12

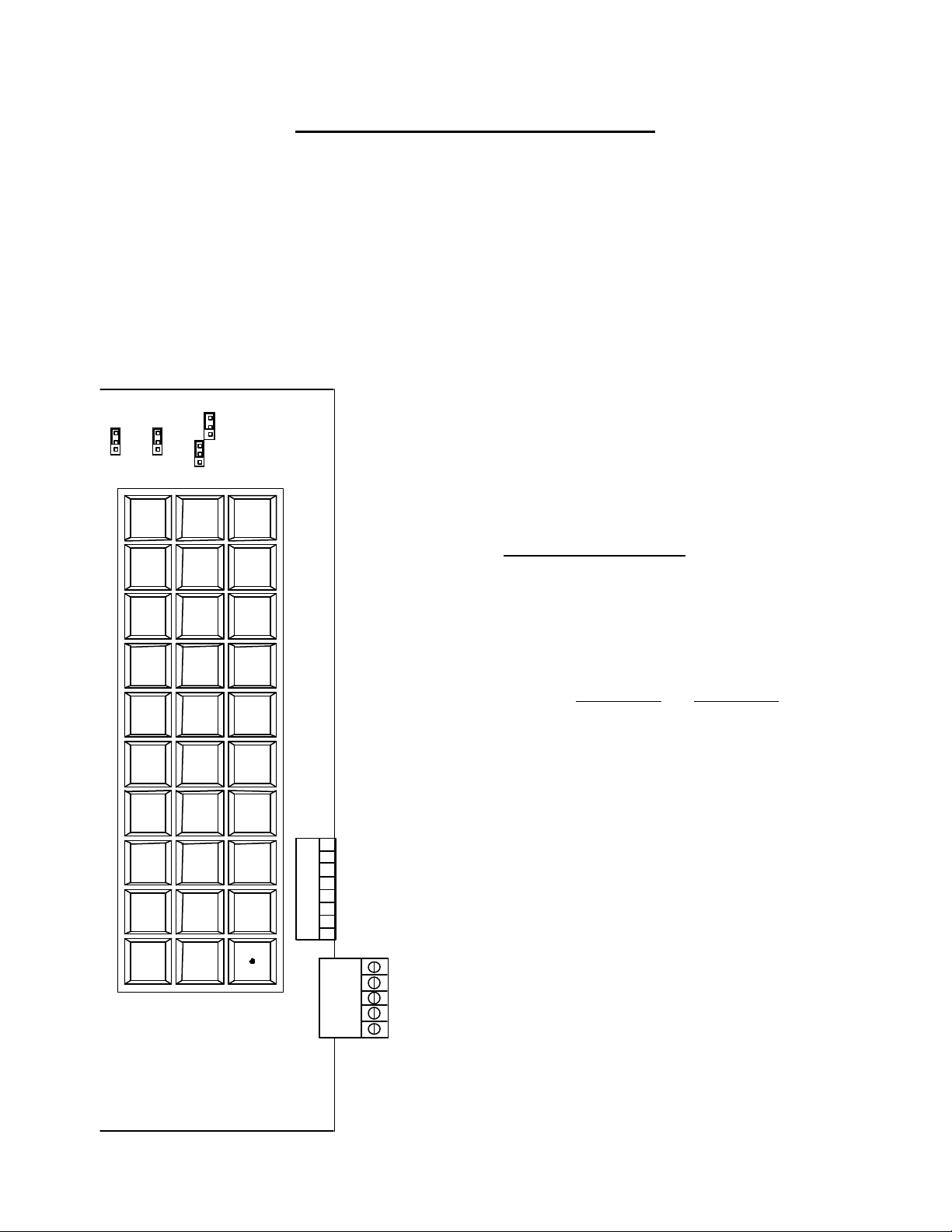

The N269 process control load meter is used to control the variable material fill of a press on the

basis of the peak load. System input can be from one or two strain gage bridge type sensors. In a

single channel system the input is usually a load cell. Systems with two channels generally use

two press frame mounted load sensors. When two sensor inputs are used, the side to side load as

well as the total load is displayed by the N269. The peak load displayed in channel 0 is used to

perform the process control functions. Five relays are used: four control the process and a fifth

can shutdown the machine.

The N269 divides the range of loads into five zones using four process control setpoints. These

setpoints, form the highest to the lowest, are labeled 3, 4, 5 & 6. All loads above #3 are

considered high rejects and all loads below #6 are low rejects. A load value between #3 and #6 is

considered a good part. Setpoint #4 must be set below #3 and above #6. Setpoint #5 is between

#4 and #6. Any load above #4 is in the decrease zone and any load below #5 is in the increase

zone. A load which falls between #4 and #5 is in the OK zone where no adjustment is made.

Any load in the reject zone (low or high) causes the REject relay to operate. Any load in the good

zone (between #3 and #6) causes the GOod relay to operate. The INcrease and DEcrease relays

have preset counters associated with each relay. In order for the DEcrease relay to operate the

load must be in the decrease zone a number of times in a row determined by the setting of the

decrease preset counter. The INcrease relay will operate only when the load has been in the

increase zone the same number of times in a row as is set on the increase preset counter.

The REject relay has a preset counter as well. However, this counter determines the number of

consecutive rejects which must occur before the machine is shutdown using the shutdown relay.

Each process control relay (RE, DE, IN, GO) has a timer which determines the length of time for

which the relay stays on. These timers may be set from 0 to 99.99 seconds in increments of .01

sec.

The machine can also be shutdown immediately in the event of a high load on either sensor input

(channels 1 or 2 if more than one sensor input is used) or the total load (channel 0). The setpoints

which determine the high shutdown load are the high setpoints #0, #1 and #2. When two sensor

inputs are used, another setpoint is used to shutdown the machine if the difference in load between

channels 1 and 2 exceeds this "difference" setpoint. This setpoint is the channel 0 low setpoint.

The N269 keeps track of many counts. Each of the five zones has an 8 digit counter. Each relay

has an 8 digit counter which increments when the relay operates. All loads above setpoint #4 are

counted (decrease zone) as well as all loads below #5 (increase zone) by 8 digit counters. Each

high alarm setpoint and the difference setpoint has a 4 digit counter which counts these

shutdowns. A stroke counter counts every press stroke (8 digits). Finally there is a

predetermined counter (8 digit batch) which can be set to shutdown the press at the end of a

certain number of parts.

Whenever a shutdown occurs, the channel 4 display shows the word "STOP" and the channel 5