TOMCAR Utility Vehicle User manual

TOMCAR

Service Manual

06222010-v2.0

Table of Contents

PreRideInspection 1

MaintenanceChart 2

Lubrication Specification 4

PeriodicMaintenance 6

Brake System

Brake Pedal Adjustment 15

Brake Pad Replacement 17

Brake Caliper Removal 18

Brake Caliper Installation 19

Brake Rotor Replacement 20

Brake Booster Replacement 24

Master Cylinder Replacement 26

Steering System

Steering Alignment 28

Steering Tie-Rod End Replacement 33

Steering Rod Replacement 34

Ball Joint Replacement 35

A-Arm Removal and Installation 38

CVT System

CVT Belt Removal and Installation 40

CVT Removal and Installation 45

Transmission CVT Reconditioning 49

Engine CVT Reconditioning 58

Shock System

Removal and Installation 63

Shock Disassembly and Assembly 64

Accumulator Disassembly and Assembly 85

TOMCARUSA, Inc. |1727 E. Deer Valley Road |Bldg. 2, Ste. 1 |Phoenix, AZ 85024

06222010-v2.0

TOMCARUSA, Inc. eer Valley Road Z 85024

|1727 E. D |Bldg. 2, Ste. 1 |Phoenix, A

Final Drive

Final Drive and Axle Removal 91

Final Drive Disassembly 93

Final Drive Assembly 103

Final Drive and Axle installation 123

Transmission

Transmission Removal 125

Transmission Disassembly and Assembly 127

Transmission Installation 135

Engine

Engine Removal 137

Engine Installation 141

Water Pump Replacement (Diesel) 145

06222010-v2.0

Pre Ride Inspection

Item Pre

Ride * Remarks

1 Steering System I

2 Suspension I

Max air pressure 200psi

3 Tires I

7psi front 15psi rear

4 Brake Fluid Level I

5 Brake Pedal Travel I

6 Wheel Lugs Nuts I

80ft lb (Steel) 110 ft lb (alum)

7 Frame Hardware I

Frame nuts, bolt, and fasteners

8 Engine Oil Level I

9 Front Air Filter I,C

10 Rear Engine Air Filter I,C

11 Coolant Level I

12 Headlights / Taillights I

13 Hand Brake Operation I

14 CVT Belt I

I = Inspect C = Clean

TOMCARUSA, Inc. |1727 E. Deer Valley Road |Bldg. 2, Ste. 1 |Phoenix, AZ 85024

1

06222010-v2.0

1500 Miles Maintenance Chart

Item

1 Check tires and wheels

2 Check and adjust tire pressure (maximum 7psi front & 15psi rear)

3 Check for free play in wheel bearings

4 Remove wheels

Check A-Arm bushings

Adjust and grease ball joints (replace rubber boots as needed)

Check steering rod ends

Check shock mounts

5 Fill shock air chambers ( maximum air pressure 200psi)

6 Remove drums/disc inspect brake shoes/pads & drums/disc

7 Check for free play in rear end

Final drives

Shock mounts

8 Change engine oil and filter (refer to engine maintenance chart)

9 Change fuel filters (refer to engine maintenance chart)

10 Check rear air filter

Inspect air intake hoses

11 Check spark plugs (refer to engine maintenance chart)

12 Check coolant level

Inspect radiator hoses

13 Change transmission oil

14 Change final drive oil 1 qrt 80w90 gear oil each side

15 Grease CVT and axles

16 Grease the engine CVT (CVT will have to be removed )

17 Inspect CVT belt for cracks and proper tension

18 Install wheels

19 Adjust parking brake

20 Check for leaks

21 Check electrical system

Lights

Horn

Warning lights

Windshield wipers

22 Check wiper blades

TOMCARUSA, Inc. |1727 E. Deer Valley Road |Bldg. 2, Ste. 1 |Phoenix, AZ 85024

2

06222010-v2.0

TOMCARUSA, Inc. eer Valley Road Z 85024

|1727 E. D |Bldg. 2, Ste. 1 |Phoenix, A

23 Check front air filter (clean/replace as needed)

24 Check brake fluid Dot 4

25 Clean battery terminals

26 Inspect fuses

27 Grease steering box and check steering system for free play

28 Check windshield washer fluid

29 Inspect throttle cable and linkage

30 Test CVT for proper operation

31 Test drive vehicle

3

06222010-v2.0

Lubrication and Fluid Recommendations

Make sure that all the components listed in the Periodic Maintenance Chart are checked and lubricated at

their required intervals. Items not listed in the chart should be lubricated at the General Lubrication

interval.

Item Lubricant Capacity Procedure

Engine Oil TMx7C [Gas] SEA 5W-30 Below -20C Oil Dipstick Should Indicate

SEA 15W-40 Above -

20C Safe Range.

TMx7B

[Diesel] Engine Oil: SEA 15W-

40

Transmission Case

Oil SEA 80W140 synthetic 2.4L Maintain as Recommended

Final Drive Oil SEA 80W90 0.75L Per

Side Maintain as Recommended

Brake Fluid DOT 4 0.5L Maintain Level Between

Lines

Coolant

Front Ball Joints

Steering Box Multipurpose Grease As Needed Locate Fittings and Grease

Rear Drive Shafts

CVT (Transmission Side)

TOMCARUSA, Inc. |1727 E. Deer Valley Road |Bldg. 2, Ste. 1 |Phoenix, AZ 85024

4

06222010-v2.0

Maintenance & Lubrication

Diesel Engine 300 Miles

1500 Miles

3000 Miles 18,000 Miles

500km

2500 km

5000 km 30000km

Alternator Belt Check/Adjust

Check/Adjust Replace/2 Years

Oil Filter Replace

Replace Replace

Engine Oil* Replace

Check

Replace Replace

Air Filter Clean

Clean/Replace

Clean/Replace Replace

Fuel Filter

Replace Replace

Coolant Check/Add

Check/Add

Check/Add Replace

Cooling System

Hoses Check/Tighten

Check/Tighten

Check/Tighten

Valve Adjustment

Check/Adjust

Fuel Injector

Pressure

Check/Adjust

Preliminary Fuel

Filter Replace

Replace

Replace Replace

Repeat Every

1500M

Repeat Every

3000M Repeat Every

18000M

*Engine Oil: SEA 15W40

TOMCARUSA, Inc. |1727 E. Deer Valley Road |Bldg. 2, Ste. 1 |Phoenix, AZ 85024

5

06222010-v2.0

Periodic Maintenance ProceduresPeriodic Maintenance Procedures

Tires/WheelsTires/Wheels

Check the wheels for dents, cracks and leaks.

Inspect all tires for wear and/or damage.

Always replace tire when tread depth is worn to

less then 8mm.

Adjust the tire pressure.

Front - 7 psi max

Rear - 15 psi max

Wheel bearing

Raise the wheel off the ground.

With one hand on the top of the tire and the

other hand on the bottom, alternate pushing and

pulling the top while pushing and pulling the

bottom.

A 1 to 2 mm of free play is normal

If the wheel bearings have excessive free play,

replace wheel bearings.

A-arm bushing inspection

Raise the front wheels off the ground and secure

vehicle on jack stands.

Remove the front wheels.

Aggressively shake the a-arms while observing

the a-arm hinge points. There should be no free

play.

TOMCARUSA, Inc. |1727 E. Deer Valley Road |Bldg. 2, Ste. 1 |Phoenix, AZ 85024

6

06222010-v2.0

Front ball joint adjustmentFront ball joint adjustment

Loosen the 2 set screws (1) located on the sides

of the ball joint housing.

Tighten the ball joint cap (2) all the way

Tighten the ball joint nut (3).

Loosen the ball joint cap (2) 1/8th turn.

Tighten the set screws (1).

Repeat this process to all 4 of the front ball

joints.

Add 1 – 2 pumps of grease to each ball joint.

Steering tie rods

Inspect the steering tie rods for damage. Make

sure the rubber boot at the tie rod ends and the

steering rack are not torn, dry and/or cracked.

Inspect that the tie rod end is straight. The

threaded section is the weakest point and will

bend first.

Make sure the tie rod end lock nut (1) and the

ball joint nuts (2) are tight.

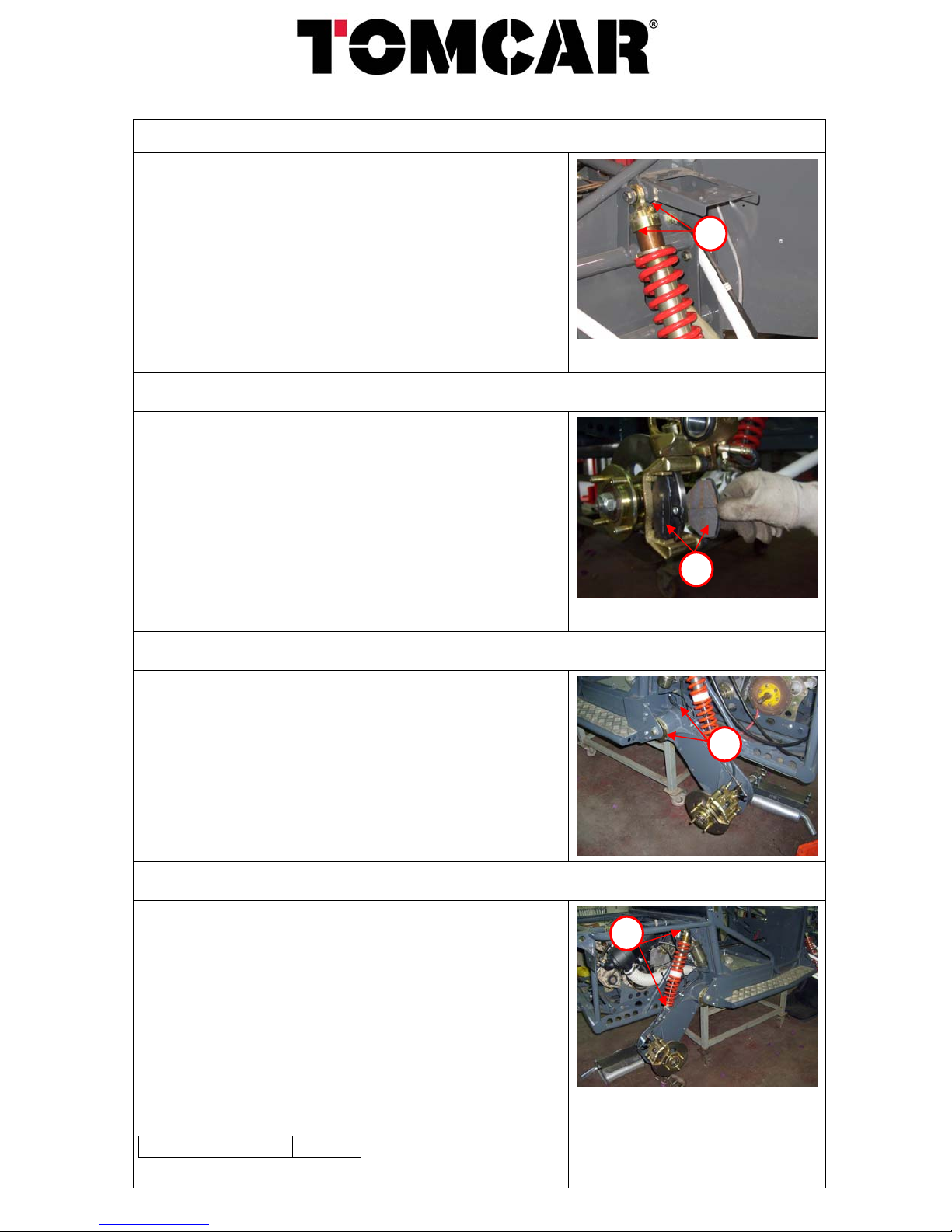

Shock mounts

With the wheel raised off the ground grab the

bottom of the a-arm and quickly lift and release

the a-arm repeatedly.

The suspension should feel solid and not have

more than 2 to 3 mm of free play at the shock

mounts (1) and (2)

If more than 2 to 3 mm of free play is present

replace the shock ball joints.

Inspect the shock for leaks.

Shock Ball Joint TJ15

3

2

1

1

1

2

2

TOMCARUSA, Inc. |1727 E. Deer Valley Road |Bldg. 2, Ste. 1 |Phoenix, AZ 85024

7

06222010-v2.0

Shock air chamberShock air chamber

Raise the wheel off the ground and secure with

jack stands.

Fill the shock air chamber with up to 200psi. Do

not check pressure with a gauge. The volume is

too small to measure accurately.

Spray the valve stem and the area where the

top cap is attached to the shock tube (1) and

look for bubbles indicating an air leak.

Front brake pads

Remove the lower caliper bolt and swing the

caliper up to access the brake pads.

Inspect the brake pads for wear and/or damage

(1).

Inspect the caliper piston and hose for leaks.

Check brake fluid level. Use DOT 3 or 4 brake

fluid

Upper final drive bearings

CAUTION: For this step, make sure the vehicle is

completely secure and solidly supported by jack

stands.

Grab the brake rotor and repeatedly push and

pull the final drive assembly checking for free

play at the upper bearings. If large amount of

free play is present replace bearings.

Rear shock mounts

CAUTION: For this step, make sure the vehicle is

completely secure and solidly supported by jack

stands.

Grab the bottom of the brake rotor and

repeatedly lift up and release the final drive.

Look for play in the upper and lower shock

mounts. If more than 2 to 3 mm of free play is

present replace shock ball joints.

Inspect the shocks for leaks.

Shock Ball Joint TJ15

1

1

1

1

TOMCARUSA, Inc. |1727 E. Deer Valley Road |Bldg. 2, Ste. 1 |Phoenix, AZ 85024

8

06222010-v2.0

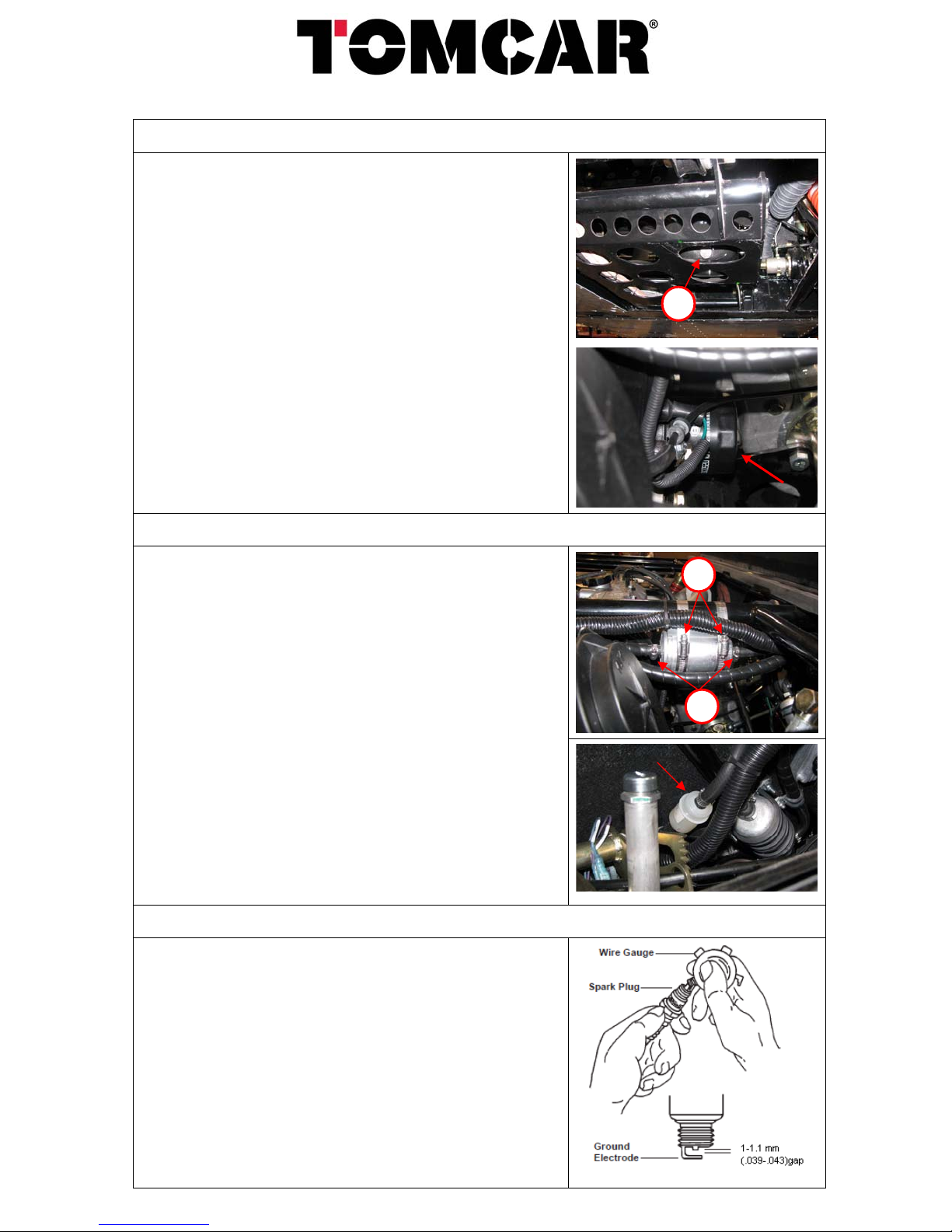

Engine oil and filter (Gas engine TM**C models)Engine oil and filter (Gas engine TM**C models)

Run engine at an idle for 15 min.

Allow engine to cool enough to safely drain

engine oil.

Drain engine oil by removing drain plug (1).

Remove and replace engine oil filter.

Refill engine with the recommended lubricating

oil.

Start the engine and allow engine to idle for

several minutes.

Shut off engine.

Recheck engine oil level.

Drain plug torque 40Nm

* Refer to Lubrication and Fluid

Recommendations for specifications. *

Fuel filters

Carefully remove the hose clamps (1) securing

the fuel lines to the filter.

Remove and replace the filter by removing the

filter clamps. Pay close attention when installing

the filter, there is an arrow indicating the

direction of flow.

Located close to the rear firewall next to the fuel

pump is the suction fuel filter. Remove and

replace filter paying close attention to the

direction of flow indicated by an arrow stamped

on the filter.

Spark plug service

Before removing the spark plug, thoroughly

clean the area around the base of the plug to

keep dirt and debris from getting in the engine.

Check the gap using a feeler gauge. Adjust the

gap to 1.0 – 1.1mm (0.039 – 0.043 in) carefully

bending the ground electrode.

2

1

1

TOMCARUSA, Inc. |1727 E. Deer Valley Road |Bldg. 2, Ste. 1 |Phoenix, AZ 85024

9

06222010-v2.0

Engine oil and filter (diesel engine TM**B models)Engine oil and filter (diesel engine TM**B models)

Run engine at an idle for 15 min.

Allow engine to cool enough to safely drain

engine oil.

Drain engine oil.

Remove and replace engine oil filter.

Refill engine with the recommended lubricating

oil.

Start the engine and allow to idle for several

minutes.

Shut off engine.

Recheck engine oil level.

Drain plug torque 40Nm

* Refer to Lubrication and Fluid

Recommendations for specifications. *

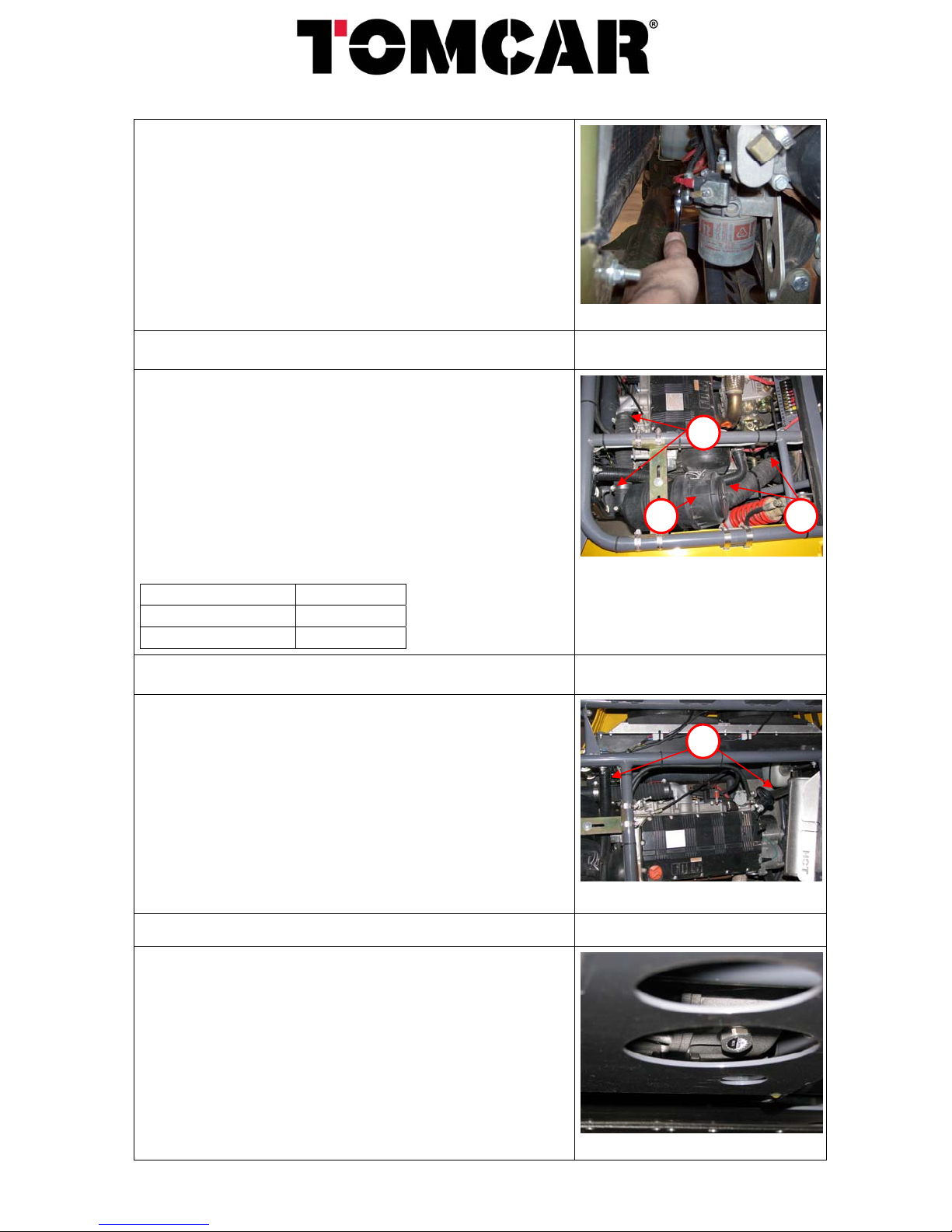

Fuel filters

Carefully remove the spin on primary fuel filter

and install a new filter.

Change fuel filter every 5000 Km

Fuel filter bleed and primer procedure

Locate the fuel filer housing. Using a 19mm

wrench, loosen the rear Banjo Bolt to allow fuel

to escape as pressure is built up.

Using the prime lever on the fuel pump (1), build

fuel pressure by pressing down several times

until fuel begins to leak from the Banjo Bolt at

the fuel filter housing. If a new filter was

installed, it may take some time for fuel to fill the

filter before dripping from the Banjo Bolt.

1

TOMCARUSA, Inc. |1727 E. Deer Valley Road |Bldg. 2, Ste. 1 |Phoenix, AZ 85024

10

06222010-v2.0

Tighten the Banjo Bolt. Start the engine and

inspect the fuel filter housing and Banjo Bolt for

leaks before driving.

Tighten the Banjo Bolt. Start the engine and

inspect the fuel filter housing and Banjo Bolt for

leaks before driving.

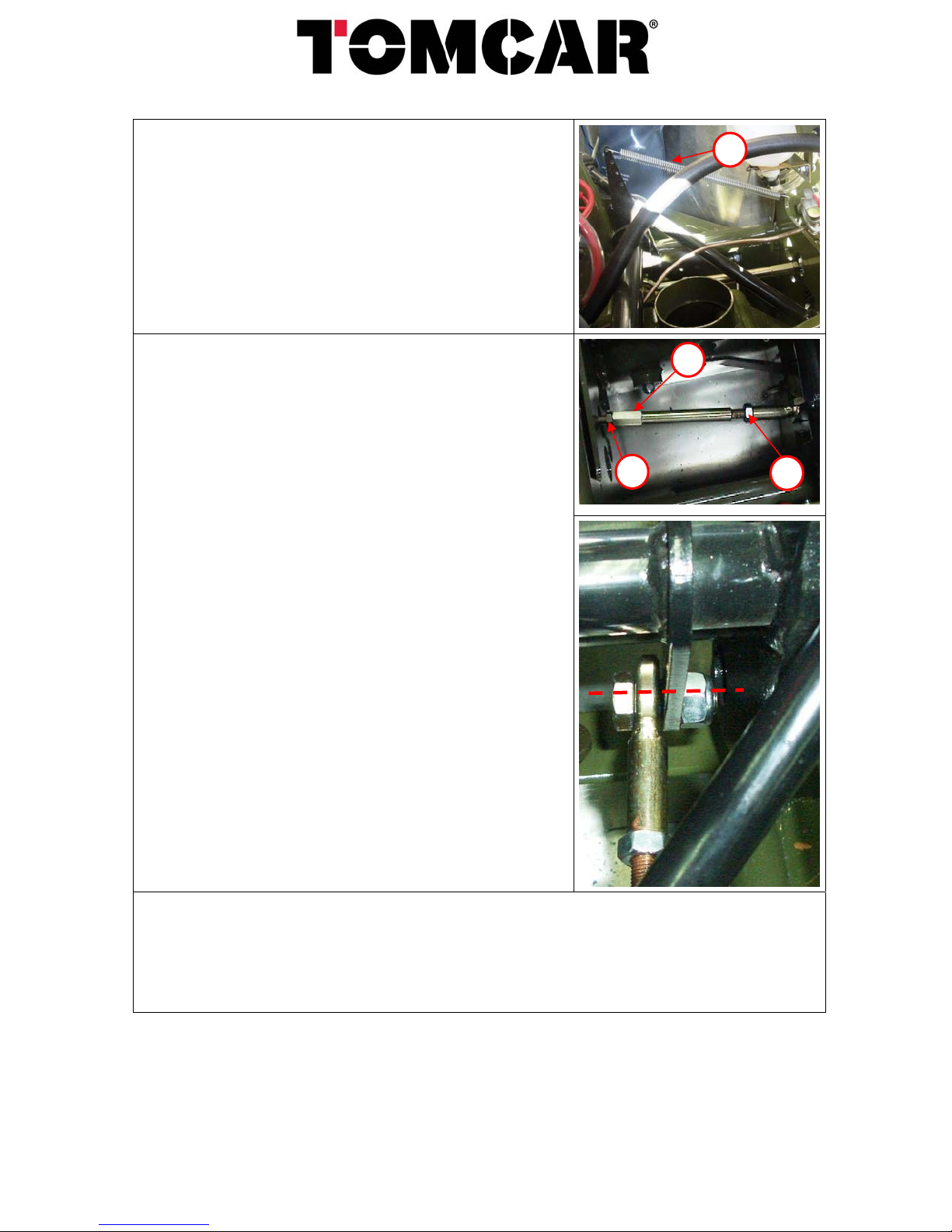

Air intake system

Inspect all air intake hoses for any visible

damage.

Check that all hose clamps (1) and (2) are tight

and are positioned correctly.

Remove and clean the front cone filter.

Remove and replace the rear air filter (3).

Front Filter TM3801

Inner Air Filter TM84050

Outer Air Filter TM84040

Cooling system

Inspect the upper and lower radiator hoses (1)

for damage.

Make sure all hose clamps are tight and

positioned properly.

Inspect the radiator and fans, and thoroughly

clean area.

Inspect the radiator cap. Make sure the rubber

seal is in good condition.

Check the coolant overflow bottle for leaks and

fill bottle to the full level.

Transmission oil

Position vehicle on level ground

Remove the fill plug.

Remove the drain plug and drain oil into drain

pan.

Clean and reinstall drain plug. Small metal

shavings on magnet are normal.

Fill transmission with 2.5 qrt of 80w90 gear oil.

Make sure the transmission breather is clean.

Reinstall fill plug.

3

1

2

1

TOMCARUSA, Inc. |1727 E. Deer Valley Road |Bldg. 2, Ste. 1 |Phoenix, AZ 85024

11

06222010-v2.0

Final driveFinal drive

Position vehicle on level ground

Remove the fill plug (1).

Remove the drain plug (2) and drain oil into

drain pan.

Clean and reinstall drain plug.

Fill the final drive with 1 qrt of 80w90 gear oil.

Reinstall fill plug.

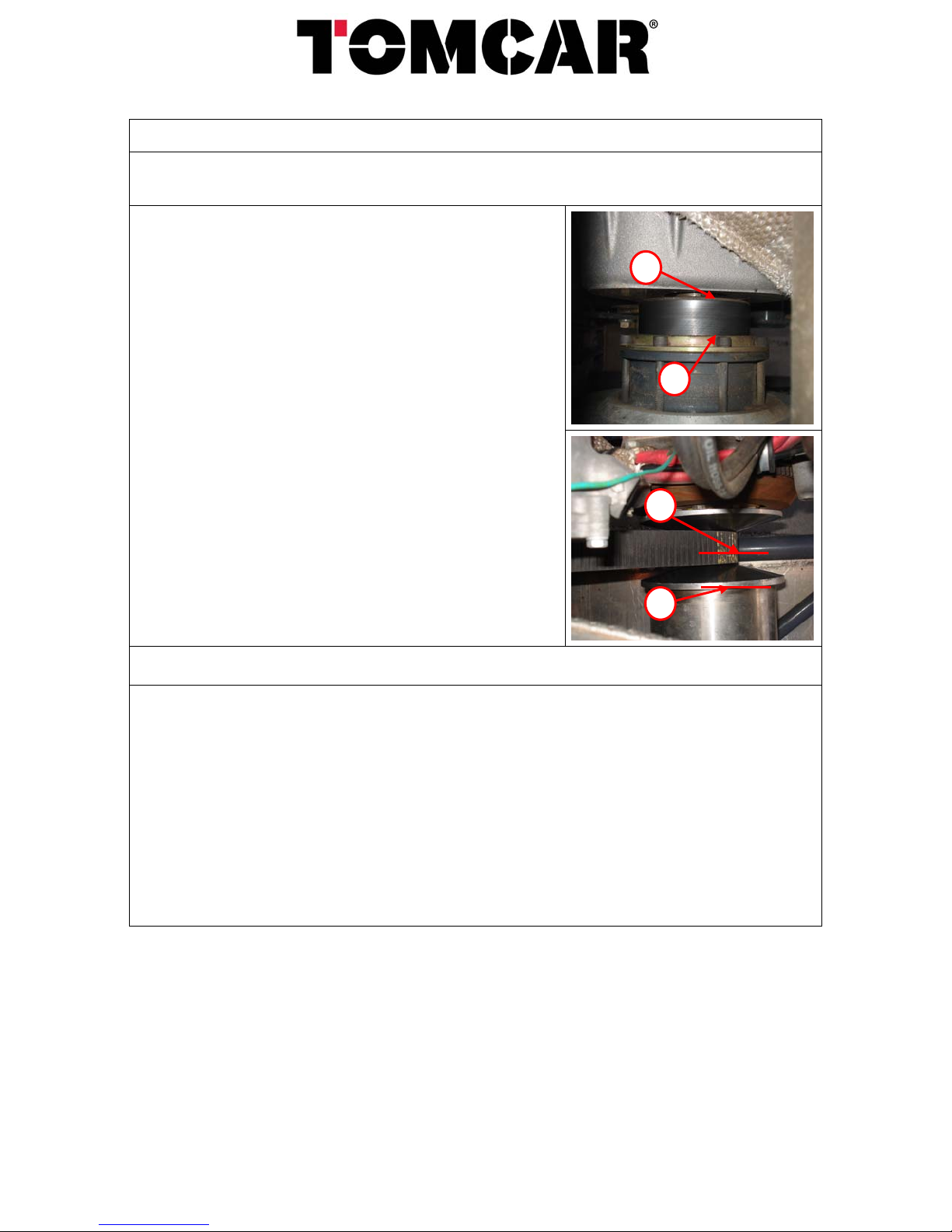

Transmission CVT

Thoroughly clean the inner collar hub (1).

Grease the CVT. The grease fitting (2) is located

on the inner collar. 2 to 3 pumps from a grease

gun are all that is required.

Drive axles

Inspect the drive axles and make sure the o-ring

is not exposed and/or torn.

Grease the axle grease fittings. There are 2, one

at each end of each axle. 1 to 2 pumps from a

grease gun is all that is required.

CVT belt

The gap should be 5-7 cm (2.0-2.9in) measured

at midpoint between the two CVTs. If an

adjustment is necessary see Belt Tension

Adjustment

Belt should not be dry, cracked, or otherwise

damaged.

1

2

1

2

TOMCARUSA, Inc. |1727 E. Deer Valley Road |Bldg. 2, Ste. 1 |Phoenix, AZ 85024

12

06222010-v2.0

Install wheelsInstall wheels

Install wheels and lug nuts.

Tighten lug nuts in a criss-cross pattern

Torque vehicles with steel wheels to 80 ft-lb

Torque vehicles with aluminum wheels to

110 ft-lb

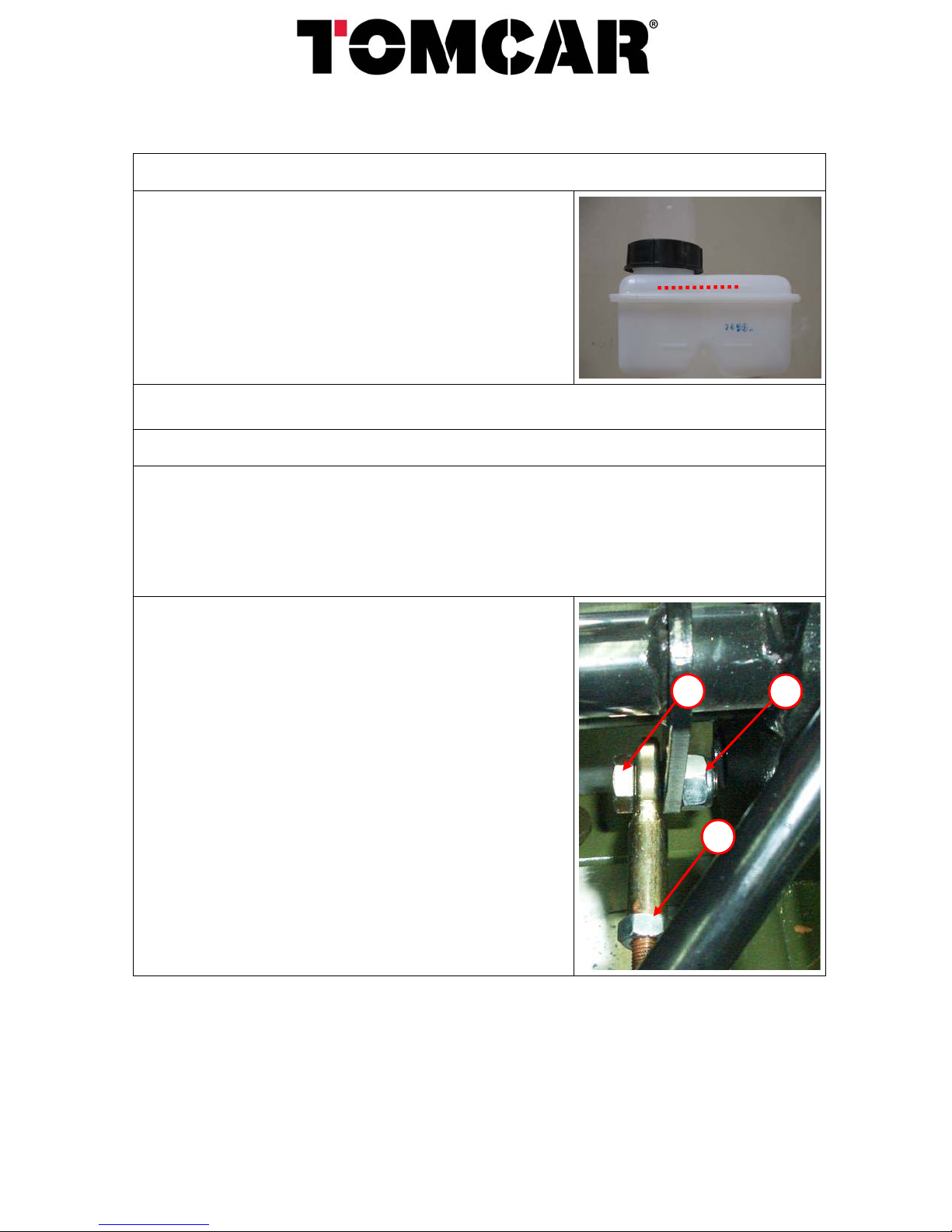

Parking brake

Make sure parking brake is disengaged.

Loosen the lock nuts and adjust the parking

brake cable free play to 2 – 5 mm.

Tighten the lock nuts and check that when the

parking brake is applied the vehicle will not

move.

Leak Check

Check vehicle for leaks.

Brake fluid

Coolant

Engine oil

Transmission oil

Final drive oil

Shock oil

Note: Small leaks/oil built up around the breathers and shafts of the final

drives and transmission are normal.

Electrical System

Check that all electrical components are in operating condition.

Check for any loose cables and/or connectors.

Inspect harness to make sure the harness is clear of all moving

parts and all hot surfaces. Add zip ties if original ties have come

loose.

Inspect and clean battery terminals.

4

3

2

1

TOMCARUSA, Inc. |1727 E. Deer Valley Road |Bldg. 2, Ste. 1 |Phoenix, AZ 85024

13

06222010-v2.0

TOMCARUSA, Inc. eer Valley Road Z 85024

CVT operation

Lift the cargo box up to expose engine work area.

Place transmission in neutral and engage parking brake.

1. Slowly rev engine several times while

watching both CVTs.

2. Both CVTs should open and close in a smooth

continuous motion. From (1) to (2).

3. If there is any hesitation or they do not reach

full travel, there is a problem in one or both

of the CVTs.

See CVT repair section.

Test drive

Test drive vehicle and check:

Steering operation

Brake operation

Acceleration

Noises

Gauge operation

Seat belt operation

Transmission operation High/Low/ Reverse/Diff lock

1

2

2

1

|1727 E. D |Bldg. 2, Ste. 1 |Phoenix, A

14

06222010-v2.0

Brake Pedal AdjustmentBrake Pedal Adjustment

Brake fluid levelBrake fluid level

1. Park vehicle on level ground.

2. Open the brake fluid reservoir.

3. Check that the fluid reaches the full mark on

the reservoir.

4. If the fluid level is low check for leaks and

replace the fluid to the required level. Use

DOT3 or DOT4 brake fluid only.

5. Change the brake fluid every 10,000 Km or 2 years.

Adjusting the distance of the brake pedal to the booster.

If the booster or rod were changed the pedal push-rod length will have to be

checked.

Note: There is a small amount of free play encountered when pushing on the brake

pedal before the pressure starts to build up, this is ok but it should not be more than

a 2-7mm movement at the pedal end.

1. Break loose the ball joint jam nut (1).

Remove the bolt (2) and nut (3) that hold the

push rod to the pedal.

1

23

TOMCARUSA, Inc. |1727 E. Deer Valley Road |Bldg. 2, Ste. 1 |Phoenix, AZ 85024

15

06222010-v2.0

TOMCARUSA, Inc. eer Valley Road Z 85024

2. Make sure that the brake pedal return spring

is connected.

3. Adjust the push-rod length by releasing (1) &

(2) jam nuts on the brake pedal push-rod (3),

and by turning the push-rod to achieve the

required length.

1 - 14mm wrench

2 - 17mm wrench

3 - 14mm wrench

4. The appropriate length is reached, once the

hole in the push rod ball joint is aligned with

the hole in the brake pedal, and the bolt can

be inserted freely into the holes. Lock the bolt

with a new self lock nut.

Bolt/nut – 19mm

Retighten jam nut (1 & 2) shown in top

picture, once push rod distance is set. Make

sure that the ball joint can pivot freely on the

bolt and does not bind.

Tech Tip: It is very important that the push rod is adjusted properly. If

the push rod is not adjusted correctly the brakes can drag and or lock

up.

3

1

1

2

|1727 E. D |Bldg. 2, Ste. 1 |Phoenix, A

16

06222010-v2.0

Brake Pad ReplacementBrake Pad Replacement

Rear padsRear pads

1. Raise the vehicle and take off the wheel.

Remove the rear caliper bolt

2. Raise caliper and remove brake pads. Clean

the exposed piston surface. Push piston back

into caliper. Install new pads. Install and

tighten caliper bolt.

Front pads

1. Remove the caliper bolt.

Raise caliper and remove brake pads. Clean

the exposed piston surface. Push piston back

into caliper. Install new pads. Install and

tighten caliper bolt.

Rear brake pads

1. When replacing the rear brake pads it will be

be necessary to reset the caliper piston.

Using a brake caliper wrench reset the

piston by rotating the wrench clockwise until

the piston completely retracted back into

the piston housing.

WARNING:

TOMCARUSA, Inc. |1727 E. Deer Valley Road |Bldg. 2, Ste. 1 |Phoenix, AZ 85024

17

06222010-v2.0

Table of contents

Other TOMCAR Utility Vehicle manuals

Popular Utility Vehicle manuals by other brands

Equinox Systems

Equinox Systems Canyon Assembly Instructions and Operations Handbook

The Handy

The Handy THFST Operator's manual

Egholm

Egholm City Ranger 2250 Operator's manual

PRONAR

PRONAR T780 Translation of the original instructions

Columbia

Columbia Summit SU5-L-2 2017 Owner's and operator's manual

Clam

Clam Polar Trailer 8272 manual