bonitron M3628PUT User manual

Model M3628PUT

Portable Ultracapacitor Tester

Customer Reference Manual

Bonitron, Inc.

2

Bonitron, Inc.

Nashville, TN

An industry leader in providing solutions for AC drives.

ABOUT BONITRON

Bonitron designs and manufactures quality industrial electronics that improve the reliability of

processes and variable frequency drives worldwide. With products in numerous industries, and

an educated and experienced team of engineers, Bonitron has seen thousands of products

engineered since 1962 and welcomes custom applications.

With engineering, production, and testing all in the same facility, Bonitron is able to ensure its

products are of the utmost quality and ready to be applied to your application.

The Bonitron engineering team has the background and expertise necessary to design,

develop, and manufacture the quality industrial electronic systems demanded in today’s market.

A strong academic background supported by continuing education is complemented by many

years of hands-on field experience. A clear advantage Bonitron has over many competitors is

combined on-site engineering labs and manufacturing facilities, which allows the engineering

team to have immediate access to testing and manufacturing. This not only saves time during

prototype development, but also is essential to providing only the highest quality products.

The sales and marketing teams work closely with engineering to provide up-to-date information

and provide remarkable customer support to make sure you receive the best solution for your

application. Thanks to this combination of quality products and superior customer support,

Bonitron has products installed in critical applications worldwide.

Bonitron, Inc.

3

AC DRIVE OPTIONS

In 1975, Bonitron began working with AC inverter drive specialists at synthetic fiber plants to

develop speed control systems that could be interfaced with their plant process computers.

Ever since, Bonitron has developed AC drive options that solve application issues associated

with modern AC variable frequency drives and aid in reducing drive faults. Below is a sampling

of Bonitron’s current product offering.

WORLD CLASS PRODUCTS

Undervoltage Solutions

Overvoltage Solutions

Uninterruptible Power for Drives

(DC Bus Ride-Thru)

Voltage Regulators

Chargers and Dischargers

Energy Storage

Braking Transistors

Braking Resistors

Transistor/Resistor Combo

Line Regeneration

Dynamic Braking for Servo Drives

Common Bus Solutions

Portable Maintenance Solutions

Single Phase Power Supplies

3-Phase Power Supplies

Common Bus Diodes

Capacitor Formers

Capacitor Testers

Power Quality Solutions

Green Solutions

12 and 18 Pulse Kits

Line Regeneration

M3628PUT

4

1. INTRODUCTION..........................................................................................................................7

1.1. Who Should Use........................................................................................................................7

1.2. Purpose and Scope.....................................................................................................................7

1.3. Manual Version and Change Record.........................................................................................7

Figure 1-1: M3628PUT ........................................................................................................................7

1.4. Symbol Conventions Used in this Manual and on Equipment..................................................8

2. PRODUCT DESCRIPTION /FEATURES........................................................................................9

2.1. Related Products........................................................................................................................9

2.2. Part Number Breakdown.........................................................................................................10

Figure 2-1: Example of Part Number Breakdown..............................................................................10

2.3. General Specifications.............................................................................................................10

Table 2-1: General Specifications Table ............................................................................................10

2.4. General Precautions and Safety Warnings ..............................................................................11

3. INSTALLATION INSTRUCTIONS................................................................................................13

3.1. Environment............................................................................................................................13

3.2. Wiring and Customer Connections .........................................................................................13

3.2.1. Power Wiring ..............................................................................................................................13

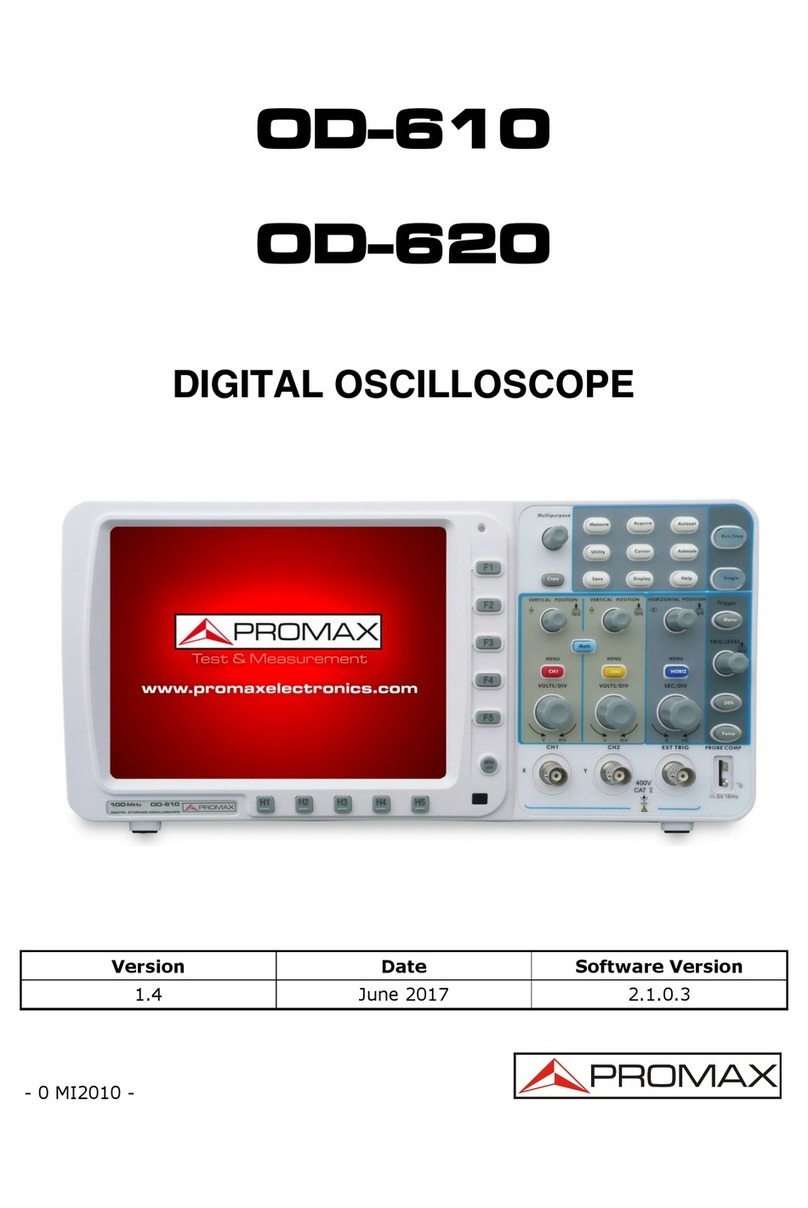

Figure 3-1: M3628PUT Faceplate......................................................................................................13

3.2.2. Source Considerations.................................................................................................................14

3.2.3. Load Considerations....................................................................................................................14

4. OPERATION..............................................................................................................................15

4.1. Functional Description............................................................................................................15

4.2. Features .............................................................................................................................15

4.2.1. AC Power Input Connector .........................................................................................................15

4.2.2. DC Output Connectors ................................................................................................................15

4.2.3. Display ........................................................................................................................................15

4.2.4. Interface Buttons .........................................................................................................................15

4.2.5. LEDs............................................................................................................................................15

4.2.6. Abort Button................................................................................................................................15

4.2.7. Voltage Present Indicator ............................................................................................................16

4.2.8. Fuse .............................................................................................................................................16

4.2.9. Power Switch / Circuit Breaker...................................................................................................16

4.3. Screens & Menu Navigation ...................................................................................................16

4.3.1. Main Menu..................................................................................................................................16

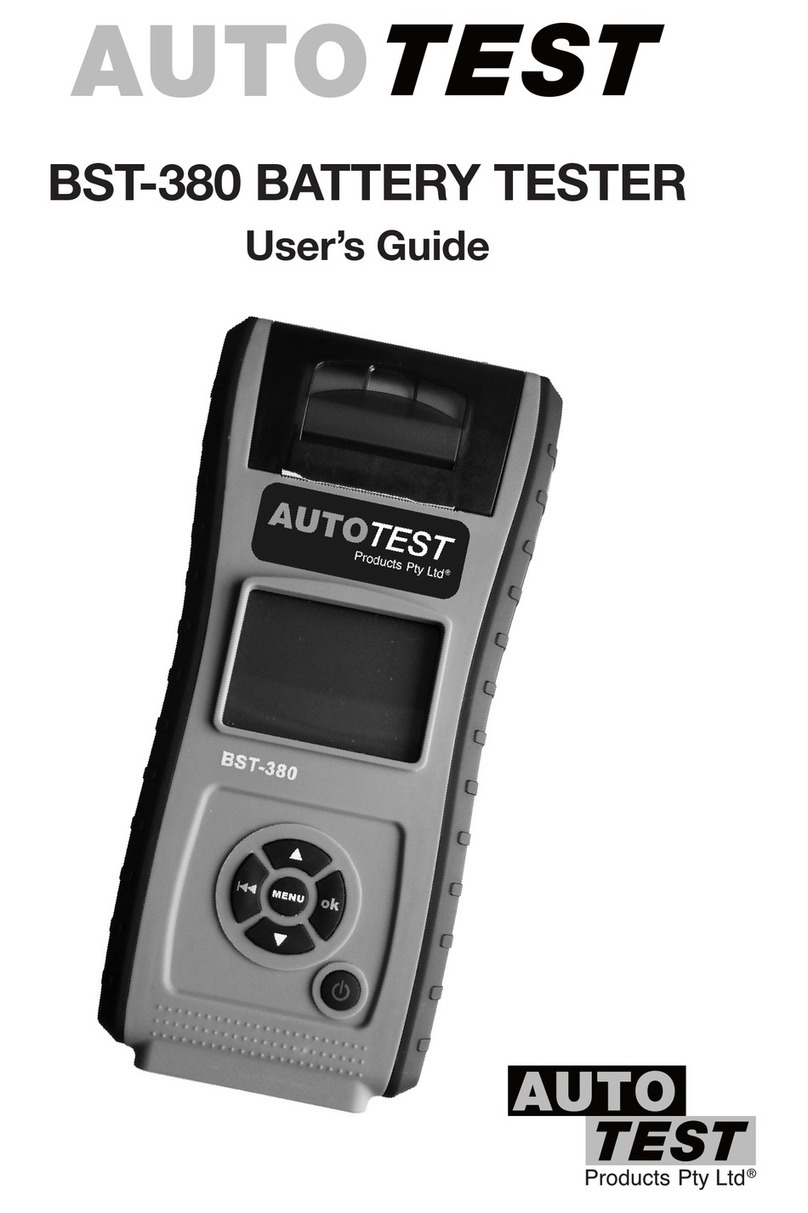

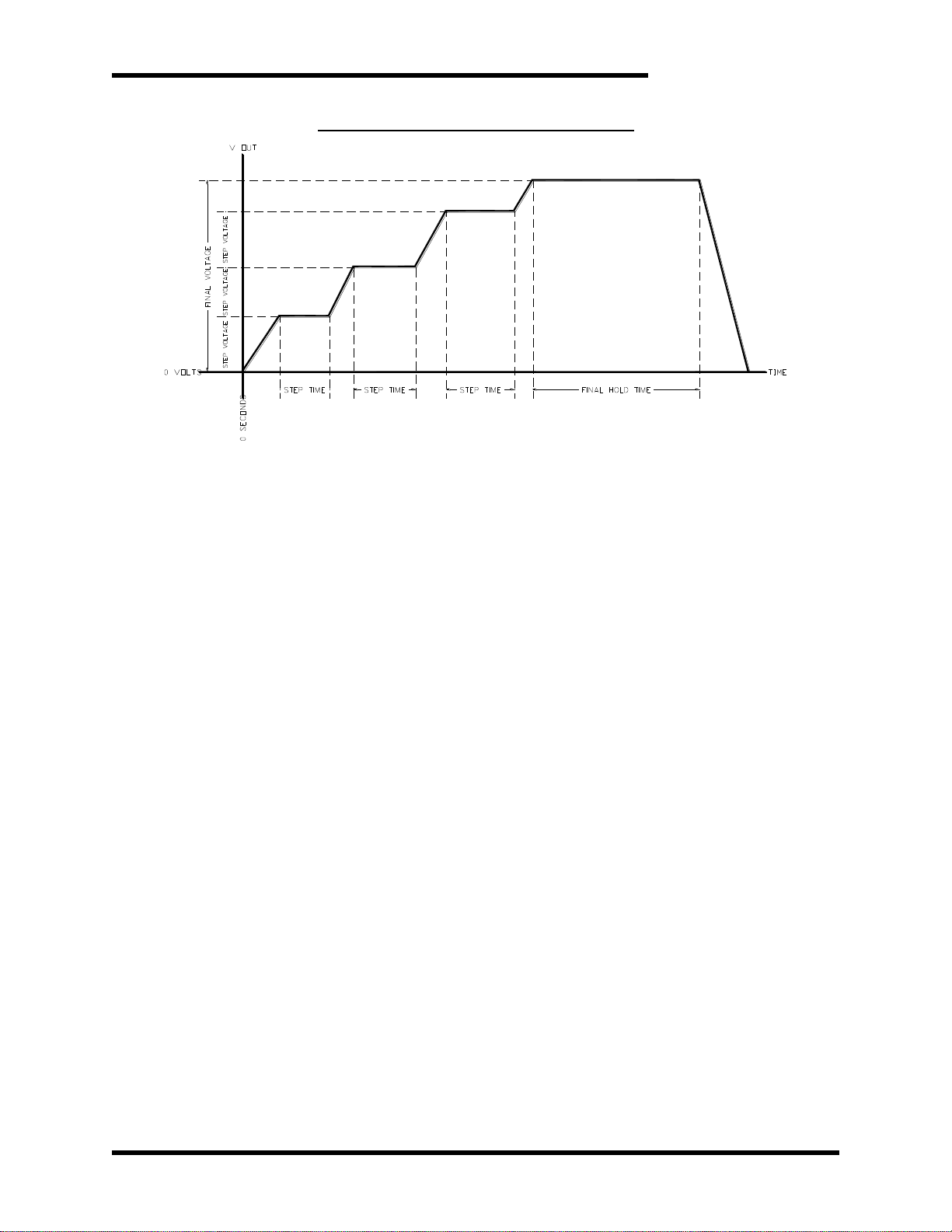

Figure 4-1: M3628PUT Charging Profile...........................................................................................17

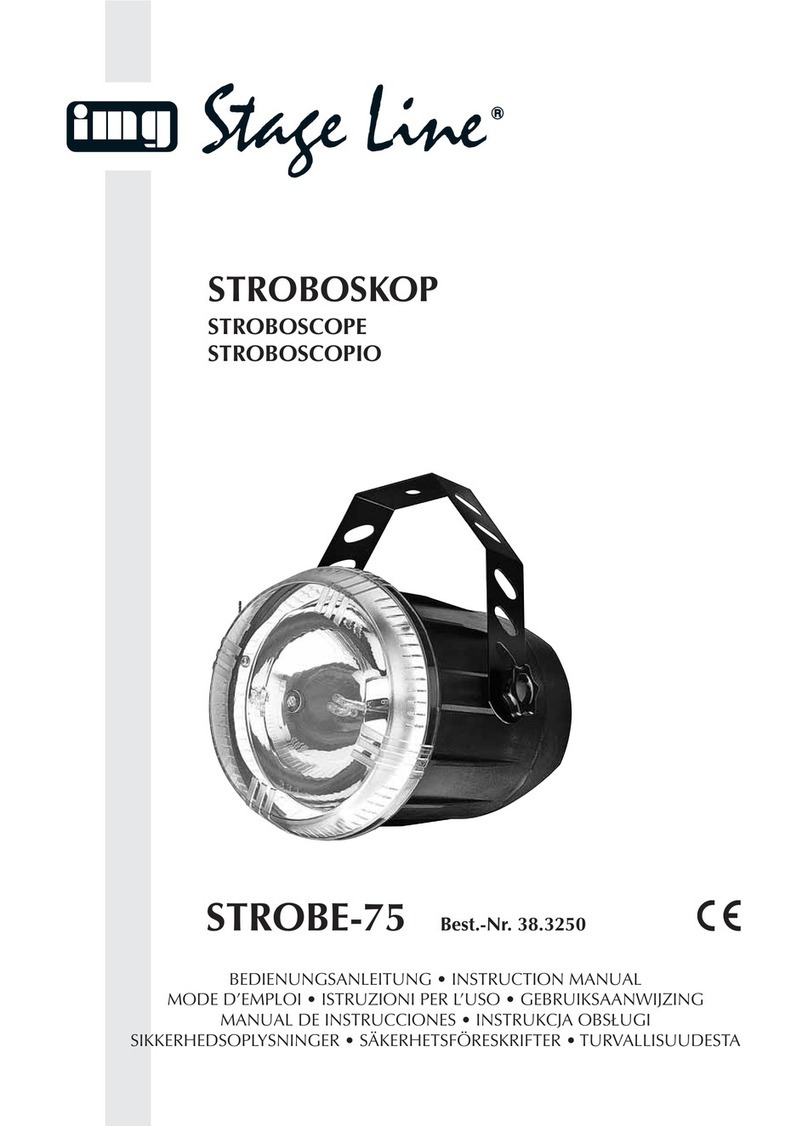

Figure 4-2: M3628PUT Interface Screen Tree...................................................................................18

4.4. Faults .............................................................................................................................20

4.4.1. Overtemp.....................................................................................................................................20

4.4.2. Communication Loss...................................................................................................................20

4.4.3. Reverse Bias................................................................................................................................20

4.4.4. Fuse Loss.....................................................................................................................................20

4.4.5. Relay Failure ...............................................................................................................................20

4.4.6. Short IGBT..................................................................................................................................20

5. MAINTENANCE AND TROUBLESHOOTING...............................................................................21

5.1. Maintenance Items ..................................................................................................................21

5.2. Troubleshooting.......................................................................................................................21

Table 5-1: Troubleshooting ................................................................................................................21

5.3. Technical Help ........................................................................................................................22

6. ENGINEERING DATA................................................................................................................23

Table of Contents

5

6.1. Ratings Chart...........................................................................................................................23

Table 6-1: Ratings Chart.....................................................................................................................23

6.2. Dimensional Drawing..............................................................................................................23

Figure 6-1:M3628PUT Dimensions ...................................................................................................23

6.3. Block Diagram ........................................................................................................................23

Figure 6-2: Block Diagram.................................................................................................................23

7. APPENDIX.................................................................................................................................25

7.1. Application Notes....................................................................................................................25

7.1.1. Typical Capacitor Bank Forming / Testing Procedure ................................................................25

M3628PUT

6

This page intentionally left blank

User’s Manual

7

1. INTRODUCTION

1.1. WHO SHOULD USE

This manual is intended for use by trained personnel responsible for maintaining or

testing Ultracapacitors.

Please keep this manual for future reference.

1.2. PURPOSE AND SCOPE

This manual is a user’s guide for the Model M3628PUT. It will provide the user with

the necessary information to successfully connect and operate the M3628PUT.

In the event of any conflict between this document and any publication and/or

documentation related to any associated hardware (capacitor bank, etc.), the latter

shall have precedence.

1.3. MANUAL VERSION AND CHANGE RECORD

Rev 00 is the original printing of the M3628PUT manual.

The Example of the Part Number Breakdown was changed in Rev 00a.

Input Voltage options were added in Rev 01.

The manual template was updated in Rev01a.

Figure 1-1: M3628PUT

M3628PUT

8

1.4. SYMBOL CONVENTIONS USED IN THIS MANUAL AND ON

EQUIPMENT

Earth Ground or Protective Earth

AC Voltage

DC Voltage

DANGER!

Electrical Hazard - Identifies a statement that indicates a shock

or electrocution hazard that must be avoided.

DANGER!

DANGER: Identifies information about practices or

circumstances that can lead to personal injury or death,

property damage, or economic loss.

CAUTION!

CAUTION: Identifies information about practices or

circumstances that can lead to property damage, or economic

loss. Attentions help you identify a potential hazard, avoid a

hazard, and recognize the consequences.

CAUTION!

Heat or burn hazard - Identifies a statement regarding heat

production or a burn hazard that should be avoided.

User’s Manual

9

2. PRODUCT DESCRIPTION / FEATURES

The M3628PUT is designed for testing of ultracapacitors. As ultracapacitors age and

wear, their capacitance decreases, and their ESR increases. This can result in

decreased system performance, and ultimately, process failure. Measurement of an

ultracapacitor's capacitance and ESR can help avoid expensive preemptive

replacement.

The M3628PUT is a portable digitally-controlled capacitor tester. The digital interface

allows the user to charge an attached ultracapacitor to a specified voltage, and then

discharge the capacitor. After discharge is complete, the display will show the

capacitance and ESR of the ultracapacitor.

2.1. RELATED PRODUCTS

M3528 ULTRACAPACITOR/BATTERY CHARGER

The M3528 Charger can charge strings of batteries or ultracapacitors to voltages

required for industrial and commercial applications. AC or DC input is available,

along with separate float and equalization charge levels. The charger is current

limited, and designed for use in integrated storage and backup systems, but can also

be used in bench or mobile systems.

M3628 ULTRACAPACITOR DISCHARGE CONTROLLER

Large capacitor banks store huge amounts of energy, and can be a hazard when

systems are shut down for system maintenance. The M3628 system discharges

capacitor banks to safe working levels quickly, allowing work on the system to begin

in seconds, rather than hours.

M3628PCFPORTABLE CAPACITOR FORMER

The M3628 Portable Capacitor Former can be used to charge or discharge capacitor

banks as large as 50 kJ. The output voltage is manually variable between 0 and 900

VDC, and the system is capable of supplying 1 ADC continuously. The unit can be

used for reforming disused capacitors.

M3628PCT PORTABLE CAPACITOR TESTER

The M3628 Portable Capacitor Tester can be used to charge, discharge and

measure capacitor banks as large as 300 kJ. The output voltage can be set by

digital control to between 0 and 800 VDC, and the system is capable of supplying 1

ADC up to 450 VDC. When discharging, the unit times the discharge and gives a

capacitance value for capacitor banks between 2200 uF and 1F. The unit can also

be used for automatic reforming of disused capacitors.

M3628PUT

10

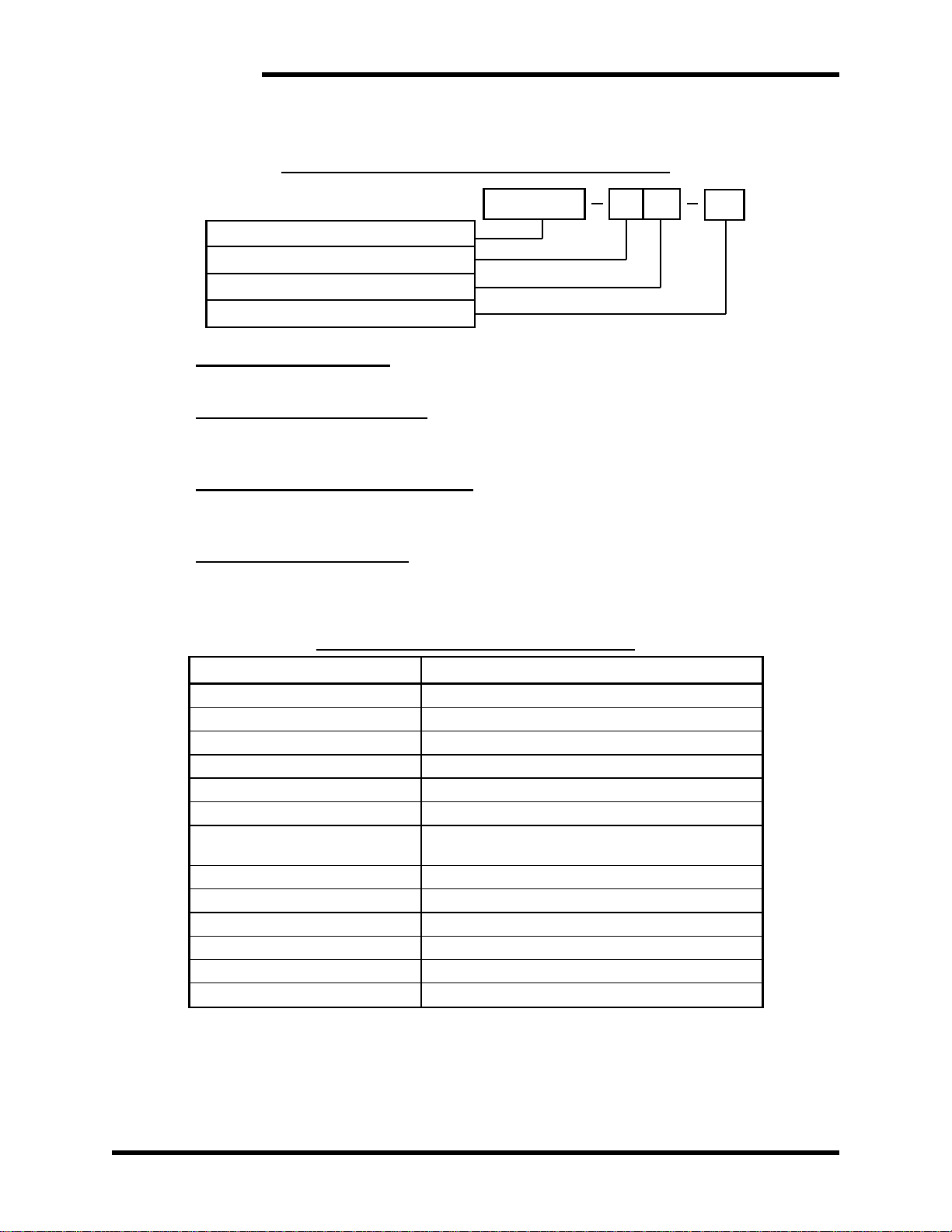

2.2. PART NUMBER BREAKDOWN

Figure 2-1: Example of Part Number Breakdown

BASE MODEL NUMBER

The Base Model Number for all Portable Ultracapacitor Testers is M3628PUT.

OUTPUT VOLTAGE RATING

The Maximum Output Voltage Rating indicates the DC output voltage the unit can

supply. At present there is only a U model.

MAX OUTPUT CURRENT RATING

The Maximum Output Current rating indicates the maximum DC current the unit can

supply at its maximum voltage.

INPUT VOLTAGE RATING

This indicates the input voltage for the unit.

2.3. GENERAL SPECIFICATIONS

Table 2-1: General Specifications Table

PARAMETER

SPECIFICATION

Input Voltage

110-120VAC, 220-240VAC, 1ø

Output Voltage

0-130VDC

Output Current

1-7ADC

Minimum Load Capacitance

1 Farad

Maximum Load Energy

500 kJ

Minimum Cycle Voltage

5V

Controls

Six display soft keys

Abort button

Display

Four line, eighty character LCD (4x20)

Unit Size (H x W x D)

18.00" x 22.00" x 10.50"

Weight

50 lbs.

Storage Temp

-20°C to +65°C

Humidity

Below 90% non-condensing

Atmosphere

Free of corrosive gas and dust

M3628PUT

U

07

BASE MODEL NUMBER

OUTPUT VOLTAGE

MAXIMUM OUTPUT CURRENT

INPUT VOLTAGE

110

User’s Manual

11

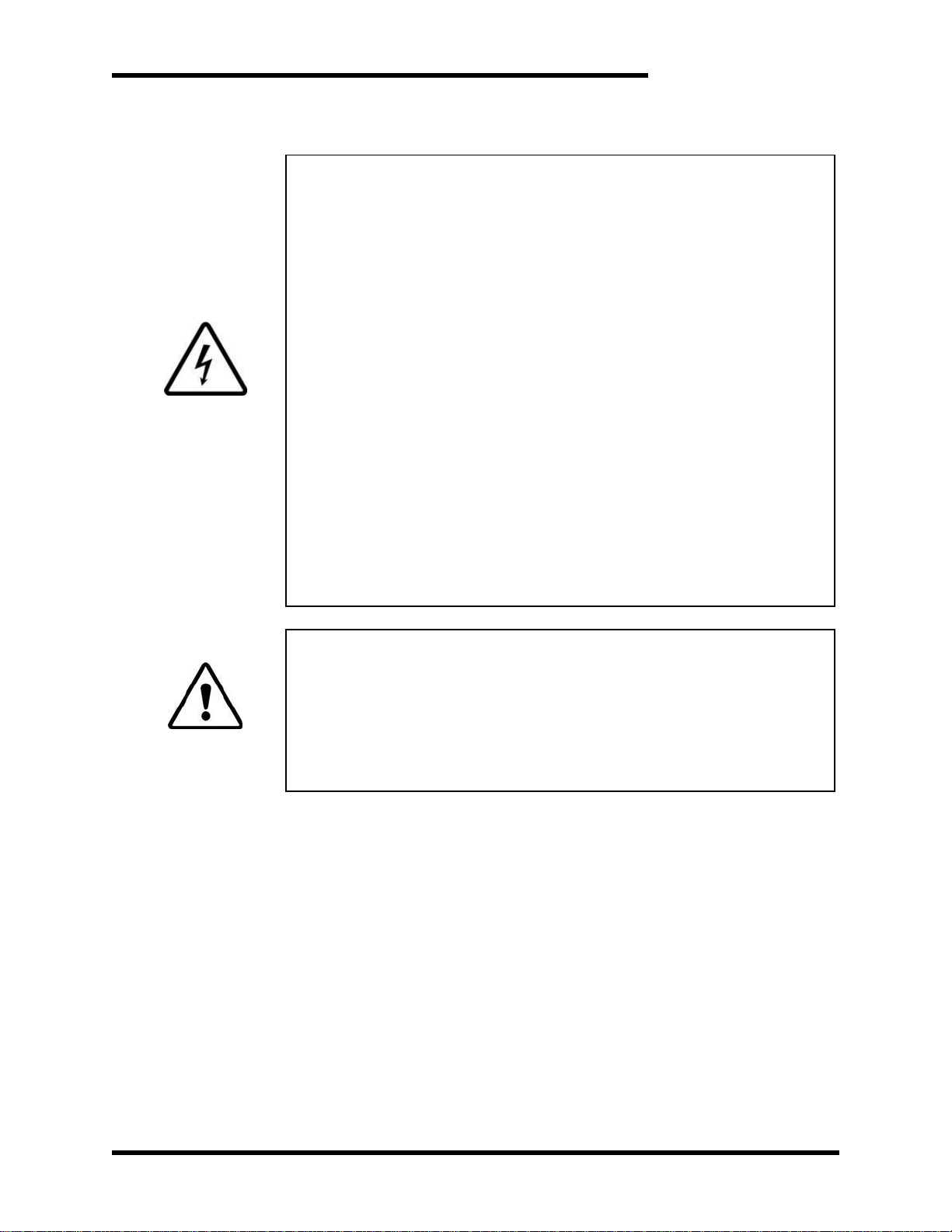

2.4. GENERAL PRECAUTIONS AND SAFETY WARNINGS

ELECTROCUTION

HAZARD!

THIS UNIT PRODUCES VOLTAGES CAPABLE OF CAUSING INJURY

OR DEATH!

FOR USE BY QUALIFIED AND TRAINED PERSONNEL ONLY!

IMPROPER OPERATION OF THE PRODUCT OR

IGNORING THESE WARNINGS MAY RESULT IN

SERIOUS BODILY INJURY OR DEATH!

BEFORE CONNECTING THE M3628PUT TO A CAPACITOR BANK,

ENSURE THAT THE BANK IS FULLY DISCHARGED BY CHECKING

WITH A VOLTMETER.

CONNECTING THE M3628PUT’S VOLTAGE OUTPUT TO A LOAD

WITH THE POLARITY REVERSED CAN CAUSE DAMAGE TO YOUR

EQUIPMENT AND POTENTIALLY CREATE A FIRE OR EXPLOSION

HAZARD,THREATENING LIVES.ENSURE THAT THE POSITIVE

AND NEGATIVE TERMINALS ON BOTH THE SOURCE AND LOAD

ARE POSITIVELY IDENTIFIED AND CORRECTLY CONNECTED

BEFORE OPERATION.

NEVER OPERATE THIS PRODUCT WITH THE ENCLOSURE COVER

REMOVED.

DANGER!

NEVER ATTEMPT TO SERVICE THIS PRODUCT.

CERTAIN PARTS INSIDE THIS PRODUCT MAY GET HOT DURING

OPERATION.

BEFORE CONNECTING THIS DEVICE TO ANY OTHER PRODUCT,

BE SURE TO REVIEW ALL DOCUMENTATION OF THAT PRODUCT

FOR PERTINENT SAFETY PRECAUTIONS.

ANY QUESTIONS AS TO APPLICATION, INSTALLATION, OR SERVICE

SAFETY SHOULD BE DIRECTED TO THE EQUIPMENT SUPPLIER.

M3628PUT

12

This page intentionally left blank

User’s Manual

13

3. INSTALLATION INSTRUCTIONS

3.1. ENVIRONMENT

While closed, the M3628PUT is water, dust, and crush resistant. When open and in

operation, the unit should be used only in dry, clean areas. Ensure that the interior

of the unit casing is kept dry.

3.2. WIRING AND CUSTOMER CONNECTIONS

3.2.1. POWER WIRING

The Power Input connector accepts 50-60Hz AC from the included standard

C13 power cable. The DC Output connectors supply DC voltage at the

user-selected level via a pair of high-current connectors. Output leads can

be constructed as needed. The unit should be powered ON before

connecting to a load, as the unit is in discharge mode when powered off.

WARNING!

Attaching the unit to an AC input voltage other than that specified for your

unit may cause improper operation or damage!

Figure 3-1: M3628PUT Faceplate

ABORT

ON

OFF

110 VAC IN

NEGATIVE POSITIVE

VOLTAGE PRESENT

0-130 VDC OUT

M3628PUT

PORTABLE ULTRACAPACITOR TESTER

Dwg: 120270 Rev: 20120726

M3628PUT

14

3.2.2. SOURCE CONSIDERATIONS

It is important to only connect this unit to a source that meets the specified

voltage and current requirements.

The source must be capable of supplying 14A @110VAC or 7A @ 220VAC

under normal operating conditions.

Failure to meet the minimum current requirement may result in improper

operation.

Connecting the unit to an input voltage other than that specified on the unit

faceplate may also result in improper operation or damage to the unit.

3.2.3. LOAD CONSIDERATIONS

To ensure the most accurate possible measurements, the capacitor under

test should be charged to its full rated voltage. Note that the M3628PUT will

discharge the attached load capacitor to 2VDC. This unit is thus not

recommended for use on ultracapacitors rated at less than 5VDC.

Before charging or discharging an attached capacitor, ensure that the

capacitor is capable of safely sourcing the current which will be drawn by

the .6 ohm discharge resistor at the desired charge voltage. I=V/R.

WARNING!

Drawing current from a capacitor in excess of its maximum rated current

can cause the capacitor to overheat and explode! Confirm the maximum

current rating of the capacitor before charging or discharging.

User’s Manual

15

4. OPERATION

4.1. FUNCTIONAL DESCRIPTION

The M3628PUT is a digitally controlled DC supply capable of sourcing between 1

and 7 amps at between 0 and 130VDC. The unit is powered by standard 50-60 Hz

AC. The output voltage is controlled by the digital interface panel on the front of the

unit. The unit is capable of safely charging and discharging connected capacitors. It

is also capable of executing a pre-programmed charging profile, with defined step

voltages and hold times. When a capacitor is discharged, the unit will calculate and

display the capacitance and ESR of the capacitor. An Abort button is present in case

of user error when selecting charge voltage. The unit automatically enters discharge

mode when powered off.

4.2. FEATURES

4.2.1. AC POWER INPUT CONNECTOR

The M3628PUT is equipped with a standard IEC C14 connector for input

power. This connector mates with a standard C13 cable, commonly used

with desktop computers, to provide power to the unit.

4.2.2. DC OUTPUT CONNECTORS

Two high-current jacks provide the user with DC output voltage between 0

and 130VDC, and provide a discharge path for the current from the

capacitor being tested. Cables are included, and can be constructed as

desired.

4.2.3. DISPLAY

The digital display presents the user with information about the present

status of the system, including the output voltage and current. The display

also presents the user with options to control system operation, including

charging and discharging attached capacitors.

4.2.4. INTERFACE BUTTONS

The function of each button depends on the active screen. For menu

screens, enter selects a menu option, while cancel moves back to the

previous screen. Up and down move the menu curser. On screens where

numbers are input by the user, the left and right buttons move the cursor,

while the up and down buttons change the selected digit. Enter stores the

present value, while cancel undoes any changes. On some screens,

certain buttons may perform no function.

4.2.5. LEDS

Three LEDs indicate the present status of the PUT. Red indicates a fault

condition. Yellow indicates that the unit is presently charging or discharging.

Green indicates that the unit has power.

4.2.6. ABORT BUTTON

There is a red Abort button on the face of the unit. This button will cause

the system to immediately switch to discharge mode, regardless of the

M3628PUT

16

present system activity. In the event the unit is accidentally set to charge to

a higher voltage than is safe for one load, this button should be pressed

immediately.

4.2.7. VOLTAGE PRESENT INDICATOR

WARNING!

Do not use this light as an indication that the output is safe to work on!

Always check the output with a working voltmeter before servicing

equipment, as the lamp may be malfunctioning!

ELECTROCUTION HAZARD! This unit produces dangerous levels of

voltage that can cause injury or death. Always follow safety protocols

when working with high voltages!

A red light indicates that there is an unsafe voltage on the DC output of the

unit. Do not touch the output connectors or the attached equipment while

this light is on, as electric shock will result.

4.2.8. FUSE

This fuse is in the charging output of the PUT. If the fuse fails, power down

the unit, and replace it with the same fuse. (see Section 5) Do not replace

the fuse while the system is live!

4.2.9. POWER SWITCH /CIRCUIT BREAKER

The Power Switch also acts as a circuit breaker to protect from overload

conditions. If the breaker is tripped, you can reset it by simply turning the

switch back on.

NOTE: When switched OFF, the unit is in Discharge mode.

4.3. SCREENS &MENU NAVIGATION

Many screens are menus allowing access to other screens, or lists presenting a

number of options. The presently selected item on the menu is indicated by a ‘>’

character. This selection indicator is moved using the up and down buttons. If a line

on the menu represents another screen, that screen may be accessed with the enter

key. The cancel button will typically return the display to the parent screen.

4.3.1. MAIN MENU

The Charging Profile, Single Charge, Discharge, and Previous Results

screens may be accessed from the Main Menu.

4.3.1.1. CHARGING PROFILE

From this selection, the user may input the variables necessary to

execute an automatic Charging Profile. A charging profile charges the

capacitor in steps, each step a specified voltage apart. When each step

voltage is reached, the load is held at that voltage for a specified

number of seconds before charging to the next step voltage. When the

final voltage is reached, the load is held at that voltage for a specified

number of seconds before discharging. See Figure 4-2.

User’s Manual

17

Figure 4-1: M3628PUT Charging Profile

4.3.1.1.1. SET PROFILE FINAL VOLTAGE

From this screen the user may set the final charge voltage. The

right and left buttons control which digit is being edited, and the

up and down buttons increment or decrement that digit. Enter will

save changes. Cancel will abort changes.

4.3.1.1.2. SET PROFILE STEP VOLTAGE

From this screen the user may set the voltage step by which the

load will approach the final voltage. The right and left buttons

control which digit is being edited, and the up and down buttons

increment or decrement that digit. Enter will save changes.

Cancel will abort changes.

4.3.1.1.3. SET PROFILE CURRENT

From this screen the user may set the maximum charge current.

The right and left buttons control which digit is being edited, and

the up and down buttons increment or decrement that digit. Enter

will save changes. Cancel will abort changes.

4.3.1.1.4. SET PROFILE STEP HOLD TIME

From this screen the user may set the number of seconds each

step voltage will be held. The right and left buttons control which

digit is being edited, and the up and down buttons increment or

decrement that digit. Enter will save changes. Cancel will abort

changes.

4.3.1.1.5. SET PROFILE FINAL HOLD TIME

From this screen the user may set the number of seconds the

final voltage will be held. The right and left buttons control which

digit is being edited, and the up and down buttons increment or

decrement that digit. Enter will save changes. Cancel will abort

changes.

Dwg: 090115 Rev: 20090421

M3628PUT

18

Figure 4-2: M3628PUT Interface Screen Tree

MENU

MAIN

RESULTS/

CONFIRM

DISCHARGE DISCHARGING

PREVIOUS RESULTS

STATUS

VOLTAGE

CHARGE

SINGLE CHARGE

DISCHARGE

CURRENT

CHARGE CHARGE

CONFIRM CHARGE

EXECUTING

CHARGE PROFILE

VOLTAGE

FINAL

PROFILE

VOLTAGE

STEP

PROFILE

CURRENT

PROFILE

TIME

STEP

PROFILE

TIME

FINAL

PROFILE

PROFILE

CONFIRM PROFILE

EXECUTING

Dwg: 090114 Rev: 20120803

User’s Manual

19

4.3.1.1.6. CHARGE PROFILE CONFIRM

At this screen the user is asked to confirm the Profile settings.

Enter will start charging. Cancel will abort charging.

4.3.1.1.7. EXECUTING PROFILE

This screen displays the present output voltage and current and

seconds left for each step. It transitions to the "Discharging"

screen (4.3.1.2.6.) when the output voltage reaches the set point

and is held for the specified number of seconds. Charging may

be aborted by pressing cancel. This will not initiate discharging; if

charging is aborted via the cancel button, the load will remain at

voltage until discharging is manually initiated or the unit is turned

off.

4.3.1.2. SINGLE CHARGE MENU

The user may set the charge voltage and current, and initiate charging

from here.

4.3.1.2.1. SET CHARGE VOLTAGE

From this screen the user may set the charge voltage. The right

and left buttons control which digit is being edited, and the up and

down buttons increment or decrement that digit. Enter will save

changes. Cancel will abort changes.

4.3.1.2.2. SET CHARGE CURRENT

From this screen the user may set the maximum charge current.

The right and left buttons control which digit is being edited, and

the up and down buttons increment or decrement that digit. Enter

will save changes. Cancel will abort changes.

4.3.1.2.3. CHARGE CONFIRM

At this screen, the user is asked to confirm the charge voltage

and current. Enter will start charging. Cancel will abort charging.

4.3.1.2.4. CHARGING

This screen displays the present output voltage and current. It

transitions to the Results screen (4.3.1.2.7) when the output

voltage reaches the set point. Charging may be aborted by

pressing any of the four directional buttons. This does not initiate

discharging. Caps will remain at voltage until discharging is

manually initiated or the unit is turned off.

4.3.1.3. DISCHARGE CONFIRM

At this screen the user is asked to confirm their intent to discharge the

capacitor bank. If the user confirms, the capacitor starts discharging,

until the load voltage reaches 2VDC. The time the capacitor takes to

discharge is measured, and from this value the load capacitance is

calculated.

4.3.1.4. DISCHARGING

This screen displays the present output voltage and discharge current.

It transitions to the “Results” screen when the output voltage reaches

2VDC.

M3628PUT

20

4.3.1.5. RESULTS

This screen presents the user with the present output voltage and the

results of the previous capacitor discharge and measurement, including

capacitance and ESR. The system transitions to this screen after a

period of inactivity.

4.4. FAULTS

If a fault condition occurs, the red LED will illuminate, and the display will indicate the

nature of the fault. Once a fault state has cleared, the red LED will turn off; and the

description of the fault will remain. Press the cancel button to return to the main

menu.

4.4.1. OVERTEMP

This fault indicates that the unit has exceeded its safe operating

temperature range. Leave the unit connected to power and load, and allow

the unit to cool. The fault should clear within 60 minutes.

4.4.2. COMMUNICATION LOSS

This fault indicates that a serial connection has been lost within the

M3628PUT. This is not user-serviceable. Contact Bonitron for service

options (Section 5.3).

4.4.3. REVERSE BIAS

This fault indicates that the voltage on the output terminals of the

M3628PUT is of the incorrect polarity; the negative terminal is higher than

the positive terminal. Check the polarity of the leads attached to the

ultracapacitor under test.

4.4.4. FUSE LOSS

This fault indicates that the fuse in the charging link of the M3628PUT has

failed. Power down the unit and replace the fuse with one of comparable

specifications (Section 5.1).

4.4.5. RELAY FAILURE

This fault indicates that the relay driving the output of the M3628PUT is

open. If the fault will not clear, your unit is damaged. Contact Bonitron for

service options (Section 5.3).

4.4.6. SHORT IGBT

This fault indicates that the discharge control transistor has shorted. If this

fault will not clear, your unit is damaged. Contact Bonitron for service

options (Section 5.3).

Table of contents

Other bonitron Test Equipment manuals