Chapter 1 Overview

6

notify Changzhou Tonghui Electronics Co., Ltd. or its

distributors. Our customer service center will repair or

replace the machine for you. Please do not return the

product immediately without notifying Changzhou TongHui

Electronics Co., Ltd. or its dealers.

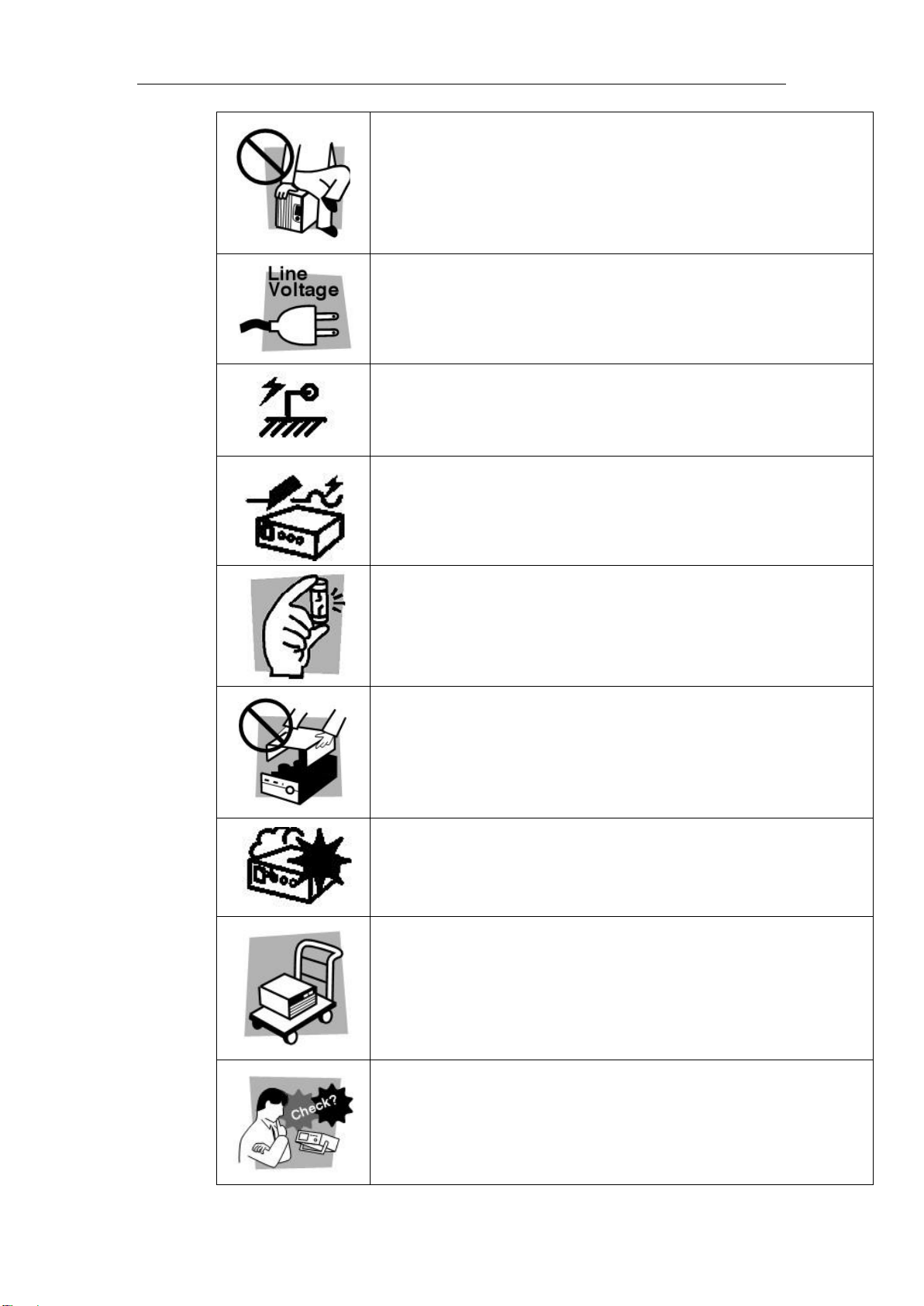

(4) To prevent accidental electric shock, please do not open the

top cover of the instrument by yourself. If any abnormality

happens to the instrument, please seek technical support

from Changzhou Tonghui Electronics Co.,Ltd. or its

designated distributors.

1.4.2 Environment

(1) Power supply in the installation should maintain good

ventilation and heat dissipation, power supply inlet (outlet)

and the distance between the wall or shelter should be more

than 30cm, and contact with corrosive substances is strictly

prohibited.

(2) Please make sure that the AC power to be connected meets

the specifications.

(3) Please refer to the specification parameters of each model

for ambient temperature and humidity.

(4) After the power supply is installed and test run, it is

recommended that the power supply should be left in an

energized state so that it can provide the best operating

conditions forthe electronic components and can keep some

of the important components from getting wet. If the power

supplyhasnotbeen used foralongtime,itshouldbevisually

inspected first, and if moisture is found in any internal

location, this part must be made dry before use. General

environmental conditions:

⚫Not for outdoor use.

⚫Keep away from flammable and explosive corrosive

media: such as alcohol, diluent, sulfuric acid and other

flammable and explosive corrosive materials.

⚫Keep away from heat sources and avoid exposure to the

sun.

⚫Operating environment temperature: 0℃~+50℃

⚫Storage environment temperature: -25℃~+65℃

⚫Keep away from boilers, humidifiers, water sources, etc.

⚫Working relative humidity:10~95%RH, no condensation.

⚫Storage relative humidity: not more than 80% (storage

in high humidity environments, it is recommended to run

the machine regularly for 20 minutes to avoid

condensation of water vapor).

⚫Keep away from strong electromagnetic interference

sources and significant vibration and shock.

⚫The working environment must be well ventilated and

free of dust. Please keep the area around the vent open