Toledo Transducers PressWatch LS-ZT Series User manual

LS-ZT User’s Manual - Installation

DOC #18445 Page

Toledo Integrated Systems

1

PressWatch

Load Signature ZT Series

Load Monitor

User’s Manual

Revision: A

LS-ZT User’s Manual - Installation

DOC #18445 Page

Toledo Integrated Systems

2

Table of Contents

Limited Warranty..................................................................................................................4

Features Overview ................................................................................................................5

Specifications........................................................................................................................7

Installation ...........................................................................................................................9

Mounting the LS-ZT ...........................................................................................................9

LS-ZT Components...........................................................................................................10

Conduit Hole Selection.....................................................................................................11

AC Power Requirement and Connection ............................................................................12

Tonnage Sensor Connection .............................................................................................13

Resolver Connection........................................................................................................17

Resolver Input Setup........................................................................................................19

Shutdown (Stop) Relays ...................................................................................................22

Serial Port Connection .....................................................................................................23

Operation...........................................................................................................................25

Overview ........................................................................................................................25

Initial Startup ..................................................................................................................26

Main Window .................................................................................................................27

Tonnage .........................................................................................................................29

Signatures.......................................................................................................................32

Statistics.........................................................................................................................35

Setpoints ........................................................................................................................36

Configure........................................................................................................................40

Calibration ..................................................................................................................60

Job Settings.....................................................................................................................62

External Configuration Files ..............................................................................................66

Live Data Output Feature .................................................................................................69

Calibration Procedure..........................................................................................................71

Operator’s Guide ................................................................................................................81

Appendix............................................................................................................................83

A) Sensor Installation (Doc# 11080).............................................................................83

B) Calibration Sheets (2) (Form# 1224)........................................................................83

Table of Figures

Figure 1-1: Mounting Dimensions.........................................................................................9

Figure 1-2: LS-ZT Components............................................................................................10

Figure 1-3: Conduit Hole Selection......................................................................................11

Figure 1-4: AC Power Wiring ..............................................................................................12

Figure 1-5: Tonnage Sensor Input.......................................................................................14

Figure 1-6: Tonnage Sensor Cable Stripping.........................................................................15

LS-ZT User’s Manual - Installation

DOC #18445 Page

Toledo Integrated Systems

3

Figure 1-7: Tonnage Sensor Wiring..................................................................................... 16

Figure 1-8: Resolver Input Descriptions .............................................................................. 17

Figure 1-9: Resolver Wiring................................................................................................. 18

Figure 1-10: Resolver Setup ................................................................................................ 19

Figure 1-11: Shutdown Relay Wiring .................................................................................... 22

Figure 1-12: Serial Port Connection...................................................................................... 23

Figure 1-13: Serial PressNet Connection............................................................................... 24

Figure 2-1: System Overview ............................................................................................. 25

Figure 2-2: Communication Error Alert ............................................................................... 26

Figure 2-3: Communication Error (Historical Data Box)......................................................... 26

Figure 2-4: SlimWare Main Window................................................................................... 27

Figure 2-5: Tonnage Screen (4-Channel) ............................................................................. 29

Figure 2-6: Signature Screen (4-Channel) ............................................................................ 32

Figure 2-7: Statistics Screen............................................................................................... 35

Figure 2-8: Standard Setpoints Screen (4-Channel) .............................................................. 36

Figure 2-9: Envelope Setpoints Screen (4-Channel).............................................................. 39

Figure 2-10: Configure Settings - Names Screen .................................................................... 40

Figure 2-11: Configure Settings - User Preferences Screen ..................................................... 41

Figure 2-12: Configure Settings - External App Screen............................................................ 44

Figure 2-13: Configure Settings - Job Settings Screen............................................................. 45

Figure 2-14: Configure Hardware/Trigger - Hardware Configuration Screen............................. 46

Figure 2-15: Configure Hardware/Trigger - Capacity Screen ................................................... 48

Figure 2-16: Configure Hardware/Trigger - Trigger Screen...................................................... 49

Figure 2-17: Configure Alarm Settings Screen (4-Channel)...................................................... 51

Figure 2-18: Configure Comms/Network - Common Screen.................................................... 52

Figure 2-19: Configure Comms/Network - Ethernet Screen .................................................... 54

Figure 2-20: Configure Comms/Network - Serial Screen......................................................... 56

Figure 2-21: Configure Comms/Network - PLC Screen............................................................ 58

Figure 2-22: Configure Calibration Screen............................................................................. 60

Figure 2-23: Load Existing Job Screen................................................................................... 62

Figure 2-24: Edit Existing Job Screen .................................................................................... 63

Figure 2-25: Create New Job Screen..................................................................................... 64

Figure 2-26: Delete Existing Job Screen ................................................................................ 65

Figure 2-27: Ext_Job.ini File................................................................................................. 66

Figure 2-28: Slimware_Stat.ini File....................................................................................... 67

Figure 2-29: livedata.csv File ............................................................................................... 69

LS-ZT User’s Manual - Installation

DOC #18445 Page

Toledo Integrated Systems

4

Limited Warranty

This unit is warranted by the manufacturer, Toledo Transducers, Inc., to be free of

defects in workmanship and materials for one year from date of manufacturer’s

shipment. This warranty is limited to repairing or replacing products which

manufacturer’s investigation shows were defective at the time of shipment by the

manufacturer.

All products subject to this warranty must be returned for examination, repair or

replacement

F.O.B. to: Toledo Transducers, Inc.

6834 Spring Valley Drive

Holland, Ohio 43528

The express warranty set forth herein is in lieu of all other warranties, expressed

or implied, including without limitation any warranties of merchant-ability or

fitness for a particular purpose. All such warranties are hereby disclaimed and

excluded by the manufacturer.

Repair or replacement of defective products as provided above is the sole and

exclusive remedy provided thereunder. The manufacturer shall not be liable for

any further loss, damages, or expenses, including incidental or consequential

damages, directly or indirectly arising from the sale or use of this product.

Any unauthorized repair voids this warranty.

There are no warranties that extend beyond those expressly set forth herein.

LS-ZT User’s Manual - Installation

DOC #18445 Page

Toledo Integrated Systems

5

Features Overview

The PressWatch LS-ZT Series is a press tonnage monitor with signatures. It integrates tonnage

monitoring and signatures with enveloping into ONE system. It features a large 10.1” touch

screen interface, making the tonnage and signatures easy to read and access.

FEATURES

•2 or 4 channel tonnage monitoring

•Hard Hit signature storage

•Reverse tonnage

•Job storage

•Signatures - each press corner and total

•3 password levels

•5 signature zones for enveloping

•PressNet 5 compatibility

•Critical Curve Monitoring - CCM

OPTIONS

•Additional 2 or 4 channels for tonnage

•TR-1 Resolver

•

monitoring or analog input

LS-ZT User’s Manual - Installation

DOC #18445 Page

Toledo Integrated Systems

6

THIS PAGE

INTENTIONALLY

LEFT BLANK

LS-ZT User’s Manual - Installation

DOC #18445 Page

Toledo Integrated Systems

7

Specifications

Tonnage

No. of Channels

Two or Four (Six or Eight optional)

Sensor Inputs

Full bridge strain gage sensors

120 to 1,000 ohms

Up to (8) 350 ohm sensors

Sensor Excitation

Built-in 10VDC @ 250mA max

Sensor Input Connections

Terminal blocks

Balance Range

+/- 1mV/V of sensor imbalance

Gain Ranges

Low range = x50 to x550 adjustable

High range = x500 to x5,500 adjustable

Inaccuracy

+/- 1% of full scale max

Non-linearity

+/- .02% of full scale max

Frequency Response

DC to 5 KHz

Resolution

Each channel provides a 4-digit load value in

1024 count resolution

Calibration Shunts

Built-in 1 mega ohm (.1%). Accepts custom shunt.

Job Storage

Yes

Limited only by available PC storage capacity

Password

Master level

For supervisor

Setup level

For die setter

Operator level

For general operation

Speed Limit

Up to 1200 SPM

Human Machine

Display

10.1" diagonal TFT LCD display

Interface (HMI)

Unit

Full color SVGA graphics

Input

Touch screen standard

(4) USB 3.0 ports available

Operating System

Windows 10

Storage

64GB SSD for operating system and data storage

Network

Integrated Ethernet NIC (x2)

LS-ZT User’s Manual - Installation

DOC #18445 Page

Toledo Integrated Systems

8

Shutdown Relays

(2) solid state relays (N.O.) –Top and Immediate Stop

0.5 AMP @ 250V AC/DC

General

Resolver

Built-in excitation supports standard 5000Hz

rotor excited positional resolver

Computer Interface

Giga LAN Ethernet (x2)

Power requirements

95 Watts max.

85-132VAC @ 50-60Hz or

170-264VAC @ 50-60Hz

Operating temperature

0-50 degrees Celsius

Enclosure Dimensions

13.8" W x 15.75" H x 6.3" D, or

350mm W x 400mm H x 161mm D

LS-ZT User’s Manual - Installation

DOC #18445 Page

Toledo Integrated Systems

9

➢Installation

1. Mounting the LS-ZT

The LS-ZT is an electronic instrument and must therefore be protected from physical stresses such

as shock and vibration. Shock mounts are provided with every LS-ZT for this purpose. Failure to

use these shock mounts may result in premature failure of the instrument and possibly void your

warranty.

The LS-ZT may be mounted directly to the press or to an adjacent structure. It should be

positioned so that the display is easily read, and the instrument is readily accessible. Figure 1-1

below provides the mounting dimensions and demonstrates the proper attachment of the

provided shock mounts. A ground wire is also provided for proper instrument grounding and

should be installed across one of the shock mounts.

Figure 1-1: Mounting Dimensions

LS-ZT User’s Manual - Installation

DOC #18445 Page

Toledo Integrated Systems

10

2. LS-ZT Components

Figure 1-2: LS-ZT Components

Note: The above figure details the layout of a standard 8-Channel LS-ZT. The layout of a

4-Channel LS-ZT will vary slightly.

LS-ZT User’s Manual - Installation

DOC #18445 Page

Toledo Integrated Systems

11

3. Conduit Hole Selection

Follow Figure 1-3 to select the proper conduit hole for cabling. The holes are for ¾” conduit, but

they can be enlarged in the field if a larger fitting is required.

DOOR

#1 #2

#3

CONDUIT HOLES

BOTTOM VIEW

•AC Line •Shutdown

Relay •Tonnage Sensors

Resolver

Serial Communication

•

•

Figure 1-3: Conduit Hole Selection

LS-ZT User’s Manual - Installation

DOC #18445 Page

Toledo Integrated Systems

12

4. AC Power Requirement and Connection

AC power is connected to the LS-ZT as shown in Figure 1-4. Use Conduit Hole #1 (see Figure 1-3)

for the AC Power Wiring. Use the proper fuse as indicated.

Figure 1-4: AC Power Wiring

LS-ZT User’s Manual - Installation

DOC #18445 Page

Toledo Integrated Systems

13

5. Tonnage Sensor Connection

Refer to Figure 1-5 for the procedures below to connect tonnage sensors properly:

1) Power down the unit. Open the door of the LS-ZT enclosure.

2) Run Tonnage Sensor Cables through the Conduit Hole #3 (see Figure 1-3), and upward through

the central wireway. For channels 1-4, route them to the right toward the CH1-4 terminal

blocks. For channels 6-9, route them to the left toward the CH6-9 terminal blocks.

3) Prepare the sensor cable for termination as described in Illustration A on page 15.

4) Wire each sensor cable as described in Illustration B on page 16.

5) The tonnage sensor cable connections are now complete.

LS-ZT User’s Manual - Installation

DOC #18445 Page

Toledo Integrated Systems

14

Figure 1-5: Tonnage Sensor Input

LS-ZT User’s Manual - Installation

DOC #18445 Page

Toledo Integrated Systems

15

Illustration A - Sensor Cable Termination

1) Strip the sensor cable as shown in Figure 1-6 below. Be sure not to nick any of the signal

conductors or cut the braid shield.

Figure 1-6: Tonnage Sensor Cable Stripping

2) Strip approximately ¼" of insulation from each of the four signal conductors.

Note: If your sensor cable is not double shielded with both foil and a braid, electrical noise may

affect your output readings.

LS-ZT User’s Manual - Installation

DOC #18445 Page

Toledo Integrated Systems

16

Illustration B - Sensors Connection

The LS-ZT accepts the signals from Toledo Transducers T-400 sensors as well as other strain gage

sensors. Figure 1-7 illustrates the sensor connections.

T400 Sensor T400 Sensor

Figure 1-7: Tonnage Sensor Wiring

Tension Force

Compression

Force

Tension connection

shown. For compression

connections, switch the

red and white wires

LS-ZT User’s Manual - Installation

DOC #18445 Page

Toledo Integrated Systems

17

6. Resolver Connection

The LS-ZT resolver input has a built-in excitation which supports standard 5,000 Hz rotor-excited

positional resolvers. The input can be configured in Master Mode or Slave Mode. In Master

Mode, the LS-ZT supplies excitation voltage to the resolver and is wired directly to the resolver. In

Slave Mode, the LS-ZT does not supply excitation voltage to the resolver and is wired to the

resolver input terminal of a Master device, where the resolver signal is shared.

Use Conduit Hole #2 (see Figure 1-3) for the Resolver Cable. The resolver input consists of the

following components:

Figure 1-8: Resolver Input Descriptions

LS-ZT User’s Manual - Installation

DOC #18445 Page

Toledo Integrated Systems

18

Resolver Wiring:

Figure 1-9: Resolver Wiring

LS-ZT User’s Manual - Installation

DOC #18445 Page

Toledo Integrated Systems

19

7. Resolver Input Setup

1) The resolver input is set up by configuring the resolver dip switches on the control

module.

Figure 1-10: Resolver Setup

LS-ZT User’s Manual - Installation

DOC #18445 Page

Toledo Integrated Systems

20

2) If the LS-ZT is the only equipment to interface with the resolver, the control module’s DIP

switches should be set to MASTER mode. If the resolver also connects to an AMCI resolver

card, or other similar equipment, the control module should be set to SLAVE mode.

Note: The top two DIP switches must both be set to MTR (Master) or SLA (Slave).

3) Make resolver connection.

4) With the system on (press can be either running or not running), check the brightness of the

ROT LED on the control module.

G

GO

OO

OD

D

D

DI

IM

M

5) If the ROT LED appears to be dim, toggle the ROT, ST1, and ST2 DIP switches to X2.

Table of contents

Other Toledo Transducers Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Tyredog

Tyredog TD-2300A Programming Replacement Monitor

Zoom

Zoom H6essential QuickTour

Audio Precision

Audio Precision B Series Installation Instructions and Specifications

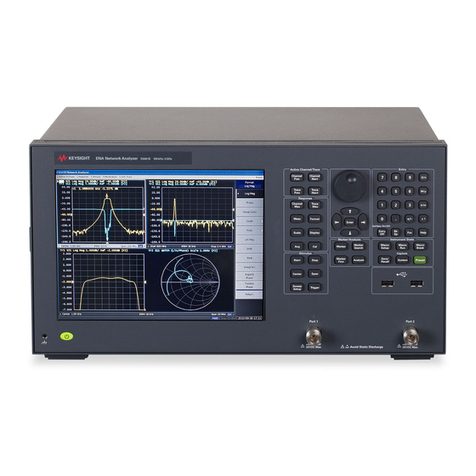

Keysight Technologies

Keysight Technologies E5061B Service guide

AngioDynamics

AngioDynamics DELTA 15 Operator's manual

Major tech

Major tech MT745 instruction manual