Toolshop 61832 Quick reference guide

CONTENTS

SUMMARY

SPECIFICATIONS

SAFETYWARNINGS&CAUTIONS

UNPACKING

SETTING

CONNECTINGTHETOOLTOAN AIRSUPPLY

LOADINGTHEFASTENERS

OPERATINGTHETOOL

REGULARMAINTENANCE

TROUBLE SHOOTING

EXPLODEDVIEWDRAWING

PARTSLIST

1

1

1

2

2

3

3

3

3

4

5

6

Characteristic

MinimumOperatingAirPressure

MaximumOperatingAirPressure

NailLengthRange

NailSize

NailCapactity

AirInlet

AirConsumption

ToolWeight

Value

60PSI

95PSI

5/8"--1-1/4"

18 &19 Gauge

100

1/4"NPT

0.38Lat 80PSI

2.7lbs

1

SPECIFICATIONS

SUMMARY

Youwillneedtheinstructionforthesafetywarningandprecautions,assemblyinstruction,operatingandmain-

tainsprocedures,partslistanddiagram.Keepyourinvoice withthisinstruction.Writetheinvoicenumberon

theinsideofthefrontcover.Keeptheinstructionand invoiceina safeand dryplaceforfuturereference.

READALLINSTRUCTIONSBEFOREOPERATINGTHETOOL

SAFETYWARNINGS& CAUTIONS

1.KEEPWORKINGAREACLEAN.Clutteredareasinviteinjuries.

2.DON TALLOWCHILDRENKEEPATTHEWORKINGAREA. Don tletthemhandlethetool.

3.DONOTOPERATETHISTOOLIFUNDERTHEINFLUENCEOFALCOHOLORDRUGS.

Readwarninglabelonprescriptionstodetermineifyourjudgmentorreflexesareimpairedwhiletaking

drugs.Ifthereis anydoubt,donotattempttooperate.

4.USESAFETYGLASSES.SafetyglassesshouldconformtoANSIZ87.1specifications.Beforeoperating,

wearsafetyglassesagainstflyingdebrisfromthefrontandside. Safetyglassesshouldbewornwhen

loading,operating,unloadingorservicingthistool.

5.USEEAR PROTECTION. Theworkingareamaybeexposedtohighnoiselevelsthatcanleadto

hearingdamaged.

6.NEVERUSEOXYGENCOMBUSTIBLEGASES,BOTTLEDGASESORHIGHPRESSURE

COMPRESSEDGASASAPOWERSOURCEFORTHISTOOL. Thetoolmayexplodeand

causeseriousinjury.

7.DRESS SAFELY. Protectivegloves andnonskidfootwearorsafetyshoesarerecommendedwhen

workingwithandoperatingthistool.Don twearlooseclothingorjewelry.Theycangetcaughtinmoving

parts.Also,wearaprotectivehaircoveringtopreventlonghairfromgettingcaughtinthetool.

8.DONOTFIRETOHARDMATERIALS. Donotattempttoshoottowardhardorbrittlematerial

suchasconcrete,steelortile.

9.WHENOPERATINGTOOL. keeptheproperfooting andbalancetoavoiddamagedresultingfrom

losingbalance.

10.CHECKDAMAGEDPARTS. Beforeusingtool,carefullycheckifthereis anypartdamaged.

11.REPLACEPARTSANDACCESSORIES.Onlyallowusesamereplacementpartswhileservicing.

Approvedaccessoriesand replacementpartsareavailable.

12.KEEPALERT. Watchwhatyouaredoing.Usecommonsense.Donotoperateanytoolwhenyouare

tired.

2

Figure 1

13.STORETHETOOL. Whennotinuse,toolshouldbecleaned,fullyassembledandthen,storedinadry

locationtoreduce rust.Forsafety,keepoutofreachofchildren.

14.OUTDOORSEXTENSIONCORDS. Whenaircompressorisusedoutdoors,useonlyrounded

jacketsextensionscordsintendedforoutsideuse.See manufacturer smanualfortheAWGrequiredfor

thecompressor s amperagedraw.

15.PAYATTENTIONTOAIRHOSEANDTHEIRCONNEATIONS. Don ttripoverhoses. Make

sureallconnectionsaretight.

16.AFTERLOADINGTHEFASTENERS. neverpointthetoolatyourselforbystanders.

17.USETHECORRECTAIRCONNECTOR.Theconnectoronthetoolmustnotholdpressurewhen

theairsupplyisdisconnected. Ifthewrong fitting isused,thetoolcanbechargedwithairafterbeing

disconnectedand still beabletodriveafastener.

18.WHENCONNECTINGTHEAIR.Thetoolmaypossiblyfirethefastenersassoonasyouplug itinto

airhose.Therefore,removeallthefastenersbeforeconnectingtotheair.

19.DONOTDEPRESSTHESAFEBRACKETANDTHETRIGGERWHENLOADING.

20.IF THEFASTENERSAREJAMMED. Disconnectthetoolfromtheairandremovethejammed

fastenersout.

WARNING: Thewarning,caution,andinstructionsexplainedinthisinstructionmanualcannot

coverall possibleconditionsand situationsthatmay occur.Itmustbeunderstoodbytheopera-

torthatCOMMONSENSEAND CAUTIONAREFACTORSWHICHCANNOTBE BUILT

INTOTHISPRODUCT,BUTMUSTBE SUPPLIEDBYTHEOPERATOR.

UNPACKING

Whenunpacking,checkandmakesurethatalltheaccessories areincluded.Ifanyoneismissedor

broken,pleasecallsellerforhelp.Refertothefollowlists.

Description

Nailer

S3HexKey

S4HexKey

AirToolOil

Operatinginstruction

Qty

1

1

1

1

1

SETTING

Yourairtoolisfullyassemblywhenyoureceiveit.Before using it,attachtheairlineanddesiredairsystem

accessories.See Figure1fortherecommendedaccessoriesand connection order.Besuretheairhoseis

depressurizedwheninstalling orremoving adapterstotheairline.

NAILER

QUICK

CONNECTOR

OILER FILTER

AIRSUPPLY

REGULATOR

AIR HOSE

Figure 2

Figure 3

3

CONNECTINGTHETOOLTOAN AIRSUPPLY

1. Determineifthetoolneedsoil and, ifnecessary, placetwodropsof

oil intheAIRPLUG(GJ003)asshowninFigure2.Ifyouareusing an

automaticin-lineoiler, checkand add oilifnecessary.

2.Turnthecompressoron and settheregulatortotheproperpressure

forthesize andtypeoffastenerbeingused.

3. Connectthetooltotheairsupply(see Setup forairsupplyconnec-

tionrecommendations).

LOADINGTHEFASTENERS

1. Depress theLOCK(DB011)toreleasetheMOVABLEMAGA-

ZINE(HM033)andpull themagazineoutfullyasshowninFigure

3.

2. Placeafullclipofthespecifiedtypeandsize fastenersonthe

FIXEDMAGAZINE(GD038), upto100fastenersmaybe loaded

inthemagazine.

3.PushtheMOVABLEMAGAZINEASSEMBLYforwarduntil

itwaslocked.

OPERATINGTHETOOL

Testthedriving depthina samplepieceofwood beforeusing.If thefastenersarebeing driventoo farornot

farenough, adjusttheregulatortoprovideless airpressureormoreairpressure.

1.Connectthetooltotheairsupply.Makesuretheairpressureisincorrectrangedenotedinsection of

SPECIFICATIONS.

2.Loadfastenerasabovethedirectiongiveninthesection calledLOADTHEFASTENER.

3. HoldtheBody (KT046)and press theDriveguide(DT047)and safebrackettoworksurface, being surethe

toolisstraightandthengentlydepress theTrigger(BB007)todrivethefastener.

4.Liftthetooloff theworksurface.

5. Thetoolhastwodriving modes:

1). Putthedriveguideontheworking surface,lightlypushthetooltowardtheworkingsurfaceuntil the

safebracketisdepressed,then,depressthetriggertodrivethefastener.

2).First,depresstheTrigger,then,repeatedlyimpacttheSafebracket,thetoolcanrepeatedlydrivethe

fasteners.ThetoolwilldriveonefastenerwhentheSafebracketisimpactedonetime.

REGULARMAINTENANCE

1. Frequent, butnotexcessive, lubricationisrequiredforbestperformance.Oil addedthroughtheairlinecon-

nection willlubricateinternalparts.Anautomaticairlineoilierisrecommendedbutoil maybeaddedmanually

beforeeveryoperation orafterabout1hourofcontinuoususe. Onlya fewdropsofoil ata timearenecessary.

Toomuchoilwill collectinsidethetooland beblownoutduring theexhaustcycle. ONLYUSEPNEUMATIC

TOOLOIL. Donotusedetergentoiloradditives,astheselubricantswillcauseacceleratedweartotheseal

inthetool.

2. Usea small amountofoil on all moving surfaceand pivots.

3.Dirtand waterintheairsupplyaremajorcausesofpneumatictoolwear.Useafilter/oilerforbetter

performanceand longerlife.Thefiltermusthaveadequateflowcapacityforthespecificapplication. Con-

sultthemanufacturer'sinstructionsforpropermaintenanceofyoufilter.

4. Keeptoolscleanforbetterand saferperformance. Usenonflammablecleaning solutions (CAUTION: Such

solutionsmaydamagedO-ring and othertoolparts) onlyifnecessary- DONOTSOAK.

FIXEDMAGAZINE

MOVABLEMAGAZINE

LOCK

4

STOPUSINGTHETOOLIMMEDIATELYIFANYOFTHEFOLLOWINGPROBLEMS

OCCUR.SERIOUSPERSONALINJURY COULDOCCUR.ANYREPAIRSORREPLACE-

MENTSMUSTBEDONEBYAQUALIFIEDPERSONORAN AUTHORIZEDSERVICECEN-

TERONLY.

TROUBLE SHOOTING

1. Lubricateasinstructed.

2. Checkairsupply.

3. Replacespring.

4.Replacedamagedinternal

parts.

1.Usetherecommendedand

undamagedfastenerls.

2.Tightenscrews.

3. Replacepiston assembly.

1. Replacepiston assembly.

2.Adjusttoadequateair

pressure.

3.Checkcylindrecapspring for

brokencoilsorreducedlength.

Checkifexhaustportofcylin-

dercapisrestricted.

1.Replacebumperorpusher

spring.

2.Checkhoseand compressor

fittings.

3. ReplaceO-ring orlubricate.

4.ReplaceO-ring.

5. Replaceseal.

PROBLEM

Airleaking at

Triggerarea

PROBLEMCAUSE SOLUTION

1. O-ring intriggervalvearedamaged.

2.Triggervalveheadaredamaged.

3.Triggervalvestem,sealorO-ring are

damaged.

1.CheckandreplaceO-ring.

2.Checkandreplacetrigger

valvehead.

3.Checkandreplacetrigger

vlavestem, sealorO-ring.

Airleakingbetween

body and driveguide Damagedbumper.

Airleakingbetween

bodyandcylindercap 1.Screwloose.

2.Damagedseal. 1.Tightenscrews.

2.Checkandreplace seal.

Bladedrivingfastener

toodeeply 1.Wornbumper.

2.Airpressureistoohigher. 1.Replacebumper.

2.Adjusttheairpressure.

Checkand replacebumper.

Runsslowlyorhas

powerloss

Toolskipa fasteners

Fastenersarejammed

Toolwillnotdrive

downtight

1.Insufficientoil.

2.Insufficientairsupply.

3. Brokenspring incylindercap.

4. Exhaustportincylindercapisblocked.

1.Wornbumperordamagedspring .

2. Inadequateairflowtotool.

3.WornordryO-ring on piston.

4.DamagedO-ring ontriggervalve.

5. Cylindercapsealleaking.

1. Fastenersarewrongsizeordamaged.

2.Magazineorfrontplatescrewsareloose.

3. Bladeinpiston assemblyisdamaged.

1.Wornbladeinpiston assembly.

2. Lackofpower.

3. Slowcycling and loss ofpower.

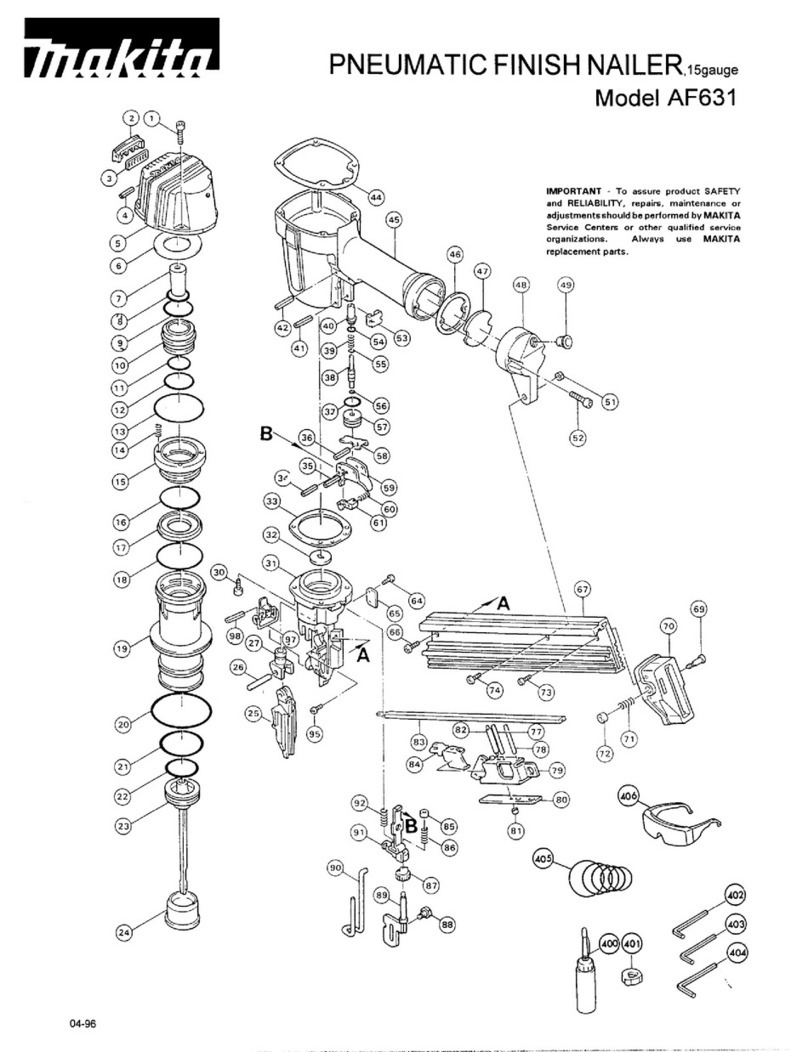

EXPLODEDVIEWDRAWING

5

PARTSLIST

RefertotheExplodedViewDrawingforthelocationofpartslistedbelow.

6

DESCRIPTION

O-RING15.7 2

O-RING27.3 2

O-RING27.4 3

O-RING33.5 3.5

O-RING36.3 2.5

O-RING40.2 2.3

O-RING48.5 2.5

VALVE

TRIGGERSPRING

CYLINDER

GASKET

CYLINDERCAP

TRIGGERVALVEGUIDE

FEEDERSHOE

SOFTGRIPSLEEVE

SLEEVE

SPRINGWASHER

SPRINGPIN

SPRINGPIN

SPRINGPIN

SPRINGPIN

SPRINGPIN

RAIL

SPRING

SPRING

SPRING

SPRING

LATCH

STOPPEDPIECE

PIN

PIN

ITEM

BB007

BX029

DB011

DE001

DT047

DX003

DZ015

FG022

FZ004

GB022

GD038

GF020

GJ003

GZ025

HC002

HM033

HS042

JD014

JQ003

JX005

JX006

KQ001

KT046

ND008

ND010

ND013

ND016

ND032

NH003

NM003

OR003

OR021

ITEM

OR022

OR042

OR043

OR051

OR055

OR065

OR078

PF003

PH005

QC026

QD003

QG006

QT007

SF025

ST003

ST010

TD003

TX009

TX013

TX014

TX020

TX032

XT009

YH003

YH006

YH008

YH061

YZ002

ZD004

ZX008

ZX045

DESCRIPTION

TRIGGER

SAFEBRACKET

LOCK

ENDCAP

DRIVEGUIDE

SAFEGUIDER

STOPPEDPLATE

TRIGGERVALVESTEM

TRIGGERVALVEHEAD

PLATE

FIXEDMAGAZINE

FRONTPLATE

AIRPLUG

SUPPORT

BUMPER

MOVABLE MAGAZINE

PISTONASSEMBLY

JOINTGUIDE

COLLAR

SEAL

SEAL

LOCKINGWASHER

BODY

SCREW

SCREW

SCREW

SCREW

SCREW

TORSIONSPRING

NUT

O-RING5.5 1.5

O-RING15 1.9

Table of contents

Other Toolshop Nail Gun manuals

Popular Nail Gun manuals by other brands

KMR

KMR 3483 Series Technical data spare parts

Ryobi

Ryobi R18N16G-120S Original instructions

Husky

Husky H200BND Operator's manual

Delta

Delta ShopMaster DBN125 instruction manual

Central Pneumatic

Central Pneumatic 92359 Assembly and operating instructions

Central Pneumatic

Central Pneumatic 94446 Assembly and operating instructions