Toolshop 208-2196 User manual

Operator’s Manual

SAVE THIS MANUAL

You will need this manual for safety instructions, operating procedures and warranty.

Put it and the original sales receipt in a safe dry place for future reference.

For questions about this product, Please call 1-866-915-8626

208-2196

34° CLIPPED-HEAD 3-1/2"

FRAMING NAILER

!

IMPORTANT SAFETY INSTRUCTIONS

INSTRUCTIONS PERTAINING TO A RISK OF FIRE, OR INJURY TO PERSONS.

WARNING! When using tools, basic precautions should always be followed, including

the following.

WORK AREA

Keep the work area clean and well lit. Cluttered benches and dark areas

increase the risk of electric shock, fire, and injury to persons.

Do not operate the tool in explosive atmospheres, such as in the presence of

flammable liquids, gases, or dust. Be careful not to nail on top of another nail,as

this can create sparks, resulting in the ignition of dust or fumes.

Keep bystanders, children, and visitors away while operating the tool. Distractions

may result in personal injury and/or the injury of others.

PERSONAL SAFETY

Always wear eye protection. Operator and others in the work area should always

wear ANSI-approved safety goggles with side shields. Eye protection is used to

guard against flying fasteners and debris, which may cause severe eye injury.

Always wear hearing protection when using the tool. Extended exposure to high

intensity noise may cause hearing loss.

Use safety equipment. A dust mask, non-skid safety shoes and a hard hat must be

used for the applicable conditions.

Do not wear loose fitting clothing or jewelry.Use a helmet for long hair.These items

can get caught in moving parts,causing serious personal injury.

Stay alert, watch what you are doing and use common sense when operating the

tool while tired or under the influence of drugs, alcohol, or medication. A moment

of inattention while operating the tool increase the risk of injury to persons.

Avoid unintentional firing. Keep fingers away from trigger when not driving

fasteners, especially when connecting the tool to the air supply.Be sure the

hammer cap is off before connecting to the air supply. Do not carry the tool with

your finger on the hammer cap or connect the tool to the air supply with the trigger

on.

Keep proper footing and balance at all times. Do not overreach. Do not use on a

ladder or unstable support. Proper footing and balance enable better control of the

tool in unexpected situation.

Make sure the hose is free of obstructions or snags. Entangled or snarled hoses

can cause loss of balance or footing and may become damaged, resulting in

possible injury.

Do not attach the hose or tool to your body. Attach the hose to the structure to

reduce the risk of loss of balance if the hose shifts.

Always assume that the tool contains fasteners. Do not point the tool toward

yourself or anyone whether it contains fasteners or not.

Wash hands after handling. This product or its power cord may contain chemicals

to cause cancer and birth defects or other reproductive harm.

!

WARNING! Do not fire a nail on top of another nail. This may cause the nail to be

deflected and hit someone, or cause the tool to react which may result in a risk of

injury to persons.

2

!

!

IMPORTANT SAFETY INSTRUCTIONS

TOOL USE AND CARE

Know this tool. Read manual carefully, learn its application and limitations, as well

as the specific potential hazards related to this tool.

Use only fasteners listed in the Accessories section of this manual. Fasteners not

identified for use with this tool by the tool manufacturer may result in a risk of injury

to persons or tool damage when use in this tool.

Check for misalignment or binding of moving parts, breakage of parts, and any

other condition that may affect the tool’s operation. If damaged, have the tool

serviced before using. Many accidents are caused by poorly maintained

tools.There is a risk of bursting if the tool is damaged.

Maintain the tools with care. Keep a cutting tool sharp and clean. A properly

maintained tool, with sharp cutting edges reduces the risk of binding and is easier

to control.

Store the tools,in a secure place,when not in use and out of reach of children and

other untrained persons. A tool is dangerous in the hands of untrained users.

Do not use the tool if the hammer cap does not turn the tool on or off. Any tool that

cannot be controlled with the hammer cap is dangerous and must be repaired.

Do not force tool. Use the correct tool for your application. The correct tool will do

the job better and safer at the rate for which it is designed.

Use clamps or another practical way to secure and support the workpiece to a

stable platform. Holding a tool by hand or against the body is unstable and may

lead to loss of control.

Keep the tool and its handle dry, clean and free from oil and grease. Always use a

clean cloth when cleaning. Never use brake fluids, gasoline, petroleum-based

products, or any strong solvents to clean your tool.

Do not use the tool as a hammer.

Never use this tool in a manner that could cause a fastener to be directed toward

anything other than the workpiece.

Never use gasoline or other flammable liquids to clean the tool. Never use the tool

in the presence of flammable liquids or gases. Vapours could ignite by a spark and

cause an explosion which will result in death or serious personal injury.

Do not remove, tamper with, or otherwise cause the trigger lock or trigger to

become inoperable. Do not operate any tool which has been modified in a like

fashion. Death or serious personal injury could result.

Do not touch the trigger unless driving fasteners. Never attach air line to tool or

carry tool while touching the trigger. The tool could eject a fastener which will result

in death or serious personal injury. Also actuate the trigger lock to the safe position

when not in use.

Always fit tool with a fitting or hose coupling on or near the tool in such a manner

that all compressed air in the tool is discharged at the time the fitting or hose

coupling is disconnected. Do not use a heck valve or any other fitting which allows

air to remain in the tool. Death or serious personal injury could occur.

Never place hands or any other body parts in the fastener discharge area of the

tool. The tool might eject a fastener and could result in death or serious personal

injury.

Never carry the tool by the air hose or pull the hose to move the tool away from a

compressor. Keep hoses away from heat, oil and sharp edges. Replace any hose

that is damaged, weak or worn. Personal injury or tool damage could occur.

WARNING! Remove finger from the trigger when not driving fasteners. Never carry

the tool with finger on trigger, the tool may fire a fastener.

WARNING! Disconnect the tool from the air source before making adjustments,

doing tool maintenance, clearing jams, leaving work area, or unloading the tool. Such

precautionary measures reduce the risk of injury to persons.

3

IMPORTANT SAFETY INSTRUCTIONS

Always assume the tool contains fasteners. Respect the tool as a working

implement; no horseplay. Always keep others at a safe distance from the work

area in case of accidental discharge of fasteners. Do not point the tool toward

yourself or anyone whether it contains fasteners or not. Accidental triggering of the

tool could result in death or serious personal injury.

Do not drop or throw the tool. Dropping or throwing the tool can result in damage

that will make the tool unusable or unsafe. If the tool has been dropped or thrown,

examine the tool closely for bent, cracked or broken parts and air leaks. Stop and

repair before using, or serious injury could occur.

Avoid using the tool when the magazine is empty. Accelerated wear on the tool

may occur.

Clean and check all air supply hoses and fittings before connecting the tool to an

air supply. Replace any damaged or worn hoses or fittings. Tool performance or

durability may be reduced.

Do not use the tool if it leaks air or does not function properly.

Do not operate the tool if it does not contain a legible warning label.

TOOL SERVICE

Use only accessories that are identified by the manufacturer for the specific tool

model.

When servicing a tool, use only identical replacement parts. Use only authorized

parts.

Use only the lubricants supplied with the tool or specified by the manufacturer.

Tool service must be performed only by qualified repair personnel.

OPERATION

Do not drive fasteners near edge of material. The workpiece may split causing the

fastener to ricochet, injuring you or others around you.

Do not carry the tool from place to place holding the trigger. Accidental discharge

could result. Choice of triggering method is important. Check manual for triggering

options.

During normal use the tool will recoil immediately after driving a fastener. This is a

normal function of the tool. Do not attempt to prevent the recoil by holding the tool

against the work. Restriction to the recoil can result in a second fastener being

driven from the tool. Grip the handle firmly and let the tool do the work. Failure to

heed this warning can result in serious personal injury.

Do not drive fasteners on top of other fasteners or with the tool at an overly steep

angle as this may cause deflection of fasteners which could cause injury.

Do not actuate the tool unless you intend to drive a fastener into the workpiece.

Always handle the tool with care:

a. Respect the tool as a working implement.

b. Never engage in horseplay.

c. Never pull the trigger unless nose is directed toward the work.

d. Keep others a safe distance from the tool while tool is in operation as accidental

actuation may occur, possibly causing injury.

AIR SUPPLY AND CONNECTIONS

The air supply connection must not hold pressure when air supply is disconnected.

If an incorrect fitting is used, the tool can remain charged with air after

disconnecting and thus will be able to drive a fastener even after the air line is

disconnected, possibly causing injury.

Do not use any type of reactive gases, including, but not limited to, oxygen carbon

dioxide and combustible gases, as a power source. Use filtered, lubricated,

regulated compressed air only. Use of a reactive gas instead of compressed air

may cause the tool to explode which will cause death or serious personal injury.

4

SPECIFICATIONS

The framing nailer is designed to install Grip Fast framing nails of

0.113” to 0.131” (2.87-3.33 mm) diameter, 2" to 3-1/2" (50mm to 90mm)

long with a fastener collation angle of 34 degrees.

Operating pressure: 70-100 PSI (120 Max.)

Magazine capacity: 75 nails

Air inlet: 1/4” (6 mm)NPT

Padded hand grip

ACCESSORIES

3 Hex Keys

Combination Wrench

Oil Bottle

Fig.1

B

A

E

F

D

C

G

FUNCTIONAL DESCRIPTION

Figure 1 names the major components of the TOOL SHOP 34° Framing

Nailer.

A. Deflector

B. Body

C. Non-marring rubber tip

D. Pusher

E. Magazine

F. Air plug

G. Trigger

Use only a pressure-regulated compressed air source to limit the air pressure

supplied to the tool. The regulated pressure must not exceed 110 PSI. If the

regulator fails, the pressure delivered to the tool must not exceed 120 PSI. The

tool could explode which will cause death or serious personal injury.

Always disconnect air resource:

a) Before making adjustments.

b) When servicing the tool.

c) When clearing a jam.

d) When tool is not in use.

e) When moving to a different work area, as accidental actuation may occur,

causing injury.

Never connect tool to an air source that may exceed 180 PSI. Over pressurizing

the tool may result in bursting, abnormal operation, breakage of the tool or

serious injury to persons. Use only clean, dry, regulated compressed air at the

rated pressure or within the rated pressure range as marked on the tool. Always

verify prior to using the tool that the air source has been adjusted to the rated air

pressure or within the rated air-pressure range.

IMPORTANT SAFETY INSTRUCTIONS

5

min. 2" (50 mm)

Min Max

.113

(2.87mm)

(6.8mm)

(7.1mm)

.131

(3.33mm)

0.266"

0.28"

max. 3-1/2 "(90 mm)

0

34

®

OPERATING PROCEDURES

SETUP

AIR SOURCE

The TOOL SHOP 34° framing nailer is designed to operate on clean, dry,

compressed air, regulated at 70-100 PSI (120 Max.) The preferred system would include a filter,

a pressure regulator, and an automatic oiler located as close to the tool as possible.

Within 15 feet (5 m) is ideal. Do not use bottled air or gases. Please see below:

PREPARING THE TOOL

1. After reading and understanding this entire manual, connect tool to the air

supply.

2. Turn on the air compressor and adjust the regulator to the proper pressure for the

fastener size you are using.

CAUTION:

Keep tool pointed away from yourself and others at all times.

Always disconnect tool to air supply before loading fasteners.

Do not load fasteners with trigger or safety pressed.

Always wear approved safety glasses, and hearing protection when preparing

or operating the tool.

Never use a tool that leaks air or needs repair.

Fig.3

!

!

CAUTION:

All air line components (including hoses, pipe, connectors, filters, & regulators,

etc.) must be rated for a minimum working pressure of 150 PSI or 150% of the

maximum system pressure, whichever is greater.

Disconnect the tool from the air supply before performing maintenance, clearing a

jammed fastener, leaving the work area, moving the tool to another location, or

handing it to another person.

All compressed air contains moisture and other contaminants that can harm the

internal components of the tool. An air line filter will remove most of these and

significantly extend the life of the tool. Ensure the in-line oiler has sufficient oil. If

an in-line oiler is not available, place 2 drops of oil into the tool’s air inlet at the

beginning of each workday. More than this will be expelled from the tool’s exhaust

during firing.

Air fitting: The framing nailer should be equipped with a 1/4” NPT male ‘quick

connector’. To prevent accidental cycling even though disconnected, the tool must

always be connected to the air supply in such a way that all air pressure in it is

released when the coupling is disconnected.

Airhose

Filter

Oiler

Regulator

34oframing nailer

Quick coupling

Air connector

Fig.2

6

in two different ways:

Intermittent operation (Trigger fire ). This mode will drive a nail each time the

trigger is pressed and the contact mechanism is in contact with the nailing surface.

OPERATING PROCEDURES

1. Insertstrip of nails into rear of magazine. Slide nail strip towards the front

of the magazine, making sure strip is past the nail stop.(Fig.4)

2. Pull feeder shoe completely behind the nail strip.(Fig.5)

3. Release the latch and the nail strip will be pushed to the front of the

magazine.(Fig.6 & Fig.7)

Nail stop

Fig.5

Fig.4

Fig.6

Fig.7

USING THE TOOL

Complete all the steps in PREPARING THE TOOL before using. This tool drives nails

LOADING NAILS

1. Set the bump/sequential switch to Intermittent operation (Trigger fire ). Push

switch in and then down.

2. Position the nail outlet on the workpiece with finger off the trigger.

3. Depress the contact mechanism firmly until it is completely depressed, then pull

the trigger to drive a nail.

4. After each nail is driven, completely release the trigger and lift the nailer off the

workpiece. To drive another nail, move the nailer along the workpiece and

repeat this procedure.

7

Continuous Operation (Bump Fire ). This mode will drive a nail each time the contact

mechanism is pushed while the trigger is pulled and held.

1. Set the bump/sequential switch to Continuous operation(Bump Fire ). Push switch

in and then up.

2. Pull trigger with nailer off workpiece.

3. Depress the contact mechanism firmly until it is completely depressed to drive a nail.

4. Move the nailer along the workpiece in a bouncing motion.

5. Each time the contact mechanism is fully depressed a nail will be driven.

CAUTION: Do not load with contact safety mechanism or trigger depressed.

!

MAINTENANCE

CAUTION: Disconnect tool from the air supply before removing or installing the

contact tip. !

r, reassemble in reverse order.

REGULAR MAINTENANCE

Clean and inspect the tool daily. Make sure the tool is disconnected from the air

supply.

Blow the tool clean with compressed air and inspect for wear or damage.

Use

necessary. DO NOT SOAK tool with cleaning solutions. Such solutions can

damage internal parts.

Inspect the trigger and the safety mechanism to assure the system is complete

and functional. Check for loose or missing parts, and any parts that may be

sticking.

Keep all the screws tight. Loose screws may cause personal injury.

Place two or three drops of pneumatic oil (included) into the air inlet of the tool

daily.

ADJUSTINGFASTENERDEPTH

The depth to which a fastener is driven is controlled by the depth adjustment (Fig.8).

The depth drive is adjusted to the maximum setting by the factory.

1. Fire a fastener into a scrap work piece to check depth.

2. Using wrench provided, adjust the safety element to achieve desired depth.

3. Fire another fastener in a scrap work piece and check the depth.

4. REPEAT AS NECESSARY UNTIL DESIRED DEPTH IS ACHIEVED. The amount

of air pressure required will vary depending on the size of the setting.

OPERATING PROCEDURES

Fig.8

!

CAUTION:

Never attempt to drive a fastener into material that is too hard, at too steep an

angle, or near the edge of the work piece. The fastener can ricochet causing

personal injury.

Carefully check for proper operation of the trigger and safety.

Do not use the tool unless both the trigger and the safety mechanism are

functional, or if the tool is leaking air or needs any other repair.

8

TROUBLESHOOTING

9

PROBLEM CAUSE SOLUTION

Air leak at trigger area O-ring in trigger valve

damaged or cracked Check and replace O-ring

Trigger valve head damaged Check and replace trigger valve head

Trigger valve stem, seal, or

O-ring damaged Check and replace trigger valve stem

Air leak between body and

front plate Piston O-ring or bumper

damaged Check and replace O-ring or bumper

Air leak between body and

cylinder cap Screw loose Tighten screws

Damaged seal Check and replace seal

Tool driving fasteners too

deeply Worn bumper Replace bumper

Air pressure too high Adjust air pressure at regulator

Tool runs slowly or has power

loss Insufficient lubrication Add oil as instructed

Insufficient air supply Check air supply

Broken spring in cylinder cap Replace spring

Exhaust port in cylinder head

is blocked Replace damaged internal parts

Tool skips fasteners Worn bumper or damaged

spring Replace bumper or pusher spring

Dirt in front plate Clean drive channel in front plate

Inadequate airflow to tool Check hose and compressor fittings

Worn or dry O-ring on piston Replace or lubricate O-ring

Damaged O-ring on trigger

valve Replace O-ring

Cylinder cap is leaking Replace seal

Fasteners jam in tool or in

magazine Joint guide is worn Replace joint guide

Fasteners in tool are the

wrong size or damaged Use only recommended fasteners

Magazine screws or front

plate clamp are loose Tighten all

Blade in piston assembly is

damaged Replace piston assembly

Tool will not drive fasteners

down tight Worn blade in piston

assembly Replace piston assembly

Lack of power Adjust regulator to adequate pressure

Slow cycling and loss of

power Check cylinder cap spring for broken coils, reduced

length, or if exhaust port is blocked

10

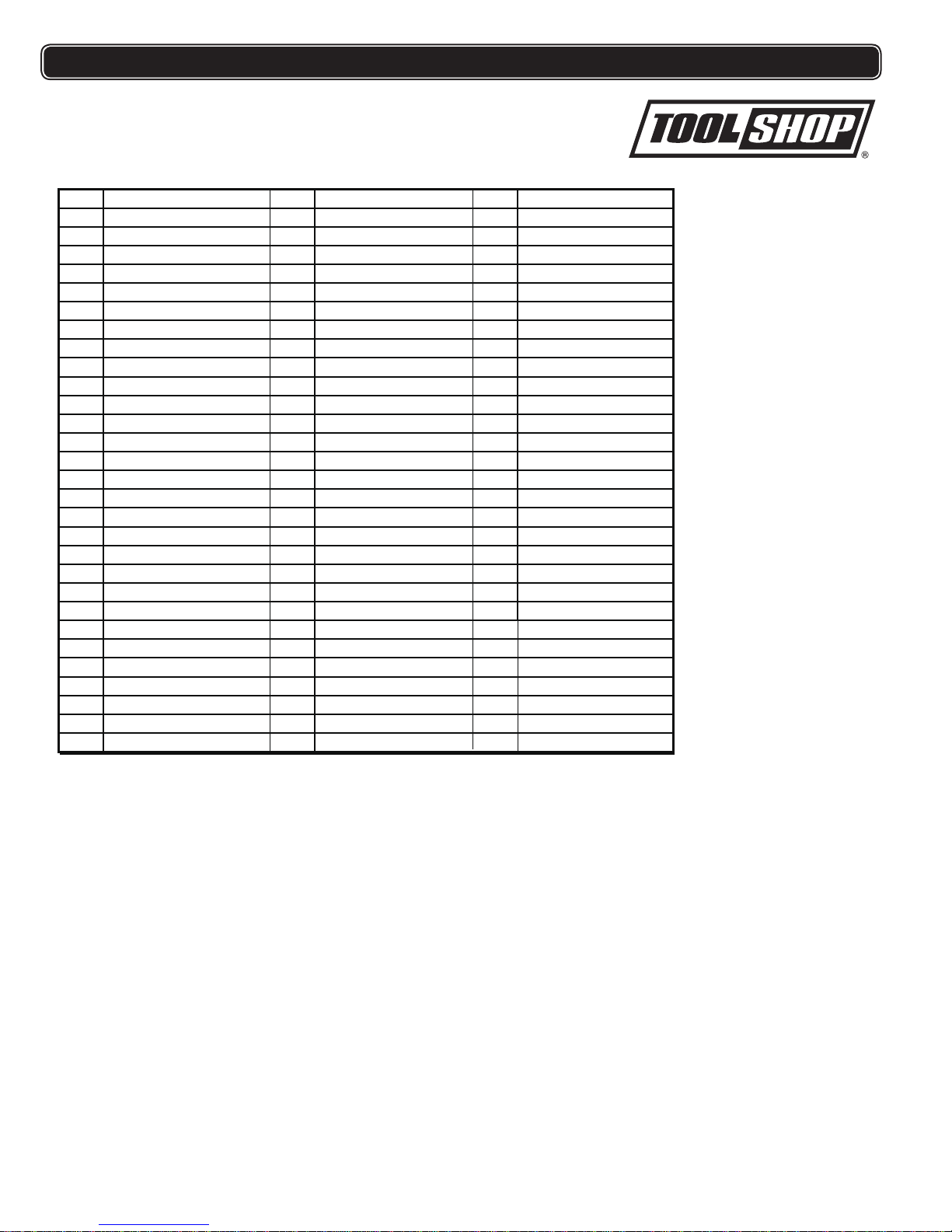

PARTS LIST

Please refer to the schematic drawing on page 11.

Part Description Part Description Part Description

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

SCREW 5*16 4

WASHER

O-RING 16*1.7

EXHAUST DEFLECTOR

WASHER

SCREW 6*35

WASHER

CAP

GASKET

WASHER

PISTON RETAINER

SPRING

O-RING 40*2.65

O-RING 56.7*2.9

PISTON HEAD

O-RING 42.9*4.8

PISTON HEAD

DRIVER BLADE

SEAL,AIR

O-RING 58*2

CYLINDER

BUMPER(A)

BUMPER(B)

O-RING16*1.8

O-RING19*2.3

HOUSINGLOWERREMOTE

O-RING5.6*1.8

O-RING8*1.8

REMOTE HOUSING

O-RING 2.3*1.4

CONICAL SPRING

REMOTE CORE

SEAL,AIR

RELEASING BLADE

TRIGGER

SCREW 5*18

WASHER

BUSHING

NYLON NUT M5

PIN 3*14

SPRING

SPRING PIN 3*16

TRIGGER

SAFETY COVER

SPRING PIN 3*32

CATCH SUPPORT(B)

SCREW 5*12

CATCH SUPPORT(A)

NO MAR PAD

SPRINGPADRETAINER

O-RING 89*2.9

SPACER

GRIP

WASHER

BODY

O-RING 62.5*2

GUIDE BODY

SPRING

SCREW 5*25

WASHER

TAIL COVER

GASKET

SCREW 5*18

FEEDER SHOE STOP

SCREW 8*25

RIVET

MAGAZINE SUPPORT

RIVET

TAIL COVER

RELEASING BLADE

PIN

FEEDER CLIP

MAGAZINE

MAGAZINE GASKET

STEEL BAR

STOPPER

SPRING

PUSHER

ROLLER

SPRING

PIN

SPRING

SCREW 4*8

AIR PLUG

COLLAR

WASHER

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

11

SCHEMATIC DRAWING

!WARNING Repairs should be made by an authorized repair center.Do not open or

disassemble this power tool.

1-YEAR LIMITED WARRANTY:

Notwithstanding the foregoing, this

limited warranty does not cover any damage that has resulted from abuse or

misuse of the merchandise. This warranty: (1) excludes expendable parts

including but not limited to connectors, o-rings, driver blades, air hoses, gaskets,

etc. (2) shall be void if this tool is used for commercial and/or rental purposes;

and (3) does not cover any losses, injuries to persons/property or costs. This

warranty does give you specific legal rights and you may have other rights,

which vary from state to state. Be careful, tools are dangerous if improperly

used or maintained. Seller’s employees are not qualified to advise you on the

use of this merchandise. Any oral representation(s) made will not be binding

on seller or its employees. The rights under this limited warranty are to the

original purchaser of the merchandise and may not be transferred to any

subsequent owner. This limited warranty is in lieu of all warranties,

expressed or implied including warranties or merchantability and fitness for a

particular purpose. Seller shall not be liable for any special, incidental, or

consequential damages. The sole exclusive remedy against the seller will be

for the replacement of any defects as provided herein, as long as the seller is

willing or able to replace this product or is willing to refund the purchase price

as provided above. For insurance purposes, seller is not allowed to

demonstrate any of these power tools for you.

For questions / comments, technical assistance or repair parts –

Please call toll free at: 1-866-915-8626

(M-F 8am – 5pm EST)

SAVE YOUR RECEIPTS. THIS WARRANTY IS VOID WITHOUT THEM.

9

34°CLIPPED HEAD 3-1/2" FRAMING NAILER WARRANTY

This TOOL SHOP® brand power tool carries a 1-Year Limited Warranty

to the original purchaser. If, during normal use, this TOOL SHOP® tool

fails due to a defect in material or workmanship within one (1) year from

the date of purchase, simply bring this tool with your original sales receipt

back to your nearest MENARDS® retail store. At its discretion, TOOL SHOP®

agrees to have the tool replaced with the same or similar TOOL SHOP® product

free of charge, within the stated warranty period, when returned by the original

purchaser with original sales receipt.

Table of contents

Other Toolshop Nail Gun manuals

Popular Nail Gun manuals by other brands

Metabo HPT

Metabo HPT NR 3675DD Instruction and safety manual

EXTOL PREMIUM

EXTOL PREMIUM 8894580 Translation of the original user manual

DeWalt

DeWalt XR Li-Ion DCN680D2 Original instructions

Performance Tool

Performance Tool M643 owner's manual

Hitachi

Hitachi VH650 - Fencing Nailer, Full Head instruction manual

Parkside

Parkside PET 25 B1 Operation and safety notes