ADTEK CS2-T User manual

CS2-T-2010-09-27 C2-09-1/8

CS2-T TEMPERATURE

Indicator

DESCRIPTION

CS2-T Temperature Indicator has been designed with high accuracy

measurement, display and communication of Thermocouple or

Pt100.

They are also building in 4 Relay outputs, 3 External Control Inputs, 1

Analogue output and 1 RS485 (Modbus RTU Mode) interface with

versatile functions such as control, alarm, re-transmission and

communication for a wide range of machinery and testing equipments

application.

FEATURE

●Measuring RTD: Pt100; Thermocouple: K, J, E, T, R, S, B

●4 relay can be programmed individual to be a Hi / Lo / Hi Latch / Lo Latch / Go energized with Start Delay /

Hysteresis / Energized & De-energized Delay functions, or to be a remote control.

●Analogue output and RS 485 communication port in option

●3 external control inputs can be programmed individual to be Relative PV (Tare) / PV Hold / Maximum or

Minimum Hold / DI (remote monitoring) / Reset for Relay Energized Latch….

●CE Approved & RoHS

ORDERING INFORMATION

CS2TInput

Signal −Relay

Output −Analogue

Output −RS 485

Port −

Aux.

Powered

CODE INPUT RANGE CODE INPUT RANGE

CODE

RELAY O/P

CODE

ANALOG O/P

CODE

RS485 PORT CODE AXU. POWER

P1 Pt100-50.00~199.99 °C K1 Type K 0.0~1200.0 °C

N None

NNone

NNone A AC115/230V

P2 Pt100-150.0~800.0 °C J1 Type J 0.0~750.0 °C

R2 2 Relay

8 RS 485

E1 Type E 0.0~1000.0 °C

R4 4 Relay

V0(1) ~ 5 V

0 ~ 10 V

T1 Type T 0.0~400.0 °C

ADH AC 85~264V

DC 100~300V

R1 T/C type R 400~1600 °C

I 0 ~ 10 mA

0(4)~20 mA

ADL DC 20~56V

S1 T/C type S 400~1600 °C

B1 T/C type B 400~1800 °C

Low cut: Settable range: -19999~29999 counts

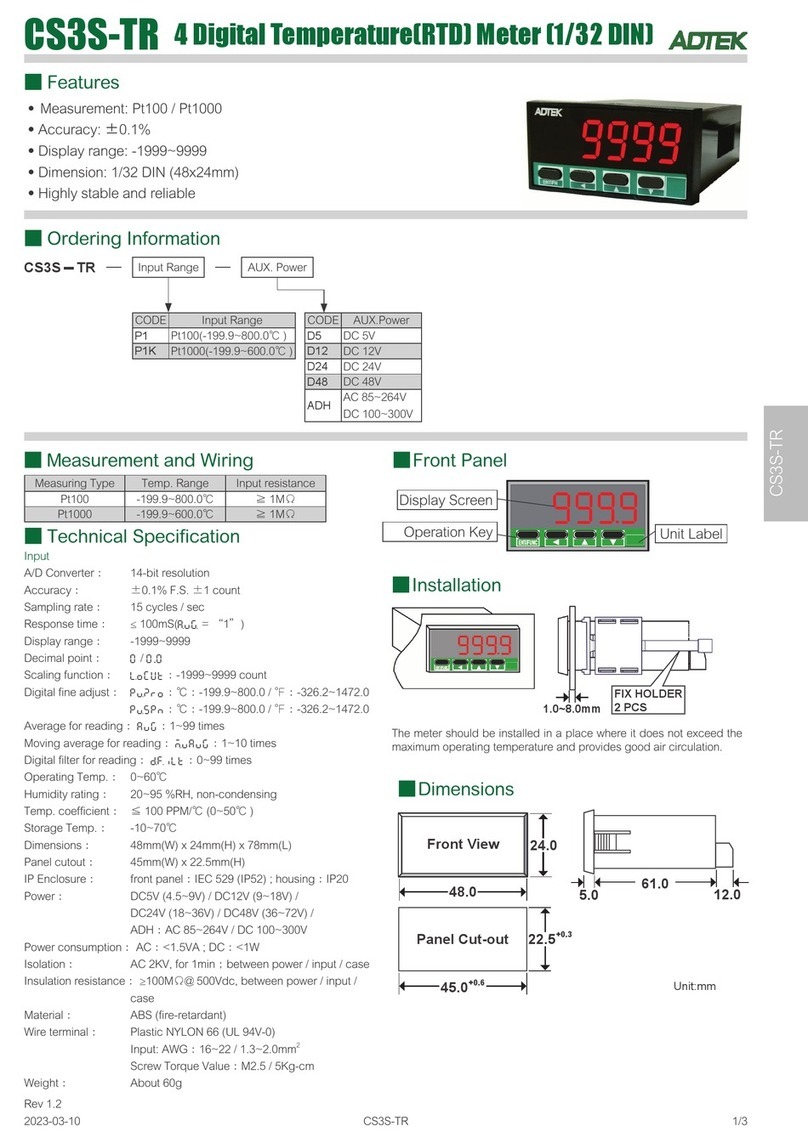

TECHNICAL SPECIFICATION

Digital fine adjust: pVzro: Settable range: -19999~+29999

Input

pVspn: Settable range: -19999~+29999

Measuring Range Input Impedance Excitation Supply

P1 Pt100-50.00~199.99 °C 1M ohm

Reading Stable Function

P2 Pt100-150.0~800.0 °C 1M ohm Sensing Current: 1.6mA

Average: Average:

K1 Type K 0.0~1200.0 °C 1M ohm

Moving average: Moving average:

J1 Type J 0.0~750.0 °C 1M ohm

Digital filter: Digital filter:

E1 Type E 0.0~1000.0 °C 1M ohm

T1 Type T 0.0~400.0 °C 1M ohm

Control Functions(option)

R1 Type R 400~1600 °C 1M ohm

Set-points: Four set-points

S1 Type S 400~1600 °C 1M ohm

Control relay: Four relays

B1 Type B 400~1800 °C 1M ohm

Relay 2 & Relay 3: Dual FORM-C, 5A/230Vac, 10A/115V

Relay 1 & Relay 4: Dual FORM-A, 1A/230Vac, 3A/115V

Calibration: Digital calibration by front key

Relay energized mode: Energized levels compare with set-points:

A/D converter: 16 bits resolution

Hi / Lo / Go.12 / Go.23 / Hi.HLd / Lo.HLd; programmable

Accuracy: Pt100: ±0.1% of FS ±1C;

DO function: Energized by RS485 command of master.

Thermocouple: ±0.2% of FS ±1C;

Banks pre-set: 4 banks pre-set for all relay functions to relative 4

Sampling rate: 15 cycles/sec

difference scaling, and selectable by 3 External

Response time: 100 m-sec.(when the AvG = “1”) in standard

Control Inputs(E.C.I.) Or front key

Cold junction in T/C: 25 ±10˚C, error 0.5˚C

Energizing functions: Start delay / Energized & De-energized delay / Hysteresis /

Energized Latch

Display & Functions

Start band(Minimum level for Energizing): 0~9999counts

LED: Numeric: 5 digits, 0.8”(20.0mm)H red high-brightness LED

Start delay time: 0:00.0~9(Minutes):59.9(Second)

Relay output indication: 4 square red LED

Energized delay time: 0.00.0~9(Minutes):59.9(Second)

RS 485 communication: 1 square orange LED

De-energized delay time: 0.00.0~9(Minutes):59.9(Second)

E.C.I. function indication: 3 square green LED

Hysteresis: 0~5000 counts

Max/Mini Hold indication: 2 square orange LED

Display range: According to sensor range

External Control Inputs(ECI)

Scaling function: Fix range, please don’t set.

Input mode: 3 ECI points, Contact or open collect input, Level trigger

Fix range, please don’t set.

Functions: Relative PV (Tare) / PV Hold / Reset for Max or Mini. Hold /

Decimal point: Fix range, please don’t set.

DI / Reset for Relay Energized latch / 4 Banks selection

Over range indication: ovfl,when input is over 20% of input range Hi

Debouncing time: Settable range 5 ~255 x (8m seconds)

Under range indication: -ovfl,when input is under -20% of input range Lo

Max / Mini recording: Maximum and Minimum value storage during power on.

Display functions: PV / Max(Mini) Hold / RS 485 Programmable

Front key functions: Relative PV / PV Hold / Reset for maxi(mini) hold /

Reset for relay energized latch programmable

CSM-321S

CS2-

V

A

CSM-321S CSM-CSM-

CS2-T

CSM-321S CSM-CSM-

CSM-321SCSM-

CSM-321S

OPTION 2 OPTION 3

OPTION 1

OPTION 4

CS2-T-2010-09-27

C2-09-2/8

Analogue output(option)

Accuracy: ≤±0.1% of F.S.; 16 bits DA converter

DIMENSIONS

Ripple: ±0.1% of F.S.

Response time: 100 m-sec. (10~90% of input)

Isolation: AC 2.0 KV between input and output

Output range: Specify either Voltage or Current output in ordering

Voltage: 0~5V / 0~10V / 1~5V programmable

Current: 0~10mA / 0~20mA / 4~20mA programmable

Output capability: Voltage: 0~10V: ≥1000Ω;

Current: 4(0)~20mA: ≤600Ωmax

Functions: aOhs(output range high): Settable range: -19999~29999

aOls(output range Low): Settable range: -19999~29999

aOlmt (output High Limit): 0.00~110.00% of output High

Digital fine adjust: aOzro: Settable range: -38011~+27524

aOspn: Settable range: -38011~+27524

92.0+0.2

44.0+0.2

PANEL CUT-OUT

96.0

48.0

FRONT VIEW

Unit: mm

8.0 12.0

100.0

Dimensions: 96mm x 48mm x 120mm

Panel Cutout: 93mm x 45mm (advise)

RS 485 Communication(option)

Protocol: Modbus RTU mode

INSTALLATION

Baud rate: 1200/2400/4800/9600/19200/38400 programmable

Data bits: 8 bits

The meter should be installed in a location that does not exceed the

maximum operating temperature and provides good air circulation.

Parity: Even, odd or none (with 1 or 2 stop bit) programmable

Address: 1 ~ 255 programmable

Remote display: to show the value from RS485 command of master

Distance: 1200M

Terminate resistor: 150at last unit.

Electrical Safety

Dielectric strength: AC 2.0 KV for 1 min, Between Power / Input / Output / Case

Insulation resistance: 100M ohm at 500Vdc, Between Power / Input / Output

Isolation: Between Power / Input / Relay / Analogue / RS485 / E.C.I.

1.0~8.0 mm

FIX HOLDER:

104 mm(L) / W M3

R

RL

R

R

COM

C

C

C

ENT/FN

?

?

?

°C

PANEL CU

T

-OUT:

92+0.2(W) x 44+0.2(H) mm

EMC: EN 55011:2002; EN 61326:2003

Safety(LVD): EN 61010-1:2001

CONNECTION DIAGRAM

Environmental

Operating temp.: 0~60 ˚C

Operating humidity: 20~95 %RH, Non-condensing

Temp. coefficient: 100 PPM/˚C

Storage temp.: -10~70 ˚C

Enclosure: Front panel: IEC 549 (IP54); Housing: IP20

Mechanical

Dimensions: 96mm(W) x 48mm(H) x 120mm(D)

Panel cutout: 92mm(W) x 44mm(H)

Case material: ABS fire-resistance (UL 94V-0)

Mounting: Panel flush mounting

Terminal block: Plastic NYLON 66 (UL 94V-0)

10A 300Vac, M2.6, 1.3~2.0mm2(16~22AWG)

21 22 24 2523 27 2826 29 30 31 33 32 34

Relay 3

b

c

a

Relay 2

b

c

a

Relay 1

a

c

Relay 4

a c

Analogue

output

A B

RS 485

port

ECI1 ECI3 COMECI2

External Control Input

FG

1

2

4 53 6 7 8 9

10

11

12

14

15

13

Terminal blocks:

10A/300Vac, M2.6,

M2.6, 1.3~2.0mm2

(16~22AWG)

A

C

86~265V

DC 100~300V

DC 20~56V

AC230V

AUX. POWER

AC115V

ADH

A

DL

SIGNAL

INPUT

T/C

A

B b

Pt100Ω

Weight: 550g / 350g(Aux. Power Code: ADH or ADL)

Power

Please check the voltage of power supplied first, and then connect to

the specified terminals. It is recommended that power supplied to the

meter be protected by a fuse or circuit breaker.

Power supply: AC115/230V,50/60Hz;

Optional: AC 85~264V, DC 100~300V, DC 20~56V

Power consumption: 5.0VA maximum

Back up memory: By EEPROM

FRONT PANEL

Power Supply

AC115/230V

AC85~264V

Filter or Transformer

L

N

G

L

N

G

1A Fuse

7

9

10

8

RL1

RL

2

2

RL

3

RL

4

C

OM

CI11

CI2

CI3

ENT/FN

?

?

?

°C

Comm. status

Relay status

Indication

Operation Key

Control Input

status

Engineer Unit

Display screen

M.H

Max. Hold status

M.H

Mini. Hold status

RS485 Communication Port

RS485 Port

31

32

33

A

B

Max. Distance: 1200M

Terminate Resistor

(at latest unit):

120~300ohm/0.25W

(typical: 150ohm)

CSM-321S

CS2-

V

A

CSM-321S CSM-CSM-

CS2-T

CSM-321S CSM-CSM-

CSM-321SCSM-

CSM-321S

CS2-T-2010-09-27 C2-09-3/8

FUNCTION DESCRIPTION

Display & Functions

Max / Mini recording:

The meter will storage the maximum and minimum value in

[ user level] during power on in order to review drifting of PV.

Display functions:

(Please refer to step A-07)

PV / Max(Mini) Hold / RS 485 programmable in [dsply]

function of [input group]

Present Value p v :The display will show the value that Relative to Input signal.

Maximum Hold maXhd / Minimum Hold miNhd :

The meter will keep display in maximum(minimum) value

during power on, until manual reset by front key in [User

level], rear terminal is close [External Control Input(ECI)]

or press front down or up key to reset (according to setting,

please refer to the function of the ECI Group

)

Default Input:[

l

Os

c

]: )00 , [ hIsc]: 19(99

Digital fine adjustment:

input 2.75mV, [pVzro]set to be 8)00

input 9.00mV, [pVspn]set to be 17)00

Display: Low point from 55.00 to 80.00

High point from 180.00 to 170.00

SCALE

INPUT

0V 10.0m

V

5.0m

V

2.75m

V

9.00mV

19(99

[

h

Is

c

]

[

l

Os

c

]

)

00

10)00

18)00

5

%00

8

)00

17)00

Excit. Pw.

10Vdc

Sensor

1.0mV/V

XPlease find the

M.H

sticker that enclosure the package

of the meter to stick on the right side of square orange LED

Reading Stable Function

Average display:

Max. ( Mini.) Hold & Reset

Reset the Max

(M ini) H o ld by

ECI or F . K e y

O

N

Level

Trigger

Maximum Hold

Present

Value

Jittery Display caused by the noise or unstable signal. User can set the times to average

the readings, and to get smoothly display.

The meter’s sampling is 15cycle/sec. If the [avg](Average) set to be 3 to

express the display update with 5 times/sec. The meter will calculate the sampling 1-3

and update the display value. At meantime, the sampling 4-6 will be processed to

calculate.

Remote Display by RS485 command rs485 :

The meter will show the value that received from RS485

sending. In past, The meter normally receive 4~20mA or 0~10V

from AO or digital output from BCD module of PLC. We support

a new solution that PV shows the value from RS485 command

of master can so that can be save cost and wirin

g

from

PLC.

Other functions :

Average set to be 3

…….Sample 1 Sample 2 Sample 3 Sample 4 Sample 5 Sample 6 …….

Display Update Value =

(Sample 1 + Sample 2 + Sample 3)/3

Display Update Value =

(Sample 4 + Sample 5 + Sample 6)/3

Remark: The higher average setting will cause the response time of

Relay and Analogue output slower.

Moving average:

The meter is also support relative PV (PV) and PV hold

functions that set in [eci group]. Please refer to

explain of ECI functions.

Low cut: Settable range from -19999~+99999 counts.

Jittery Display caused by the reasons as like as noise or unstable signal. User can set

the times to average the readings, and get smoothly display.

The meter’s sampling is 15cycle/sec. If the [ Mavg](Moving Average) set to be 3

expressed the display update with 15 times/sec.,

In the first updated display value will be same as average function. In the next updated

display value, the function will get the new fourth sample (sample 4) then throw away the

first sample (sample 1) that the newest 3 samples(sample 2,3,4) will be calculated for the

u

p

dated dis

p

la

y

value.

The users can set the value range.

1. If set the positive value (X1) here to display "0" which it

expressed to be low-cut the PV between "+X1 (plus)" &

"-X1(minus)" /absolute value

PV< l Setting value (X1) l, the display will be shown 0

EX: Low Cut is set for 0.50. If the display is from

-0.50~+0.50, that will be 0.

Low Cut set to be +0.50

Low Cut is set for 0.50, if the PV is

from -0.50~+0.50, that display will be 0.

PV according

to input signal

Present

Value

Low cut

function

0.50

-0.50

)50

[

lOcut

]

X

1

X

1

Moving Average set to be 3

Sample 1 Sample 2 Sample 3 Sample 4 Sample 5 Sample 6 …….

In first 3 samples, Display Update Value

= (Sample 1 + Sample 2 + Sample 3)/3

Display Update Value

= (Sample 2 + Sample 3 + Sample 4)/3

Display Update Value

= (Sample 3 + Sample 4 + Sample 5)/3

Display Update Value

= (Sample 4 + Sample 5 + Sample 6)/3

…….

Remark: The higher moving average setting wouldn’t cause the

response time of Relay and Analogue output slower after first 3

samples.

Digital Filter: The digital filter can reduce the magnetic noise in field.

2. If set the negative value (X2) here to display "X2" which it

expressed to be low-cut the PV that it's under the X2 setting

value;

PV< Setting value(X2), the display will be shown X2.

EX: Low Cut is set for -0.01. If the display is < -0.01, and all

the dis

p

la

y

will be -0.01.

The digital filter can reduce the influence of spark noise caused by

magnetic of coil.

If the values of samples are over digital filter band (fix in firmware and about

5% of stable reading) 3 times (Digital Filter set to be 3) continuously, the

meter will admit the samples and update the new reading. Otherwise, it

will be as treat as a noise and ski

p

the sam

p

les.

Low Cut set to be -0.10

-0.10

Low cut

function

Low Cut is set for -0.10, if the PV is

under (< = -0.10), that display will be -0.10.

Present

Value

PV according

to input signal

-)10

[

lOcut

]

X2

Digital fine adjust: Settable range: -19999~+29999

Users can get Fine Adjustment for Zero & Span of PV by front key of the

meter, and “Just Key In” the value which user want to show in the

current input signals.

Especially, the [pVzro] & [pVspn] are not only in zero & span of PV, but

also any lower point for [pVzro] & higher point for [pVspn]. The meter

will be linearization for full scale.

CS2-

V

A

CSM-321S CSM-CSM-

CS2-T

CSM-321S CSM-CSM-

CSM-321SCSM-

CSM-321S

CS2-T-2010-09-27

C2-09-4/8

Control Functions(option)

Start band rYsb (Fig.2-c): Settable range from 0~9999 Counts

Relay energized mode: Hi / Lo / Go-1.2 / Go-2.3 / Hi.HLd / Lo.HLd / DO programmable

Start delay time rYsd (Fig.2-d): Settable range from 0.0(s)~9(m)59.9(s);

Hi hi(Fig.1-c): Relay will energize when PV > Set-Point

Lo lo (Fig.1-d): Relay will energize when PV < Set-Point

Start Delay Fig.2

Start Dela

y

Time

Start Band

Hi Setting

Relay

Energized ON

Inhibit

Inhibit

[

r

Y

sb]

[

r

y_.

s

p

]

[

rYsd

]

c

d

Hi / Lo Relay Energized Fig.1

Hi Setting

Hi Relay Energized ON

Lo Setting

Lo Relay Energized ON

hi

lo

[ry_.sp]

[ry_.sp]

[ry_.md]c

d

Hysteresis ry_.hy (Fig.3-c): Settable range from 0~9999 Counts

Go-1.2 go-!2:

As the display value is swing near by the set point to cause the relay on

and off frequently. The function is to avoid the relay on and off frequently

such as compressor…….etc.,

Relay energized delay ry_.rd (Fig.3-d): Settable range from 0.0(s)~9(m)59.9(s);

This function is programmable in Relay 4 only.

If the Relay 4 set to be Go function, the relay will compare with

[ry!sp] and [ry@sp].

Go relay energized when the condition is

[

ry!sp

]

(

Hi

)

> PV >

[

ry@sp

]

(

Lo

)

Go-2.3 go-@3:.

The function is to avoid the miss action caused by noise. Sometime, the

display value will swing caused by spark of contactor…etc.. User can set

a period to delay the relay energized.

Relay de-energized delay ry_.fd (Fig.3-e): Settable range from 0.0(s)~9(m)59.9(s);

This function is programmable in Relay 4 only.

If the Relay 4 set to be Go function, the relay will compare with

[ry@sp] and [ry#sp].

Go relay energized when the condition is

[

ry@sp

]

(

Hi

)

> PV >

[

ry#sp

]

(

Lo

)

Energized / De-energized

Delay & Hysteresis

Fig.3

ON

Hysteresis

De-energized

dela

y

time

Hi Setting

Relay

Energized

[

r

y_.

s

p]

[

r

y_.

h

y

]

[

ry_.rd

]

[

r

y_.

f

d

]

Energized delay time

c

de

Hi / Lo / Go Relay Energized

Hi Settin

g

Hi Relay Energized ON

Lo Setting

Lo Relay Energized

ON

ON

Go Relay Energized ON

ON

Hi.HLd hIhld (Lo.HLd lOhld) :

External Control Inputs(ECI)

The three external control inputs are individually programmable to

perform specific meter control or display functions. All E.C.I. have been

designed in level trigger actions. Please pay attention, the ECI1 or ECI2

input will be disable while UP or Down Key has been set to be “ yes”.

Functions:

Relative PV / PV Hold / Reset Max or Mini. Hold / DI / Reset

for Relay Energized latch programmable.

Relative PV reLpv:

The [ ecI_]can be set to be reLpv function. When the

E.C.I. is closed, the reading will show the differential value.

The relay energized with latched function is for electrical

safety and human protection.

For example, a current meter relay installed for the over

current alarm of motor. Generally, over current of motor

caused by over load, mechanical dead lock, aging of

insulation and so on.

Above cases will alarm in the meter, if the user doesn't figure

out the real reason and re-start the motor. It may damage the

motor. The functions of Hi.HLd & Lo.HLd are designed must

be manual reset the alarm after checking out and solving the

issue. It's very important idea for electrical safety and human

protection.

As the PV Higher (or lower) than set-point, the relay will be

energized to latch except manual reset by from key in [ user

level

]

or

[

eci

]

(

ECI

)

set to be rYrst is closed.

Relative PV

Relative

PV(?PV) by

ECI or F.Key

ON

Level

Trigger

Present

Value

r

eLpv

[

e

cI_

]

ECI_ has closed, and

then P V g oes to “0”

ECI_ has opened,

and then display

shows PV

Relativ e PV

PV Hold pVhld:

The [ ecI_]can be set to be pVhld(PV Hold) function. The

display will be hold when the E CI is closed, until the ECI is to

be open. Please refer to the below figures,

Hi(Lo) Energized Latch & Reset

Hi.HLd(High Hold)

Rela

y

Ener

g

ized ON

Reset the relay Hold

by ECI or Front Key

ON

Level Trigger

Hi Setting

hIhld

[ry_.md]

rYrst

[ ecI_]

[ry_.sp]

DO function d o :

PV Hold & Reset

Present

Value

Reset PV Hold

by E.C.I. or

Front Key

O

N

Level

Trigger

ON ON

PV Hold

p

Vhld

[

ecI_

]

Reset for Maximum or Minimum Hold Mrst:

The function has been designed not only a meter but also an

I/O interface. In the case of motor control cabinet can't get the

remote function. It's very easily to get the ON/OFF status of

switch from CS2 series with RS485 function.

If the [ry_.md]had been set d o , the relay will be

energized by RS485 command directly, but no longer to

com

p

are with set-

p

oint.

Start delay band and Start delay time:

When the [dsply] function in [input group] selected

maXhd or miNhd, the display will show Maximum or

Minimum value.

The [ ecI_] function can be set to be Mrst

function to reset the maximum and minimum value in

[User Level] by terminals of ECI (close). Please refer to

the fi

g

ure

as below.

The functions have Been designed for,

►To avoid starting current of inductive motor (6 times of rated current)

with alarm.

►If the ry_.md relay energized mode had been set to be lo(Lo) or

lOhld(Lo & latch). As the meter is power on and no input to display

the "0" caused the relay will be energized. User can set a band and

dela

y

time to inhibit the ener

g

ized of rela

y

.

CSM-321S

CS2-

V

A

CSM-321S CSM-CSM-

CS2-T

CSM-321S CSM-CSM-

CSM-321SCSM-

CSM-321S

CS2-T-2010-09-27 C2-09-5/8

Fine zero & span adjustment:

Users can get Fine Adjustment of analogue output by front key of the

meter. Please connect standard meter to the terminal of analogue

output. To press the front key(up or down key) of meter to adjust and

check the output.

Zero adjust [aOzro]:Fine Zero Adjustment for Analog Output;

Settable range: -38011~27524;

Max. ( Mini.) Hold & Reset

Reset the max storage

when ECI has closed

Reset the Max.

(Mini.) storage

by E.C.I.

O

N

Level

Trigger

Maxi in User Level

Present

Value

M

rst

[

e

cI_

]

Span adjust [aOspn]:Fine Span Adjustment for Analog Output;

DI d i :

Settable range: -38011~27524;

The E.C.I can be set to be d i function, when the meter

building in RS485 port. It is easier to get remote monitoring a

switch status through the meter as like as DI of PLC.

Reset for Relay Energized Latch rYrst:

RS 485 communication(option)

If the relay energized mode has been set to be

hIhld(Energized latch), and the [ecI_]can be set to be

rYrst(Reset the Relay energized latch). When the PV

meets the condition of relay energizing, the relay will be

ener

g

ized and latch until the ECI is to be closed.

CS2 series supports Modbus RTU mode protocol to be used as Remote

Terminal Unit (RTU) for monitoring and controlling in a SCADA

(Supervisor Control And Data Acquisition) system. The baud rate can be

up to 38400 bps. It's not only can be read the measured value and DI

(external control inputs) status but also controls the relays output (DO) by

RS485 communication

p

orts.

Hi(Lo) Energized Latch & Reset

Hi.HLd(High Hold)

Rela

y

Ener

g

ized ON

Reset the relay Hold

by ECI or Front Key

ON

Level Trigger

Hi Setting

hIhld

[ry_.md]

rYrst

[ ecI_]

[ry_.sp]

Debouncing time:

The function is for avoiding noise signal to into the meter. And The basic

period is 8mseconds. It means you set the number that has to multiple 8

m-seconds.

For example: [debnc]set to be 5, it means 5 x 8mseconds = 40mseconds

CS2-T & SC2-RL APPLICATION MEASURING & RS485 COMMUNICATION

RS 485

Modbus RTU Mode (up to 38400bps)

RS485 wiring 1.2KM maximum

T

erminate Resistor:

Analo

g

Output 0~10V/0(4)~20mA

3 External Control Inpu

t

s:

Functions: Relative PV / PV hold / Reset for

Max(Mini) / Reset for relay latch / DI

Application: Leakage test / Thermal Switch /

Circuit Breaker / Push Button / …

4 Relay outputs:

Functions: Hi(Lo) alarm / Hi(Lo)

energized hold / Go

function / DO function

RL1

RL2

RL

3

RL4

COM

ECI1

ECI2

ECI3

ENT

/

FN

◄

▲

▼

Kg/cm

2

RL

1

RL

2

RL

3

RL4

COM

ECI1

ECI2

ECI3

ENT

/

FN

◄

▲

▼

Kg/c

m

2

Analogue output(option)

Remote Display:

Please specify the output type either an 0~10V or 4(0) ~ 20mA in

ordering. The programmable output low and high scaling can be based

on various display values. Reverse slope output is possible by reversing

point positions.

Output range: Voltage: 0~5V / 0~10V / 1~5V programmable

The meter will show the value that received from RS485 command. In

past, The meter normally receive 4~20mA or 0~10V from AO or digital

output from BCD module of PLC .We support a new solution that PV

shows the value from RS485 command of master so that can be save

cost and wirin

g

from PLC.

Current: 0~10mA / 0~20mA / 4~20mA programmable

Functions: Output High / Low scale, output limit, fine adjustment

Output range high [ aOhs]:

When the [ dsply] set to be RS485, it means, the PV screen will show the

number from RS485 command & data. The data (number) will be same as

PV that will compare with set-point, analogue output and ECI functions so

that is to control analogue output, relay energized and so on.

To setting the Display value High to versus output range

High(as like as 20mA in 4~20)

Output range low [ aOls]:

To setting the Display value Low to versus output range

Low(as like as 4mA in 4~20)

CS2 APPLICATION FOR REMOTE DISPLAY FROM RS485 COMMAND

RS 485

Modbus RTU Mode

(

u

p

to 38400b

p

s

)

RS485 wiring 1.2KM maximum

Terminate Resistor:

RL1

RL

2

RL

3

RL4

COM

E

C

I1

E

C

I

2

E

C

I

3

ENT/FN

◄

▲

▼

Kg/cm

2

RL1

RL

2

RL

3

RL4

COM

E

C

I1

E

C

I

2

E

C

I

3

ENT/FN

◄

▲

▼

Kg/cm

2

Calibration

System calibration by front key. The process of calibration,

please refer to the operating manual

Set Scaling: [ lOsc]: 0.00, [ hIsc]: 199.99;

Output: [ aOls]: 50.00(Display Value Low),

[ aOhs]: 150.00(Display Value High)

0.00% 100.00%50.00% OUTPUT

199.99

100.00

0.00

50.00

150.00

SCALE

[

aOls

]

[

aOhs

]

The range between [ aOhs]and [ aOls]should be over

20% of span at least; otherwise, it will be got less resolution of

analogue output.

Output High Limit [ aOlmt]:

0.00~110.00% of output High User can set the high limit of

output to avoid a damage of receiver or protection system.

Set Scaling: [ lOsc]: 0.00, [ hIsc]: 199.99;

Output: [ aOls]: 50.00(Display Value Low),

[ aOhs]: 150.00(Display Value High)

[aOlmt]: 80.00%( of Output Range)

0.00% 100.00%50.00%

OUTPUT

199.99

100.00

0.00

50.00

150.00

SCALE

Ao.LMt: 80.00%

80.00%

[

aOhs

]

[

aOls

]

[

aOlmt

]

CSM-321S

CS2-

V

A

CSM-321S CSM-CSM-

CS2-T

CSM-321S CSM-CSM-

CSM-321SCSM-

CSM-321S

CS2-T-2010-09-27

C2-09-6/8

ERROR MESSAGE

BEFORE POWER ON, PLEASE CHECK THE SPECIFICATION AND CONNECTION AGAIN.

SELF-DIAGNOSIS AND ERROR CODE:

DISPLAY DESCRIPTION REMARK

ovfl Display is positive-overflow (Signal is over display range) (Please check the input signal)

-ovfl Display is negative-overflow (Signal is under display range) (Please check the input signal)

ovfl ADC is positive-overflow (Signal is higher than input range

high 20%) (Please check the input signal)

-ovfl ADC is negative-overflow (Signal is lower than input range low

-20%) (Please check the input signal)

eep

fail EEPROM occurs error (Please send back to manufactory for repaired)

aiCng

p v Calibrating Input Signal do not process (Please process Calibrating Input Signal)

aic

fail Calibrating Input Signal error (Please check Calibrating Input Signal)

aoCng

p v Calibrating Output Signal do not process (Please process Calibrating Output Signal)

aoc

fail Calibrating Output Signal error (Please check Calibrating Output Signal)

FRONT PANEL:

RL1

RL

2

2

RL

3

RL4

C

OM

CI11

CI2

CI3

ENT/FN

?

?

?

°C

Comm. status

Relay status

Indication

Operation Key

Control Input

status

Engineer Unit

Display screen

M.H

Max. Hold status

M.H

Mini. Hold status

Numeric Screens

0.8”(20.0mm) red high-brightness LED for 4 2/3 digital present value.

I/O Status Indication

●Relay Energized: 4 square red LED

RL1

display when Relay 1 energized;

RL

2

display when Relay 2 energized;

RL

3

display when Relay 3 energized;

RL4

display when Relay 4 energized;

●External Control Input Energized: 3 square green LED

ECI1

display when E.C.I. 1 close(dry contact)

ECI

2

display when E.C.I. 2 close(dry contact)

ECI3

display when E.C.I. 3 close(dry contact)

●RS485 Communication: 1 square orange LED

CO

M

will flash when the meter is receive or send data, and CO

M

flash

quickly means the data transient quicker.

●Max/Mini Hold indication: 2 square orange LEDs

CO

M.H

displayed: When the display function has been selected in

Maximum or Minimum Hold function.

Stickers:

Each meter has a sticker what are functions and engineer label

enclosure.

●Relay energized mode: H

H

H i

L

o

L

L

D

O

●E.C.I. functions mode:

PV.H(PV Hold) / Tare /

DI(Digital Input)

M.RS(Maximum or Minimum Reset) /

R.RS(Reset for Relay Latch)

●Engineer Label: over 80 types.

Operating Key: 4 keys for

Enter(Function) /

Shift(Escape) /

Up key /

Down key

Setting Status Function Index

Up key Increase number Go back to previous

function index

Down key Decrease number Go to next

function index

Shift key Shift the setting

position

Go back to this function

index, and abort the setting

Enter/Fun

key

Setting Confirmed

and save to EEProm

From the function index to

get into setting status

Pass Word Pcode: Settable range: 0000~9999;

User has to key in the right pass word so that get into【Programming

Level】. Otherwise, the meter will go back to measuring page. If user

forgets the password, please contact with the service window.

Function Lock: There are 4 levels programmable.

●None none: no lock all.

●User Level user: User Level lock. User can get into

User Level for checking but setting.

●Programming Level eng: Programming level lock.

User can get into programming level for checking but setting.

●ALL a l l : All lock. User can get into all level for checking but

setting.

Front Key Function

●The

Key can be set to be the same function as the setting of ECI1.

Ex. The ECI1 set to be pVhld and the function [E1=up]set to be

yes in [ eci group]. When user presses

Key, the PV will hold

as like as ECI1 close.

●The

Key can be set to be the same function as the setting of ECI2.

Ex. The ECI2 set to be reLpv and the function [E2=dn]set to be

yes in [ eci group]. When user presses

Key, the PV will show

relative value as like as ECI2 close.

XIf the front key function has been set, the terminal input for ECI

will be disabling.

CSM-321S

CS2-

V

A

CSM-321S CSM-CSM-

CS2-T

CSM-321S CSM-CSM-

CSM-321SCSM-

CSM-321S

CS2-T-2010-09-27 C2-09-7/8

OPERATING DIAGRAM (The detail description of operation, please refer to operating manual.)

Power ON

*****

Self-diagnosis

001

2

99(9

pv

If the [dsply]

function has

been set rs485

pv: Present

Value

04

10000

r

y

$

s

p

ry$sp: Relay 4

Set-point

-19999~29999

08

no

Mrst

Mrst: Reset the

saved value of

Maximum &

Minimum

yes / no

cs@t

Show the model

number

01

10000

r

y!sp

ry!sp: Relay 1

Set-point

-19999~29999

05

n

o

r

Y

rst

rYrst: Reset

for energized

Latch of Relay

yes / no

09

ver!4

cs@t

model number

firmware

version

Checking only

ver!4

Show

the firmware

version

02

10000

r

y@sp

ry@sp: Relay 2

Set-point

-19999~29999

06

)

0000

m

in

min: the

Minimum value

of PV saving

Checking only

001

299(9

pv

Cyclic to first

page

299(9

ENT

MEASURING

PAGE

Press

1sec

Press

1sec

03

10000

r

y#sp

ry#sp: Relay 3

Set-point

-19999~29999

07

2

9

999

m

ax

max: the

Maximum value

of PV saving

Checking only

enter

Pcode

ENT

Enter the

password to

access Engineer

Level

YES

Pass Code

NO

Default:1000

input

group

ENT

INPUT

GROUP

▲

▼

r

elay

g

roup

ENT

RELAY

GROUP

▲

▼

e

ci

g

roup

ENT

EXTERNAL

CONTROL

INPUT (E.C.I)

GROUP

▲

▼

ao

group

ENT

ANALOGUE

OUTPUT

GROUP

▲

▼

A1

0

pVdp

pVdp: Decimal

Point

Don’t set

B1

0

rYsb

rYsb: Start band

for Relay

energized

0~9999counts

C1

r

eLpv

e

cI1

ecI1: External

Control Input 1

none / reLpv /

pVhld / Mrst /

rYrst / d i

D1

A4-20

aOtyp

aOtyp: Analogue

Output type

selection

V0-10 / V 0-5 /

V 1-5 / A0-10 /

A0-20 / A4-20

A2

0

lOsc

lOsc: Low scale

of PV

Don’t set

B2

)0)0

rYsd

rYsd: Start delay

time for Relay

energized

0.00.0~

9(M).59.9(S)

C2

p

Vhld

e

cI

2

ecI2: External

Control Input 2

none / reLpv /

pVhld / Mrst /

rYrst / d i

D2

)0

aOls

aOls: Analogue

Low Output

versus Low

Scale

-19999~29999

A3

10000

hIsc

hIsc: High

scale of PV

Don’t set

B3

hi

r

y!md

ry!md: Relay 1

energized mode

off / lo /

hi / lOhld /

hIhld / d o

C3

M

rst

e

cI3

ecI3: External

Control Input 3

none / reLpv /

pVhld / Mrst /

rYrst / d i

D3

100)0

aOhs

aOhs: Analogue

High Output

versus High

Scale

-19999~29999

A4

0

pVzro

pVzro: Fine Low

point

Adjustment for

PV display

-19999~29999

B4

0

r

y!hy

ry!hy: Relay 1

Hysteresis

0~5000 counts

C4

12

d

ebnc

debnc:

Debouching of

external control

Input

5~255(x8ms)

D4

0

aOzro

aOzro: Fine Zero

Adjustment for

Analogue Low

Output

-38011~27524

A5

0

pVspn

pVspn: Fine

High point

Adjustment for

PV display

-19999~29999

B5

)0)0

r

y!rd

ry!rd: Relay 1

energized delay

time

0.00.0~

9(M).59.9(S)

C5

n

o

E

1=up

E1=up: ECI.1 set

to be UP Key

function

yes / no

D5

0

aOspn

aOspn: Fine

Span Adjust. for

Analogue High

Output

-38011~27524

A6

none

ZSclr

ZSclr: Clear

Fine Zero &

Span

Adjustment for

PV display

none / pVzro /

pVspn / both

B6

)0)0

r

y!fd

ry!fd: Relay 1

de-energized

delay time

0.00.0~

9(M).59.9(S)

C6

n

o

E

2

=

d

n

E2=dn: ECI.2 set

to be Down Key

function

yes / no

D6

none

ZSclr

ZSclr: Zero &

Span Clear for

Adjustment

none / aOzro /

aOspn / both

Next Page

Next Page

Next Page

CSM-321S

CS2-

V

A

CSM-321S CSM-CSM-

CS2-T

CSM-321S CSM-CSM-

CSM-321SCSM-

CSM-321S

User Level

Press

for 1 sec. can back to Measuring

Pro

g

rammin

g

Level

Press

for 1 sec. can back to Measuring

▼

▲

CS2-T-2010-09-27

C2-09-8/8

A7

pv

dsply

dsply: Display

Function

p v / miNhd /

maXhd / rs485

B7

hi

r

y@md

ry@md: Relay 2

energized mode

off / lo /

hi / lOhld /

hIhld / d o

D7

11)00

aOlnt

aOlmt: Analog

Output High

Limit

0.00~110.00%

A8

0

lOcut

lOcut: Low Cut

Function

-19999~29999

B8

0

r

y@hy

ry@hy: Relay 2

Hysteresis

0~5000 counts

A9

5

avg

avg: Average

update for PV

1(None)~

99 times

B9

)0)0

r

y@rd

ry@rd: Relay 2

energized delay

time

0.00.0~

9(M).59.9(S)

A10

1

Mavg

Mavg: Moving

Average

update for PV

1(None)~

10 times

B10

)0)0

r

y@fd

ry@fd: Relay 2

de-energized

delay time

0.00.0~

9(M).59.9(S)

rs485

group

ENT

RS485

GROUP

A11

0

Dfilt

Dfilt: Digital

filter

0(None)/1~

99 times

B11

hi

r

y#md

ry#md: Relay 3

energized mode

off / lo /

hi / lOhld /

hIhld / d o

E1

1

adres

adres: Device

number of the

meter

1~255

A12

0

Pcode

Pcode: Pass

Code for enter

Engineer Level

0000~9999

B12

0

r

y#hy

ry#hy: Relay 3

Hysteresis

0~5000 counts

E2

9600

baud

baud: Baud

rate

1200 / 2400 /

4800 / 9600 /

19200 / 38400

A13

none

Flock

Flock: Function

Level Lock

none / user /

eng / all

B13

)0)0

r

y#rd

ry#rd: Relay 3

energized delay

time

0.00.0~

9(M).59.9(S)

E3

NstB2

prity

prity: Parity

NstB1 / NstB2 /

odd / even

B14

)0)0

r

y#fd

ry#fd: Relay 3

de-energized

delay time

0.00.0~

9(M).59.9(S)

B15

hi

r

y$md

ry$md: Relay 4

energized mode

off / lo /

hi / lOhld /

hIhld / d o /

go-!2 / go-@3

B16

0

r

y$hy

ry$hy: Relay 4

Hysteresis

0~5000 counts

B17

)0)0

r

y$rd

ry$rd: Relay 4

energized delay

time

0.00.0~

9(M).59.9(S)

B18

)0)0

r

y$fd

ry$fd: Relay 4

de-energized

delay time

0.00.0~

9(M).59.9(S)

XPlesae refer to operating manual for detail description

CSM-321S

CS2-

V

A

CSM-321S CSM-CSM-

CS2-T

CSM-321S CSM-CSM-

CSM-321SCSM-

CSM-321S

Table of contents

Other ADTEK Measuring Instrument manuals

ADTEK

ADTEK CPM-80 Series User manual

ADTEK

ADTEK CS1 Series User manual

ADTEK

ADTEK CPM-12A User manual

ADTEK

ADTEK CS2-SG User manual

ADTEK

ADTEK CS3S VA User manual

ADTEK

ADTEK MWH-10A User manual

ADTEK

ADTEK CPM-12D User manual

ADTEK

ADTEK CS2-SG User manual

ADTEK

ADTEK CM1-TC User manual

ADTEK

ADTEK CM1 Series User manual