Toolots FMJ-1600E-WARM User manual

Ving 63" Entry Level Full Auto

Wide Format Heat Assisted Cold

Laminator

User’s Manual

FMJ-1600E-WARM

- 1 -

I. Description

FMJ-1600-E-WARM is a new type of laminator with auto-peeling of liner

paper and print take-up function based on the FMJ-1600-II-Warm. It is simple

in structure, rational, user-friendly and low in cost. The top and bottom rollers

are driven by the motor while the film mandrel and liner paper roll are driven by

its own material, that is the straight internal force motion of the printed picture

between the main rollers. It saves labor power and easy to operate. Due to its

innovated structure, it is popular among users since its launch.

The machine has film mandrel, S bar and prints roller to support

consecutive laminating or long picture laminating. And the auto-peeling of liner

paper and print take-up are achieved by the rolling force of the main rollers. It is

easy to use, efficient, energy-saving and easy to regulate the velocity.

It has two types of mains values, 220-240VAC or 110VAC. Please make

sure that the power indication in the machine ID label conforms to your power

supply when you buy or install the machine.

The machine has pedal switch. You can use either hand switch or pedal

switch to operate.

II. Specifications

Maximum Laminating Width: 1600mm (63")

Maximum Laminating Thickness: 35mm (1.4")

Laminating Speed: 0 - 6m (236") / min

Forward / Reverse: Yes

Foot Pedal: Yes

Roller’s Diameter: 120mm (4.7")

Maximum heating temperature: 60 degree, 140F

Heating Mode: Upper roller heating

Motor power: 90W

Heating Power: 1300W

Rated Power: 1400W

Auto rewind liner pickup: Yes

After Laminating Pickup: Yes

Emergency Stops: Yes

Safety Photocell: Yes

Media Core Size: 3"

power supply: AC 110V - 240V, 50Hz or 60Hz

1N/PE 220V 7A; 1N/PE 110V 13A

- 2 -

III. Parts identifications

Figure 1

1. Left cabinet 2. Emergent stop 3. Left bracket plate 4. Liner paper roll 5.

Film mandrel 6. roller 7. Right bracket plate 8. Right cabinet 9. In-feed

table 10. Lift knob 11. prints roll 12. Base plate 13. Pedal switch 14.

castor 15. Underframe 16. Damping knob

1. Circuit breaker

2. 2. Power wire

3. Pedal switch plug-in

1

2

3

- 3 -

Control Panel:

-Power on/off:Press the button to turn on or turn off the machine.

When the machine is turned off, the motor and electricity heating

will shut down automatically, the roller will be lifted automatically.

F/R-Direction Switching Button:

Control the rotation direction of the

roller.

-Motor on/off:Start or stop the motor

-Heating Button: Start or stop the heating

function.

1)Temperature setting: Pressure the up

or down button to set the

temperature of the roller.

6 seconds after setting the actual

temperature will be displayed.

Figure 2

Specifications setting:Press and hold:“”for 3 second to enter in the

specification setting;

Press to show D-1, D-2, D-3, D-4, D-5 in order.;

END to indicate the end of setting;

Press up and down button to regulate the value of specification;

If the buttons are not pressed in minute, the specification setting

state will be automatically ended.

Spec. No.

Spec. Content

Temp. Range

Default Temp.

D-1

Temp. Correction

-100---100

0 ℃

D-2

High temp. alarm

point

10-170C

150 ℃

D-3

Max. temp.

10-150

120℃

D-4

Temp. unit

0-℃, 1-℉

0-℃

END

Setting completed

Installation Warnings:

1)Pressure transducer debugging: When the upper roller touches the down roller,

observe the temperature increase display, regulate the position of the transducer to

reach the value of the lifting height to (). Then fix the position of the transducer.

- 4 -

2)When install the upper and down limit, do not confuse the wire number.

3)Fix the film panel first and then test the button, or else the bulb and cable lines may

be damaged.

V. Installation and operating

1. Move the machine to its final location, make sure it is free of any damage

and ready of all the parts and accessories.

2. Connect the machine to the mains. Check the mains values before

connecting.

3. Install the film mandrel and left and right cabinet of print roll (fasten the

screws). Make sure the ends are symmetrical. Press the start button and the

rollers are rotating. Make sure the machine run normally. Then try

lamination and check the effect and quality of lamination.

4. Film mandrel and liner paper roller can be installed or removed quickly.

three rubber strips which can be rolled are mounted on the aluminum

mandrel to lock the core of the film roll. A Bakelite knob on one end of the

liner paper roller can regulate friction to ensure the same speech of main

rollers and liner paper roller to ensure the laminating quality. Turn the knob

clockwise, damping increases. While turn the knob counterclockwise, the

damping decreases.

5. The knob on the right cabinet is for lift or drop the roller. Turn it clockwise

and the roller is lifted. Turn it counterclockwise and the roller is dropped.

When turn it counterclockwise and the top roller reaches the bottom roller,

the turning force is significantly reduced. This phenomenon is called idle

stroke. When the weight of the top roller is well-distributed on the bottom

roller, the laminating can be started. If you continue to turn the knob

counterclockwise, the pressure can be increased.

Adjust the parallelism and pressure of the main rollers::

- 5 -

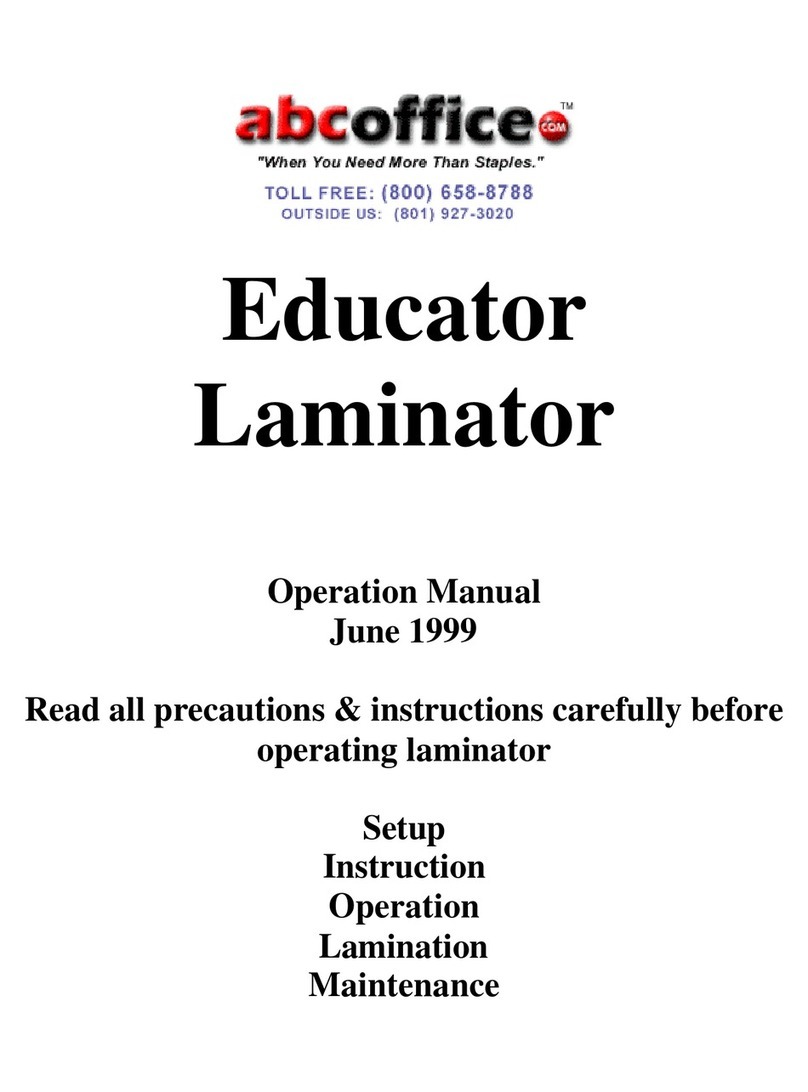

Figure 3

1. Middle bracket of compression on the left 2. Left cabinet 3. Compression

spring 4. Upper compression bracket 5. Compression bolt 6. Compression nut

The alignment of the main rollers is the crucial factor to ensure the

balance of pressure and further affect the quality of lamination and the

off-tracking of image. The main rollers are well-aligned before the

shipment from factory. While violent vibration in transportation or

long-time operation may lead to the misalignment of the main rollers. You

can readjust the rollers with the following measures.

1. Reset the pressure of the main rollers

When the pressure of the main rollers is imbalanced, the image may be

mounted off track or show up wrinkles. Adjust the pressure with the

following steps.

1) Observe and record the off-tracking direction of the image, turn off the

power of the machine and remove the board of the wheel cabinet.

Caution: compared with the right cabinet, the parts in the left cabinet is

- 6 -

fewer. Please remove the left cabinet first to avoid excessive work or

damage of other parts.

As the figure shown above, the middle bracket of the left compression and

the upper compression bracket are connected by two bolts. Each bolt has a

spring and two screws (see the figure above). One screw is welded with the

compression plate and the other below is movable clamp nut.

2) If the image is off-tracking on the left right of the machine, it indicates

the pressure on the left side is higher than that on the right side. Adjust the

screw bolt to reduce the deflection of the spring on it. The range of

adjustment of both bolts shall be as the same as possible.

Note: You can use a ruler to measure the height of the two bolts and make

sure they are at the same level in the adjustment.

3) If the image is off-tracking on the right side, it indicates that the

pressure on the level side is lower than that on the right side. Increase the

deflection of the spring on the two bolts then. The range of adjustment

depends on the range of off-track of image.

Caution: When the deflection of spring is adjusted, please turn the pressure

of the machine to its maximum level to ensure there is margin for the

deflection. Or else the spring may be damaged. When the left side does not

have margin, remove the right-side board to adjust the screw bolt on this

side.

4)Tighten the nuts after adjustment.

5) Install the left side board on the machine.

Adjustment principle: if the image is off-tracking to the left side, the

pressure of the left side is higher than the right side. Loosen the spring on

the left side to reduce its deflection.

1. Align the main rollers

Set the space between the main rollers to 1-2mm. Observe the evenness of space

- 7 -

by eyes (or measured by a feeler). If it is not even, record the side with small

space. Then set the main rollers to idle stroke, cut the main power, open the side

board of the wheel carbine, as the figure shows below, screw out the bolt,

increase or reduce the number of the insert plates between the lifting plate and the

compression plate (the insert plates are supplied as the accessory of the machine)

to align the main rollers and then re-install the side board.

Caution: The main rollers are aligned and fixed before the shipment from the

factory. When the image is off-tracking or other problems occur in lamination,

please check the pressure balance of the main rollers first. Only after confirming

the problems are caused by the misalignment of the main rollers, the insert plates

can be increased or reduced. Reset the pressure of the main rollers after the

adjustment.

6. Lamination process:

Figure 4

- 8 -

VI. Safety Cautions:

1. Read this manual carefully before starting the machine. Familiarize yourself

thoroughly with the structure, functioning and operation of this machine.

Observe all the warning symbols on the machine to prevent accidents.

2. The mains supply must match the type indicated on the machine

identification label. And reliable ground connection shall be ensured.

3. This machine does not have optical safety device. Do not approach the

rolling rollers to prevent injury.

4. Lift the roller after operation to prevent deformation after long-time

pressure and cut the power supply.

5. Keep distance with the rollers when cut the films or images to prevent

damage to the rollers by the edge tools. You can swipe the glue on the rollers by

cotton cloth with alcohol. You may not use organic solvent to swipe the roller or

wash the roller by water, which may lead to damage of the rubber or

short-circuit.

6. Install the machine in a dry and well ventilated environment. Make sure the

ground is free of water or moisture. Keep the machine from any inflammable

and explosive objects to prevent fire accident.

7. Check the electricity leaky of the machine and power lines regularly. If

there is any abnormal phenomena in operation, please check and eliminate

problem in time to prevent further damage.

- 9 -

Warranty Card

Model

Production No.

Buyer

Purchase time

Dealer

Tel

Notes

1. The above card shall be filled by the dealer and kept by the

buyer. Any alternation will invalid the card.

2. The standard warranty period of this machine is one year. You

can get free repair service with the warranty card within half a

year. Material and service fee will be charged after this

period.

3. Any machine damaged by improper usage may not enjoy free

repair service.

Table of contents