Tohnichi AMLD1CN User manual

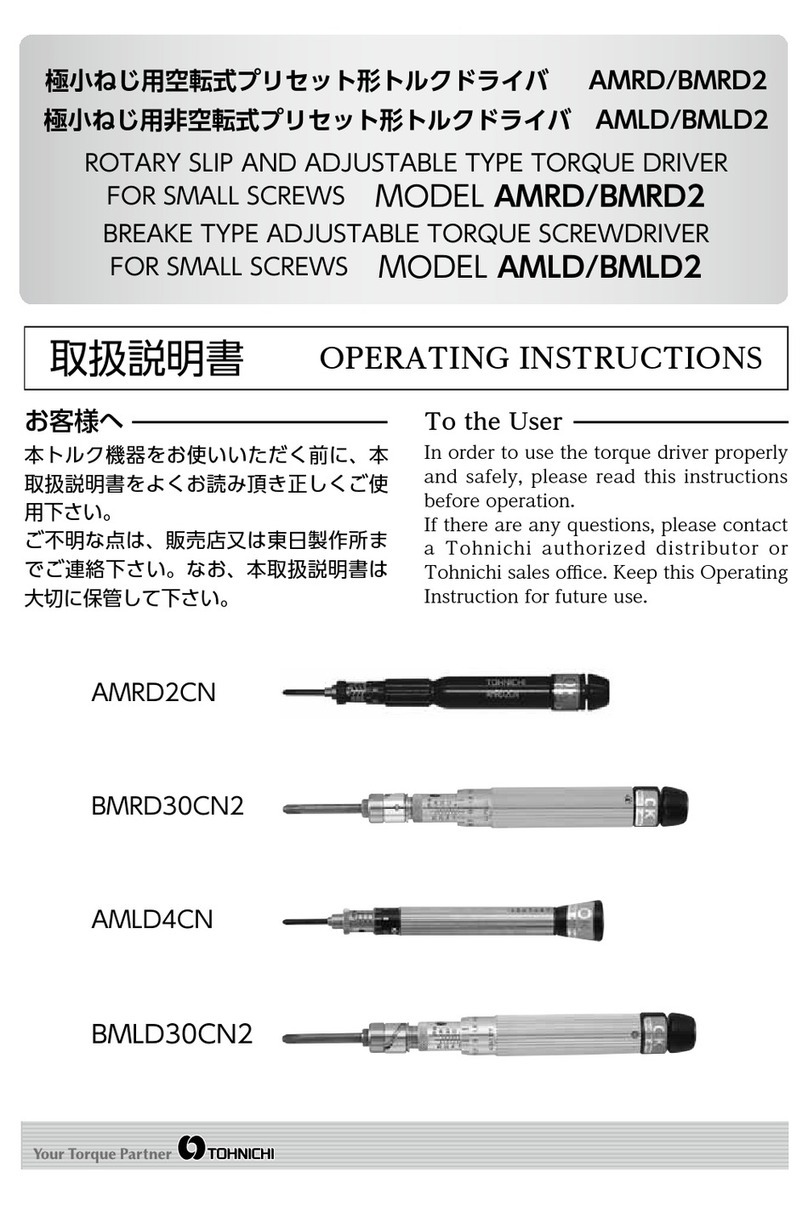

極小ねじ用空転式プリセット形トルクドライバ AMRD/BMRD2

極小ねじ用非空転式プリセット形トルクドライバ AMLD/BMLD2

AMRD/BMRD2

AMLD/BMLD2

OPERATING INSTRUCTIONS

お客様へ

To the User

In order to use the torque driver properly

and safely, please read this instructions

before operation.

If there are any questions, please contact

a Tohnichi authorized distributor or

Tohnichi sales oce. Keep this Operating

Instruction for future use.

Warnings

Precautions when Handling

Application

Features

Specications

Operating Procedure

Torque Set

How to Change Bits

Daily Check and Maintenance

シグナルワード

Signal Words

Signal word is the title which shows the

item which should be known on safe

reservation of people and the handling

of equipment. The signal Word on

safe has the classication of “danger”,

“warning” and “cautions” by the degree

of a risk of doing to people. It uses with

a safe cautions symbol and the following

situation is shown, respectively.

安全注意シンボル

The safety alert symbol

This symbol means Attention! become alert! Your safety is involved.

Take preventive measures in this manual and performing “safety use

and appropriate management.”

“Danger”:Imminent danger acting as a serious obstacle.

“Warning”:A potential risk of becoming a serious obstacle.

“Cautions”: A potential risk of becoming an obstacle although it does not result

seriously.

■ 目次 ■ Contents

1. 警告 1. Warnings

●

Make sure there is no oil or grease on the grip.

A slip of the hand while tighteninig, may cause

an accident or injury.

●

Do not set the torque driver beyond the maximum

torque capacity.This will cause damage or injury.

●

Check for cracks, scratches and rust. These will

cause damage to the driver and may result in

an injury. If such conditions exist, have a func-

tional test performed and repair if necessary.

●

Do not drop the torque driver or apply a strong

shock or jolt. This will cause damage or defor-

mation as well as decrease the accuracy and du-

rability, which may cause an accident or injury.

●

Do not use the torque driver in the rain, high

temperature or high humidity, this may result

in malfunction due to the rust.

●

Do not use the torque driver where there are

high levels of dirt or dust.

2. 取扱上の注意 2.

Precautions when Handling

1.

Make sure a torque driver is set correctly

before using. Set torque is its minimum

when delivered.

2. Don’t use without its scale lange.

3.

Don’t set torque below minimum scale torque.

4. Conrm torque is set according to the

correct unit of measure before using.

(kgf.cm, kgf.m, N.m, cN.m etc)

5. Select a proper bit to adapt to the slit of

the screw head. If not correct, the screw

head may be damaged by the bit.

6. Don’t use in water. The inside mecha-

nism will be in malfunction and cause

an accident or injury. If you drop in

water, Repairing is required.

7. Even with rotary slip clutch, extra clicks

will result in clutch engagement wear-

ing and may shorten durability.

8. When storing, keep from dirt, mud, oil

and water, etc.

3. 用途 3. Application

For tightening screws of watches, preci-

sion electoric components, computer, etc.

4. 特長 4. Features

● Adjustable type torque screwdriver.

Easy torque adjustment with scale.

● Enhanced reliability and durability by

adopting toggle clutch torque mechanism.

●

AMRD/BMRD2 is designed to ratchet freely upon

reaching the set torque to prevent over-torque.

● When reaching the set torque, the

break is felt by hand in 15 degrees.

Stop and complete the tightening work

within the 15 degrees. Ideal for torque

management in the field of precision

electric components due to prevention

of the large shock and vibration.

●

Index nger holding feature allows the op-

erator to tighten with precise movements.

5. 仕様 5. Specications

主目盛

major scale

副目盛

minor scale

Φ8

72

93

13

Φ13

Φ10

フィンガータッチ

finger touch

14

Φ11

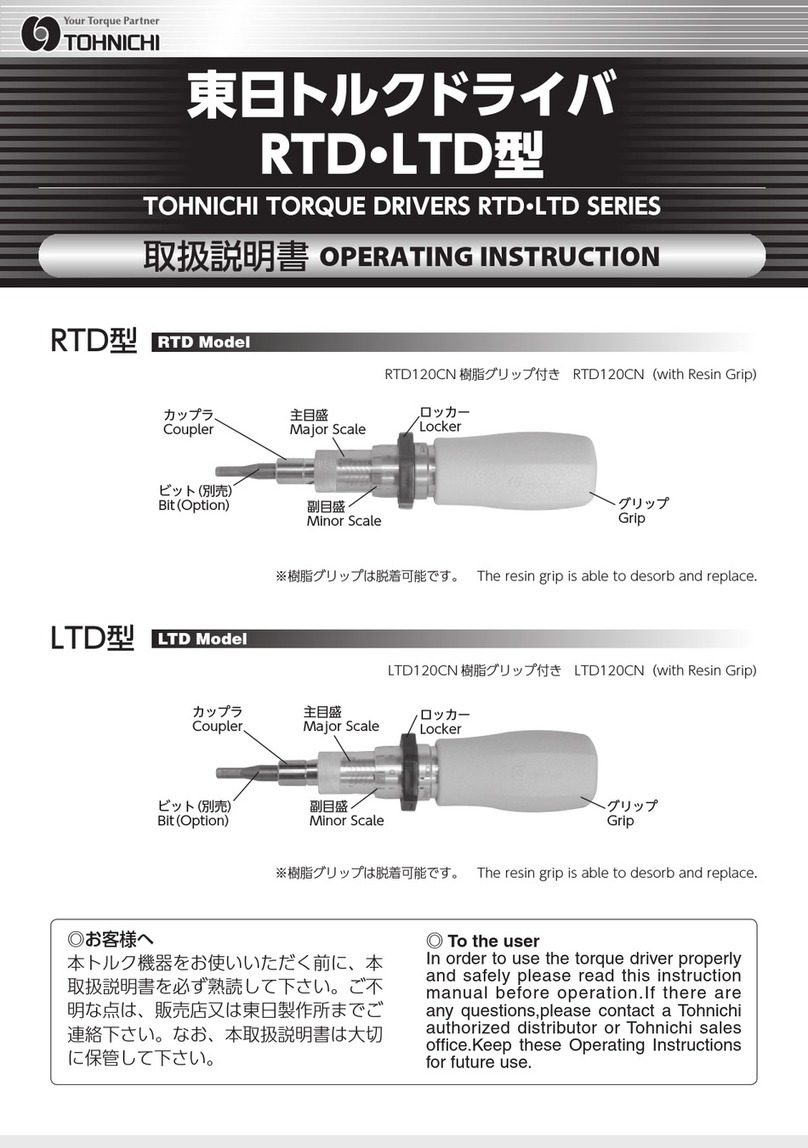

Fig.1 AMRD

φ2

0.2

30°

0.8

2

負荷方向

Direction

6. 使用方法 6. Operating Procedure

1. Hold the knurled part of the main

scale and turn the handle unit the

desired torque is reached.

■ How to set the torque

(1) Turn the handle until the edge of

the minor scale is lined up with the

torque line of the major scale.

(2) Set the vertical torque line of the minor

scale to vertical line of the major scale.

(Refer to “7.Torque Set”)

2. Insert the bit.

* For the AMRD/AMLD, push up the

coupler and insert the bit.

* For the BMRD/BMLD, push the bit

until the ball in the adapter stays in the

center of bit groove.

3. Insert the tip of the bit into slit of

screwhead.

4. Turn the torque screwdriver clockwise

to tighten.

* For AMRD/BMRD2 slips when set

torque reaches.

* For AMLD/BMLD2, when reaching

the set torque, the break is felt by hand

in 15 degrees. Stop and complete the

tightening work within the 15 degrees.

18

Φ11

62

116

10

Φ15

Φ15

主目盛

major scale

副目盛

minor scale

フィンガータッチ

finger touch

Fig.2 BMRD2/BMLD2

22

50 96.35

HEX

Φ8

48

83

14

Φ13

Φ9

14

主目盛

major scale 副目盛

minor scale

フィンガー タッチ

finger touch

Fig.3 AMLD

φ2

0.2

30°

0.8

2

1. Figure4 shows the setting of 0.3cN・m

(major scale points 0.3, minor scale

points 0).

Minor scale has 0.02cN・m of one

graduation, and moves 0.1cN・m

in one roration. Making 4 rotations

clockwise sets 0.7cN・m.

2. From the setting of 0.7cN・m(Fig.5),

turning the minor scale clockwise to

the scale marking of 0.02 sets 0.72cN・

m(Fig.6).

3. From the setting of 0.7cN・m, turning

the minor scale counterclockwise to

the scale marking of 0.08 sets 0.68cN・

m(Fig.7).

7. トルク設定方法 7. Torque Set

主目盛

Main Scale

主目盛基本線

Main Scale Base Line

副目盛

Graduation Sup. 上がる(右回り)

Up

下がる(左回り)

Down

cN m

0.4

0.6

0.8

1

0.9

0.7

0.5

0.3

00.08

0.02

cN m

0.6

0.8

1

0.9

0.7

00.08

0.02

0.6

0.8

1

0.9

0.7

0.02 0

0.04

cN m

cN m

0.6

0.8

1

0.9

0.7

0.5

0.08 0.06

0

Fig.4

0.3cNm

Fig.5

0.7cNm

Fig.6

0.72cNm

Fig.7

0.68cNm

8. ビットの交換方法 8. How to Change Bits

AMRD/BMRD(Fig.8)

1. Insert the bit into the coupler.

2. Push the coupler collar.

3. Push the bit to the end with pushing

the coupler collar.

4. When releasing the coupler collar, bit

will be connected.

・For removing the bit, push the coupler

collar and pull out the bit.

BMRD2/BMLD2(Fig.9)

・Push the bit until the ball in the

adapter stays in the center of bit groove.

・

Use the plier to pull out the bit when the bit is tight.

ビ ット

Bit

カプラカラ

Coupler Collar

①

②

③

④

Fig.8

AMRD/AMLD

ビ ット

Bit

Fig.9

BMRD/BMLD

9. 日常の点検・手入れ 9.

Daily Check and Maintenance

●

Perform regular inspection for function

and accuracy.For torque checking, refer

to ATGE models(digital torque gauge

for very low torque)on the next page.

● Stop operation immediately if there

is any sign of abnormality. Refer all

servicing to your Tohnichi dealer.

● Since professional repair is required,

contact your Tohnichi dealer for re-

pair service. Do not attempt to repair

the Torque Driver yourself.

●

When storing the Torque Driver for a long time, set

at the minimum torque and keep in a dry

place.

0120-1

ト ル ク

69-1

ト ー ニ チ

21

本社

株式会社 東日製作所

トルクのことならお気軽に、ご相談ください。

●営業所(ダイヤルイン)

● Overseas Dept.(Dial in)

●大阪営業所(トルクセンター大阪)

●名古屋営業所 (トルクセンター名古屋)

●広島営業所

■ TOHNICHI MFG.CO.,LTD.

■ N.V.TOHNICHI EUROPE S.A.

■ TOHNICHI AMERICA CORP.

URL http://tohnichi. jp

日常点検用機器のご紹介

Introduction of Daily Torque Checking Equipment

デジタルトルクゲージ ATGE

Digital Torque Gauge model ATGE-G

● 6 models cover torque capacities from

0.1cN・m to 20cN・m.

● Ideal for daily checking for 8 AMRD/

AMLD models(1CN to 8CN)

ATGE-G features multiple units of measure through keypad setup.

(Not available to use in Japan)

測定方向

Direction

This manual suits for next models

25

Table of contents

Other Tohnichi Power Screwdriver manuals