TOMATECH CHC-200F User manual

Capacitive Torch Height Controller

CHC-200F

1

Capacitive Torch Height Controller

CHC-200F Instruction

(Revision 2017)

TOMATECH AUTOMATION CO., LTD.

303, No.6 Minhuan Road,Longhua New District,Shenzhen,China Tel.: +86-0755 85276656

Mob/What‟s app: +86 18617165968

Email: [email protected]

Web.: www.tomatech-cnc.com

2

SAFETY:

Please read this manual fully before use CHC-200F

DO NOT open cabinet of THC unless trained

technician. DO NOT adjust the sealed resister.

Turn off Powersupply if when THC is

unused. DO NOT put liquid on THC.

Attention Anti-dust work, DO NOT let metal dust into

THC. DO NOT use on plasma over 100A or HF plasma

Installation Note:

CHC-200F uses AC24V

GND Port must be well grounded, GND

resister≤1Ω. UP/DOWN on THC must be same to

Z-axis Lifter

IMPORTANT NOTE

:

All our THCs have been tested in our workshop before delivery, all

commissioning work has been done. Please NOT change the setting

without informing your supplier.

3

1 Introduction

1.1 Basic specs

Power supply:CHC-200F:AC24V±10%,50Hz/60Hz;

DC motor used on lifter:CHC-200F:DC24V (From THC to DC motor);

Output current:CHC-200F:1A-4A,max:100W;

Work temperature:THC-10∽60℃;HF cable:-10∽200℃;

Sensor parts:-10∽350℃。

Accuracy:±0.1mm (matters with lifter design);

Auto height range:from cutting material surface 1mm — 25mm.

HF-cable:200mm∽1800mm。

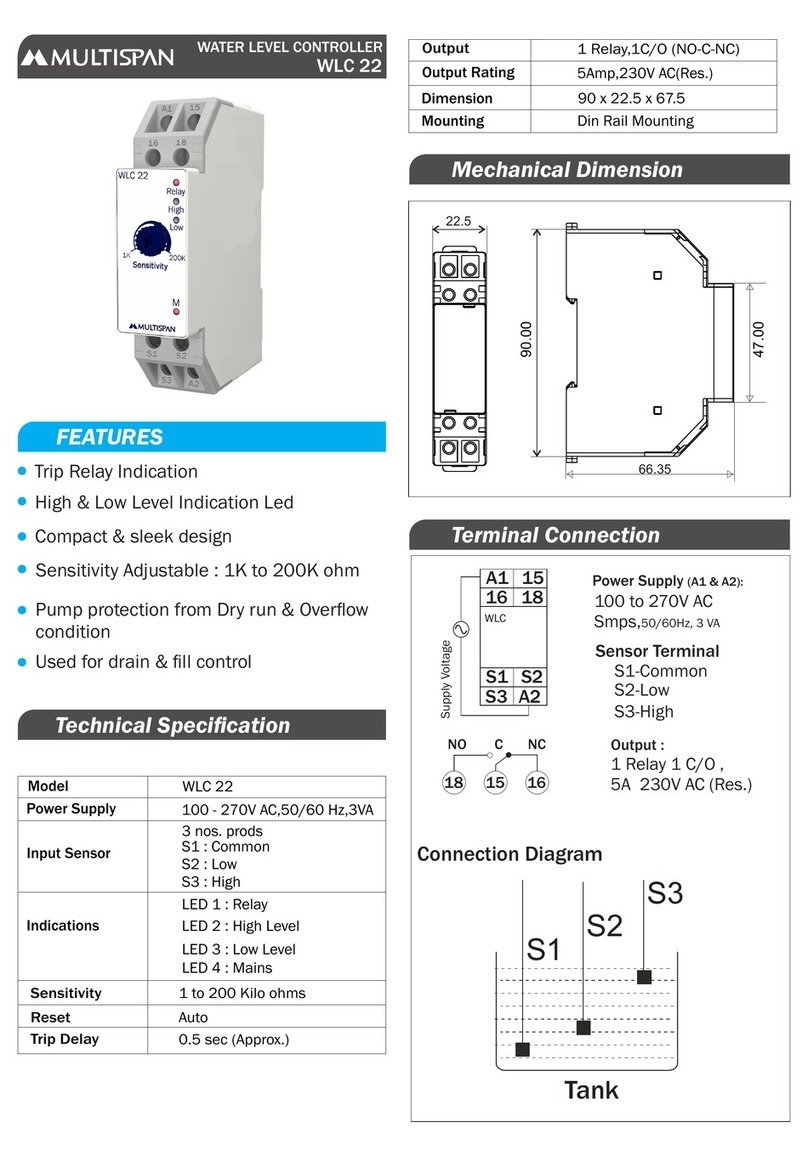

Product size shows as figure 1-1 L*W*H:176mm * 105mm * 50mm。

Figure 1-1

4

1.2 New features

Comparing to CHC-200E, CHC-200F has new features as follow,

1、Increased more indicators to shows different states of THC.

2、Output of collision-alarm, which is optical isolation output from THC, can be sent to CNC’s

Alarm input to freeze machine’s move. This signal is effective on both manual/auto mode.

The max output is 200mA, capable to drive most relays.

3、Anti-collision function. On manual/auto mode, when metal or low-conductive item like hand

touches sensor ring, THC would send out collision signal and lift torch up until no collision

exist.

4、When HF cable is disconnected or weakly connected, it would be indicated on the

disconnection indicator. So after installation of HF cable, just shake the HF cable, the

connection will be showed by the indicator.

5、Sensitive and Accuracy is increased 100%.

6、CHC200F uses digital logic control circuit for logic control, greatly improved anti-

interference performance.

1.3 Work elements

CHC-200F work elements: It detects the distance between Sensor ring and the cutting material

(steel, metal material) via detecting the capacitance between the two parts, and keep the two parts

at a set distance by control the DC motor move. CHC-200F is a closed-loop control system, with 4

parts: Position Signal Sensing, Signal Process, Logic Control and Motor Drive.

5

2 Components

2.1 For flame cutting

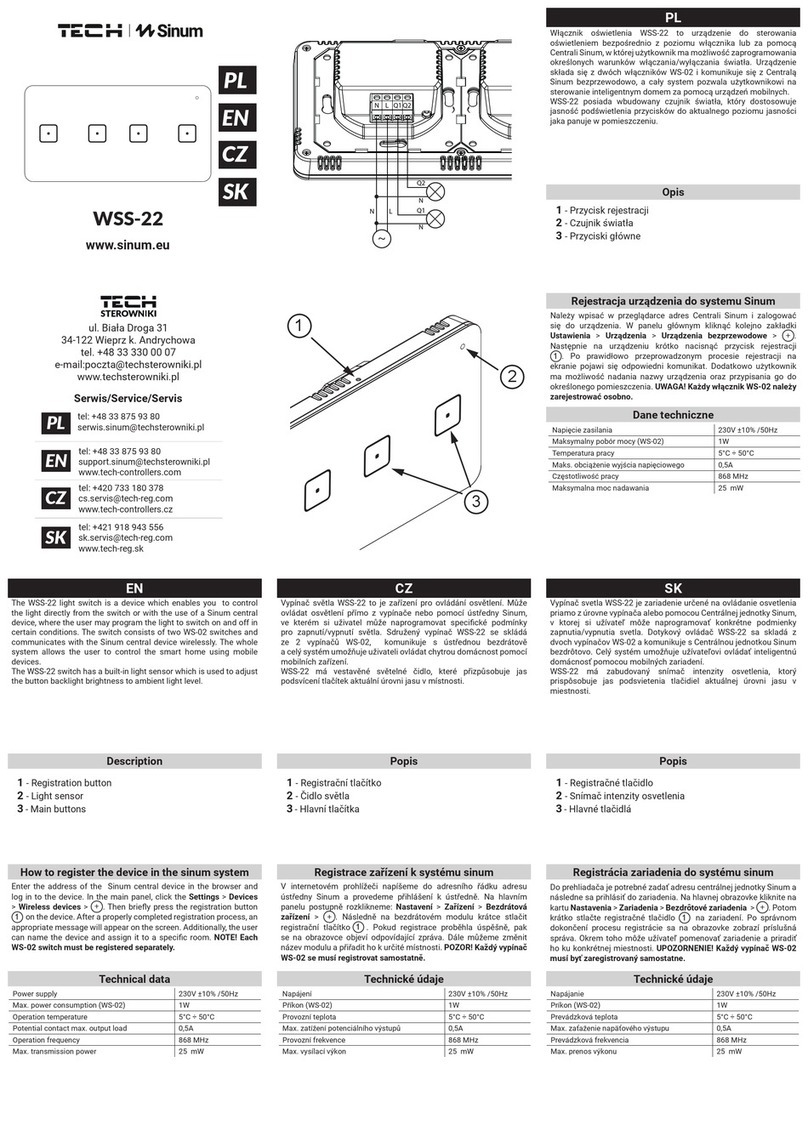

CHC-200F/300 full package includes follow parts: THC control module, socket connector,

sensor ring, elastic connector, insulation part, fixture, HF cable. As figure 2-1shows,

THC control

Socket

module

connector

Sensor ring elastic connector insulation part fixture HF cable

Figure 2-1

6

3 THC control and connection

3.1 operation panel intro.

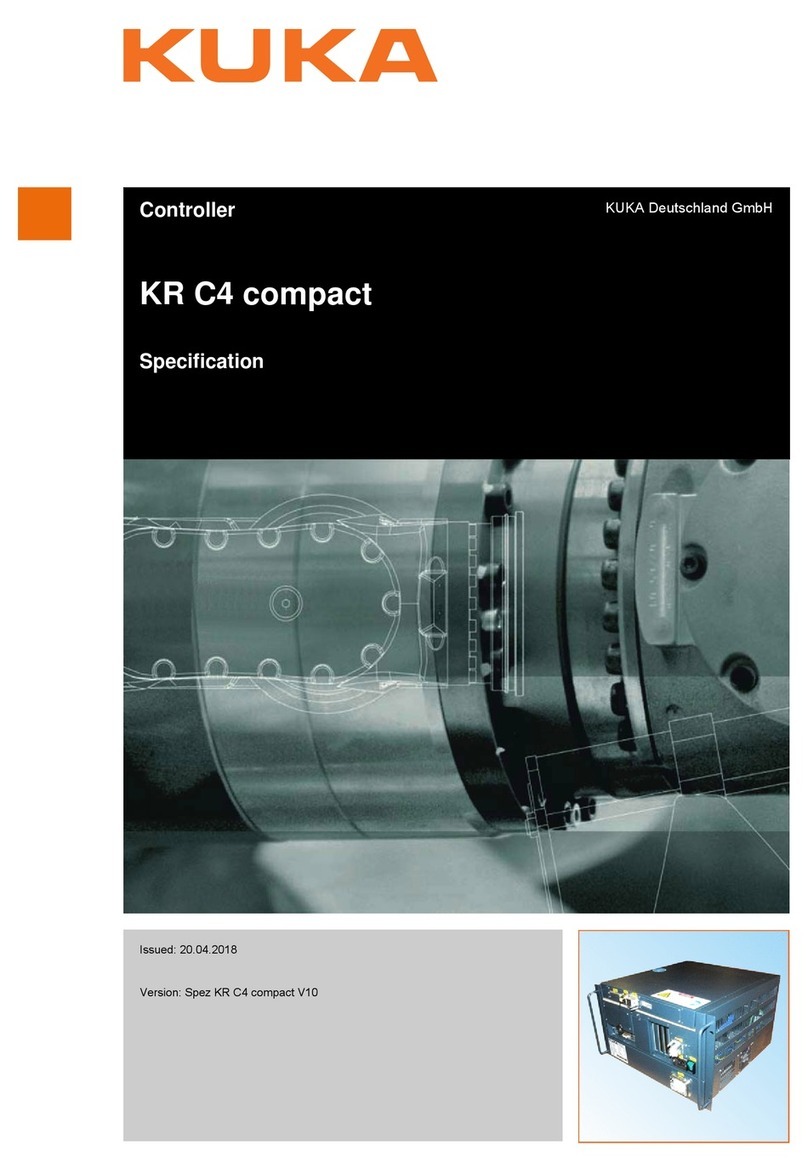

(Power)(Height found) (Disconnection) (collision)

UP

AUTO HEIGHT adjustor

DOW

Auto/manual SENSITIVE adjustor

Indicator Connect to sensing part

intro

Figure 3-1

Indicators:

PPower:Power indicator, red, Off means no power supply.

H Height Found:Turn on when torch reaches auto height, green.

DDisconnection:Disconnection indicator, red. When HF cable is unconnected or disconnected,

it turns on. On auto mode, if disconnection happens, torch would keep lifting up until it’s solved.

C Collision:Turn red when sensor ring collision happens, both on manual/auto mode. Torch

would keep lifting up until collision disappears. At this moment, press Down doesn’t work. If HF

cable short-connected with shield net, it is same as collision to THC.

Buttons on operation panel

Up/Down Button

It is active on any mode. Priority is always given to Manual mode. For UP and Down, priority’s given

to UP. In case HF gets problem, it’s always on UP mode, so the Down doesn’t work.

Auto Button

Press the AUTO button, THC is always on Auto Mode, no matter there is a auto signal from outside

7

or not. During cutting, THC needs to work on Auto Mode and it should be controlled by CNC, having

nothing to do with this Auto button

Height

It is used to adjust cutting torch height during Auto Mode. Height increases when it is turned

clockwise. At the first commissioning, turn clockwise maximum to reach the highest height.

Sensitive

On Auto Mode, the Sensitive increases when it is turned clockwise.

Sensor ring Port

One end of HF Cable link with the socket, the other end link with the sensor ring groupware

3.2 THC Connectors

As figure 3-2 shows,CHC-200F has only two connectors for installation, one is to CNC(X1-

CNC), the other one is to lifter motor (X2-TORCH).

To CNC controller

GND

To lifter motor

and limit switch

Figure 3-2

8

3.2.1、X1- CNC ( TO CNC)

It is a 7-pin socket, pin definition as follow,

Pin

signal

Specs

CHC200F

:

AC24V

1 , 2

POWER

The rated power should be more than motor 20w

Collision output to CNC,

3

Collision

OC door open

output

Max drive current :200mA

4

COM

I/O COM

5

UP

Up control, low-level effective

6

DOWN

Down control, low-level effective

7

AUTO/MAN

Auto control, low-level effective

9

Figure 3-3

CHC-200F to CNC (X1-CNC),input/output both use optical isolation, UP/DOWN/AUTO is external

signal input to THC, Collision output from THC. All those signals share same COM. The input/output

shows as Figure 3-4,

Input circuit

10

Output circuit

Figure 3-4

3.2.2 X2-TORCH (to torch lifter motor)

It is a 5-pin socket, pin definition as follow,

Pin

signal

specs

DC Motor Drive

DC motor connection

1 ,

2

Max 100W

(

Output

)

PWM

3

LIMIT COM

Limit

COM

4

Down LIMIT

Down limit input

(Input)

Limit switch normally closed

5

Up LIMIT

Up limit input

(Input)

Limit switch normally closed

Figure 3-5

11

Note:

1、Pin 1、2 are DC motor connector,H bridge drive,PWM speed control.

2. CHC-200F limit switch must be normally closed contact, when one side limit is open,

the move at this direction must be stopped,but the other direction move is still effective.

Limit switch connection as figure 3-6.

12

4. Installation and Commissioning.

4.1 Installation

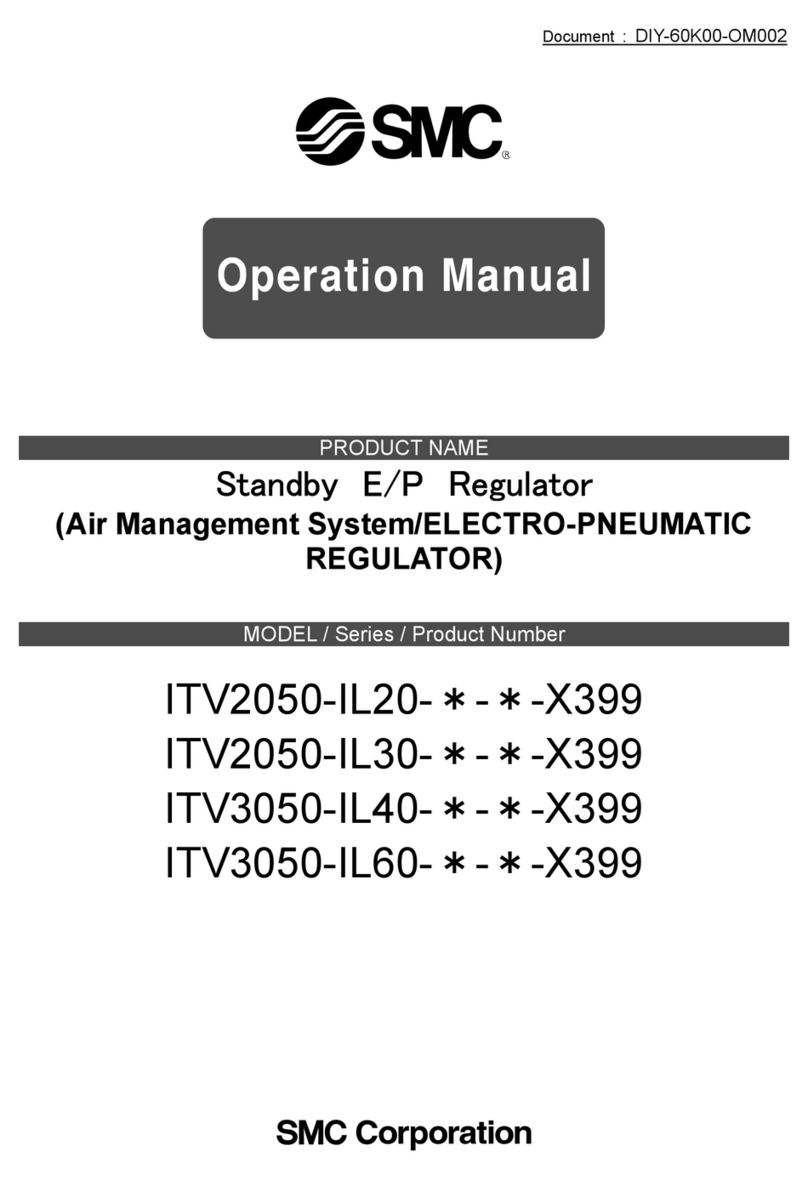

4.1.1 Sensor ring installation

47m

(Note: The flame torch and ignitor is not the parts of the CHC-200F)

Figure 4-1 flame cutting installation

4.2 Installation of sensor ring: According to our years practice, sensor ring should be

installed lower about 1∽2mm than torch head to avoid the edge effect during cutting edge of

workpiece, and it anti-collision more effectively, as showed in Figure 4-1.

4.3 While on plasma cutting, the sensor ring shall be installed little higher than the torch head,

to avoid the effect of plasma arc voltage, and it needs a special insulation part supplied from

TOMATECH. Please inform us when order it.

4.2.2 Commissioning.

4.2.1 Test after installation

Up/Down connects with GND, motor moves up and down, firstly make sure on Manual mode,

torch up/down is same direction as Up/Down control button.

13

Auto/Manual connects with GND, THC is on Auto Mode. When it’s unconnected, the manual

mode is active.

On Auto mode, if the sensor ring is not connected with THC and THC is under disconnection

protection, the indicator “D” Disconnection would turn on, cutting torch would keep lifting up.

If sensor ring is connected with THC, the cutting torch should stop at a position via adjusting

the Height button (THC finds the Auto Height),

On Auto Mode, the height of cutting torch is under control of Height button. At first

commission, always turn clockwise maximum to get the highest height, then turn anti-

clockwise, the height decreases. If adjusting the height is too low, when cutting torch touches

the workpiece; motor will be on a shocking-state.

THC always drives motor to make sensor ring close to the Balance Position ( the set Auto

Height), and it stops when ring is around the Balance Position, 0.2m lower or higher). The

closer, the more slowly the motor runs.

Auto sensitivity meets the request of THC when sensor ring is 5—20mm away from workpiece.

4.2.2 Commissioning Step

1, Install the THC according to the “4.1 Installation”, offer the enough power supply to THC

(CHC-200F use the AC 24V)

2, When power on, check the red indicator lights (“D”、“C”) to confirm the connection ok

or not. “D” light is on, means disconnection; please check the HF cable, insulator, elastic

connector and sensor ring are connected well or not. “C” light is on, means collision, it might

be short-circuit occur between the sensor ring to torch or HF cable short-circuit.

14

Fig 4-2 Disconnection Fig4-3 Collison Fig4-4 Auto setting(D.C flashing)

“D” light is on, could operate it up/down manually; at auto mode, torch will keep lifting up

“C” light is on, THC will control the torch to go up until the up limit. The instantaneous

collision could not activate the collision alarming signal. When the collision over 0.3s, then will

activate the collision alarm signal, and the torch will be lifted up until up limit, and send the

collision signal to CNC.

3, When “D” and “C” lights are off, please test the “UP”/ “DOWN” buttons. “UP”---torch goes

up; “DOWN”---torch goes down; if the torch moves opposite way, please exchange the

connection of the “MOTOR1” and “MOTOR2” shown in Fig 3-5. If the motor don’t move,

please check the UP_limit switch and Down_limit switch. The limit switch of the CHC-200F is

Normally Closed(NC).

4, After all function test ok, then do the auto setting work (found the Height).

First, please turn the “Height” knob at the middle position, and press the “UP” and “DOWN”

with 2s at the same time, THC begins to detect and set automatically.

Second, During the Auto setting process, the torch will go up to the up-limit(if not the up-limit

switch, THC will go up with 10s,please wait), then do the auto detection work. THC will go up

and down to detect the signal until it found the height. After finishing the Auto setting, THC

will go up to a certain height quickly.

Third, during the auto setting, the “D” and “C” lights will continue flashing until finishing the

auto setting work.

If any unstable situation appears during the auto setting, please do the auto setting again.

5, After complete the auto setting work, can set the cutting height via adjust the “Height” knob,

then controlled by the CNC controller via connecting “TO CNC” port.

15

4.3 THC driver circuit com mission

5A fuse

Motor brrake adjustment

Fig 4-5 THC POWER AND DRIVE CIRCUIT BOARD

1, Motor brake adjustme nt

The potentiometer RP3 is to adjust the motor stop’s brake. Before delive ry, we have adjusted it

ok, please do not adjust before inquiry.

2, About the buzz sound of the motor when at the balance position

It’s normal phenomenon. CHC-200F’s driver circuit is adopted th e H-bridge circuit,

controlled by the PWM drive way to realize the speed adjustion. PWM is 9KHz, when at the

auto balance mode, the motor will send “buzz” sound.

NOTE: CHC-200F has be en adjusted ok before delivery, please DO NOT

adjust the THC’s inside circuit without permission.

This manual suits for next models

1

Table of contents

Popular Controllers manuals by other brands

SMC Networks

SMC Networks ITV2050-IL20-X399 Series Operation manual

Viessmann

Viessmann VITOTRONIC 200 Quick start programming guide

Neptronic

Neptronic TSUB00 Series Specification and installation instructions

Emerson

Emerson AW Series Installation and operation manual

S&C

S&C 6800 Series instruction sheet

Smartgen

Smartgen HGM8140 user manual