voltage must be observed; not more than the rated

voltage of the TOE 9261 may be applied.

[6]

Longitudinal path switch S1 of the power switch. Across this the connection between

the sockets Plus and OUT is applied. When S1 is conductive the red LED below the

switch symbol will be illuminated.

[7]

Output socket OUT and right-hand Minus socket of the power switch. In order to

switch the positive supply line of a consumer, this must be connected to OUT and to

the right-hand Minus socket. If, on the other hand, the return line of the consumer is to

be switched, the consumer must be connected with the positive pole to the right-hand

Plus socket [5] and the negative pole to OUT.

The voltage connected to OUT (in the case of a buffered and possibly preloaded

consumer) must not be more positive than the voltage at the Plus sockets or more

negative than the voltage at the Minus sockets.

Section 2 –Operation

TOELLNER Electronic Instrumente GmbH

8

[8]

Selectable base load 10 kΩ or 100 kΩ. This appears parallel to the output socket pair

OUT –Minus. The selection is indicated by the green LED next to the switch symbol.

[9]

Branch path switch S2 of the power switch. This is used when switching the positive

supply line of a consumer to jumper the consumer during the switch-off time (switch

S1 of longitudinal path non-conductive) in order e.g. to discharge a buffer stage

present in the consumer. To this end, S2 is connected via the corresponding switching

function of the 8-fold DIL switch [2]. It is possible to select use of S2 without or with the

inserted 0.1 Ωseries resistor (2.4.9 Use of the branch path). The 0.1 Ω series

resistor is used e.g. to implement the test signal in accordance with LV 124, version

2009, test E-10, test case 3.

If, on the other hand, the return line of a consumer is switched, S2 carries the load

current (2.4.5 Connection of the consumer for switching a ground line).

When S2 is conductive the red LED above the switch symbol will be illuminated.

[10]

0 Ω series resistor for the branch path. When the branch path is selected in

conjunction with this resistor, the green LED next to the switch symbol will be

illuminated.

[11]

0.1 Ω series resistor for the branch path. When the branch path is selected in

conjunction with this resistor, the green LED next to the switch symbol will be

illuminated.

[12]

Red OVL LED (Overload). Comes on when a shutdown has occurred due to one of

the following fault conditions:

Max. switching frequency of 100 kHz on the control input has been exceeded

Overcurrent

Excessive temperature

A reset following a switching frequency fault is done by reducing the frequency at the

control input, or in case of overcurrent or excessive temperature by turning the unit off

and on using the mains switch. The reason for the overcurrent must be identified and

the cause removed. In case of excessive temperature the unit can be restarted only

after a sufficient cooling down time (2.6 Protection).

[13]

Polarity notice for the power switch. Voltages must be connected only with the correct

polarity. This means for the OUT socket that the connected voltage (in the case of a

buffered and possibly preloaded consumer) must not be more positive than the

voltage at the Plus sockets or more negative than the voltage at the Minus sockets.

[14]

Terminal block for signal line switches S3 and S4. These can be used with suitable

terminal block plugs (4.1 Technical data TOE 9261, Connections, Signal line

switches).

The control and signal lines to be switched are routed through the signal line switches

indicated by the switch symbols S3 and S4. The connections for unused signal line

switches are left open.

The signal line switches are closed and opened synchronous with each other and

synchronous with closing and opening of the longitudinal path S1 of the power switch.

[15]

The terminal block for the signal line switches S5 and S6. The same explanations

apply as for S3 and S4 [14].

Section 2 –Operation

TOELLNER Electronic Instrumente GmbH

9

2.2.2 Rear panel controls

[20]

Identifier

The identifier shows the current version and the installed options for the unit.

[21]

Protective earth

This screw connects the housing to the protective earth.

Attention: This connection must never be removed!

[22]

Rear-side BNC input CONTROL for controlling the switching state both for the power

switch and the signal line switches (2.4.7 Control of switching paths and operation

of the consumer2.5.2 Control).

[23]

Rating plate

The rating plate contains the following information: Company name, device series,

serial number, supply voltage with mains fuse and current draw.

[24]

Mains plug with

mains fuse

This 3-pole standardized plug is used with the mains power cord. Integrated into the

plug is the chamber for the device fuse with an additional compartment for a spare

fuse.

2.3 General operation features

Operation of the TOE 9261 for setting the desired switch and control configuration is carried

out using an 8-fold DIL switch on the front panel. The states of the selectable elements for

the load circuit as well as the switching states of the power switch are displayed by LEDs.

Switching time settings are made on the clock source used (e.g. function generator), which

may if desired be connected to the front or rear BNC input CONTROL on the TOE 9261.

2.4 Power switch operation

2.4.1 Connection of the input voltage source

To operate the power switch a DC voltage source (power supply, battery) is connected to the

input socket pair Plus –Minus. If the right-hand Plus socket is not used by the load for

carrying out ground interruptions (2.4.5 Connection of the consumer for switching a

ground line), the input voltage should be connected to this socket and to the Minus socket;

otherwise to the left-hand Plus socket and the Minus socket.

The applied voltage must be not greater than the rated voltage for the TOE 9261. Overlaying

with AC voltage is permissible as long as the input buffer capacitor is not applied and the

maximum momentary value of the total applied voltage does not exceed the rated voltage of

the TOE 9261 and the minimum momentary value is not negative. Setting a current limit at

the source with a value appropriate to the consumer or providing protection against

overcurrent is required.

Warning

It is imperative that the source be connected to the input sockets Plus –Minus with the

correct polarity! Otherwise damage to the Electronic Switch may result.

A current limiter or overcurrent fuse for the feed source is absolutely required.

2.4.2 Insertion of artificial networks

Depending on the requirement an impedance network, for example when operating or

testing motor vehicle components, an artificial network (AN) can be placed between the

voltage source and the input sockets or the output sockets and the consumer. In case of an

artificial network (AN) between voltage source and input sockets the input buffer capacitor

should not be applied, because otherwise the artificial network (AN) will be without effect.

2.4.3 Application of the internal input buffer capacitor

In all cases in which the internal input buffer capacitor can be used (DC input voltage without

overlaying with AC voltage, no artificial network between voltage source und input sockets),

this capacitor should be connected using the DIL switch INPUT C / ON . This results in an

improvement of the switching times, especially a shorter rise time. For indication the green

LED next to the related switch symbol is illuminated.

Section 2 –Operation

TOELLNER Electronic Instrumente GmbH

10

2.4.4 Connection of the consumer for switching the positive supply line

The consumer to be operated is connected to the OUT socket and the right-hand Minus

socket. Since the S1 switch carries the load current, the DIL switch S1 ENABLE must be in

the left position.

Warning

In the described switch configuration, the negative return line must always be connected

from the consumer to the voltage source via the minus sockets of the TOE 9261. These

minus sockets must never be bypassed, because otherwise some protection mechanisms

of the Electronic Switch are without effect, and damage to the Electronic Switch may

result.

2.4.5 Connection of the consumer for switching a ground line (minus)

The consumer to be operated is connected with the positive pole to the right-hand Plus

socket and the negative pole to the OUT socket. The latter is the switched ground point.

Since the load current is connected via the S2 switch in this configuration, this must be

activated using the DIL switch S2 + 0 Ωin position ON . The green LED next to the related

switch symbol is illuminated.

Warning

When switching a ground line (minus), the S2 + 0.1 Ωsetting must never be selected,

otherwise the internal 0.1 Ωresistor would be overloaded during the flow of current.

The S1 switch parallel to the load can be deactivated by setting the DIL switch S1 ENABLE to

OFF . Otherwise the load would be discharged via S1 during the interruption. With

deactivation of the S1 switch also the above-mentioned improper load current flow via the

0.1 Ω resistor is automatically locked.

Warning

In the described switch configuration, the positive supply line from the voltage source to

the consumer must always be connected via the Plus sockets of the TOE 9261. These

plus sockets must never be bypassed, because otherwise some protection mechanisms of

the Electronic Switch are without effect, and damage to the Electronic Switch may result.

2.4.6 Connection of the control signal

A digital switching signal for controlling the power switch can be connected as desired to the

front panel or rear BNC CONTROL socket. A suitable clock source must be provided. This

signal should be compatible with one of the logic standards CMOS 5 V, LVCMOS 3.3 V or

TTL. Suitable devices include function generators in square wave or pulse mode as well as

arbitrary waveform generators (AWG) with digital waveforms. Voltages above 5 V as well as

negative voltages or voltages which extend into the negative range may not be used. Control

signals with a frequency up to 100 kHz can be used. An overload switch-off is carried out

above this frequency.

2.4.7 Control of switching paths and operation of the consumer

The digital switching signal is used to control the state of the paths S1 and S2. A conductive

path is thereby indicated by the red LED at the switch symbol S1 or S2 (2.4.8 Display of

the switching states). If the DIL switch CONTROL / INV is in the left position (i.e. no inversion),

S1 is conductive and S2 is non-conductive during a High level of the switching signal.

If however the DIL switch CONTROL / INV is set to INV , S1 is non-conductive and S2 is

conductive during a High level of the switching signal.

Section 2 –Operation

TOELLNER Electronic Instrumente GmbH

11

This results in the following possible operating conditions:

Configuration of TOE 9261

and consumer

DIL switch

CONTROL / INV

CONTROL

signal

Consumer status

Switching of positive supply line

--

Low

Disconnected (OFF)

--

High

Supplied (ON)

INV

Low

Supplied (ON)

INV

High

Disconnected (OFF)

Switching of return line (ground)

--

Low

Supplied (ON)

--

High

Disconnected (OFF)

INV

Low

Disconnected (OFF)

INV

High

Supplied (ON)

The appropriate setting of the CONTROL / INV DIL switch can therefore be selected

depending on the desired configuration (switching of positive supply line or of return line) and

the desired function of the control signal (High level should lead to supply of consumer or to

disconnection from the supply).

In the disconnected status of the consumer, a buffer stage present in the consumer and

possibly still charged is discharged if one of the two following cases exists:

TOE 9261 and consumer were connected in the configuration for switching the positive

supply line, and one of the two DIL switches S2 + 0.1 Ωand S2 + 0 Ωis set to ON

(2.4.9 Use of the branch path).

TOE 9261 and consumer were connected in the configuration for switching the return line

(ground), and the DIL switch S1 ENABLE was not set to OFF .

Note

If the CONTROL input is not connected or controlled but left in a high-impedance state,

this is evaluated as Low level. If in this case either the DIL switch CONTROL / INV is set to

INV or the DIL switch PULL-UP / ON to ON , the internally evaluated level changes to High,

resulting in switching path S1 becoming conductive and switching path S2 non-conductive.

In the configuration for switching the positive supply line, the consumer is then

permanently connected to the supplying voltage source.

In the configuration for switching the return line (ground), on the other hand, the consumer

is permanently connected to the supplying voltage source if –with the CONTROL input left

in a high-impedance state –the named DIL switches are either both in the left-hand or

both in the right-hand positions.

2.4.8 Display of the switching states

A conductive path S1 or S2 is indicated by the red LED at the related switch symbol. To

ensure always the perceptibility of the display, in case of high frequencies or short High or

Low pulses of the switching signal at the CONTROL input, not the actual fast changing

switching states are displayed, but it is calculated a slowed down signal for the display LEDs.

The switching paths themselves, however, are controlled by the timing of the switching

signal.

2.4.9 Use of the branch path

In the configuration for switching the positive supply line, S2 represents the load parallel

branch path. The switching state of the branch path S2 is always complementary to the state

of the longitudinal path S1. This means the consumer can be jumpered with S2, while S1 is

open (not conducting). This allows for example a buffer stage in the consumer to be

discharged.

To achieve the fastest possible discharging without a series resistor, DIL switch S2 + 0 Ω

must be set to ON . For indication the green LED next to the related switch symbol is

illuminated.

Section 2 –Operation

TOELLNER Electronic Instrumente GmbH

12

If, instead of this, DIL switch S2 + 0.1 Ωis set to ON , discharging is via a series resistor of

0.1 Ω, e.g. for realization of the test signal according to LV 124, version 2009, test E-10, test

case 3. Again, the green LED next to the related switch symbol is illuminated for indication.

This setting is only possible if not already the discharging without series resistor was chosen.

If no discharging is to carried out using S2, make sure that the two named DIL switches are

in the left-hand positions.

It must always be noted with buffered consumers that the rise and fall times are lengthened.

High buffer capacities with low series resistance values (ESR) can also result in triggering of

the overcurrent fuse.

Warning

Feedback from the (buffered) load side to the OUT output of the power switch must have

the indicated polarity and not exceed the rated voltage of the TOE 9261! A voltage

inversion into the negative is only permissible after blocking S1 by means of inductance-

dependent, further flowing load current.

Non-observance of this may result in damage to the Electronic Switch.

In the configuration for switching the return line (ground), the switching path S1 is parallel to

the consumer. If e.g. a test setup in accordance with LV 124, version 2013, test E-13 is used

and this test is applied to a ground line, discharging of the load is not intended during the

ground interruption. The DIL switch S1 ENABLE must then be set to OFF .

If in other applications the consumer is to be jumpered during the ground interruption, the

switching path S1 can be used for this by setting the DIL switch S1 ENABLE to the left-hand

position. Direct load jumpering is then available during the ground interruption; the looping-in

of a series resistor into the jumpering path is not possible in this configuration.

Note that with buffered consumers the rise and fall times are lengthened. High buffer

capacities with low series resistance values (ESR) can also result in triggering of the

overcurrent fuse.

Warning

Feedback from the (buffered) load side to the OUT output of the power switch must have

the indicated polarity and not exceed the rated voltage of the TOE 9261, i.e. the voltage

connected to OUT must not be more positive than the voltage at the Plus sockets or more

negative than the voltage at the Minus sockets! A voltage exceedance into the positive is

only permissible after blocking S2 by means of inductance-dependent, further flowing load

current.

Non-observance of this may result in damage to the Electronic Switch.

2.4.10 High-impedance base load

DIL switches R = 10 kΩ / ON and R = 100 kΩ / ON can be used to permanently switch

corresponding resistances to the output socket pair OUT –Minus, i.e. independent of the

switching state of paths S1 and S2. These serve in the configuration for switching the

positive supply line as high-impedance base loads. For indication the green LED next to the

related switch symbol is illuminated. It is also possible to select both resistors at the same

time, i.e. as a parallel circuit.

No connectable base loads are available in the configuration for switching the return line

(ground).

2.4.11 PWM operation of a consumer

Consumers which are suitable for use with pulse width modulation (PWM) can be used with

the TOE 9261. The frequency of the digital switching signal which is sent to one of the

CONTROL inputs corresponds to the frequency of the PWM signal; the pulse/pause ratio of

the switching signal results in the duty cycle of the PWM.

The current which is drawn by the consumer during the turn-on phase of the PWM is allowed

to have values up to the rated current of the TOE 9261. If the current draw is higher, the

overcurrent protection on the TOE 9261 may be triggered during the turn-on phase of the

PWM.

The TOE 9261 is in principle suitable for switching frequencies up to 100 kHz. Depending on

the voltage and current requirement of the consumer as well as the cable inductance from

Section 2 –Operation

TOELLNER Electronic Instrumente GmbH

13

the feeding source to the input socket pair Plus –Minus, this maximum frequency may

however not be reached, but rather the TOE 9261 will shut off at even a significantly lower

frequency due to overload, which is indicated by the OVL LED.

The reason for this overload in this case will be the inductive energy from the incoming line,

which continues to flow into the TOE 9261 for each turn-off event in the longitudinal path and

which is converted as a product factor of the switching frequency into power loss.

The following measures must be taken to increase the achievable switching frequency:

Minimize the cable length to the input socket pair Plus –Minus

Parallel, closely adjacent routing of both cable conductors

Use of a feed source with high output buffer capacity

Applying the input buffer capacitor of the TOE 9261by setting the DIL switch

INPUT C / ON to ON . The built-in capacitor is thermally protected against too high ripple

current load which may be caused by high consumer currents at high PWM switching

frequencies.

Warning

Consumers which are not expressly approved for PWM operation may not be turned on

and off at high switching frequencies, since otherwise buffer stages in the consumer, e.g.

electrolytic capacitors, can overheat and be damaged by excessive ripple current loads!

2.5 Operation of the signal line switches

2.5.1 Connection

To switch signal lines, they are routed through the bidirectional switches S3 –S6. They are

connected using the correspondingly labeled front panel connectors. These can be used with

suitable terminal block plugs (4.1 Technical data TOE 9261, Connections, Signal line

switches)

S3 –S6 provide four bidirectional signal line switches, for example to be able to turn on or

interrupt a multi-pole signal connection simultaneously. The terminals for unneeded signal

line switches are left unconnected.

The direction of current flow through the signal line switches S3 –S6 can be selected as

desired and independent of each other.

The upper limit of the applied signal levels is limited to the rated voltage of the TOE 9261.

The electrical isolation between the signal line switches and to the CONTROL input is for up

to 42 Vpeak.

2.5.2 Control

Closing and opening the signal line switches S3 –S6 takes place synchronous with each

other as well as synchronous with closing and opening of the longitudinal path S1 of the

power switch. The signal line switches are controlled further even if the longitudinal path S1

is disabled per DIL switch S1 ENABLE in the OFF position.

The functions and possible uses of the CONTROL input are the same as described for the

power switch (2.4.7 Control of switching paths and operation of the consumer) except for

the information which explicitly refers to operation of a load via the paths S1 and S2.

Section 2 –Operation

TOELLNER Electronic Instrumente GmbH

14

2.6 Protection

Series TOE 9261devices use various protective devices which serve to prevent serious

damage to the units.

Warning

Make absolutely sure that the supplying voltage source is connected to the input sockets

Plus –Minus with the proper polarity!

Feedback from the (buffered) load side to the OUT output of the power switch must have

the indicated polarity and not exceed the rated voltage of the TOE 9261, i.e. the voltage

connected to OUT must not be more positive than the voltage at the Plus sockets or more

negative than the voltage at the Minus sockets! A voltage exceedance into the negative or

positive direction is only permissible after blocking S1 or S2 by means of inductance-

dependent, further flowing load current

Non-observance of these instructions may result in damage to the Electronic

Switch.

2.6.1 Overcurrent and short-circuit protection of the switching paths

The overcurrent and short-circuit protection of the switching paths is designed to guard the

TOE 9261 against overload from excessive currents. It extends through the longitudinal and

branch paths of the power switch as well as through the signal line switches.

When the overcurrent and short-circuit protection is triggered, the internal driver stages are

permanently turned off, i.e. the switching paths are no longer driven.

This fault status is indicated by the OVL LED.

A reset is accomplished by turning the unit off and on using the mains switch. The cause of

the overcurrent or short-circuit must be identified and eliminated.

2.6.2 Input overcurrent protection

The input overcurrent protection guards the power switch against excessively high periodic

supply of power which results from the inductance on the input cable at the moment the

longitudinal path is turned off.

When the input overcurrent protection is triggered, the internal driver stages are permanently

turned off, i.e. the switching paths are no longer driven.

A fault condition is indicated by the OVL LED.

Reset by turning the unit off and on using the mains switch.

The following measures can be taken to prevent too high periodic supply of inductive energy

and thereby an undesired triggering of the input overcurrent protection:

Minimize the cable length to the input sockets Plus –Minus

Parallel, closely adjacent routing of both cable conductors

Use of a feed source with high output buffer capacity

Apply the built-in input buffer capacitor

2.6.3 Protection against exceeding of the maximum switching frequency

To protect against excessive switching losses and against excessive driver output, the

maximum switching frequency is limited.

Applying a higher frequency at the CONTROL input results in shutting off of the internal

driver stages, i.e. the switching paths are no longer driven.

This fault condition is indicated by the OVL LED.

The fault condition remains as long as the non-permitted switching frequency is present. If

the frequency is first reduced significantly below the permissible limit (taking into account a

Section 2 –Operation

TOELLNER Electronic Instrumente GmbH

15

hysteresis), the device automatically clears the fault condition and the switching paths are

again driven. The permissible switching frequency range is then again available.

2.6.4 Excessive temperature protection

The excessive temperature protection responds to excessive component temperatures in the

unit. This protection is provided in two stages. For continuous operation at high voltage, high

current and high switching frequency, the fan speed is first increased.

If the component temperatures continue to rise, the internal driver stages are shut off, i.e. the

switching paths are no longer driven.

This fault condition is indicated by the OVL LED.

After an appropriate cool-down time the unit can be reset by turning it off and on using the

mains switch.

Section 3 –Configuring for 19" rack mount

TOELLNER Electronic Instrumente GmbH

16

3. Configuring for 19" rack mount

3.1 19" adapter set (2 HU) for 1x TOE 9261 (option)

The series TOE 9261Electronic Switches are 19" rack-capable tabletop devices. By using

the optional TOE 9521 one TOE 9261can be easily converted for 19" 2 HU rack mount.

The optional 19" adapter set TOE 9521 includes a 19" adapter piece with handle and a 19"

compensation panel with handle as well as the necessary installation materials.

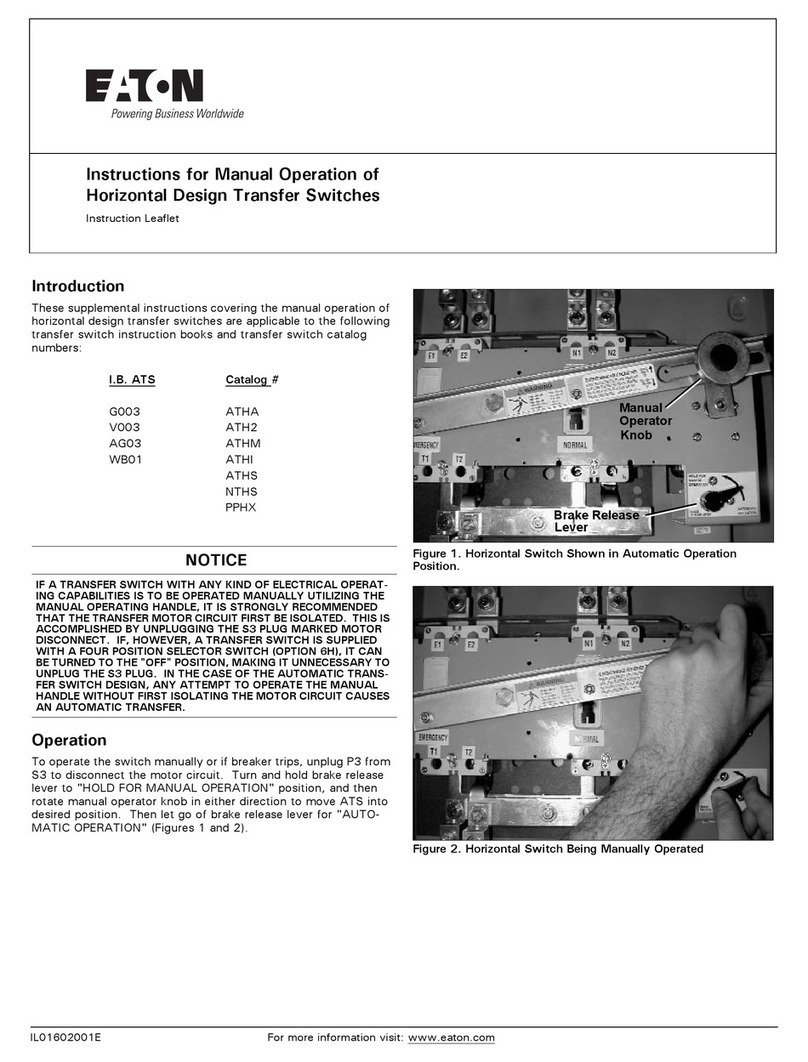

Reconfiguring from 1x TOE 9261 to 19" rack mount

1. Use the included TX 20 screwdriver to remove the feet from the Electronic Switch. First

remove the rubber inserts on the front feet.

2. Use the included Allen wrench to remove the two inner screws (6) on the left and right

side of the front panel of the Electronic Switch. Pull the two fill strips (5) from the side.

3. For the left or right side attach a handle (4) with countersunk screws (7) to the 19”

adapter piece (1). Insert this unit in replacement for the fill strip and screw it on to the

front panel using the hexagon socket screws (6).

4. For the other side attach the adapter bracket (3) to the 19” compensation panel (2) using

the hexagon socket screws (6), the spring washers (9), and the nuts (8). Also attach the

handle (4) with countersunk screws (7) to the 19” compensation panel (2). Insert this pre-

assembled unit in replacement for the fill strip and screw it on to the front panel using the

hexagon socket screws (6).

5. Use the thread-forming screws (10) to attach the adapter bracket (3) of the above-

mentioned unit additionally to the side holes provided as shown in the diagram.

1: 19" adapter piece 2 HU

2: 19" compensation panel 2 HU

3: Adapter bracket

4: Handle

5: Fill strip

6: Hexagon socket screw M3 x 8

7: Countersunk screw M5 x 12

8: Nut M3

9: Spring washer for M3

10: Thread-forming screw 3.9 x 6.5

Installing in the 19" rack

The 19" unit must be located on the device side on a slide rail. This slide rail as well as the

fasteners needed for attaching the unit in the 19" rack are not included in the scope of

delivery for this option.

Section 3 –Configuring for 19" rack mount

TOELLNER Electronic Instrumente GmbH

17

3.2 19" adapter set (2 HU) for two Toellner Instruments ½ 19" (option)

The series TOE 9261Electronic Switches are 19" rack-compatible tabletop devices. By

using the optional TOE 9522 two Toellner Instruments ½ 19" (2 HU) of equal length can be

easily converted for 19" 2 HU rack mount.

The optional 19" adapter set TOE 9522 includes two 19" adapter pieces with handle, a front

connecting profile, and a rear connecting profile as well as the necessary installation

materials (see diagrams on the following page).

Reconfiguring from two Toellner Instruments ½ 19" to 19" rack mount

1. Use the included TX 20 screwdriver to remove the feet from the two devices. First remove

the rubber inserts on the front feet.

2. Use the included Allen wrench to remove the two inner screws (6) on the left and right

side of the front panel of each device. Pull the four fill strips (5) from the side.

3. For the outer faces of the devices attach a handle (4) to a 19” adapter piece (1) each

using the countersunk screws (7). Insert these units in replacement for the fill strips and

screw them on to the front panels using the hexagon socket screws (6).

4. In the center insert the front connecting profile (2) in replacement for the fill strips and

screw it on to the front panels using the hexagon socket screws (6).

5. Use the Allen wrench to remove the inner mounting screw (6) of each housing at the rear

of the two devices.

6. Fasten the two devices together using the rear connecting profile (3), the provided screws

M3x10 (6), and the contact disks (8).

1: 19" adapter piece 2 HU

2: Front connecting profile

3: Rear connecting profile

4: Handle

5: Fill strip

6: hexagon socket screw M3 x 8

7: Countersunk screw M5 x 12

8: Contact disk for M3

Installing in the 19" rack

The 19" unit must be located on both sides on slide rails. These slide rails as well as the

fasteners needed for attaching the unit in the 19" rack are not included in the scope of

delivery for this option.

Section 4 –Technical Data

TOELLNER Electronic Instrumente GmbH

18

4. Technical data

Note

The technical data are based on a warm-up time of at least 30 minutes under constant

conditions and a reference temperature of 23°C ±1°C.

4.1 Technical data TOE 9261

Model

TOE 9261-50

TOE 9261-100

Input voltage

Power switch

0 - 60 V

0 - 60 V

Signal line switches

0 - 60 V

0 - 60 V

Load current

Power switch, longitudinal path

Continuous current

0 - 50 A

0 - 100 A

Peak current

300 A

300 A

Power switch, branch path

Continuous current

0 - 50 A

0 - 100 A

Peak current

300 A

300 A

Signal line switches

0 - 2 A

0 - 2 A

Voltage drop

Power switch, longitudinal path

< 0.2 V at 50 A

< 0.3 V at 100 A

Power switch, branch path

< 0.2 V at 50 A

< 0.3 V at 100 A

Signal line switches

< 0.4 V at 2 A

Switching frequency fMAX

100 kHz

Power switch switching times

Rise time trwith reference resistor 1 Ω

With connected input buffer capacitor

Without buffer capacitor, input cable 0.50 m twisted

Without buffer capacitor, input cable 1.20 m twisted

Rise time trwith reference resistor 100 Ω

With or without input buffer capacitor,

input cable ≤1.2 m twisted

< 0.5 µs

< 1.2 µs

< 2.0 µs

< 0.5 µs

Fall time tfwith reference resistor 1 Ω or 100 Ω

With or without input buffer capacitor,

input cable ≤ 1.2 m twisted

< 0.5 µs

PWM operation of power switch

Operating duration

With load current ≤50 A

With load current > 50 A … ≤100 A

(automatic switch-off at overload)

No limitation

--

No limitation

Typ. 5 min

Switching frequency

With duty cycle 50 %, input cable 0.50 m twisted

With input voltage 14 V

With input voltage 40 V

DC up to 100 kHz

DC up to typ. 20 kHz

(2.4.11 PWM operation of a consumer)

Switching times for signal line switches

Rise time tr

With 1 Ω load, VIN = 2 V

With 1 kΩ load

< 2.5 µs

< 0.1 µs

Fall time tf

With 1 Ω load, VIN = 2 V

With 1 kΩ load

< 1.5 µs

< 6.5 µs

Section 4 –Technical Data

TOELLNER Electronic Instrumente GmbH

19

(Technical data, cont.)

Attenuations for signal line switches

Blocking attenuation

With 100 Ω system impedance

8 kHz / -40 dB

Bandwidth

With 100 Ωsystem impedance

38 MHz / -3 dB

Protection functions

Overcurrent or short-circuit of the switching paths

Monitoring

Reaction

Reset

Continuous current and peak current

Switching off of switching paths, display OVL

Switching off and on again using mains switch

Input current

Monitoring

Reaction

Reset

Averaging of the inductive energy supplied per switching

operation from the supply line to the device input

Switching off of switching paths, display OVL

Switching off and on again using mains switch

Note: The incoming energy can be minimized by a short cable,

arranged for low-inductance.

Max. switching frequency exceeded

Monitoring

Reaction

Reset

Frequency present at the control input

Switching off of switching paths, display OVL

Reduction in the switching frequency below the permissible

value with consideration of a hysteresis of typically 5 kHz

Excessive temperature

Monitoring

Reaction

Reset

Temperatures of the power components

Stage 1: Increase in fan speed

Stage 2: Switching off of switching paths, display OVL

Switching off and on again using mains switch following

appropriate cooling period

Power switch is not reverse polarity protected!

Reverse polarity voltage applied to the input or output can

damage the unit from excess current or thermal overload.

Connections

Mains voltage

Appliance plug. Voltage range see “General”

Control input

Rated voltage range and impedance

Trigger threshold

Protective circuit / overvoltage range

Impedance outside the rated voltage range

1x BNC, unearthed, at front

1x BNC, unearthed, at rear

-0.5 … 5.5 V / 1 MΩ

<2V (compatible with TTL, CMOS 5V and LVCMOS 3.3V)

Self-resetting fuse / protection up to ± 20 V

> 1 kΩ

Power switch

Input sockets Plus –Minus

High-current socket pair 6 mm red / blue, with touch protection

Output socket OUT

High-current socket 6 mm gray, with touch protection

Second pair of sockets Plus –Minus

High-current socket pair 6 mm red / blue, with touch protection

Signal line switches

Inputs/outputs

Front side connector for connecting screw terminal blocks with

3.81 mm spacing

Matching screw terminal blocks are e.g.:

Phoenix MC 1.5 / 4-ST-3.81 = Article No. 1803594

Würth Elektronik plug-in cable system WR-TBL Series 361

= Article No. 691361300004

Electrical isolation

Between power switch, signal line switches, control input and

PE, max. 42 Vpeak each

Section 4 –Technical Data

TOELLNER Electronic Instrumente GmbH

20

(Technical data, cont.)

General

Mains voltage

Wide-range input 90…264 V AC, 47-63 Hz, Imax = 0.4 A,

rear appliance plug with fuse T1AL according to IEC 127-2/III,

DIN 41662

Power consumption, mains side

Max. 35 VA

Protection

Protection Class I according to DIN EN 61140

Degree of protection IP20 according to IEC 60529

Overvoltage category II according to IEC 60664-1

Pollution degree 2 according to IEC 60664-1

Operating temperature

0 - 40°C

Storage temperature

−20 - 70°C

Reference temperature

23°C ±1°C

Cooling

2-stage thermostatically controlled fan

Overall dimensions (W x H x D)

224 mm x 103 mm x 348 mm

Rack mount dimensions (W x H x D)

224 mm x 88 mm x 325 mm

19" system

Compatible with ½ 19", 2 HU

Weight

Approx. 4 kg

Housing

Aluminum/steel

4.2 General data

Ordering

options

0-50 A, 0-60 V.....TOE 9261-50

0-100 A, 0-60 V.....TOE 9261-100

Included

accessories

1 mains cable

2 terminal blocks for signal line switches

1 Instruction Manual

Optional

accessories

0.50 m connection cable with 1 safety socket, red ...........................................TOE 9260/22

0.50 m connection cable with 1 safety socket, blue..........................................TOE 9260/23

1.20 m connection cable with 1 safety socket, red ...........................................TOE 9260/24

1.20 m connection cable with 1 safety socket, blue..........................................TOE 9260/25

19" adapter set 2 HU (asymmetrical) for 1x TOE 9261 ....................................TOE 9521

19" adapter set 2 HU (parallel connector) for 2 Toellner Instruments ½ 19"....TOE 9522

4.3 Specification of the high-current connectors

The built-in high-current connectors of the TOE 9261 are the following components:

TOE 9261-50.........Safety flush-mounting plug, type ID/S6AR-N-B4S, manufacturer Multi-

Contact

TOE 9261-100 ......Safety flush-mounting plug, type ID/S6AR-N-S, manufacturer Multi-

Contact

Suitable counter piece for crimping assembly on cables is the following:

TOE 9261-50 and TOE 9261-100....... Safety socket, type KBT6AR-N/16-S, manufacturer

Multi-Contact.

This counter piece can only be attached to a cable by

crimping assembly using special tooling, soldering is

impossible.

Table of contents

Other TOELLNER Switch manuals