iMettos HLC-300 User manual

Model: HLC-300

Please read this instruction manual carefully before operating this equipment

Vegetable Cutter

Instruction Manual

--

- 1 -

CONTENTS

1.SAFETY

2.INFORMATION ON SAFETIES

3.PERFORMANCE PARAMETER

4.INSTALLATION

5.OPERATION INSTRUCTIONS

6.CLEANING AND MAINTENANCE

7.DISK

8.EXPLODED DRAWING- 1 -

9.CIRCUIT DIAGRAM

10. WASTE DISPOSAL

12. WARRANTY

--

- 2 -

1.Safety Tips

• Position on a flat, stable surface.

• A service agent/qualified technician should carry out installation and any repairs if

required. Do not remove any components on this product.

• DO NOT immerse the appliance in water.

• DO NOT place hands in either food chute.

• DO NOT attempt to cut frozen food with the appliance.

• Suitable for indoor use only.

• Always switch off and disconnect the power supply to the appliance when not in use.

• Regularly check the screws fixing the blades to the cutting discs and tighten as

necessary.

• This appliance must only be used in accordance with these instructions and by persons

competent to do so.

• This appliance is not suitable for use by children.

• Keep all packaging away from children. Dispose of the packaging in accordance to the

regulations of local authorities.

• If the power cord is damaged, it must be replaced by an agent or a recommended

qualified technician in order to avoid a hazard.

Read this instruction manual before using and keep them

available at all times!

--

- 3 -

2. INFORMATION ON SAFETIES

2.1. GENERAL PRECAUTIONS

• THE VEGETABLES CUTTING MACHINE MUST BE MANAGED BY SKILLED PERSONNEL,FAMILIAR WITH THE

INSTRUCTIONS FOR USE AND SAFETY CONTAINED IN THIS MANUAL.

• EVEN IF THE MACHINE COMES WITH SEVERAL SAFETY SYSTEMS, AVOID SETTING THE HANDS NEAR THE

CUTTING DISCS AND MOVING PARTS.

• BEFORE ANY CLEANING AND MAINTENANCE OPERATIONS, CHECK TO MAKE SURE THE MACHINE IS

DISCONNECTED FROM THE MAINS.

• PERIODICALLY CHECK CABLES AND ELECTRIC ELEMENTS CONDITIONS.

• NEVER USE THE CUTTING MACHINE WITH FREEZED FOOD.

• NEVER REPLACE PARTS OF THE MACHINE BY YOURSELF, BUT APPLY TO THE ASSISTANCE SERVICE.

•THE APPLIANCE CAN NOT BE THE DISABLED OR CHILDREN OR BYA LACK OF EXPERIENCE AND

KNOWLEDGE OF THE PEOPLE TO USE, EXCEPT BY THE RIGHT PERSON RESPONSIBLE FOR THEIR SAFETY

SUPERVISION OR INSTRUCTION CONCERNING USE OF THE APPLIANCE.

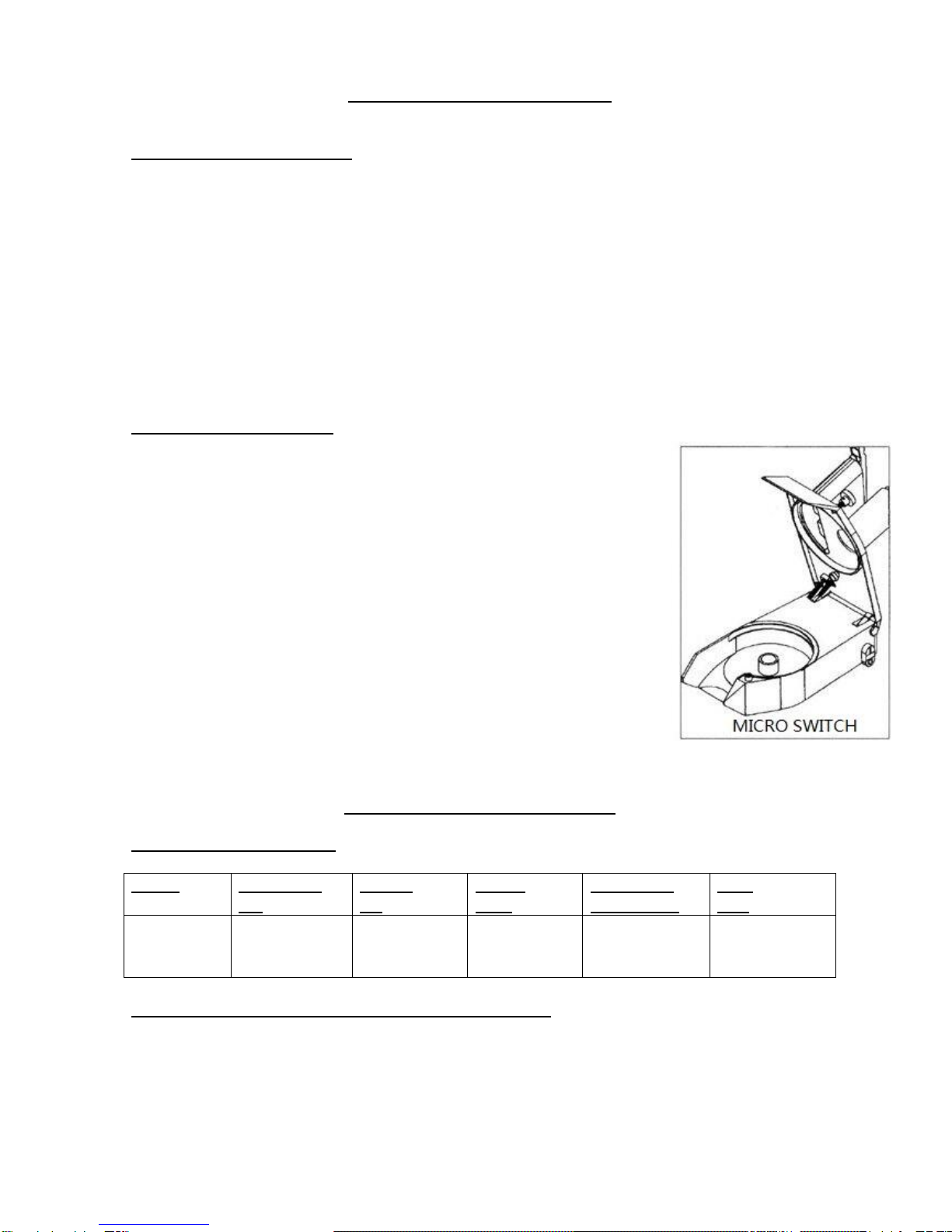

2.2 ELECTRICAL SAFETIES

THEREARE TWO MICRO-SWITCHES ON THE COVER OF THE MACHINE,

THEIR ROLE ARE: 1. WHEN LIFTING CRESCENT-SHAPED INLET PRESSURE

HANDLE

TOA CERTAIN HEIGHT, THE MACHINE STOPS RUNNING, IN ORDER TO PREVENT

ACCIDENTALLY INSERT YOUR HANDS INTO CRESCENT-SHAPED INLET AND

BRUISED

BY THE MACHINE; 2. WHEN YOU OPEN THE COVER UP, THE MACHINE STOPS

RUNNING,

TO ENSURE SAFE OPERATION.

A RELAY REQUIRING REQUIRES THE VOLUNTARY RESTART (ACTIVATION) OF THE

MACHINE WHEN THE CURRENT IS LACKING HAS BEEN SET ON THE LOW VOLTAGE

CONTROL CIRCUIT. FOR THE PERFECT INSULATION OF ALLTHE ELECTRIC

ELEMENTSAND THE REMARKABLE RESISTANCE OF THE ALUMINIUM TREATMENT,

COUPLED WITH THE MATERIAL USED, OUR MACHINES CAN BE INSTALLED

TO WORK INSIDE MOIST PREMISES.

3. PERFORMANCE PARAMETER

3.1. TECHNICAL FEATURES

MODEL

DIMENSIONS

CM.

WEIGHT

KG.

POWER

WATT

ELECTRICAL

CONNECTION

REVS

DISC

HLC-300

57X23X51

22.50

550

110/1/50~60

220~240/1/50~60

380/1/50~60

270

3.2. SUPPLY CONDITIONS AND DISPOSAL OF PACKINGS

THE CUTTING MACHINE IS PACKED IN A STURDY CARDBOARD BOX WITH INTERNAL SHAPED EDGES WHICH

GUARANTEE THE PERFECT INTEGRITY OF THE MACHINE DURING TRANSPORT.

ALL THE PACKING COMPONENTS (CARTON, FOAM, STRAPS, AND SO ON) CAN EASILY BE DISPOSED OF AS

HOUSEHOLD RUBBISH

--

- 4 -

4. INSTALLATION

4.1. SETTING THE MACHINE

THE MACHINE CONNECTION AND THE SETTINGAT WORK MUST BE MADE BY SKILLED PERSONNEL.

WARNING: BOTH THE SYSTEMAND LOCATION WHERE THE EQUIPMENT HAS TO BE SET MUST COMPLY WITH

THE REGULATIONS FOR THE ACCIDENT PREVENTIONAND ELECTRICAL REGULATIONS ICE FORCE.

THE MANUFACTURER DECLINES ANY AND ALL RESPONSIBILITY FOR DIRECT OR INDIRECT DAMAGES

WHICH MAY ENSUE FOR NON-COMPLIANCE WITH THE ABOVE MENTIONED REGULATIONS.

SET THE EQUIPMENT ON A WIDE, LEVELLED, DRY AND FIXED FACE, FAR FROM HEAT SOURCES AND WATER

SPRAYS.

4.2. ELECTRIC CONNECTIONS

THE EQUIPMENT IS SUPPLIEDWITH AN ELECTRIC CABLE TO BE CONNECTED TOA MAGNETO-THERMIC MAIN

SWITCH WHICH STOPS THE MACHINE WHEN THE OPERATOR COMES IN FORTUITOUS CONTACT WITH THE

ROTATING ELEMENTS.

IT IS IMPERATIVE THAT THE EQUIPMENT IS WELL GROUNDED ACCORDING TO THE REGULATIONS IN FORCE.

THE MANUFACTURER DECLINES ANY AND ALL RESPONSIBILITY FOR DIRECT AND INDIRECT DAMAGES

WHICH MAY ENSUE FOR NON-COMPLIANCE WITH THE REGULATIONS IN FORCE.

4.3. SAFETY MEASURES AND TRAINING THE FINAL USER

THE SKILLED PERSONNEL IN CHARGE OF THE INSTALLATION AND ELECTRIC CONNECTIONS OF THE

EQUIPMENT IS RESPONSIBLE OF THE TRAINING OF THE FINAL USER, WHICH MUSTALSO BE INFORMED ON

THE SAFETY MEASURES TO COMPLY WITH. THIS INSTRUCTION MANUAL COMES WITH EACH EQUIPMENT.

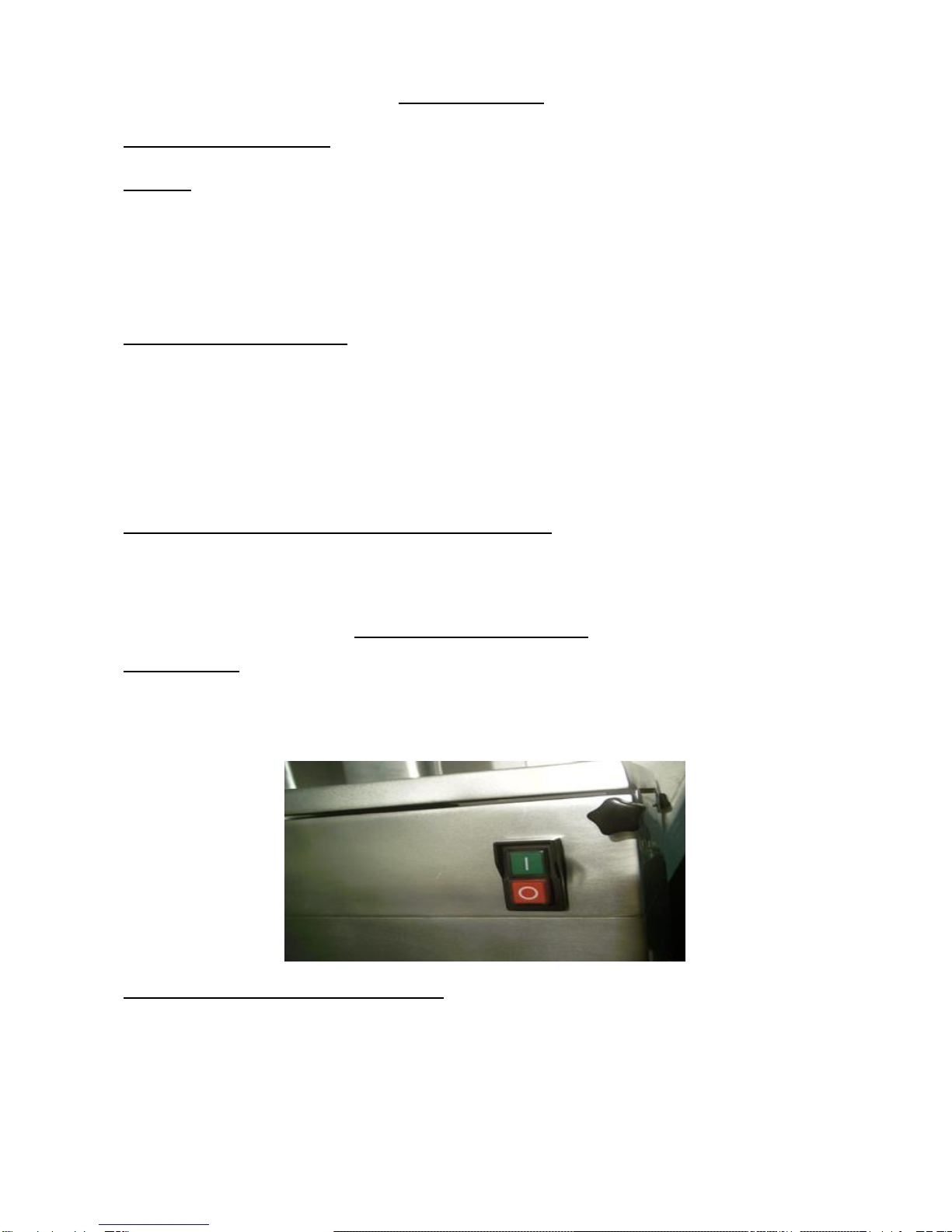

5. USE OF THE EQUIPMENT

5.1. CONTROLS

THE CONTROLS AND PILOT LIGHTARE SENT ON THE RIGHT SIDE OF THE BASE. ( WHEN THE MACHINE IS

LOCATED IN FRONT OF THE OPERATOR, THE CONTROL DEVICE IN THE OPERATOR’S RIGHT HAND.)

1. GREEN BUTTON FOR STARTING THE MACHINE

2. RED BUTTON FOR STOPPING THE MACHINE

5.2. SETTING THE DISCS ON THE MACHINE

ROTATE THE KNOBAS SHOWN IN FIGURE N.1 AND OPEN THE COVER. SET FIRST THE PLASTIC EJECTING

DISC (2), THEN INSTALL THE DISC SELECTED FOR THE CUTTING .

CLOSE THE COVER AND REVERSE THE ROTATION OF THE HANDLE. WORK ON THE START BUTTON TO

AUTOMATICALLY HOOK THE DISCS IN THE CORRECT POSITION.

--

- 5 -

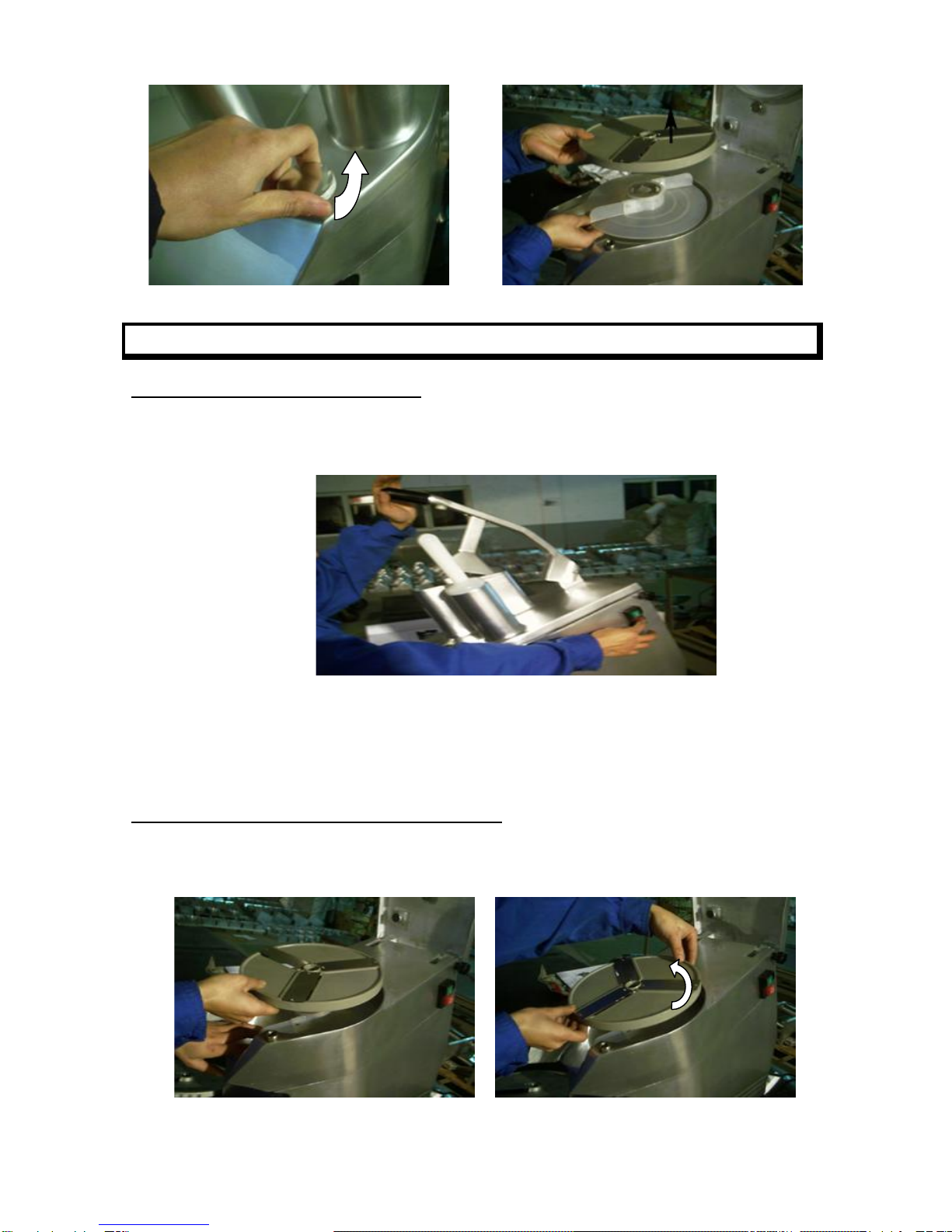

COVER OPENING (1) DISC POSITION (2)

5.3. SETTING AND CUTTING THE FOOD

LIFT THE HANDLE AND SET THE FOOD INSIDE THE OPENING AS SHOWN IN FIGURE N.3, THEN PUT DOWN

THE HANDLE, PRESS THE GREEN START BUTTON WITH YOUR RIGHT HAND, AND WITH YOUR LEFT HAND,

LIGHTLY MOVE THE HANDLE DOWNWARDS UNTIL FOOD IS FULLY USED UP.

(3)

LIFT THE HANDLE TO INTRODUCE OTHER FOOD.

THE MACHINE WILLAUTOMATICALLY STOP WHEN RAISED THE HANDLE, AND THE MACHINE WILL

AUTOMATICALLY WORK WHEN PUT DOWN THE HANDLE.

ROUND INLET IS USED FOR CUTTING SLENDER VEGETABLES SUCH AS CARROTS, CUCUMBER.

WARNING: NEVER USE THE HAND, BUT PRESS THE VEGETABLE WITH THE PESTLE SUPPLIED.

5.4. RELEASE AND REPLACEMENT OF THE DISCS

TURN THE KNURLED HANDLE AND LIFT THE COVER. (FIG.1)

TURN THE DISCANTICLOCKWISE AND COVER THE CUTTING EDGE WITH APPROPRIATE MATERIALAS

(RUBBER, FABRIC, ETC), AND THEN GET OFF THE DISCS FROM BOTTOM TO UP WITH HAND.

(4) (5)

ATTENTION TO DISC BLADES!!

--

- 6 -

6. CLEANING AND MAINTENANCE OPERATIONS

6.1. GENERALITIES AND PRODUCTS FOR CLEANING

BEFORE CARRYING OUT ANY CLEANING OR MAINTENANCE OPERATIONS, CHECK TO MAKE SURE THAT THE

MAINS SWITCH BE OFF AND THE SUPPLY PLUG DISCONNECTED FROM THE MAINS.

ACCURATELY CLEAN THE EQUIPMENT AND THE DISCS EVERY DAY FOR A CORRECT OPERATION AND LIFE

OF THE EQUIPMENT.

THE DISCS,AND THE PLASTIC EJECTOR, CAN BE REMOVED FOR WASHING UNDER AWARM WATER JET.

CLEAN THE MACHINE, AND ABOVEALL WHERE THE DISCS REST, WITH A CLOTH OR A SPONGE WET WITH

WARM WATER, ACCURATELY REMOVE ALL WASTES TO PREVENT THE DISCS FROM CHANGING THEIR

POSITION.

OPEN THE COVER AND LOOSEN THE 2 PINSAS SHOWN IN FIG.6. REMOVE THE COVER AND WASH UNDER A

WATER JET.

(6)

CLEAN THE SURFACES WITH WATER AND SOUP, ALCOHOL, DETERGENTS WITHOUTABRASIVES OR

SUBSTANCES BASED ON CHLORINE OR SODA(CHLORINE WATER, MURIATIC ACID).

NEVER USE ABRASIVES, STEEL WOOL, OR SIMILAR PRODUCTS AS THEY MAY BRING DAMAGES TO THE

PAINT, THE COAT, OT THE MACHINE BODY.

FOR CLEANING, USE NON-TOXIC PRODUCTSAND ONES THAT GUARANTEE THE BEST HYGIENE.

6.2. OPERATIONS IN THE CASE OF FAILURES

1.WHEN PRESS THE GREEN BUTTON, IF THE LIGHT IS DARK, CHECK WHETHER THE COVERING OF MACHINE

COVER TIGHTLY; IF THE LIGHT IS BRIGHT, THE MACHINE CAN NOT WORK, CHECK WHETHER HANDLE DOWN;

IF STILL CAN’T WORK, THEN CUT OFF THE POWER AND CONTACT THE SERVICE CENTER.

2.WHEN THE MACHINE DOES NOT HAVE POWER OR BLADE RUN SLOW, OPEN THE MACHINE BOTTOM,

ACCORDING TO THE FOLLOWING CHART METHOD TOADJUST MOTOR TENSION BELT (2~3 MONTHS TO

ADJUST THE NEW MACHINES TENSIONING BELT, THE OLD MACHINE IS OFTEN GIVEN). THE GUARANTEE

PERIOD OF INSTALL NEW BELT ON THE MACHINE IS 9 MONTHSAFTER MANUFACTURED. THE

NON-PROFESSIONALS DO NOT DISASSEMBLE THE MACHINE.

1) REMOVE THE BOTTOM 2) REMOVE THE BRACKET

--

- 7 -

3) BYADJUSTING THE SCREW TO

ADJUST THE BELT TENSION

6.3. MACHINE IDLE FOR ALONG TIME

SHOULD THE MACHINE BE IDLE FOR A LONG TIME, DISCONNECT THE MAIN WALL SWITCH AND CLEAN

THE MACHINE AND ITS ACCESSORIES ACCURATELY. USE WHITE VASELINE OIL (OR SIMILAR PRODUCTS)

TO PROTECT ALL THE MACHINE’S ELEMENTS.

WE ADVISE COVERING THE MACHINE WITH A NYLON (OR SIMILAR) CLOTH.

7. DISCS

IN ORDER TO ACHIEVE A RANG OF DIFFERENT SECTIONSAND SIZE, THE MACHINE FUNCTION IS APPLICABLE

TO SEVERAL DIFFERENT DISCS AS WELL AS VEGETABLES AND FRUITS. (SUCH AS APPLES, PEARS, BANANAS,

ETC.)

7.1 SLICING BLADE (WITH THE MACHNE) P2, P4

7.2 GRATING BLADE (WITH THE MACHINE) H3, H4,H7

7.3 JULIENNE BLADE (OPTION) HU2.5, HU4, HU8, HU10

7.4 DICING BLADE (OPTION) D8, D10, D12, D20

7.5 FRENCH BLADE (OPTION) T8, T10

7.6 SLICING BLADE (OPTION) H8, H10, H14, E1, E2, E5

7.7 RIPPLE BLADE (OPTION) PB2, PB4

7.8 POWER BLADE (OPTION) FM

E1 E2 E5 H8 H10 H3 H4 H7

--

- 8 -

HU2.5 HU4 HU8 HU10 D8 D10 D12 D20 T8 T10

P2 P4 PB4

COMPOSE H8 H10

D10 D12 D20

D8 D10 D12 D20

COMPOSE H8 T8

H8 T10

H10 T8

H10 T10

--

- 9 -

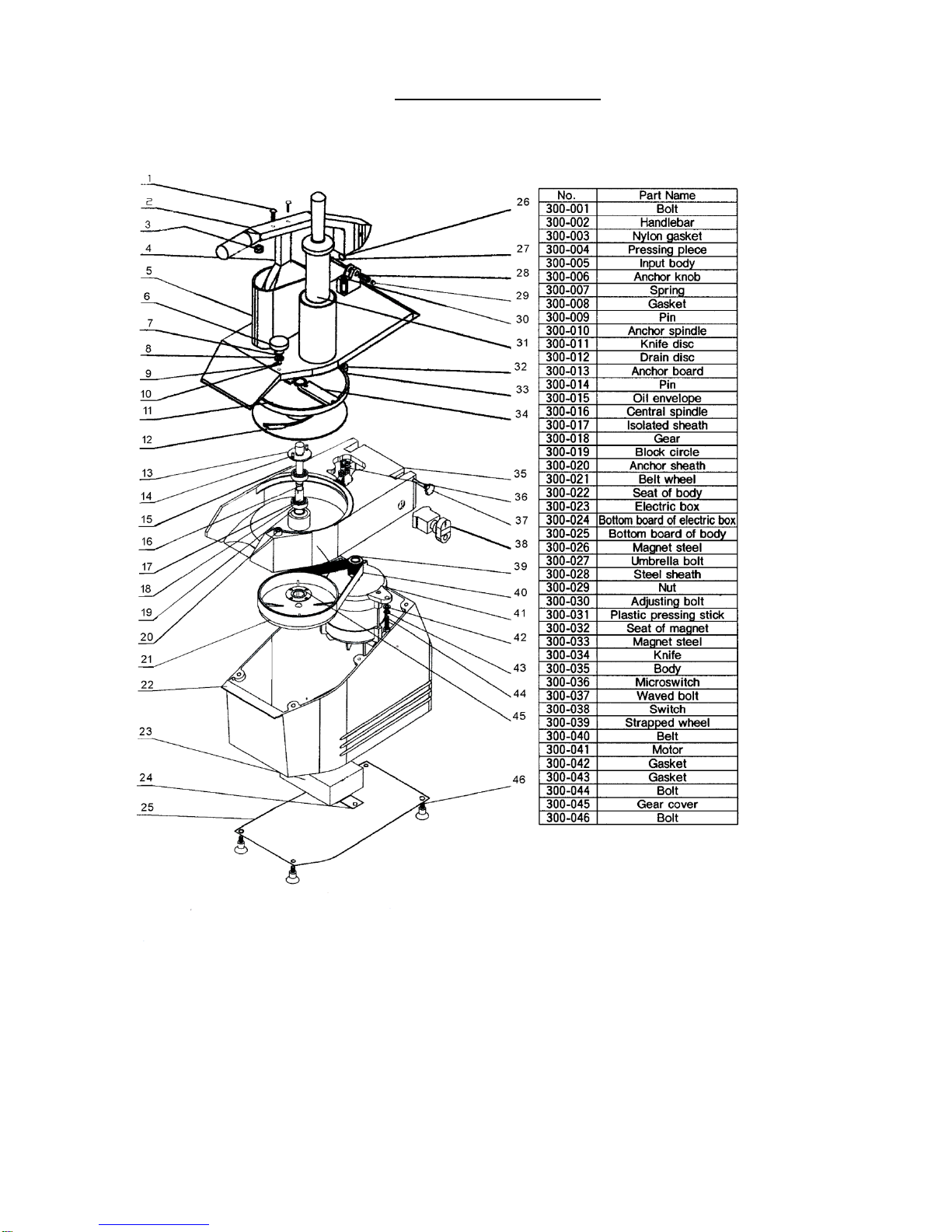

8. EXPLODED DRAWING

--

- 10 -

9. ELECTRICAL DRAWING

--

- 11 -

10.Waste disposal

Discarding old devices

At the end of its service life the discarded device has to be disposed in accordance with

the national regulations. It is advisable to contact a company which is specialized in waste

disposal, or just contact the local disposal service in your community.

WARNING!

To exclude any abuse and the dangers involved make the waste device unfit for use

before disposal. For that purpose disconnect device from mains supply and remove mains

connection cable from the device.

CAUTION!

For the disposal of the device please consider and act according to the national and local

rules and regulations.

11.Warranty

iMettos warrants to the original purchaser of every new product, under normal and proper

use and maintenance service as specified by iMettos and upon proper installation and

start-up in accordance with the instruction packet supplied with each unit. iMettos’

obligation under this warranty is limited to a period of two (2) year from the date of original

installation.

WARRANTY CLAIMS

All claims for parts must be made directly through iMettos. All claims should include:

Personal Details: Products Details:

Your name: Model number:

Your company: Serial number of the product:

Address: Date of purchase:

Email: Proof of purchase :

Phone:

Pertinent information supporting the existence of the alleged defect.(Such as picture etc.)

Our warranty departments will according to the actual situation and reply you

within 24hours.

--

- 12 -

iMettos Limited

www.imettos.co.uk

Table of contents

Popular Cutter manuals by other brands

Cembre

Cembre B35M-TFC Operation and maintenance manual

Martin Yale

Martin Yale 7000E Installation, maintenance & operating instructions

HERKULES

HERKULES STR 250 LED operating instructions

Makita

Makita DCO140 instruction manual

Husqvarna

Husqvarna K6500 Operator's manual

Staubli

Staubli MA705 operating instructions

IMER

IMER MASONRY 250 Operating, maintenance, spare parts manual

VEVOR

VEVOR QTJ-J002 instruction manual

Woods

Woods BRUSHBULL BB48 Operator's manual

SPEWE

SPEWE 212SL-30 operating instructions

Glomar

Glomar EKS-2-PRO instruction manual

ALLSPEEDS

ALLSPEEDS Webtool RCV115 Instructions for installation, operation, maintenance