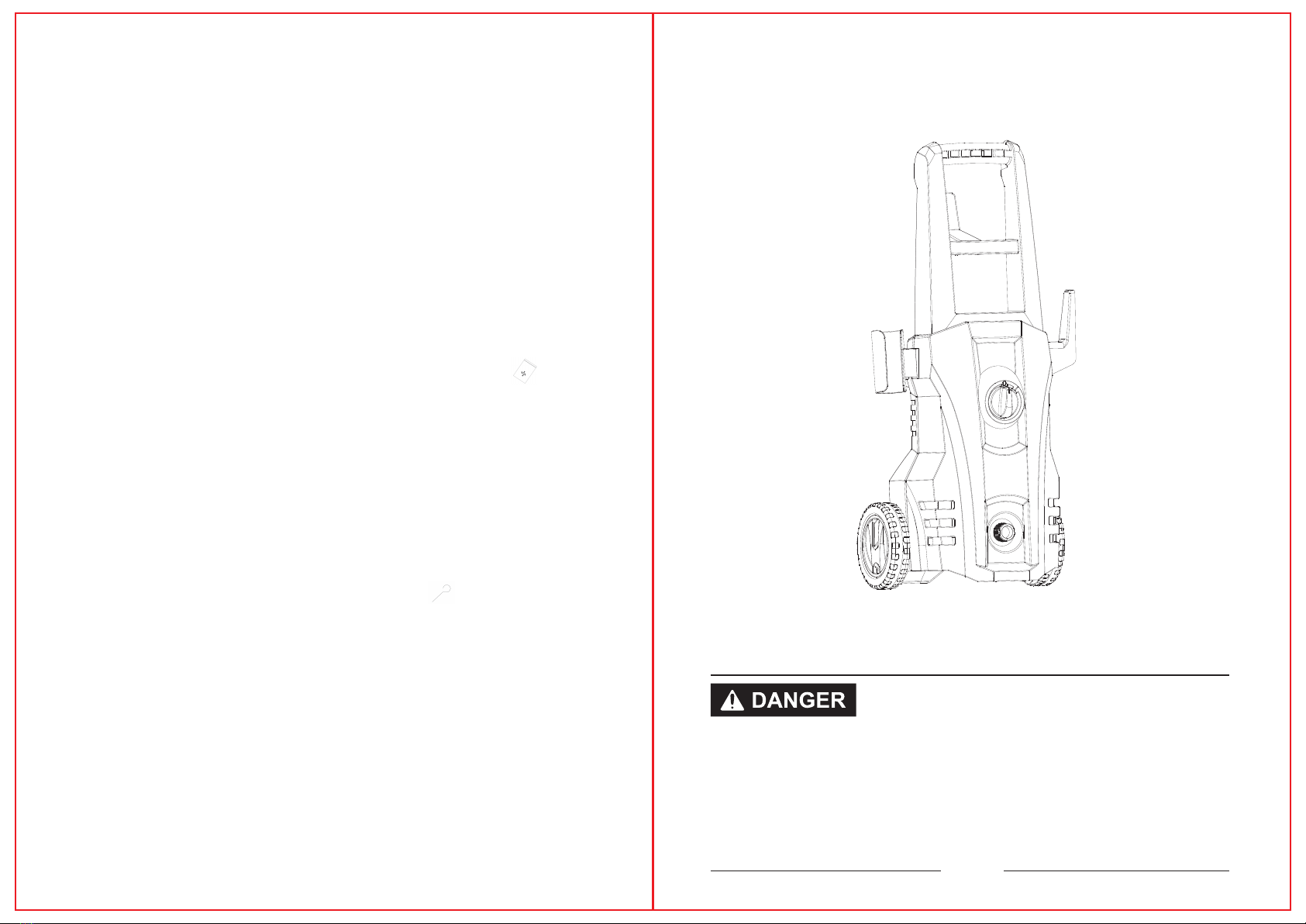

Toolots M6DDW4751 User manual

Owner's Manual

1

Please read this manual carefully before attempting

to operate, maintain or install the product.

Failure to follow the manual could result in personal injury and/or property

damage! Save this manual for future reference.

Electric

Pressure Washer

32

Electric Pressure Washer Electric Pressure Washer

CALIFORNIA PROPOSITION 65

This product may contain chemicals known

to the State of California to cause cancer and

birth defects or other reproductive harm.

Wash hands after handling.

When unpacking this product, check to make sure parts listed below are included and carefully

inspect for any damage that may have occurred during transit. If any part is missing and

damaged, do not attempt to assemble or use the product.

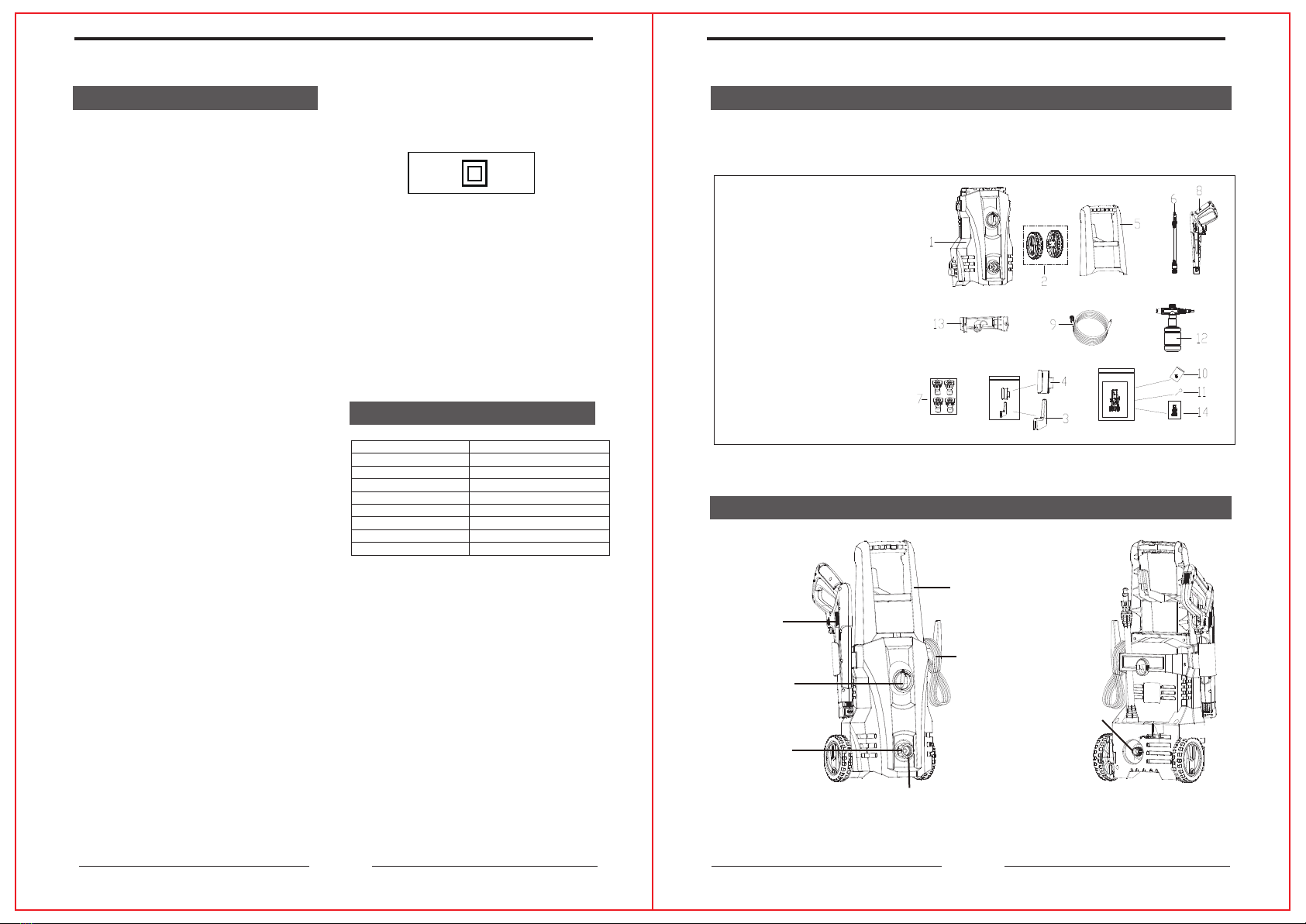

UNPACKING

SPECIFICATIONS

GENERAL SAFETY INFORMATION

IMPORTANT SAFETY INSTRUCTIONS

WARNING – When using this product basic

precautions should always be followed,includ-

ing the following:

1.Read all the instructions before using the

product.

2.To reduce the risk of injury, close supervision

is necessary when a product is used near

children.

3.Know how to stop the product and bleed

pressures quickly. Be thoroughly familiar with

the controls.

4. Stay alert – watch what you are doing.

5. Do not operate the product when fatigued

or under the influence of alcohol or drugs.

6. Keep operating area clear of all persons

7.Do not overreach or stand on unstable

support. Keep good footing and balance at all

times.

8.Follow the maintenance instructions specifi-

ed in the manual.

WARNING – Risk of Injection or Injury– Do

Not Direct Discharge Stream At Persons.

SAVE THESE INSTRUCTIONS

with the words “Double Insulation "or “Double

Insulated.” Product may also be marked with

symbol shown below.

SERVICING OF A DOUBLE- INSULATED

APPLIANCE

In a double-insulated product, two systems of

insulation are provided instead of grounding.

No grounding means are provided for a dou-

ble-insulated product, nor should grounding

means be added to the product. Servicing a

double-insulated product requires extreme

care and knowledge of the system, and should

be done only by qualified service personnel.

Replacement parts for a double-insulated

product must be identical to the original

parts. A double-insulated product is marked

Double Insulated Symbol

FUNCTIONAL DESCRIPTION

1. Pressure Washer Unit

2. Wheel

3. Power Cable Hook

4. Gun Holder

5. Handle With High Pressure Hose Hoo

6. Spray Wand

7. Quick Connect Nozzle (4Pcs)

8. Spray Gun

9. High Pressure Hose

10. Screw (Taped on the manual)

11. Spray Tip Cleaning Tool

12. Detergent Bottle

13. Detergent Bottle Bracket

14. Manual

k

Spray Gun

On/Off Switch

Water Outlet

Water Inlet

Handle

Power Cord

Garden Hose Connector

(Assembled on machine,Double side

are America standard 3/4-11.5GHT)

(Taped

on the manual)

ModelXP101C-80C

Rated pressure2500PSI

Max pressure 3000PSI

Rated flow rate 1.8GPM

Max flow ratw 2.3GPM

Power Supply Voltage120V/60Hz

Rated electrical current 13.5 A

PowerRate 1400 W

Max. Water Temperature 104 °F

54

Electric Pressure Washer Electric Pressure Washer

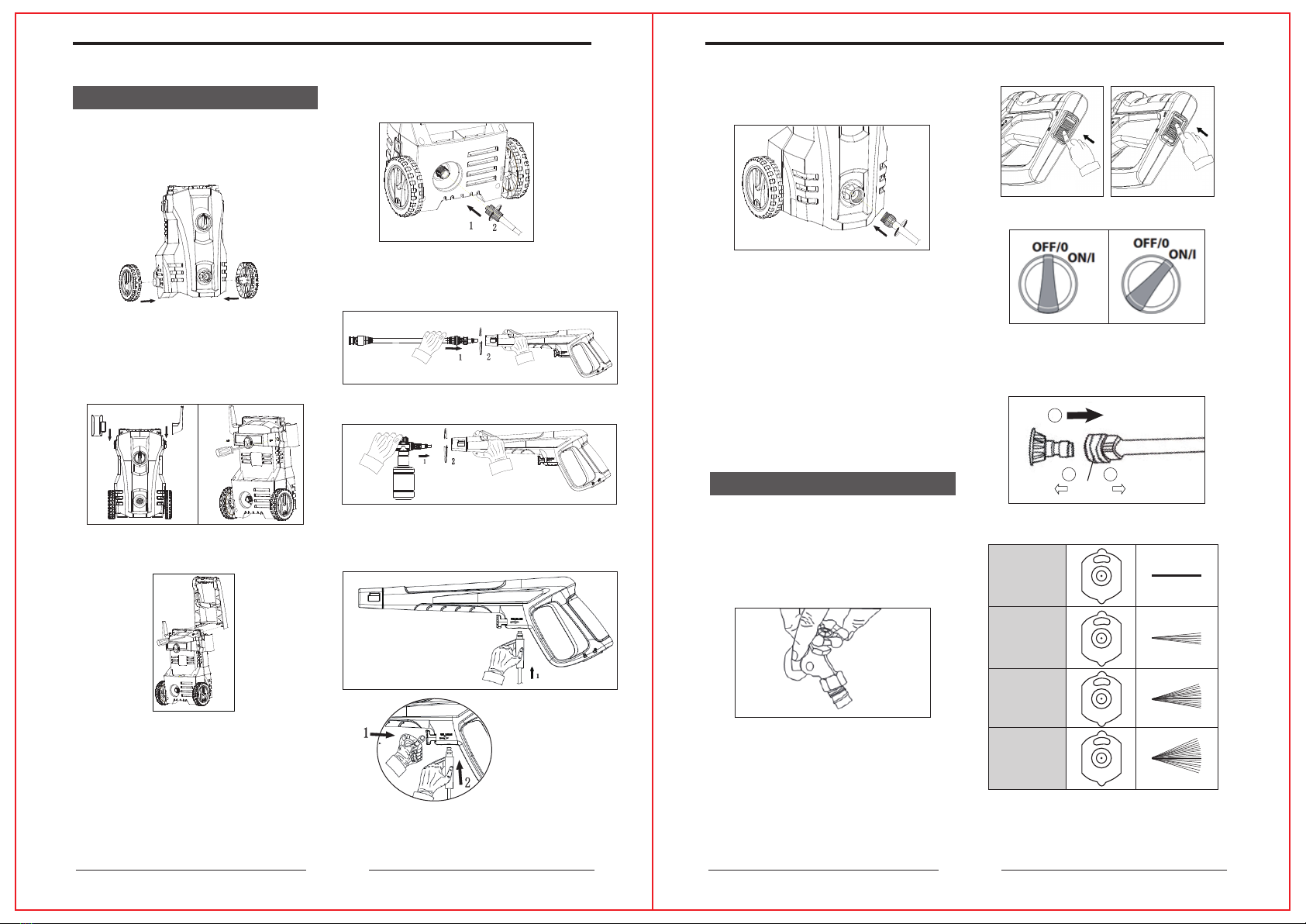

3.Attach the Handle(5) tight to the main unit.

6. Attach High Pressure Hose(9) to Spray

Gun(8) .

7. Screw the Garden Hose on to Garden

hose connector.

8. Connect the garden hose to water source.

WARNING: The appliance is INTENDED

to be used at a temperature above 0

degree.

TO WASH WITH WATER

1.Turn the water source on.

Warning: DO NOT USE DIRTY WATER,It

may clog the filter and other parts of unit

inside.

OPERATION

2.Press the UNLOCK button in the Spray Gun

(8) handle. Squeeze the trigger of gun about

1 minute until low pressure water flow out to

empty air out of the unit.

LOCK UNLOCK

PREPARATION OF OPERATION

2.Attach Gun Holder(4) and Power Cable

Hook(3) with "click" sound which indicate to

be fixed well. Screw Detergent Bottle

Bracket(13) to the main unit.

3.Turn the switch to ON(I) position.

4.Select proper nozzle ,pull the collar and

insert the nozzle, then put the collar to return

to place.

FIXED ANGLE NOZZLE

0° Nozzle

(1)

15°Nozzle

(2)

25°Nozzle

(3)

40°Nozzle

(4)

0°

15°

25°

40°

Collar

9. Connect to the power supplier.

Note: When using an electric pressure

washer, always plug it into a properly

grounded GFCI outlet.

5. Connect Spray Wand(6) to Spray Gun(8)by

pushing and twisting. For Detergent Bottle (12),

directly connect to Spray Gun (8).

1

2

3

click click

4. Attach High Pressure Hose(9) to the

pressure water outlet of the machine.

HOW TO SET UP YOUR UNIT

1.Attach Wheel (2) with "click" sound which

indicate to be fixed well.

Push button to

remove the hose

76

Electric Pressure Washer Electric Pressure Washer

10. Lock the trigger and put the Spray Gun(8)

into Gun Holder(4) ,power cable to Power

Cable Hook(3).

PUMP GUARD

Specially formulated to protect your pressure

washer from freezing, corrosion and premature

wear.The pump Guard also adds lubrication

to valves and seals to prevent sticking.Highly

recommended for all POWRYTE pressure

washers!

WINTERIZING AND LONG-TERM

STORAGE

1. Disconnect all water connections.

2. Turn on the machine for a few second,

until the remaining water in the pump exits.

Turn off immediately.

3. Do not allow high-pressure hose to become

kinked.

4. Store the machine and accessories in a

room that does not reach freezing tempera-

tures. Do not store near furnace or other

sources of heat as it may dry out the pump

seals.

TIPS FOR EXTENDING THE LIFE OF

YOUR PRESSURE WASHER

1.Never operating the machine is more than

30s without water supply.

2.Pressure washer is not meant to pump hot

water. Never connect to hot water supply –

this will significantly reduce life of the pump.

3.Using detergent other than those formulated

for pressure washers may cause damage to

pump components (o-rings, etc.). This also

applies to chemicals such as bleach, dish

soap, etc.

WATER FILTER AND NOZZLE CLEAN-

ING INSTRUCTIONS

A clogged or partially clogged water filter(in

the Garden Hose Connector) or nozzle can

cause significant reduction of water pressure

coming out of the nozzle and/ or cause the

unit to pulsate while spraying.

1.The water filter was inside the Garden hose

connector(8),should be cleaned periodically.

2.Using the Nozzle Cleaning Wire(13) (taped

to the manual) provided, insert the wire into

the nozzle hole and move back and forth until

debris is dislodged. Back flush water through

the nozzles using garden hose and highest

pressure available (either standard water

nozzle or use your thumb over the nozzle to

create water pressure for back flush).

MAINTENANCE

Choose the best nozzle for the job.

Warning: Please confirm the nozzle is

pluged in position and the nozzle holder is

returned to position before squeezing the

trigger.

The angle of spray is smaller the water outlet

pressure is higher, and the material of surface

need be cleaned should be tough enough to

support higher pressure water. Detail of

intended use see items (1)-(4) below:

(1)0° nozzle,Red, Fine spot spray means

delivering a high-pressure pencil-point jet

stream. It is used to cut heavy dirt deposits in a

small concentrated area. It is ideal for dissolv-

ing stubborn substances, like tar and grease

spots on concrete, or for removing caked mud

from equipment. It is also used to clean

hard-to-reach areas including the facades of

2-story buildings or undersides of lawn mowers

and tractors.

Note: Care should be taken when setting

nozzle spray to avoid permanently gouging

wood or damaging fragile surfaces.

(2)15° nozzle,Yellow, for intense cleaning jobs

on hard surfaces that can withstand the

high-pressure. Applications include stripping

paint, removing oil stains, grease, heavy

mildew stains, and rust from steel.

(3) 25° nozzle, Green, for cleaning home

siding, brick patios, wood decks, driveways,

sidewalks, cars or furniture.

(4) 40° nozzle, White, for cleaning items

such as cars, trucks, boats, patio furniture, or

lawn equipment.

5.Squeeze the trigger of gun,the high

pressure water will flow out.(see below

picture)

6.When you finish your clean job turn the

switch to OFF(O) position.

7.Unplug the power cord from the power

outlet

8.Turn off water supply.

9.After motor and water supply are turned off,

trigger Spray Gun(8) to depressurize system.

2. Squeeze the trigger, detergent will come out

through the nozzle .

3.Apply detergent so it thoroughly covers

cleaning surface.

4. Allow detergent to remain on the surface for

a few minutes. This is a good time to use a

brush to lightly scrub heavily soiled areas.

5. Change to Spray nozzle, Rinse detergent

from surface.

6. Cleaning up: Always draw fresh water

through the detergent bottle when done to

flush any remaining detergents from the

injection system. The bottle could be

detached if necessary in this process.

11.After each use, wipe all surfaces of the

pressure washer with a clean, damp cloth.

TO WASH WITH DETERGENT

1.Screw out the bottle and fill bottle with

detergent.Connect Detergent Bottle(6) to

Spray Gun (11).

CAUTION: NEVER using pressure washer

is more than 30S after water supply off.

Serious damage could occur to the pump

and / or motor.

WARNING: NEVER disconnect high pre-

ssure discharge hose from machine while

system is pressurized. To depressurize,

turn motor off, turn water supply off and

squeeze gun trigger 2-3 times.

WARNING:Acids, alkalines, bleaches,

solvents, can corrode the soap nozzle.

9

LIMITED WARRANTY

This tool is warranted by the manufacturer to

the original purchaser from the original

purchase date for two (2) years subject to the

warranty coverage described herein. If this

product is used for commercial, industrial or

rental purposes, the warranty will apply for

ninety days from the date of purchase. This

tool is warranted to the original user to be

free from defect in material and workmanship.

If you believe that a tool is defective, return

the tool, with proper proof of purchase to the

point of purchase. If it is determined that the

tool is defective and covered by this warranty,

the distributor will replace the tool or refund

the purchase price. Freight costs must be

borne by you.

This warranty is void if: defects in materials

or workmanship or damages result from

repairs or alterations which have been made

or attempted by others or the unauthorized

use of nonconforming parts; the damage is

due to normal wear, damage is due to abuse

(including overloading of the tool beyond

capacity), improper maintenance, neglect or

accident; or the damage is due to the use of

the tool after partial failure or use with

improper accessories or unauthorized repair

or alteration.

This limited warranty does not apply to normal

wearing parts such as O-rings, seals, piston

springs, bumper, drive blades and other

related items.

This warranty gives you specific legal rights,

and you may also have other rights that vary

from state to state.

8

TROUBLESHOOTING

WARNING: Follow all safety precautions whenever diagnosing or servicing the

product.

Problem

Possible Cause

Possible Solution

No detergent suction

Unit begins to smoke

Injector clogged on pump

Overheated, overloaded or

damaged motor

Unit is pressurized

Plug is not well connected

or electric socket is faulty

Extension cord too long or

wire size too small

Main voltage supply too

low

Thermal safety switch has

tripped

Squeeze trigger on gun

Check plug, socket and fuse

Remove extension cord

Check that main supply

voltage is adequate

Switch off unit and allow motor

to cool down

1.

2.

3.

4.

5.

Water inlet filter is clogged

Pump sucking air from

hose connections

Nozzle worn or not correct

size

Unloader clogged or worn

Valves clogged or worn

1.

2.

3.

4.

5.

Pump sucking in air

Clogged nozzle

Valves dirty, worn or stuck

Water seals worn

1.

2.

3.

4.

Extension cord too long or

wire size too small

Thermal safety switch has

tripped due to overheating

1.

2.

Remove extension cord

Check that main supply

voltage corresponds to

specifications

1.

2.

Check that hoses and

connections are tight

Clean with tip cleaner

Contact service

Contact service

1.

2.

3.

4.

Clean water inlet filter

Check that connections

and locking ring are

properly tightened

Contact service

Contact service

Contact service

1.

2.

3.

4.

5.

1.

2.

3.

4.

5.

Turn off unit and Contact

Service

Contact Service.

Pressure washer

does not start up

Pump does not

reach necessary

pressure

Fluctuating

pressure

Motor stops

suddenly

Electric Pressure Washer Electric Pressure Washer

Table of contents