TOP GUN WELDING 2040 5IN1 User manual

INTRODUCTION

Ⅰ

I

IMPORTANT: Read this Owner’s Manual Completely before attempting to use this

equipment. Save this manual and keep it handy for quick reference. Pay particular

attention to the safety instructions we have provided for your protection. Contact your

distributor if you do not fully understand this manual.

2040 5IN1

INVERTER Based Welding & Cutting Machines

OPERATORS’ MANUAL

CONTENT

- II -

CONTENT

§1 Safety.............................................................................................1

§1.1 Symbols Explanation................................................................................................... 1

§1.2 Machine Operating warnings!.................................................................................... 1

§1.3 EMC device classification........................................................................................... 8

§1.4 EMC measure............................................................................................................... 9

§1.5 Warning label............................................................................................................. 10

§2 Overview..................................................................................... 11

§2.1 Features .......................................................................................................................11

§2.2 Technical Data............................................................................................................ 13

§2.3 Brief Introduction...................................................................................................... 14

§2.4 Duty cycle and Over-heat.......................................................................................... 15

§2.5 Working Principle...................................................................................................... 15

§2.6 Volt-Ampere Characteristic...................................................................................... 16

§3 Panel Functions & Descriptions...............................................17

§3.1 Machine Layout Description .................................................................................... 17

§3.2 Control Panel of welding machine ........................................................................... 18

§4 Installation & Operation ..........................................................19

§4.1 Installation & Operation for MMAWelding........................................................... 19

§4.1.1 Set up installation for MMAWelding .................................................................................19

§4.1.2 Operation of MMA welding method...................................................................................20

§4.1.3 MMAWelding..................................................................................................................22

§4.1.4 MMAWelding Fundamentals .............................................................................................24

§4.2 Installation & Operation for TIG Welding ............................................................. 25

§4.2.1 Set up installation for TIG Welding ....................................................................................25

§4.2.2 Operation of LIFT TIG/HF TIG/Smart TIG welding method .............................................27

§4.2.3 DC TIG Welding .................................................................................................................28

§4.2.4 TIG Welding Fusion Technique...........................................................................................30

§4.2.5 Tungsten Electrodes ............................................................................................................31

§4.2.6 Tungsten Preparation...........................................................................................................34

§4.2.7 Gun switch control current..................................................................................................36

§4.3 Installation & Operation for MIG Welding............................................................ 37

CONTENT

- II -

§4.3.1 Set up installation for MIG Welding- Gas shielded wire.....................................................37

§4.3.2 Operation of MIG Synergic/MIG Pulse welding method....................................................39

§4.3.3 Wire Feed Roller Selection .................................................................................................41

§4.3.4 Wire Installation and Set Up Guide.....................................................................................42

§4.3.5 Set up installation for MIG Welding- Gasless wire.............................................................44

§4.3.6MIG Torch Liner Installation ...............................................................................................47

§4.3.7 MIG Torch Liner Types and Information ............................................................................49

§4.3.8 Torch & Wire Feed Set Up for Aluminium Wire.................................................................51

§4.3.9 MIG Welding.......................................................................................................................54

§4.3.10 Standard welding programs...............................................................................................62

§4.3.11 Welding parameters...........................................................................................................63

§4.4 Installation & Operation for Cutting....................................................................... 65

§4.4.1 Cutting Guide......................................................................................................................69

§4.4.2 Operating Techniques..........................................................................................................70

§4.5 Operation of Setting .................................................................................................. 73

§4.6 Operation of SAVE/LOAD........................................................................................ 74

§4.7 Welding parameters................................................................................................... 75

§4.8 Operation environment............................................................................................. 77

§4.9 Operation Notices...................................................................................................... 77

§5 Welding trouble shooting..........................................................79

§5.1 MIG welding trouble shooting.................................................................................. 79

§5.2 MIG wire feed trouble shooting ............................................................................... 81

§5.3 TIG welding trouble shooting................................................................................... 82

§5.4 MMAwelding trouble shooting................................................................................ 85

§5.5 MMAwelding trouble shooting................................................................................ 87

§6 Maintenance & Troubleshooting .............................................89

§6.1 Maintenance............................................................................................................... 89

§6.2 Troubleshooting ......................................................................................................... 90

§6.3 List of error code ....................................................................................................... 91

§6.4 Electrical schematic drawing.................................................................................... 93

SAFETY

-1-

§1 Safety

Welding and cutting equipment can be dangerous to both the operator and people in

or near the surrounding working area, if the equipment is not correctly operated.

Equipment must only be used under the strict and comprehensive observance of all

relevant safety regulations. Read and understand this instruction manual carefully

before the installation and operation of this equipment.

§1.1 Symbols Explanation

The above symbols mean warning!

Notice! Running parts, getting an electric shock or making contacts with thermal

parts will cause damage to your body and others. The underline message is as

follows:

Welding is quite a safe operation after taking several necessary protection

measures!

§1.2 Machine Operating warnings!

The following symbols and words explanations are for some damages to your body

or others, which could happen during the welding operation. While seeing these

symbols, please remind yourself and others to be careful.

Only people who are trained professionally can install, debug, operate, maintain

and repair the welding equipment covered with this Operator’s Manual!

During the welding operation, non-concerned people should NOT be around,

especially children!

After shutting off the machine power, please maintain and examine the equipment

according to §7 because of the DC voltage existing in the electrolytic capacitors at

the output of the power supply!

SAFETY

-2-

ELECTRIC SHOCK CAN KILL.

Touching live electrical parts can cause fatal shocks or severe burns. The electrode

and work circuit is electrically live whenever the output is on. The input power

circuit and internal machine circuits are also live when power is on. In Mig/Mag

welding, the wire, drive rollers, wire feed housing, and all metal parts touching the

welding wire are electrically live. Incorrectly installed or improperly grounded

equipment is dangerous.

Never touch live electrical parts.

Wear dry, hole-free gloves and clothes to insulate your body.

Be sure to install the equipment correctly and ground the work or metal to be

welded to a good electrical (earth) ground according to the operation manual.

The electrode and work (or ground) circuits are electrically “hot” when the

machine is ON. Do not touch these “hot” parts with your bare skin or wet clothing.

Wear dry, hole-free gloves to insulate hands.

In semiautomatic or automatic wire welding, the electrode, electrode reel, welding

head, nozzle or semiautomatic welding gun are also electrically “hot”.

Insulate yourself from work and ground using dry insulation. Make certain the

insulation is large enough to cover your full area of physical contact with work and

ground.

Be Careful when using the equipment in small places, falling-off and wet

circumstance.

Always be sure the work cable makes a good electrical connection with the metal

being welded. The connection should be as close as possible to the area being

welded.

Maintain the electrode holder, work clamp, welding cable and welding machine in

good, safe operating condition. Replace damaged insulation.

Never dip the electrode in water for cooling.

Never simultaneously touch electrically “hot” parts of electrode holders connected

SAFETY

-3-

to two welders because voltage between the two can be the total of the open

circuit voltage of both welders.

When working above the floor level, use a safety belt to protect yourself from a

fall should you get an electric shock!

FUMESAND GASES CAN BE DANGEROUS.

Smoke and gas generated whilst welding or cutting can be harmful to people’s health.

Welding produces fumes and gases. Breathing these fumes and gases can be

hazardous to your health.

Do not breathe the smoke and gas generated whilst welding or cutting, keep your

head out of the fumes. Use enough ventilation and/or exhaust at the arc to keep

fumes and gases away from the breathing zone. When welding with electrodes which

require special ventilation such as stainless or hard facing or on lead or cadmium

plated steel and other metals or coatings which produce highly toxic fumes, keep

exposure as low as possible and below the Threshold Limit Values using local

exhaust or mechanical ventilation. In confined spaces or in some circumstances,

outdoors, a respirator may be required. Additional precautions are also required

when welding on galvanized steel.

Do not weld in locations near chlorinated hydrocarbon vapors coming from

degreasing, cleaning or spraying operations. The heat and rays of the arc can react

with solvent vapors to form phosgene, a highly toxic gas, and other irritating

products.

Shielded gases used for arc welding can displace air and cause injury or death.

Always use enough ventilation, especially in confined areas, to insure breathing air

is safe.

Read and understand the manufacturer’s instructions for this equipment and the

consumables to be used, including the material safety data sheet and follow your

employer’s safety practices.

SAFETY

-4-

ARC RAYS: Harmful to people’s eyes and skin.

Arc rays from the welding process produce intense visible and invisible ultraviolet

and infrared rays that can burn eyes and skin.

Use a shield with the proper filter and cover plates to protect your eyes from

sparks and the rays of the arc when welding or observing open arc welding.

Use suitable clothing made from durable flame-resistant material to protect your

skin and that of your coworkers from the arc rays.

Protect other nearby personnel with suitable, non-flammable screening and /or

warn them not to watch the arc nor expose themselves to the arc rays or to hot spatter

or metal.

SELF-PROTECTION

Keep all equipment safety guards, covers and devices in position and in good

repair. Keep hands, hair, clothing and tools away from V-belts, gears, fans and all

other moving parts when starting, operating or repairing equipment.

Do not put your hands near the engine fan. Do not attempt to override the governor

or idler by pushing on the throttle control rods while the engine is running.

DO NOT add any fuel near an open-flame welding arc or

when the engine is running. Stop the engine and allow it to cool before refueling to

prevent spilled fuel from vaporizing on contact with hot engine parts and igniting.

Do not spill fuel when filling tank. If fuel is spilled, wipe it up and do not start

engine until fumes have been eliminated.

SAFETY

-5-

WELDING SPARKS can cause fire or explosion.

Welding on closed containers, such as tanks, drums, or pipes, can cause them to

explode. Flying sparks from the welding arc, hot work piece, and hot equipment can

cause fires and burns. Accidental contact of electrode to metal objects can cause

sparks, explosion, overheating, or fire. Check and be sure the area is safe before

doing any welding

Remove fire hazards material from the welding area. If this is not possible, cover

them to prevent the welding sparks from starting a fire. Remember that welding

sparks and hot materials from welding can easily go through small cracks and

openings to adjacent areas. Avoid welding near hydraulic lines. Have a fire

extinguisher readily available.

Where compressed gases are to be used at the job site, special precautions should

be used to prevent hazardous situation.

When not welding, make certain no part of the electrode circuit is touching the

work or ground. Accidental contact can cause overheating and create a fire hazard.

Do not heat, cut or weld tanks, drums or containers until the proper steps have

been taken to insure that such procedures will not cause flammable or toxic vapors

from substances inside. They can cause an explosion even though they have been

“cleaned”.

Vent hollow castings or containers before heating, cutting or welding. They may

explode.

Sparks and spatter are thrown from the welding arc. Wear oil free protective

garments such as leather gloves, heavy shirt, cuff less trousers, high shoes and a cap

over your hair. Wear earplugs when welding out of position or in confined places.

Always wear safety glasses with side shields when in a welding area.

Connect the work cable to the work as close to the welding area as practical. Work

cables connected to the building framework or other locations away from the

welding area increase the possibility of the welding current passing through lifting

SAFETY

-6-

chains, crane cables or other alternate circuits. This can create fire hazards or

overheat lifting chains or cables until they fail.

Rotating parts may be dangerous.

Use only compressed gas cylinders containing the correct shielding gas for the

process used and properly operating regulators designed for the gas and pressure

used. All hoses, fittings, etc. should be suitable for the application and maintained in

good condition.

Always keep cylinders in an upright position securely chained to an undercarriage

or fixed support.

Cylinders should be located:

-Away from areas where they may be struck or subjected to physical damage.

-At a safe distance from arc welding or cutting operations and any other source

of heat, sparks, or flame.

Never allow the electrode, electrode holder or any other electrically “hot” parts to

touch a gas cylinder.

Keep your head and face away from the cylinder valve outlet when opening the

cylinder valve.

Valve protection caps should always be in place and hand tight except when the

cylinder is in use or connected for use.

Gas Cylinders.

Shielding gas cylinders contain gas under high pressure. If damaged, a cylinder can

explode. Because gas cylinders are normally part of the welding process, be sure to

treat them carefully. CYLINDERS can explode if damaged.

Protect gas cylinders from excessive heat, mechanical shocks, physical damage,

slag, open flames sparks, and arcs.

SAFETY

-7-

Insure cylinders are held secure and upright to prevent tipping or falling over.

Never allow the welding electrode or earth clamp to touch the gas cylinder, do not

drape welding cables over the cylinder.

Never weld on a pressurised gas cylinder, it will explode and kill you.

Open the cylinder valve slowly and turn your face away from the cylinder outlet

valve and gas regulator.

Gas build up.

The build up of gas can causes a toxic environment, deplete the oxygen content in

the air resulting in death or injury. Many gases use in welding are invisible and

odourless.

Shut off shielding gas supply when not in use.

Always ventilate confine spaces or use approved air-supplied respirator.

Electric and Magnetic Fields.

Electric current flowing through any conductor causes localized Electric and

Magnetic Fields (EMF). The discussion on the effect of EMF is ongoing in the entire

world. Up to now, no material evidences show that EMF may have effects on health.

However, the research on the effect of EMF is still ongoing. Before any conclusion,

we should minimize exposure to EMF as few as possible.

In order to minimize EMF, we should use the following procedures:

Route the electrode and work cables together –Secure them with tape when

possible.

All cables should be put away and far from the operator.

Never coil the power cable around your body.

Make sure welding machine and power cable to be far away from the operator as

far as possible according to the actual circumstance.

SAFETY

-8-

Connect the work cable to the workpiece as close as possible to the area being

welded.

The people with heart-pacemaker should be away from the welding area.

Noise can damage hearing.

Noise from some processes or equipment can damage hearing. You must protect

your ears from loud noise to prevent permanent loss of hearing.

To protect your hearing from loud noise, wear protective ear plugs and/or ear

muffs. Protect others in the workplace.

Noise levels should be measured to be sure the decibels (sound) do not exceed safe

levels.

Hot parts.

Items being welded generate and hold high heat and can cause severe burns. Do not

touch hot parts with bare hands. Allow a cooling period before working on the

welding gun. Use insulated welding gloves and clothing to handle hot parts and

prevent burns.

§1.3 EMC device classification

Radiation Class A Device.

Only can be used in the industrial area

If it is used in other area, it may cause connection and

radiation problems of circuit.

Radiation Class B device.

It can meet the radiation requirements of residential area and industrial area. It also

can be used in residential area which power is supplied by public low voltage circuit.

EMC device can be classified by power nameplate or technical data.

SAFETY

-9-

Hanker welding machines belong to ClassA.

§1.4 EMC measure

In the special situation, The specified area may be affected, the

standard of radiation limit value has been complied with (eg: The

device, which is easy effected by electromagnetism, is used at the

installation location, or there is radio or TV near the installation location). In this

condition, the operator should adopt some appropriate measures to remove

interference.

Accoring to the domestic and international standards, the ambient devices’

electromagnetism situation and anti-interference ability must be checked:

Safety device

Power line, Signal transmission line and Date transmission line

Date processing equipment and telecommunication equipment

Inspection and calibration device

The effective measures avoid the problem of EMC:

a) Power source

Even though the power source connection meet rules, we still need to take

additional measure to remove the electromagnetic interference. (eg: Use the right

power filter. )

b) The welding line

Try to shorten the length of cable

Put the cable together

Be Far away from other cable

c) Equipotential connection

d) Ground connection of work-piece

When necessary, use appropriate capacitance to connect the ground.

e) Shielding, when necessary

Shield the ambient devices

SAFETY

-10-

Shield the whole welding machine

§1.5 Warning label

The device with a warning label. Do not remove、destroy or cover this label. These

warnings are intended to avoid incorrect device operations that could result in

serious personal injury or property damage.

OVERVIEW

-11-

§2 Overview

§2.1 Features

New PWM technology and IGBT inverter technology.

Active PFC technology for increased duty cycle ande-nergy efficiency.

Multi voltage input, can use with long extension lead.

MIG/MAG with Dual Pulse/Pulse/Manual and SYN function

-Synergic programs for Fe Ss Flux-Cored AlMg AlSi Al CuSi

-JOB mode (Save and Load 100 different job records)

- 2T /4T/S4T/Spot Weld welding mode

- function parameter adjustment

MMA function (Stick electrode)

- Hot start (improves electrode starting)

- Adjustable Arc Force

MMA pulse function (Stick electrode)

- Hot start (improves electrode starting)

- Adjustable Arc Force

- Base Current

- Peak Current

- Frequency

- Duty

AC/DC TIG

- Lift Arc ignition (prevents tungsten sticking during arc ignition)

- HF Arc ignition

- 2T /4T /Repeat/Spot Trigger Control

- Pulse function

- Gas/air cooling mode

- Multi-Wave Select

- function parameters adjustment

CUT

OVERVIEW

-12-

- Post Flow adjustment

- Non HF arc starting system for increased reliability and low EMF pollution.

-Automatic pilot arc control system for increased cutting capability and speed, especially for

discontinuous cutting.

Internal wire feeder, gear driven for up to 300mm Ø spool

Euro style MIG torch connection

IP23 rating for environmental/safety protection

Spool Gun Connection

OVERVIEW

-13-

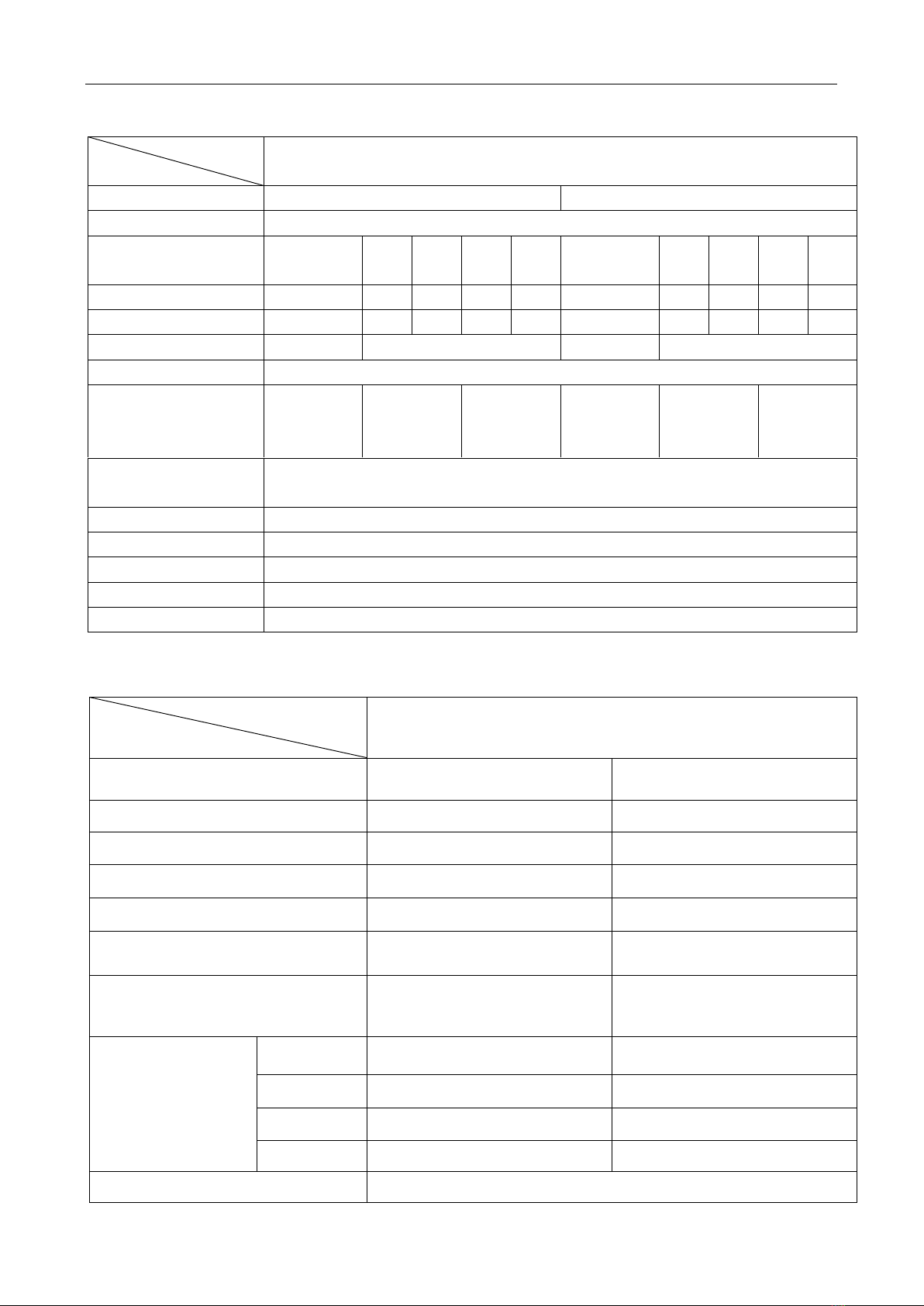

§2.2 Technical Data

Models

Parameters

OMNI-WeldCut 2040 (Welding)

Input Voltage(V)

1~110/120/130±10%

1~220/230/240±10%

Frequency (HZ)

50/60Hz

MIG

TIG

DC

TIG

AC

MMA

DC

MMA

AC

MIG

TIG

DC

TIG

AC

MMA

DC

MMA

AC

Input Current(A)

26

19

19

31

26

22

23

21

33

32

Input Power(KW)

2.8

2.1

4.0

3.4

2.8

4.8

5.0

4.6

7.2

7.0

Welding Current(A)

20-110

10-110

20-200

10-200

No-load Voltage(V)

80

Duty cycle(40℃)

40% 110A

60% 90A

100% 70A

40% 110A

60% 90A

100% 70A

40% 110A

60% 90A

100% 70A

40% 200A

60% 163A

100% 127A

40% 200A

60% 163A

100% 127A

40% 200A

60% 163A

100% 127A

Diameter (mm)

Fe:0.6 0.8 0.9 1.0 Ss:0.8 0.9 1.0 Flux-Cored 0.8 0.9 1.0 AlMg 0.8 0.9 1.0 1.2 AlSi

1.0 1.2Al 1.2 CuSi 0.8 0.9 1.0

Protection class

IP23

Insulation class

H

Dimensions(mm)

750X250X470

Weight(Kg)

26

Power Factor

0.99

Note: The above parameters are subject to change with future machine improvement!

Models

Parameters

OMNI-WeldCut 2040 (Cutting)

Rated input voltage(V)

1~110/120/130±10% 50/60Hz

1~220/230/240±10% 50/60Hz

Rated input current(A)

24

22

Rated input power(KW)

17

16

Cutting current adjustment range (A)

20-25A

20-40A

No-load voltage (V)

433V

433V

Duty cycle(40℃10minutes)

40% 25A 60% 20A 100% 16A

40% 40A 60%33A 100% 25A

The max. cutting thickness to Carbon

steel(mm)

≤10

≤20

Optimal cutting

thickness (mm)

Carbon steel

≤6

≤18

Stainless steel

≤6

≤18

Aluminum

≤4

≤12

Cuprum

≤2

≤8

Dimensions(mm)

750X250X470

OVERVIEW

-14-

Note: The above parameters are subject to change with future machine improvement!

§2.3 Brief Introduction

OMNI-WeldCut series of welding&cutting machines is a new inverter-based MIG/MMA/TIG

Welding&Cutting machine with Synergic Programs and Pulse functions. The MIG function

allows you to weld with Gas Shielded wire applications giving excellent, professional welding

results. Easy step-less adjustment of voltage and wire feed coupled with integrated digital meters

allows easy setting of welding parameters. OMNI-WeldCut series of welding&cutting machines

features MIG welding with Synergic welding programs designed for ease of use with your

selected gas mixture. The operator selects the gas mixture and wire diameter they are using then

simply start welding. Once this is done the operator can make fine adjustments to the voltage for

even greater control of the weld pool. The added AC&DC TIG Pulse capability delivers perfect

arc ignition every time and a remarkably smooth stable arc produces high quality TIG welds. TIG

functionality includes adjustable Down Slope & Post Gas as well as being gas solenoid-valve

equipped. The stick welding (DC&AC MMA) capability delivers easy electrode welding with

high quality results, including cast Iron, stainless and low hydrogen. An additional feature is the

Spool gun ready function that allows the simple connection of Spool Gun for the use of thin or

softer wires that don’t have the column strength to feed through MIG torches, such as aluminum

wire. In the JOB mode, 100 different JOB records can be stored and called , improve the quality

of welding process .

OMNI-WeldCut series of welding&cutting machines is an industrial quality machine that is

suitable for all positions welding for various plates made of stainless steel, carbon steel, alloyed

steel etc. Applications applied to pipe installment, petrochemical, architecture equipment, car

repair, bicycle repair, handicraft and common steel fabrication.

OMNI-WeldCut series of welding&cutting machines has built-in automatic protection

functions to protect the machines from over-voltage, over-current and over-heat. If any one of the

above problems happens, the alarm lamp on the front panel will be lit and output current will be

Protection class

IP23

Insulation class

H

Net weight (kg))

26

Cooling method

AF

OVERVIEW

-15-

shut off automatically for the machine to protect itself and prolong the equipment using life.

§2.4 Duty cycle and Over-heat

The letter “X” stands for Duty Cycle, which is defined as the portion of the time a welding

machine can weld continuously with it’s rated output current within a certain time cycle (10

minutes).

The relation between the duty cycle “X” and the output welding current “I” is shown as the

right figure.

If the welding machine is overheating, the IGBT over-heat protection sensing will send a signal

to the welding machine control unit to cut the output welding current OFF and light the over-heat

pilot lamp on the front panel. In that case, the machine should not be welding for 10-15 minutes

to cool down with the fanrunning. When operating the machine again, the welding output current

or the duty cycle should be reduced.

§2.5 Working Principle

The working principle of OMNI-WeldCut series of welding&cutting machines is shown as the

following figure. Single-phase 110V/220V work frequencyAC is rectified into DC(530V), then

is converted to medium frequency AC (about 20KHz) by inverter device (IGBT), after reducing

voltage by medium transformer (the main transformer) and rectifying by medium frequency

rectifier (fast recovery diodes), and is outputted by inductance filtering. The circuit adopts current

feedback control technology to insure current output stably when MMA or TIG. And adopts

OVERVIEW

-16-

voltage feedback control technology to insure voltage output stably when MIG. Meanwhile, the

welding current parameter can be adjusted continuously and infinitely to meet with the

requirements of welding craft.

Rectifier Inverter Transformer Rectifier Hall

Current

Feedback

control

Single-phase AC DC AC DC

220V 50Hz

AC DC

Welding current

regulate

(Wire feed speed) Wire feeder

motor

PWM signal

CPU control

Voltage

Feedback

control

§2.6 Volt-Ampere Characteristic

OMNI-WeldCut series of welding&cutting machines has an excellent volt-ampere

characteristic, whose graph is shown as the following figure. The relation between the rated

loading voltage U2and welding current I2is as follows: U2=14+0.05I2(V)

44

14

0600 Io(A)

Uo(V)

Working point

Volt-ampere characteristic The relation between the rated loading

voltage and welding current

110V/220V 50HZ

Current sensor

THANK YOU FOR USING OUR PRODUCTS

-17-

§3 Panel Functions & Descriptions

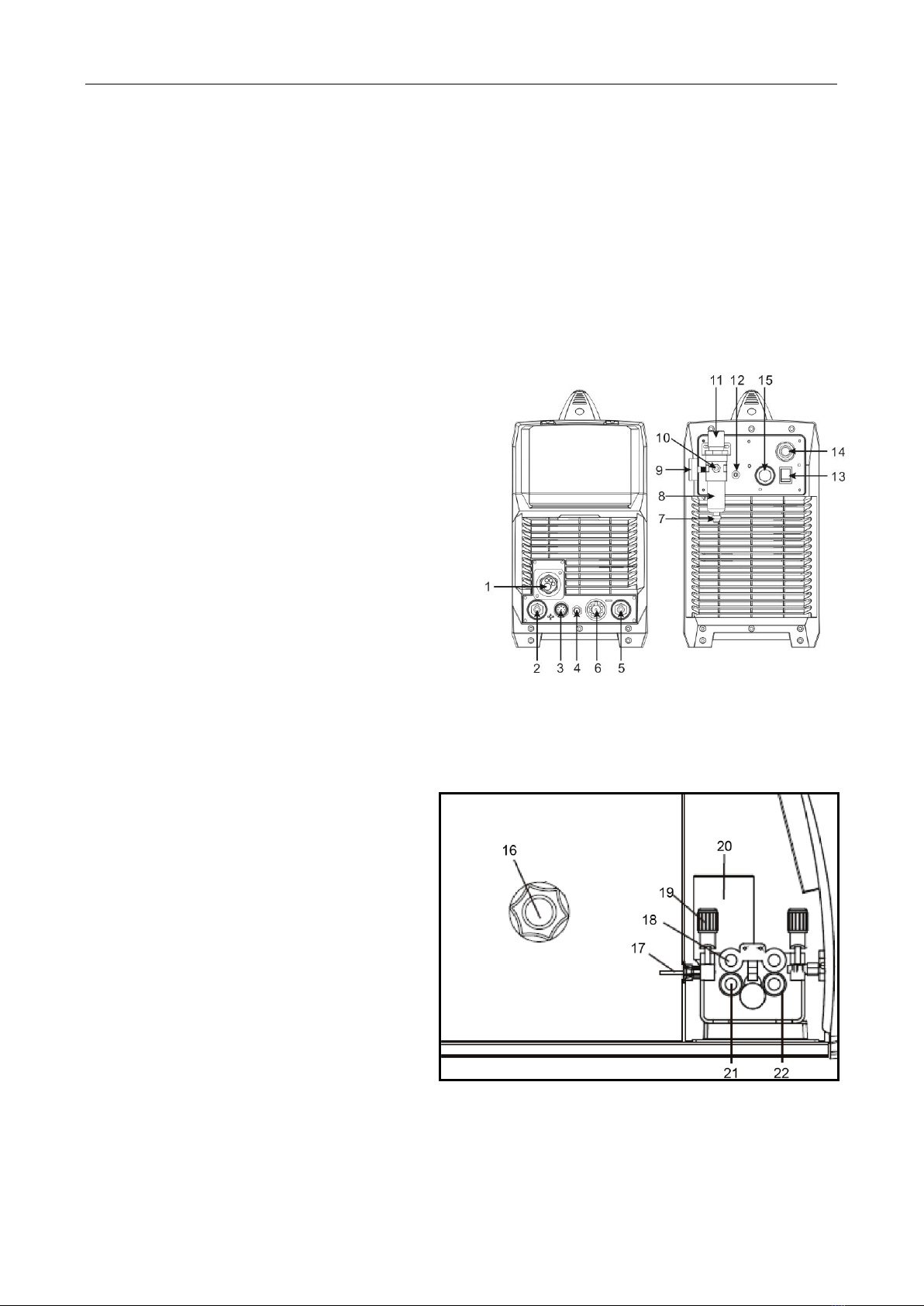

§3.1 Machine Layout Description

Front and rear panel layout of welding machine

1. MIG torch euro connector

2. Positive (+) welding power output

3. Remote connection plug

4. TIG torch gas connector

5. Negative (-) welding power output

6. Plasma Torch Euro

7. Air Filter Condensate Drain Tube

8. Air Condensate Filter/Trap Bowl

9. Air Pressure Regulator Outlet Pressure Gauge

10. Compressed Air Inlet

11. Air Pressure Regulator Knob

12. Gas inlet connector

13. Power switch

14. Input power cable

15. Earth Lead Connection Socket (CUT)

Wire Feeder of welding machine

16. Spool holder.

17. Wire feeder inlet guide.

18. Wire feed tension arm (2x).

19. Wire feed tension adjustment(2x).

20. Wire feed motor.

21. Drive roller retainer (2x).

22. Wire drive roller(2x).

Tool case of OMNI-WeldCut 2040 LCD

23. Fixed wheel.

24. Universal wheel.

Table of contents

Popular Cutter manuals by other brands

Abicor Binzel

Abicor Binzel ABICUT 25K operating instructions

Kronen

Kronen KKS 1 Translation of the original instruction manual

Hitachi

Hitachi CL 14DSL Handling instructions

Makita

Makita DSC251ZK instruction manual

Tupperware

Tupperware Mandoline RECIPES AND COOKING GUIDE

Makita

Makita SC103D instruction manual