Top Sensors T1 User manual

T1 Protocol Manual

Zemic Europe B.V. T: +31 76 50 39480

Leerlooierstraat 8 Nr. 2018.11 T1 Protocol Manual Rev1 F: +31 76 50 39481

4871 EN Etten-Leur info@top-sensors.nl

The Netherlands 1/75 http://www.top-sensors.com

Specifications and dimensions are subject to change without notice and do not constitute any liability whatsoever.

T1

Protocol Manual

T1 Protocol Manual

Zemic Europe B.V. T: +31 76 50 39480

Leerlooierstraat 8 Nr. 2018.11 T1 Protocol Manual Rev1 F: +31 76 50 39481

4871 EN Etten-Leur info@top-sensors.nl

The Netherlands 2/75 http://www.top-sensors.com

Specifications and dimensions are subject to change without notice and do not constitute any liability whatsoever.

KEY TO SYMBOLS

Below are the symbols used in the manual to draw the reader's attention:

Caution! High Voltage.

Caution! This operation must be performed by skilled workers.

Read the following indications carefully.

Further information.

T1 Protocol Manual

Zemic Europe B.V. T: +31 76 50 39480

Leerlooierstraat 8 Nr. 2018.11 T1 Protocol Manual Rev1 F: +31 76 50 39481

4871 EN Etten-Leur info@top-sensors.nl

The Netherlands 3/75 http://www.top-sensors.com

Specifications and dimensions are subject to change without notice and do not constitute any liability whatsoever.

TABLE OF CONTENTS

CONTINUOUS FAST WEIGHT TRANSMISSION PROTOCOL...................................................................... 5

CONTINUOUS WEIGHT TRANSMISSION TO REMOTE DISPLAY PROTOCOL.............................................. 6

ASCII BIDIRTECTIONAL PROTOCOL ....................................................................................................... 7

MODBUS-RTU PROTOCOL.................................................................................................................. 13

FUNCTIONS SUPPORTED IN MODBUS............................................................................................. 13

COMMUNICATION ERROR MANAGEMENT ..................................................................................... 15

LIST OF AVAILABLE REGISTERS........................................................................................................ 15

POSSIBLE COMMANDS TO BE SENT TO THE COMMAND REGISTER (40006)...................................... 20

ANALOG OUTPUT SETTINGS ....................................................................................................... 20

REAL CALIBRATION COMMANDS (WITH SAMPLE WEIGHT).......................................................... 20

COMMUNICATION EXAMPLES........................................................................................................ 21

CANOPEN.......................................................................................................................................... 23

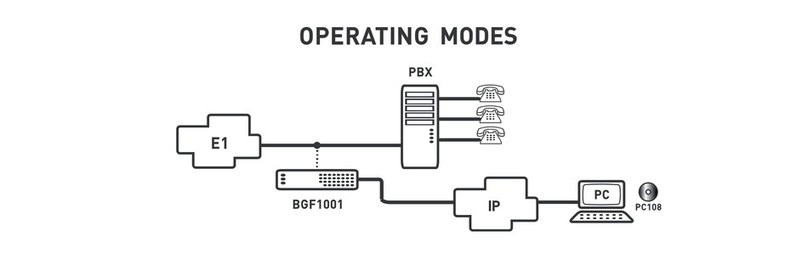

TECHNICAL SPECIFICATIONS AND CONNECTIONS............................................................................ 23

INSTRUMENT SETUP ...................................................................................................................... 24

PC/PLC SETUP................................................................................................................................ 24

POSSIBLE COMMANDS TO BE SENT TO THE COMMAND REGISTER .................................................. 26

REAL CALIBRATION COMMANDS (WITH SAMPLE WEIGHT).......................................................... 27

DEVICENET........................................................................................................................................ 27

TECHNICAL SPECIFICATIONS AND CONNECTIONS............................................................................ 27

INSTRUMENT SETUP ...................................................................................................................... 28

PC/PLC SETUP................................................................................................................................ 28

POSSIBLE COMMANDS TO BE SENT TO THE COMMAND REGISTER .................................................. 30

REAL CALIBRATION COMMANDS (WITH SAMPLE WEIGHT).......................................................... 31

CC-LINK............................................................................................................................................. 32

TECHNICAL SPECIFICATIONS AND CONNECTIONS............................................................................ 32

INSTRUMENT SETUP ...................................................................................................................... 32

PC/PLC SETUP................................................................................................................................ 32

POSSIBLE COMMANDS TO BE SENT TO THE COMMAND REGISTER .................................................. 35

REAL CALIBRATION COMMANDS (WITH SAMPLE WEIGHT).......................................................... 36

ETHERNET TCP/IP.............................................................................................................................. 37

TECHNICAL SPECIFICATIONS........................................................................................................... 37

INSTRUMENT SETUP ...................................................................................................................... 37

PC SETUP....................................................................................................................................... 38

DIAGNOSTIC .................................................................................................................................. 39

WEBSITE........................................................................................................................................ 41

ETHERCAT ......................................................................................................................................... 44

TECHNICAL SPECIFICATIONS........................................................................................................... 44

PC/PLC SETUP................................................................................................................................ 45

POSSIBLE COMMANDS TO BE SENT TO THE COMMAND REGISTER .................................................. 47

T1 Protocol Manual

Zemic Europe B.V. T: +31 76 50 39480

Leerlooierstraat 8 Nr. 2018.11 T1 Protocol Manual Rev1 F: +31 76 50 39481

4871 EN Etten-Leur info@top-sensors.nl

The Netherlands 4/75 http://www.top-sensors.com

Specifications and dimensions are subject to change without notice and do not constitute any liability whatsoever.

REAL CALIBRATION COMMANDS (WITH SAMPLE WEIGHT).......................................................... 48

ETHERNET/IP..................................................................................................................................... 49

TECHNICAL SPECIFICATIONS........................................................................................................... 49

INSTRUMENT SETUP ...................................................................................................................... 49

PC/PLC SETUP................................................................................................................................ 49

POSSIBLE COMMANDS TO BE SENT TO THE COMMAND REGISTER .................................................. 52

REAL CALIBRATION COMMANDS (WITH SAMPLE WEIGHT).......................................................... 53

MODBUS/TCP ................................................................................................................................... 54

TECHNICAL SPECIFICATIONS........................................................................................................... 54

PC/PLC SETUP................................................................................................................................ 54

IP ADDRESS SETTING...................................................................................................................... 54

POWERLINK ...................................................................................................................................... 56

TECHNICAL SPECIFICATIONS........................................................................................................... 56

INSTRUMENT SETUP ...................................................................................................................... 56

PC/PLC SETUP................................................................................................................................ 56

POSSIBLE COMMANDS TO BE SENT TO THE COMMAND REGISTER .................................................. 58

REAL CALIBRATION COMMANDS (WITH SAMPLE WEIGHT).......................................................... 59

PROFIBUS-DP .................................................................................................................................... 60

TECHNICAL SPECIFICATIONS........................................................................................................... 60

INSTRUMENT SETUP ...................................................................................................................... 60

PC/PLC SETUP................................................................................................................................ 60

POSSIBLE COMMANDS TO BE SENT TO THE COMMAND REGISTER .................................................. 64

REAL CALIBRATION COMMANDS (WITH SAMPLE WEIGHT).......................................................... 64

PROFINET-IO ..................................................................................................................................... 65

TECHNICAL SPECIFICATIONS........................................................................................................... 65

INSTRUMENT SETUP ...................................................................................................................... 65

PC/PLC SETUP................................................................................................................................ 65

POSSIBLE COMMANDS TO BE SENT TO THE COMMAND REGISTER .................................................. 68

REAL CALIBRATION COMMANDS (WITH SAMPLE WEIGHT).......................................................... 69

SERCOSIII .......................................................................................................................................... 70

TECHNICAL SPECIFICATIONS........................................................................................................... 70

INSTRUMENT SETUP ...................................................................................................................... 70

PC/PLC SETUP................................................................................................................................ 70

POSSIBLE COMMANDS TO BE SENT TO THE COMMAND REGISTER .................................................. 72

REAL CALIBRATION COMMANDS (WITH SAMPLE WEIGHT).......................................................... 73

OUTPUTS AND INPUTS CONFIGURATION ........................................................................................... 74

T1 Protocol Manual

Zemic Europe B.V. T: +31 76 50 39480

Leerlooierstraat 8 Nr. 2018.11 T1 Protocol Manual Rev1 F: +31 76 50 39481

4871 EN Etten-Leur info@top-sensors.nl

The Netherlands 5/75 http://www.top-sensors.com

Specifications and dimensions are subject to change without notice and do not constitute any liability whatsoever.

CONTINUOUS FAST WEIGHT TRANSMISSION PROTOCOL

This protocol allows the continuous transmission of the weight at high update frequencies. Up to 300

strings per second are transmitted with a minimum transmission rate of 38400 baud.

Following communication modes available (see SERIAL COMMUNICATION SETTINGS section in

instrument manual):

communication compatible with TX RS485 instruments

communication compatible with TD RS485 instruments

If is set, the following string is transmitted to PC/PLC:

xxxxxxCRLF

where: xxxxxx ............. 6 characters of gross weight (48 57 ASCII)

CR.................... 1 character return to the start (13 ASCII)

LF..................... 1 character on new line (10 ASCII)

In case of negative weight, the first character from the left of the weight characters takes on the value “-”

(minus sign - ASCII 45).

In case of error or alarm, the 6 characters of the weight are substituted by the messages found in the

table of the ALARMS section (see the instrument manual).

If is set, the following string is transmitted to PC/PLC:

&TzzzzzzPzzzzzz\ckckCR

where: &...................... 1 initial string character (38 ASCII)

T...................... 1 character of gross weight identification

P...................... 1 character of gross weight identification

zzzzzz .......... 6 characters of gross weight (48 57 ASCII)

\...................... 1 character of separation (92 ASCII)

ckck............... 2 ASCII control characters or calculated considering the characters included

between “&” and “\” excluded. The control value is obtained executing the XOR

operation (exclusive OR) for the 8 bit ASCII codes of the characters considered.

Therefore, a character expressed in hexadecimal is obtained with 2 numbers that

may assume values from “0” to “9” and from “A” to “F”. “ckck” is the ASCII code

of the two hexadecimal digits

CR.................... 1 character of end string (13 ASCII)

In case of negative weight, the first character from the left of the weight characters takes on the value “-”

(minus sign - ASCII 45).

T1 Protocol Manual

Zemic Europe B.V. T: +31 76 50 39480

Leerlooierstraat 8 Nr. 2018.11 T1 Protocol Manual Rev1 F: +31 76 50 39481

4871 EN Etten-Leur info@top-sensors.nl

The Netherlands 6/75 http://www.top-sensors.com

Specifications and dimensions are subject to change without notice and do not constitute any liability whatsoever.

In case of error or alarm, the 6 characters of the gross weight are substituted by the messages found in

the table of the ALARMS section (see the instrument manual).

FAST TRANSMISSION VIA EXTERNAL CONTACT: it’s possible to transmit the weight, just once, even

closing an input for no more than a second (see OUTPUTS AND INPUTS CONFIGURATION and SERIAL

COMMUNICATION SETTINGS sections in instrument manual).

CONTINUOUS WEIGHT TRANSMISSION TO REMOTE DISPLAYS PROTOCOL

This protocol allows the continuous weight transmission to remote displays. The communication string is

transmitted 10 times per second.

Following communication modes available (see SERIAL COMMUNICATION SETTINGS section in

instrument manual):

-: communication with RIP5/20/60, RIP50SHA, RIPLED series remote displays; the remote display

shows the net weight or gross weight according to its settings

-: communication with RIP675, RIP6125C series remote displays; the remote display shows the

net weight or gross weight according to its settings

-: communication with RIP675, RIP6125C series remote displays

The instrument sends the following string to the remote display:

&NxxxxxxLyyyyyy\ckckCR

where: &...................... 1 initial string character (38 ASCII)

N...................... 1 character of net weight identification (78 ASCII)

xxxxxx ............. 6 characters of net weight or PEAK if present (48 57 ASCII)

L....................... 1 character of gross weight identification (76 ASCII)

yyyyyy............. 6 characters of gross weight (48 57 ASCII)

\ .....................1 character of separation (92 ASCII)

ckck ................. 2 ASCII checksum characters calculated considering the characters between “&”

and “\” excluded. The checksum value is obtained from the calculation of XOR

(exclusive OR) of the 8-bit ASCII codes of the characters considered. This obtains

a character expressed in hexadecimals with two digits that can have the values

from “0” to “9” and from ”A” to “F”. “ckck” is the ASCII code of the two

hexadecimal digits

CR.................... 1 character of end string (13 ASCII)

In case of negative weight, the first character from the left of the weight characters takes on the value “-”

(minus sign - ASCII 45).

If has been set, the decimal point at the position shown on the instrument's display can also be

transmitted. In this case, if the value exceeds 5 digits, only the 5 most significant digits are transmitted,

T1 Protocol Manual

Zemic Europe B.V. T: +31 76 50 39480

Leerlooierstraat 8 Nr. 2018.11 T1 Protocol Manual Rev1 F: +31 76 50 39481

4871 EN Etten-Leur info@top-sensors.nl

The Netherlands 7/75 http://www.top-sensors.com

Specifications and dimensions are subject to change without notice and do not constitute any liability whatsoever.

while if the value is negative, no more than the 4 most significant digits are transmitted. In both cases,

however, the decimal point shifts consistently with the value to display.

If has been set, in addition to what stated in protocol, the instrument transmits the

prompt every 4 seconds in the gross weight field, if on the instrument, it has been carried out a net

operation (see SEMI-AUTOMATIC TARE (NET/GROSS) section in instrument manual).

In case of weight value is under -99999, the minus sign “-” is sent alternated with the most significant

figure.

In case of error or alarm, the 6 characters of the gross weight and net weight are substituted by the

messages found in the table of the ALARMS section (see the instrument manual).

ASCII BIDIRECTIONAL PROTOCOL

The instrument replies to the requests sent from a PC/PLC.

It is possible to set a waiting time for the instrument before it transmits a response (see

parameter in the SERIAL COMMUNICATION SETTINGS section in the instrument manual).

Following communication modes available (see SERIAL COMMUNICATION SETTINGS section in

instrument manual):

-: communication compatible with instruments series W60000, WL60 Base, WT60 Base,

TLA600 Base

-: communication compatible with TD RS485 instruments

Captions:

$...................... Beginning of a request string (36 ASCII)

&or &&........... Beginning of a response string (38 ASCII)

aa .................... 2 characters of instrument address (48 57 ASCII)

!....................... 1 character to indicate the correct reception (33 ASCII)

?....................... 1 character to indicate a reception error (63 ASCII)

#...................... 1 character to indicate an error in the command execution (23 ASCII)

ckck: ................ 2 ASCII characters of Check-Sum (for further information, see section CHECK-

SUM CALCULATION)

CR.................... 1 character for string end (13 ASCII)

\....................... 1 character of separation (92 ASCII)

T1 Protocol Manual

Zemic Europe B.V. T: +31 76 50 39480

Leerlooierstraat 8 Nr. 2018.11 T1 Protocol Manual Rev1 F: +31 76 50 39481

4871 EN Etten-Leur info@top-sensors.nl

The Netherlands 8/75 http://www.top-sensors.com

Specifications and dimensions are subject to change without notice and do not constitute any liability whatsoever.

1. SETPOINT PROGRAMMING

Warning: the new values of setpoint are active immediately.

The PC transmits the following ASCII string: $aaxxxxxxyckckCR

where: xxxxxx ............. 6 characters for the setpoint value (48 57 ASCII)

y= A ................ set the value in the setpoint 1

y= B................. set the value in the setpoint 2

y= C................. set the value in the setpoint 3

Possible instrument responses:

-correct reception: &&aa!\ckckCR

-incorrect reception: &&aa?\ckckCR

Example: to set 500 in the setpoint no. 3, the PC must transmit the following command:

$01000500C47 (Cr)

1.1. SETPOINT STORAGE IN EEPROM MEMORY

The setpoint are stored in the RAM volatile memory and lost upon instrument power off. It is necessary

to send a special command to save them permanently in the EEPROM memory. Please note that the

writing number allowed in the EEPROM memory is limited (about 100000).

The PC transmits the following ASCII string: $aaMEMckckCR

Possible instrument responses:

-correct reception: &&aa!\ckckCR

-incorrect reception: &&aa?\ckckCR

2. READING WEIGHT, SETPOINT AND PEAK (IF PRESENT) FROM PC

The PC transmits the following ASCII string: $aajckckCR

where: j= a.................. to read setpoint 1

j= b.................. to read setpoint 2

j= c.................. to read setpoint 3

j= t .................. to read gross weight

j= n.................. to read net weight

j= p ......... to read the gross weight peak if the parameter is set as ; if,

instead, the parameter is set on the gross weight will be read. To

read the points, set the equal to 50000

T1 Protocol Manual

Zemic Europe B.V. T: +31 76 50 39480

Leerlooierstraat 8 Nr. 2018.11 T1 Protocol Manual Rev1 F: +31 76 50 39481

4871 EN Etten-Leur info@top-sensors.nl

The Netherlands 9/75 http://www.top-sensors.com

Specifications and dimensions are subject to change without notice and do not constitute any liability whatsoever.

Possible instrument responses:

-correct reception: &aaxxxxxxj\ckckCR

-incorrect reception: &&aa?\ckckCR

-In case of peak not configured: &aa#CR

where: xxxxxx ............. 6 characters of the required weight value

Notes: in case of negative weight, the first character from the left of the weight characters takes on the

value “-” (minus sign - ASCII 45). In case of weight value is under -99999, the minus sign “-” is sent

alternated with the most significant figure.

Error messages:

in case of an instrument alarm for exceeding 110% of the full scale or 9 divisions above the value of the

parameter , the instrument sends the string:

&aassO-Lst\ckck

in case of faulty connection of the load cells or of another alarm, the instrument sends:

&aassO-Fst\ckck

where: s....................... 1 separator character (32 ASCII –space)

Generally refer to the ALARMS section (see the instrument manual).

3. SEMI-AUTOMATIC ZERO (WEIGHT ZERO-SETTING FOR SMALL VARIATIONS)

The PC transmits the following ASCII string: $aaZEROckckCR

Possible instrument responses:

-correct reception: &&aa!\ckckCR

-incorrect reception: &&aa?\ckckCR

-the current weight is over the maximum value resettable: &aa#CR

4. COMMUTATION OF GROSS WEIGHT TO NET WEIGHT

The PC transmits the following ASCII string: $aaNETckckCR

Possible instrument responses:

-correct reception: &&aa!\ckckCR

-incorrect reception: &&aa?\ckckCR

T1 Protocol Manual

Zemic Europe B.V. T: +31 76 50 39480

Leerlooierstraat 8 Nr. 2018.11 T1 Protocol Manual Rev1 F: +31 76 50 39481

4871 EN Etten-Leur info@top-sensors.nl

The Netherlands 10/75 http://www.top-sensors.com

Specifications and dimensions are subject to change without notice and do not constitute any liability whatsoever.

5. COMMUTATION OF NET WEIGHT TO GROSS WEIGHT

The PC transmits the following ASCII string: $aaGROSSckckCR

Possible instrument responses:

-correct reception: &&aa!\ckckCR

-incorrect reception: &&aa?\ckckCR

6. READING OF DECIMALS AND DIVISION NUMBER

The PC transmits the following ASCII string: $aaDckckCR

Possible instrument responses:

-correct reception: &aaxy\ckckCR

-incorrect reception: &&aa?\ckckCR

where: x....................... number of decimals

y= 3................. for division value = 1

y= 4................. for division value = 2

y= 5................. for division value = 5

y= 6................. for division value = 10

y= 7................. for division value = 20

y= 8................. for division value = 50

y= 9................. for division value = 100

7. TARE ZERO-SETTING

The PC transmits the following ASCII string: $aazckckCR

where: z....................... command of weight zero-setting (122 ASCII)

Possible instrument responses:

-correct reception: &aaxxxxxxt\ckckCR

-incorrect reception: &&aa?\ckckCR

-the gross weight is not displayed on the instrument: &aa#CR

where: xxxxxx ............. 6 characters to indicate the required weight value

t....................... character to indicate the weight (116 ASCII)

Example: zeroing the weight of the instrument with address 2:

For the calibration you have to make sure that the system is unloaded or that the instrument measures a

signal equal to the mV in the same situation:

query: $02z78(Cr)

response: &02000000t\76(Cr)

T1 Protocol Manual

Zemic Europe B.V. T: +31 76 50 39480

Leerlooierstraat 8 Nr. 2018.11 T1 Protocol Manual Rev1 F: +31 76 50 39481

4871 EN Etten-Leur info@top-sensors.nl

The Netherlands 11/75 http://www.top-sensors.com

Specifications and dimensions are subject to change without notice and do not constitute any liability whatsoever.

If the zeroing works correctly the instrument sends the zeroed weight value (“000000”).

The calibration values are stored permanently in the EEPROM memory and the number of

allowed writings is limited (about 100000).

8. REAL CALIBRATION (WITH SAMPLE WEIGHT)

After the tare zero-setting, this function allow the operator to check the calibration obtained by using

sample weights and correct automatically any change between the displayed value and the correct

one.

Load onto the weighing system a sample weight, which must be at least 50% of the Full Scale, or make so

that that the instrument measures a corresponding mV signal.

The PC transmits the following ASCII string: $aasxxxxxxckckCR

where: s....................... calibration command (115 ASCII)

xxxxxx ............. 6 characters to indicate the value of sample weight

Possible instrument responses:

-correct reception: &aaxxxxxxt\ckckCR

-incorrect reception or full scale equal to zero: &&aa?\ckckCR

where: t....................... character of gross weight identification (116 ASCII)

xxxxxx ............. 6 characters to indicate the value of current weight

In case of correct reception, the read value has to be equal to the sample weight.

Example: calibration of the instrument no. 1 with a sample weight of 20000 kg:

query: $01s02000070(Cr)

response: &01020000t\77(Cr)

In case of correct calibration, the read value has to be “020000”.

9. KEYPAD LOCK (BLOCK THE ACCESS TO THE INSTRUMENT)

The PC transmits the following ASCII string: $aaKEYckckCR

Possible instrument responses:

-correct reception: &&aa!\ckckCR

-incorrect reception: &&aa?\ckckCR

T1 Protocol Manual

Zemic Europe B.V. T: +31 76 50 39480

Leerlooierstraat 8 Nr. 2018.11 T1 Protocol Manual Rev1 F: +31 76 50 39481

4871 EN Etten-Leur info@top-sensors.nl

The Netherlands 12/75 http://www.top-sensors.com

Specifications and dimensions are subject to change without notice and do not constitute any liability whatsoever.

10. KEYPAD UNLOCK

The PC transmits the following ASCII string: $aaFREckckCR

Possible instrument responses:

-correct reception: &&aa!\ckckCR

-incorrect reception: &&aa?\ckckCR

11. DISPLAY AND KEYPAD LOCK

The PC transmits the following ASCII string: $aaKDISckckCR

Possible instrument responses:

-correct reception: &&aa!\ckckCR

-incorrect reception: &&aa?\ckckCR

12. CHECK-SUM CALCULATION

The two ASCII characters (ckck) are the representation of a hexadecimal digit in ASCII characters. The

check digit is calculated by executing the operation of XOR (exclusive OR) of 8-bit ASCII codes of only the

string underlined.

The procedure to perform the calculation of check-sum is the following:

-Consider only the string characters highlighted with underlining

-Calculate the exclusive OR (XOR) of 8-bit ASCII codes of the characters

Example:

character

decimal ASCII code

hexadecimal ASCII code

binary ASCII code

0

1

t

48

49

116

30

31

74

00110000

00110001

01110100

XOR =

117

75

01110101

-The result of the XOR operation expressed in hexadecimal notation is made up of 2 hexadecimal digit

(that is, numbers from 0 to 9 or letters from A to F). In this case the hexadecimal code is 0x75.

-The checksum is made up of the 2 characters that represent the result of the operation and XOR in

hexadecimal notation (in our example the character "7" and the character "5").

T1 Protocol Manual

Zemic Europe B.V. T: +31 76 50 39480

Leerlooierstraat 8 Nr. 2018.11 T1 Protocol Manual Rev1 F: +31 76 50 39481

4871 EN Etten-Leur info@top-sensors.nl

The Netherlands 13/75 http://www.top-sensors.com

Specifications and dimensions are subject to change without notice and do not constitute any liability whatsoever.

MODBUS-RTU PROTOCOL

The MODBUS-RTU protocol allows the management of the reading and writing of the following registries

according to the specifications found on the reference document for this Modicon PI-MBUS-300

standard.

To select the MODBUS-RTU communication see SERIAL COMMUNICATION SETTINGS section in

instrument manual.

Check if the Master MODBUS-RTU in use (or the development tool) requires the disclosure of registers

based on 40001 or 0. In the first case the registers numbering corresponds to the one in the table; in the

second case the register must be determined as the value in the table minus 40001. E.g.: the register

40028 shall be reported as 27 (= 40028-40001).

Certain data, when specifically indicated, will be written directly in the EEPROM type memory. This

memory has a limited number of writing operations (100000), therefore it is necessary to pay particular

attention to not execute useless operations on said locations. The instrument in any case makes sure that

no writing occurs if the value to be memorised is equal to the value in memory.

The numerical data found below are expressed in decimal notation; if the prefix 0x is entered the

notation will be hexadecimal.

MODBUS-RTU DATA FORMAT

The data received and transmitted by way of the MODBUS-RTU protocol have the following

characteristics:

-1 start bit

-8 bit of data, least significant bit sent first

-Settable parity bit

-Settable stop bit

FUNCTIONS SUPPORTED IN MODBUS

Among the commands available in the MODBUS-RTU protocol, only the following are utilised for

management of communication with the instruments; other commands could be incorrectly interpreted

and generate errors or blocks of the system:

FUNCTIONS

DESCRIPTION

03 (0x03)

READ HOLDING REGISTER (READ PROGRAMMABLE REGISTERS)

16 (0x10)

PRESET MULTIPLE REGISTERS (WRITE MULTIPLE REGISTERS)

T1 Protocol Manual

Zemic Europe B.V. T: +31 76 50 39480

Leerlooierstraat 8 Nr. 2018.11 T1 Protocol Manual Rev1 F: +31 76 50 39481

4871 EN Etten-Leur info@top-sensors.nl

The Netherlands 14/75 http://www.top-sensors.com

Specifications and dimensions are subject to change without notice and do not constitute any liability whatsoever.

Interrogation frequency is linked to the communication speed set (the instrument stands by for at least 3

bytes before starting calculations an eventual response to the interrogation query). The parameter

present in the SERIAL COMMUNICATION SETTING section in the instrument manual, allows the

instrument to respond with a further delay and this directly influences the number of interrogations

possible in the unit of time.

For additional information on this protocol refer to the general technical specifications PI_MBUS_300.

In general queries and answers toward and from one slave instrument are composed as follows:

FUNCTION 3: Read holding registers (READ PROGRAMMABLE REGISTERS)

QUERY

Address

Function

1st register address

No. registers

2 byte

A

0x03

0x0000

0x0002

CRC

Tot. byte = 8

RESPONSE

Address

Function

No. bytes

1st register

2nd register

2 byte

A

0x03

0x04

0x0064

0x00C8

CRC

Tot. byte = 3+2*No. registers+2

where: No. registers ..... number of Modbus registers to write beginning from the address no. 1

No. byte........... number of bytes of the following data

FUNCTION 16: Preset multiple registers (WRITE MULTIPLE REGISTERS)

QUERY

Address

Function

1st reg. add.

No. reg.

No. bytes

Val.reg.1

Val.reg.2

2 byte

A

0x10

0x0000

0x0002

0x04

0x0000

0x0000

CRC

Tot. byte = 7+2*No. registers+2

RESPONSE

Address

Function

1st reg. address

No. reg.

2 byte

A

0x10

0x0000

0x0002

CRC

Tot. byte = 8

where: No. registers ..... number of Modbus registers to read beginning from the address no. 1

No. byte........... number of bytes of the following data

Val.reg.1.......... Contents of the register beginning from the first

The response contains the number of registers modified beginning from the address no. 1.

T1 Protocol Manual

Zemic Europe B.V. T: +31 76 50 39480

Leerlooierstraat 8 Nr. 2018.11 T1 Protocol Manual Rev1 F: +31 76 50 39481

4871 EN Etten-Leur info@top-sensors.nl

The Netherlands 15/75 http://www.top-sensors.com

Specifications and dimensions are subject to change without notice and do not constitute any liability whatsoever.

COMMUNICATION ERROR MANAGEMENT

The communication strings are controlled by way of the CRC (Cyclical Redundancy Check).

In case of communication error the slave will not respond with any string. The master must consider a

time-out for reception of the answer. If it does not receive an answer it deduces that there has been a

communication error.

In the case of the string received correctly but not executable, the slave responds with an EXCEPTIONAL

RESPONSE. The "Function" field is transmitted with the msb at 1.

EXCEPTIONAL RESPONSE

Address

Function

Code

2 byte

A

Funct + 0x80

CRC

CODE

DESCRIPTION

1

ILLEGAL FUNCTION (The function is not valid or is not supported)

2

ILLEGAL DATA ADDRESS (The specified data address is not available)

3

ILLEGAL DATA VALUE (The data received has an invalid value)

LIST OF AVAILABLE REGISTERS

The MODBUS-RTU protocol implemented on this instrument can manage a maximum of 32 registers

read and written in a single query or response.

R.....................the register may only be read

W..................... the register may only be written

R/W................. the register may be both read and written

H...................... high half of the DOUBLE WORD containing the number

L....................... low half of the DOUBLE WORD containing the number

T1 Protocol Manual

Zemic Europe B.V. T: +31 76 50 39480

Leerlooierstraat 8 Nr. 2018.11 T1 Protocol Manual Rev1 F: +31 76 50 39481

4871 EN Etten-Leur info@top-sensors.nl

The Netherlands 16/75 http://www.top-sensors.com

Specifications and dimensions are subject to change without notice and do not constitute any liability whatsoever.

Register

Description

Saving in EEPROM

Access

40001

Firmware Version

-

R

40002

Instrument type

-

R

40003

Year of manufacture

-

R

40004

Serial Number

-

R

40005

Program type

-

R

40006

COMMAND REGISTER

NO

W

40007

STATUS REGISTER

-

R

40008

GROSS WEIGHT H

-

R

40009

GROSS WEIGHT L

-

R

40010

NET WEIGHT H

-

R

40011

NET WEIGHT L

-

R

40012

PEAK WEIGHT H

-

R

40013

PEAK WEIGHT L

-

R

40014

Divisions and Units of measure

-

R

40015

Coefficient H

-

R

40016

Coefficient L

-

R

40017

SETPOINT 1 H

Only after command 99

of the “Command Register”

R/W

40018

SETPOINT 1 L

R/W

40019

SETPOINT 2 H

R/W

40020

SETPOINT 2 L

R/W

40021

SETPOINT 3 H

R/W

40022

SETPOINT 3 L

R/W

40023

HYSTERESIS 1 H

R/W

40024

HYSTERESIS 1 L

R/W

40025

HYSTERESIS 2 H

R/W

40026

HYSTERESIS 2 L

R/W

40027

HYSTERESIS 3 H

R/W

40028

HYSTERESIS 3 L

R/W

40029

INPUTS

-

R

40030

OUTPUTS

NO

R/W

40037

Sample weight for instrument calibration

H

Use with command 101 of

the “Command Register”

R/W

40038

Sample weight for instrument calibration

L

R/W

T1 Protocol Manual

Zemic Europe B.V. T: +31 76 50 39480

Leerlooierstraat 8 Nr. 2018.11 T1 Protocol Manual Rev1 F: +31 76 50 39481

4871 EN Etten-Leur info@top-sensors.nl

The Netherlands 17/75 http://www.top-sensors.com

Specifications and dimensions are subject to change without notice and do not constitute any liability whatsoever.

40043

Weight value corresponding to ZERO of

the analog output H

Only after command 99

of the “Command Register”

R/W

40044

Weight value corresponding to ZERO of

the analog output L

R/W

40045

Weight value corresponding to the Full

Scale of the analog output H

R/W

40046

Weight value corresponding to the Full

Scale of the analog output L

R/W

40073

Preset Tare H

Use with command 130 of

the “Command Register”

R/W

40074

Preset Tare L

R/W

WARNING: at the time of writing, setpoints and hysteresis values are saved to RAM (they will be lost

upon the next power-off); to store them permanently to EEPROM so that they are maintained at power-

on, the 99 command of the Command Register must be sent.

STATUS REGISTER (40007)

Bit 0

Load cell error

Bit 1

AD convertor malfunction

Bit 2

Maximum weight exceeded by 9 divisions

Bit 3

Gross weight higher than 110% of full scale

Bit 4

Gross weight beyond 999999 or less than -999999

Bit 5

Net weight beyond 999999 or less than -999999

Bit 6

Bit 7

Gross weight negative sign

Bit 8

Net weight negative sign

Bit 9

Peak weight negative sign

Bit 10

Net display mode

Bit 11

Weight stability

Bit 12

Weight within ±¼ of a division around ZERO

Bit 13

Bit 14

Bit 15

T1 Protocol Manual

Zemic Europe B.V. T: +31 76 50 39480

Leerlooierstraat 8 Nr. 2018.11 T1 Protocol Manual Rev1 F: +31 76 50 39481

4871 EN Etten-Leur info@top-sensors.nl

The Netherlands 18/75 http://www.top-sensors.com

Specifications and dimensions are subject to change without notice and do not constitute any liability whatsoever.

INPUTS REGISTER (40029)

(read only)

OUTPUTS REGISTER (40030)

(read/write)

Bit 0

INPUT 1 status

Bit 0

OUTPUT 1 status

Bit 1

INPUT 2 status

Bit 1

OUTPUT 2 status

Bit 2

Bit 2

OUTPUT 3 status 3

Bit 3

Bit 3

Bit 4

Bit 4

Bit 5

Bit 5

Bit 6

Bit 6

Bit 7

Bit 7

Bit 8

Bit 8

Bit 9

Bit 9

Bit 10

Bit 10

Bit 11

Bit 11

Bit 12

Bit 12

Bit 13

Bit 13

Bit 14

Bit 14

Bit 15

Bit 15

The output status can be read at any time but can be set (written) only if the output has

been set as (see section OUTPUTS AND INPUTS CONFIGURATION); otherwise, the

outputs will be managed according to the current weight status with respect to the relevant

setpoint.

T1 Protocol Manual

Zemic Europe B.V. T: +31 76 50 39480

Leerlooierstraat 8 Nr. 2018.11 T1 Protocol Manual Rev1 F: +31 76 50 39481

4871 EN Etten-Leur info@top-sensors.nl

The Netherlands 19/75 http://www.top-sensors.com

Specifications and dimensions are subject to change without notice and do not constitute any liability whatsoever.

DIVISION AND UNITS OF MEASURE REGISTER (40014)

This register contains the current setting of the divisions (parameter ) and of the units of measure

(parameter ).

H Byte

L Byte

Unit of measure

Division

Use this register together with the Coefficient registers to calculate the value displayed by the

instrument.

Least significant byte (L Byte)

Most significant byte (H Byte)

Division

value

Divisor

Decimals

Unit of

measure

value

Unit of measure

description

Utilisation of the

coefficient with the

different units of

measure settings

compared to the gross

weight detected

0

100

0

0

Kilograms

No active

1

50

0

1

Grams

No active

2

20

0

2

Tons

No active

3

10

0

3

Pounds

No active

4

5

0

4

Newton

Multiplies

5

2

0

5

Litres

Divides

6

1

0

6

Bar

Multiplies

7

0.5

1

7

Atmospheres

Multiplies

8

0.2

1

8

Pieces

Divides

9

0.1

1

9

Newton Metres

Multiplies

10

0.05

2

10

Kilogram Metres

Multiplies

11

0.02

2

11

Other

Multiplies

12

0.01

2

13

0.005

3

14

0.002

3

15

0.001

3

16

0.0005

4

17

0.0002

4

18

0.0001

4

T1 Protocol Manual

Zemic Europe B.V. T: +31 76 50 39480

Leerlooierstraat 8 Nr. 2018.11 T1 Protocol Manual Rev1 F: +31 76 50 39481

4871 EN Etten-Leur info@top-sensors.nl

The Netherlands 20/75 http://www.top-sensors.com

Specifications and dimensions are subject to change without notice and do not constitute any liability whatsoever.

POSSIBLE COMMANDS TO BE SENT TO THE COMMAND REGISTER (40006)

0

No command

1

6

7

SEMI-AUTOMATIC TARE enabling

(net weight displaying)

8

SEMI-AUTOMATIC ZERO

9

SEMI-AUTOMATIC TARE disabling (gross

weight displaying)

20

21

Keypad lock

22

Keypad and display unlock

23

Keypad and display lock

98

99

Saving data in EEPROM

100

TARE WEIGHT ZERO SETTING for

calibration

101

Sample weight storage for calibration

130

Preset Tare enabling

131

Reserved

ANALOG OUTPUT SETTING

Write the weight into registers “Weight value corresponding to the Full Scale of the analog output H”

(40045) and “Weight value corresponding to the Full Scale of the analog output L” (40046), otherwise

write the weight into registers “Weight value corresponding to ZERO of the analog output H” (40043) and

“Weight value corresponding to ZERO of the analog output L” (40044). Once the value has been written,

save it to EEPROM by sending command 99 from Command Register.

REAL CALIBRATION COMMANDS (WITH SAMPLE WEIGHTS)

-Unload the system and reset to zero the displayed weight value with the command 100 “TARE WEIGHT

ZERO SETTING for calibration” of the Command Register.

-Load a sample weight on the system and send its value to the registers 40037-40038.

-To save the value send the command 101 “Sample weight storage for calibration” to the Command

Register.

If the operation is successfully completed, the two sample weight registers are set to zero.

In order to correctly set the sample weight, consider the value of the Division register (40014).

Example: to set the sample weight to 100 kg and the division is 0.001, then the value to enter is

100000 (100 / 0.001 = 100000).

Table of contents

Popular Accessories manuals by other brands

La Crosse Technology

La Crosse Technology Breeze Pro LTV-WSDTH03 quick start guide

SICK

SICK GR18 Series operating instructions

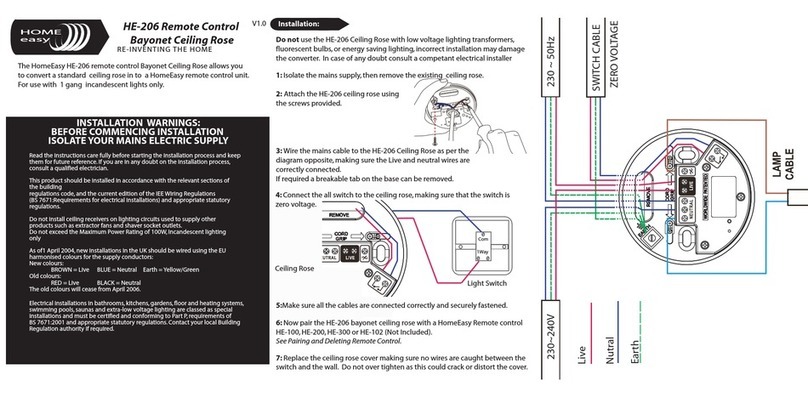

Byron

Byron Home Easy HE-206 installation instructions

Cohero Health

Cohero Health cSpirometer Instructions for use

Ednet

Ednet 8000 Quick installation guide

Frigidaire

Frigidaire FFBC4622QS use & care