Tongdy PMD-18 Series User manual

1/ 16

Instruction for PMD-In Duct Air Quality Detector

V.1912

PMD In-Duct Air Quality Detector

—Commercial Grade Detector

Please read this instrument carefully before installing and using the device. The instruction includes

installation of PMD-18XX all models. Some content if PMD in your hand is not involved, please

ignore.

Check Accessories

Unpack the box and examine PMD and the accessories as below list.

1. Instruction manual –1 piece

2. PMD In-Duct air quality detector –1 unit

3. The pitot tube of PMD –1 piece

4. Waterproof connector –1 piece

5. Pipeline seal ring -1 piece

6. PMD assembly screw 2pcs and duct

mounting screw –2pcs

7. Hexagonal screwdriver –1 piece

8. Filter –1 piece

9. 220V power cable –1 piece (optional) or

24V power adaptor (optional) –1 set

Installation Requirements (IMPORTANT!)

1. Install in the air supply duct. Then install the PMD on the main air duct where is far from the fresh

fan machine or close to the branch duct.

2. Install in the return air duct. Then Install the PMD on the main air duct close to the return air fan,

or more than 1 meter from the return air outlet.

3. Installation of pitot tube should be accordance with the direction of the wind, please see P4

“Installation”.

4. The installation location should fully consider the requirement of convenient regular

maintenance.

5. PMD has two power supply selection,24VAC/VDC or 110-230VAC power supply. Please note

the power part must be waterproof and safe.

6. Note that the S/N number on the pitot tube must be mated with the PMD device with the same

s/n number. The two parts make up a whole device. Its temperature and humidity is calibrated

for the whole device. Therefore, each pitot tube must be matched with its own main unit. Do not

mix them up.

7. When disassembling and assembling the pitot tube, power must be cut off and no live operation

is allowed. The pitot tube must be assembled and tightened on the device.

Main unit

T&RH sensor

Pitot tube

Main unit

2/ 16

Instruction for PMD-In Duct Air Quality Detector

V.1912

8. For MSD/PMD-18XXD, It is installed in a place not touched by users. The insulation

requirements for external secondary wired communication terminals and exposed secondary

circuits will be evaluated on the final connection system. It is inaccessible to users during power

on.

Dimensions and Wiring Diagram

Host size: 180mm(Height) X125mm (Width) X 65.50mm (Thickness)

Pitot tube size: Total length: 279.5mm / Insertion pipe length: 235mm /Opening diameter: Ф35mm

Flange mounting hole distance: 77.5mm

Net weight: 1000g

PMD-181XD wiring diagram (two sets of terminals, power supply wiring on the left, RS485 wiring on

the right, do not connect wrong!).

PMD-183X Insert the RJ45 crystal head into the RJ45 socket on the bottom of the PMD as shown

below and make sure it is secure.

Tongdy Sensing Technology

3/ 16

Instruction for PMD-In Duct Air Quality Detector

V.1912

Assembly of Main unit and Pitot Tube

STEP 1: See the mark of the main unit, as shown in

the figure below, REMOVE is the direction in which

the pitot tube is removed, and FIX is in the fixed

direction. The pitot tube must be matched with the

original main unit with the same s/n no.

STEP 2: The pitot tube is docked with the main unit. Their series numbers are the same, don’t mess

up.

As shown in the figure below, install the side of the pitot

tube marked with the Windward Side facing down, and

align it with the rear

mounting hole of the main

unit.

Tongdy Sensing Technology

4/ 16

Instruction for PMD-In Duct Air Quality Detector

V.1912

STEP 3: After the pitot tube is inserted into the main unit assembly hole, the alignment mark

horizontal line is rotated 90 degrees clockwise.

Installation

1. For the wind flow is from right to left (ie "right", factory default)

STEP 1: Confirm the installation position, and open a hole of 35mm diameter with the hole opener

on the air duct. Insert the pitot tube into the air duct.(Note: the side of the pitot tube marked with the

Windward Side face to the airflow direction)

STEP 2: Insert the pitot tube and screw it to the outside of the air duct.

5/ 16

Instruction for PMD-In Duct Air Quality Detector

V.1912

STEP 3: Install the main unit. Connect the main unit horizontally (Tongdy logo is on the left) with the

pitot tube interface (as shown in the left figure), and then rotate it 90 degrees clockwise

fixed. (right figure). Complete installation.

2. The direction of the wind's airflow is opposite to the above, that is, the wind flow is from

left to right (ie "left").

Note: If the end user predetermines the installation location and direction, please inform the

Manufacturer, so that below STEP1~STEP8 can be pre-completed in the factory.

STEP 1: Unscrew the four assembly screws and open the upper casing part of the main unit.

STEP 2: See the black MSM sensor module. Pull out the air inlet filter (as the left figure) pressed to

the lower right side of the MSM module, and then remove the fixing screws on the middle of the

module (as the right figure)

6/ 16

Instruction for PMD-In Duct Air Quality Detector

V.1912

STEP 3: Remove the MSM module from the sealed compartment and rotate the module 180

degrees (left figure), and replace the MSM module (right figure) with the original position.

STEP 4: Fix the MSM module and insert the air inlet filter into the upper left slot of the MSM module.

STEP 5: Put the sealing compartment casing back

and fix it.

STEP 6: Install the pitot tube. Confirm the installation position and open a hole of a 35mm diameter

with the hole opener on the air duct. Insert the pitot tube into the air duct.

(Note that the side of the pitot tube marked with Windward Side face to the airflow direction)

7/ 16

Instruction for PMD-In Duct Air Quality Detector

V.1912

STEP 7: Insert the pitot tube and fix it with screws.

STEP 8: Assemble the main unit. Insert the main unit laterally into the air duct's counter interface

(left figure) and then rotate it 90 degrees clockwise (right figure). The installation is completed.

3. PMD18-181X RS485 Wiring:

STEP 1: Open the casing of the electrical wiring

part of the main unit.

8/ 16

Instruction for PMD-In Duct Air Quality Detector

V.1912

STEP 2: Remove the two sets of terminals

for power supply and RS485 respectively

Special Note:

The left terminal is the power terminal block. The right

terminal is the RS485 terminal block. Don't get it

wrong!

STEP 3: Go through the power cable and RS485 cable

from each waterproof connector respectively.

STEP 4: Press the cable on the terminal blocks.

STEP 5: Plug the terminals of the wired cable back into the pin

position of the power supply board and lock the inlet of the

waterproof connector.

9/ 16

Instruction for PMD-In Duct Air Quality Detector

V.1912

STEP 6: Fasten the casing of the electrical wiring part and install the original screws.

Regular Maintenance:

In order to ensure the accuracy of the PMD data, the end users need to perform regular

maintenance on the equipment under typical environment. The maintenance period of the general

project is 3, 6, and 12 months, and the special environment should shorten the maintenance period.

The main maintenance should include: internal cleaning of the outer casing, internal structure

cleaning, air inlet filter cleaning, and module cleaning.

1. Cleaning of the inlet filter: The general maintenance period is up to 3 months, and the special

environment should shorten the maintenance period, especially in the environment where the return

air duct is dusty.

2. Cleaning of internal structure: The general maintenance period is up to 12 months, and the

special environment should shorten the maintenance period.

3. Sensing module cleaning: The general maintenance period is up to 12 months, and the special

environment should shorten the maintenance period.

STEP 1: Open the upper casing of the main unit.

STEP 2: Remove the dust filter next to the air inlet of the black MSM sensor module, clean the filter.

10 / 16

Instruction for PMD-In Duct Air Quality Detector

V.1912

STEP 3: Remove the mounting screw on the middle of the MSM module, take out the module, and

clean the module inlet and outlet with the air pump to clean the module inside.

STEP 4:Assembling the MSM module after cleaning.

Indicators, buttons and external windows:

(The bottom right side of the PMD is the wiring and indicator area).

1. GPRS RJ45 CONFIG: GPRS or RJ45 configuration

red indicator and button,(Optional by model) Located in the upper left

corner.

For details, see the GPRS or RJ45 communication configuration file.

Indicator

11 / 16

Instruction for PMD-In Duct Air Quality Detector

V.1912

2. WIFI CONFIG: WIFI configuration button(optional by model),

located in the middle of the left side. Use with the "WIFI" indicator in

the lower right corner. For details, see the WIFI communication

configuration file. The series of WIFI communication, the default is

MQTT protocol, the data is uploaded to the Mytongdy platform.

Tip: If the customer needs other protocol and platforms, please

contact the sales for pre-sales consultation.

3. SCALE: three-color concentration indicator, the default is the

average concentration change of PM2.5 every 1 minute.

PM2.5 <35ug/m3 green light on, 35~75ug/m3 yellow light

on, >75ug/m3 red light on.

This indicator can be controlled by RS485 communication command to be controlled by any one of

PM2.5 or CO2 or TVOC, depending on its concentration. At the same time, the measurement value

of the indicator change can be selected in the communication command to be 1-minute average or

1-hour average or 24-hour average.

4. RJ45 interface: (optional by the model), located above the indicator light.

5. RS485/TTL: NC18 interface, can be connected to NC18. Customers can select to purchase

NC18 as needed. The connection mode of NC18 is wired (default), and wireless. Can be used for

display of PMD, MSD, TFA and other series, and parameter query and setting.

For details, refer to the NC18 User's Manual.

6. ON: Located in the middle of the right side, the work indicator. Ever green: indicates that the

device is working normally. Otherwise, the device is faulty.

7. WIFI: WIFI communication configuration red indicator light, located in the lower right corner.

When the WIFI configuration is performed, the light flashes off. When the WIFI configuration is

completed and the communication is normal, the red light is always on

WIRELESS COMMUNICATIN ID and DATA FRAME FROMAT

The wireless communication model device has a unique wireless communication ID, which is

labeled with a white label and is attached to the waterproof position of the machine wiring, as shown

in the right figure.

The format is "WIFI-MQT PMD-XXXXXXXX", WIFI is the communication

method, MQT is the shorthand for MQTT communication.

protocol, and the data is sent to MyTongdy platform by default. X represents a numerical value, and

the 8-digit number has a uniform format requirement and cannot be modified.

After the wireless communication connection is successful, the device actively sends data frames to

the platform, and the default is once every 1 minute. The customer can inform the salesperson if he

needs to adjust the sending frequency. The specific WIFI configuration operation is in the third part.

RJ45

connector

Wireless communication ID

12 / 16

Instruction for PMD-In Duct Air Quality Detector

V.1912

If the customer does not use the MyTongdy platform and build their own platform, please contact the

sales staff to request the platform development documents.

WIFI CONFIGURATION (MQT VERSION)

1、Download and installAPP

1)Login website: www.mytongdy.com

2)Click the "Login" button in the upper right corner of the website interface.

3)In the account password interface, use the browser to scan and download the mobile app (for

Android). Or after the phone logs into the webpage.The IOS system APP software directly searches

for mytongdy downloads in the Apple Store.

13 / 16

Instruction for PMD-In Duct Air Quality Detector

V.1912

2、The mobile phone or mobile device is connected, and the WIFI hotspot is in the

operating environment of the device. In the following example, the WIFI hotspot is iPhone X.

1) Login account

Open the newly installed MyTongdy APP, enter your account, password, and log in. Available

account: CONFIG, password: 8899, see Figure 1. If it is only used for WIFI configuration, click

“Distribution Network”. If the customer needs the English version, after logging in, the customer

needs to change the language, as shown in Figure 2.

Figure 1 Figure 2 Figure 3

2)Click "Add Device" in the "Settings" interface. The interface that appears is the WIFI hotspot

environment that the device will run. This hotspot connection has been completed in step 2. See

Figure 2 and Figure 3.

3) The device is powered on for more than 1 minute (the indicator flashes during operation, which is

normal). Press and hold the “WIFI CONFIG” button on the bottom of the case for 5 seconds. At this

time, the device concentration indicator and the WIFI configuration indicator flash simultaneously. ,

indicating that the machine enters the WIFI configuration state and releases the button.

Note: Please complete the WIFI configuration operation within one minute. If it times out or loses

power in the middle, please start from 2).

4) After checking the WIFI hotspot information, click “Next”. See Figure 4

5) When the red light stops flashing and returns to normal, the configuration is complete. If the

configuration is successful, a prompt screen will appear (Figure 5). If it fails, please start from 2.

14 / 16

Instruction for PMD-In Duct Air Quality Detector

V.1912

Figure 4 Figure 5

4、After the configuration is successful, users can log in to the web version, add devices, view data,

graphs, and so on.

Note: The functions of the mobile app are limited. For more functions and data, please log in to the

web version to use.

RJ45 configuration-MQT version

RJ45 communication model, the product automatically obtains the IP as default, and the equipment

actively sends data to the MyTongdy platform, which is once every 1 minute. Customers only need to

connect the settings to the power supply and network cable. Next, customers can add equipment to

view data, graphs, and more on the MyTongdy platform. For specific operations, please feel free to

contact your sales representative for the platform operation manual.

Q&A for Common Faults

PMD Air Quality Detector, in normal use environment, please check it yourself when appear the

following faults. Initially determine the cause of the failure, if you can not troubleshoot, you can

contact the company's after-sales service department to resolve.

1. Communication interruption: Check whether the power supply is normal, whether the WiFi signal

is normal, whether the GPRS signal is normal, and whether the RJ45 and RS485 connections are

reliable.

2. Abnormal data deviation is too large: Check whether there are any environmental factors around

the equipment, whether there is any foreign matter inside the casing, whether the air inlet filter is

blocked by foreign matter or dust, especially in the season of catkins and poplars, the dust inside the

module needs to be cleaned , beyond the specified calibration period.

3. All models of this detector are equipped with a spare filter accessory. When the filter needs to be

cleaned, it can be replaced and cleaned up.

15 / 16

Instruction for PMD-In Duct Air Quality Detector

V.1912

Fault phenomenon

Reference Reason

PM2.5 data deviation is

too large, the value is

too high

Check whether the environmental factors around the equipment have any

influence, whether there is any foreign matter inside the housing, and there is

foreign matter inside the sensing module.

PM2.5 data deviation is

too large, the value is

too low

The air inlet filter is blocked by foreign matter or dust, and the exhaust port is

blocked. Especially in the season of catkins and poplars or the sensor module

exceeds the specified calibration period, the spare sensor module can be

directly replaced.

CO2 value is too high or

too low

The CO2 sensor has a self-calibration function that allows theABC

self-calibration function to return to normal values under normal use. In special

cases, if it is subjected to severe vibration, it cannot be repaired, and it is

necessary to recalibrate or replace the CO2 sensor.

TVOC data deviation is

too large, the value is

too high or too low

Check the influence of environmental factors around the equipment, or sudden

changes in the temperature and humidity of the environment. Whether the

power is stable for 48 hours. These will affect the large changes in TVOC

values. The TVOC value should be compared to the hourly average.

After the natural influence is removed, it can be remotely calibrated by

MyTongdy, if it cannot be calibrated, the TVOC sensor needs to be replaced.

CO value is too high or

too low

It can be remotely calibrated by MyTongdy (requires standard CO machine for

comparison or zero calibration). If the calibration is invalid, you need to return

to the factory to recalibrate or replace the CO sensor.

HCHO value is too high

or too low

Remote calibration via MyTongdy (requires a standard HCHO machine for

comparison). Otherwise, you need to return to the factory to recalibrate or

replace the HCHO sensor.

Too large deviation for

T&RH or value does not

change for a long time

Check whether the pitot tube is tightened and fixed on the main unit, the pitot

tube loosening makes the device unable to detect the external temperature

and humidity sensor.

Disassembly and installation of the pitot tube maybe with power on, should be

disassembled and installed after power off

Please try turning off power and turning on again.

Maybe need recalibrate the temperature and humidity again by MyTongdy or

by RS485 command.

Communication

interruption

GPRS ( China Mobile

4G) + GPS

Check if the power supply is normal.

Use your mobile phone to check if the nearby 4G signal strength is normal.

Check if the SIM card is insufficient fund.

Check if there is any new addition to the facility with certain electromagnetic

interference or shielding.

If everything is normal, you can try to power it off and then restore it to normal.

Check if the power supply is normal;

Use your mobile phone to check if the WIFI signal strength is normal.

Check if the SSID and password of the wirelessAP are changed;

Check the configuration of the router and firewall, and check if the port used by

the device is blocked by other people.

Check if there is any new addition to the facility with certain electromagnetic

16 / 16

Instruction for PMD-In Duct Air Quality Detector

V.1912

Warranty and Service

1. Warranty period: 12 months from the delivery date.

For the product under warranty the manufacturer is responsible for the repair and bear the

maintenance cost and material cost.

2. Product maintenance location: Manufacture (Beijing).

3. During the warranty period, customer can choose to return back the whole PMD or the sensor

module to the manufacturer for free maintenance, including: cleaning the air chamber,

calibration and other services.

4. The customer shall send the products back to the manufacture and pay the freight.. After the

product is repaired, it shall be sent to the customer and the manufacture pay the freight.

5. The following conditions are not covered by the warranty and must be repaired or replaced:

1) The user's improper installation or violation of the instructions for use of the product parts;

2) Damage to the product or its components caused by accidents (such as fires, floods, earthquakes,

etc.);

3) Damage to the sensor caused by falling and severe vibration;

4) Self-modification, damage to the product or its components caused by disassembly;

5) Physical damage caused by other non-product quality problems;

6) Product failure beyond the warranty period;

6. For the product is out of warranty, the manufacture provides paid maintenance.

7. The manufacture is not responsible for any other joint liability caused by the purchaser or the

undetermined cause caused by the use of the product.

Tongdy Sensing Technology Corporation

Http://www.tongdy.comEmail: michael@tongdy.com

Tel: +86 10 59738937/38/39

Add: Building #8, Courtyard #9, Dijin Road, Haidian Dist., Beijing 100095, China

interference or shielding;

If everything is normal, you can try to restore power after power off.

Communication

interruption

RS485 (Modbus RTU)

Check if the power supply is normal, if the RS485 terminal is loose. Whether

the RS485 communication line is accidentally cut by other constructions.

Whether an inductive load with electromagnetic interference is added or

started near the equipment or RS485 communication line, such as a water

pump.

Communication

interruption

RJ45(Ethernet TCP)

Check if the power supply is normal; whether the RJ45 plug connection is

reliable. Check the configuration of the router and firewall, check if the port

used by the device is blocked by other people.

If everything is normal, you can try to restore power after power off.

Other Tongdy Security Sensor manuals

Popular Security Sensor manuals by other brands

Comunello Automation

Comunello Automation GDARTSLMN0B00A Installation and user manual

Acconeer

Acconeer A121 user guide

Dectris

Dectris PILATUS3 X Technical specifications

Inxpect

Inxpect LBK System instruction manual

PCB

PCB 2301-02A Installation and operating manual

Veeder-Root

Veeder-Root DPLLD Site Prep and Installation Guide

Spectrex

Spectrex SharpEye 777670 installation instructions

Santa Fe

Santa Fe Sentry Installation & operation instructions

TESTO

TESTO 316-2 instruction manual

Petzl

Petzl VIZEN manual

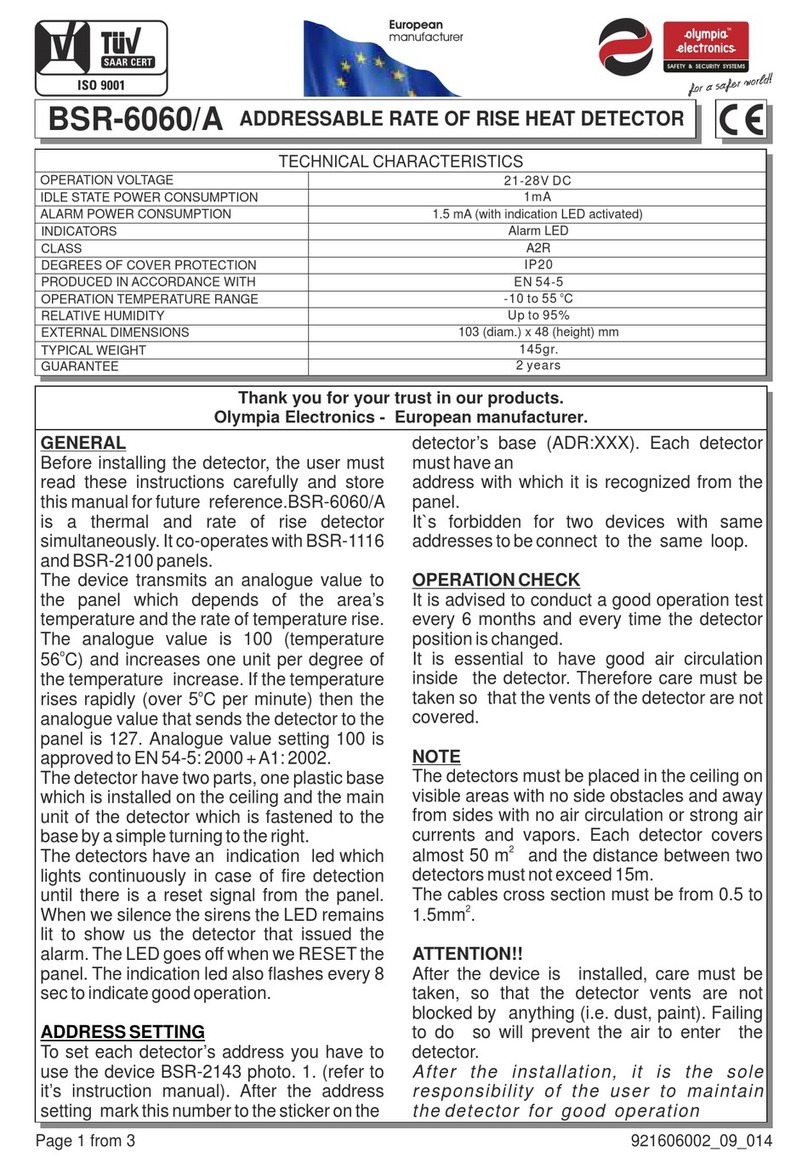

olympia electronics

olympia electronics BSR-6060/A/MAR quick start guide

iRay Technology

iRay Technology Mars1717XF Series user manual