Introduction

This manual has been prepared as a supplement for the MFS60A.

Please utilize this manual together with the service manual of our outboard motors MFS40A/MFS50A.

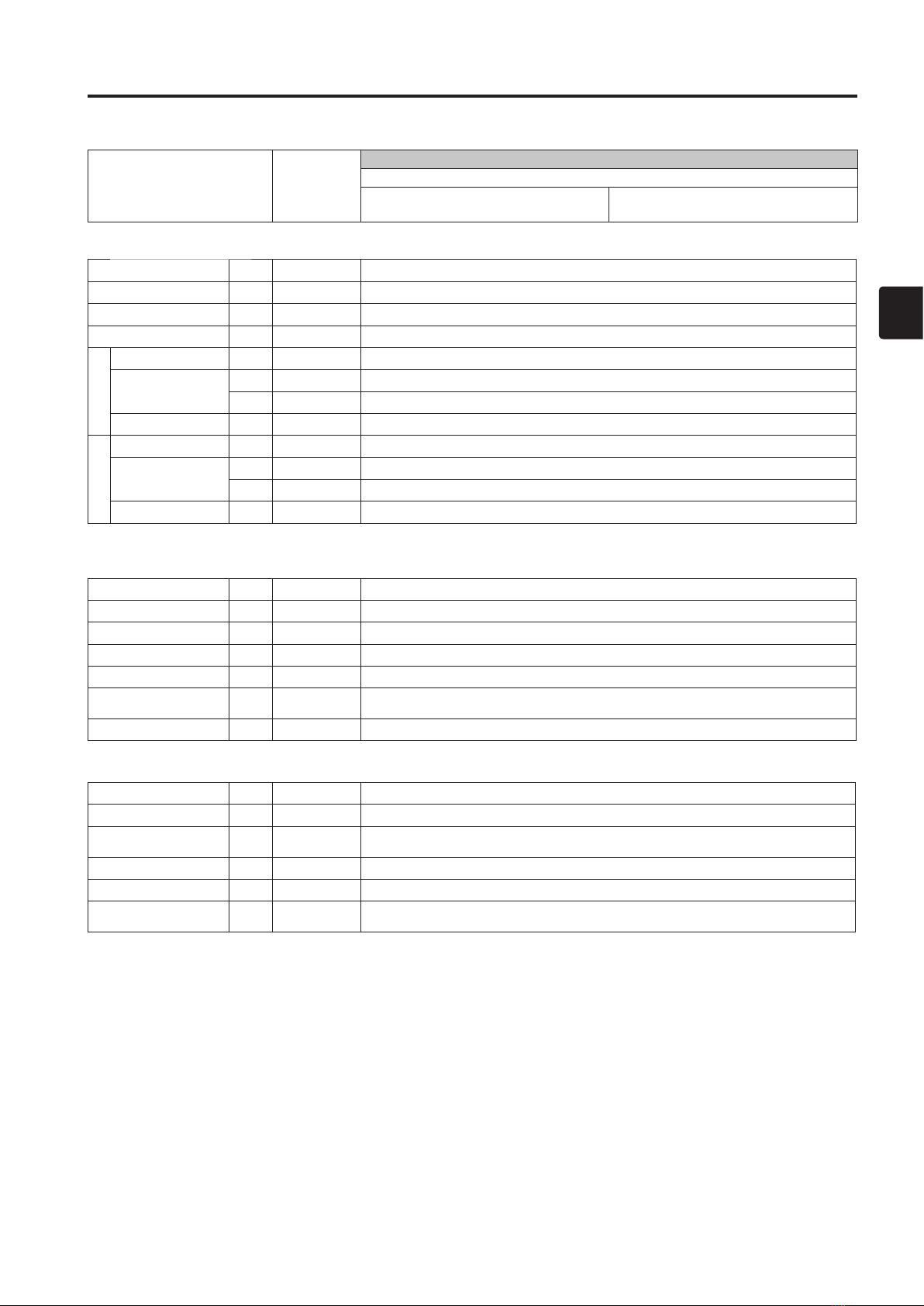

Contents

1. Service Information

1. Tools and Instruments .................. 1-2

1) Test Propeller .......................................... 1-2

2) Measuring instruments ............................ 1-2

2. Service Data

1. Specifications ............................. 2-2

2. Maintenance Data ....................... 2-6

3. Tightening Torque Data ............... 2-14

3. Maintenance

1. Inspection Schedule .................... 3-2

2. Inspection Items......................... 3-3

1) Inspection and Adjustment of

Valve Clearance ...................................... 3-3

2) Inspection of Idle Speed......................... 3-4

3) Inspection of Ignition Timing................... 3-4

4. Fuel System (Fuel Injection)

1. Piping Arrangement Diagram ......... 4-2

Fuel Hose, Vent Hose, Breather Hose,

Cooling Water Hose ...................................... 4-2

2. Ignition System ........................... 4-3

(1) Configuration of ECU System ........ 4-3

(2) Ignition Control........................... 4-4

1) Ignition Timing Controls.......................... 4-4

2) Ignition and Combustion Orders ............. 4-4

3) Ignition Timing ........................................ 4-4

4) Operations ............................................. 4-4

(3) Fuel Feed System......................... 4-5

5. Power Unit

1. Parts Layout ............................... 5-2

Engine .......................................................... 5-2

Magneto ....................................................... 5-3

Electric Parts................................................ 5-4

Fuel system .................................................. 5-6

Vapor Separator............................................ 5-8

Intake Manifold............................................ 5-10

Pulley • Timing Belt....................................... 5-12

Cylinder Head & Oil Pump............................ 5-13

Cylinder • Crankcase .................................... 5-15

Piston & Crankshaft ..................................... 5-16

Top Cowl...................................................... 5-17

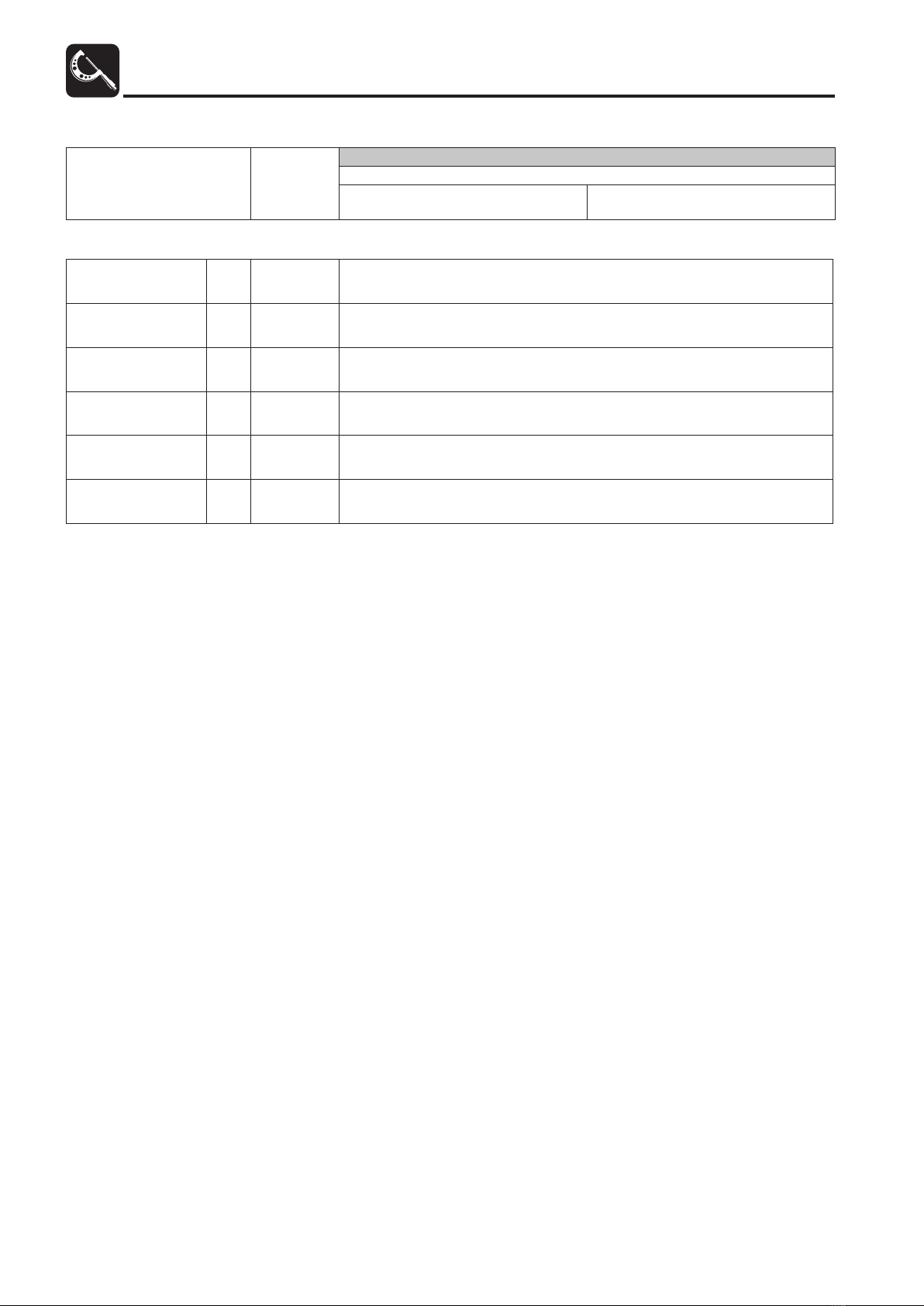

2. Inspection Items ......................... 5-18

1) Inspection of Compression Pressure ..... 5-18

2) Inspection of Oil Pressure...................... 5-18

3) Inspection of Valve Clearance................ 5-18

4) Removing Power Unit............................. 5-18

5) Removing Timing Belt and Pulley............5-22