Toplicht BLAKES LAVAC Zenith User manual

Notkestraße 97 · 22607 Hamburg

LAVAC Marine Toilets

Manual

TOPLICHT 20.August 2019

Contents

Introduction/Installation kit 2

Lavac System 3

Zenith Exploded Diagram 4

Parts list, Accessories & specification 5

Popular Exploded Diagram 6

Parts list, Accessories & specification 7

Manual Pump Exploded diagram 8

Parts list, Accessories & specification 9

Electric Pump Exploded diagram 10

Parts list, Accessories & specification 11

Zenith and Popular Spares kits 12

Lavac Operation diagrams 13

Installation

Seacocks 14

Lavac toilets 15

Electric pump 17

Holding Tanks

General 18

Lavac 19

Plumbing 20

Accessories 22

Operating your marine toilet 23

Lavac Maintenance 24

Replacing perishable parts 25

Operational solutions 27

LAVAC marine toilets

Tel.: +49 (0)40 - 88 90 100

www.toplicht.de

Schisausrüster

2

The Lavac

Congratulations on the purchase of a Lavac

marine toilet. Lavac marine toilets are firm

favourites with sailors throughout the world,

providing their owner with a long and trou-

ble free working life.

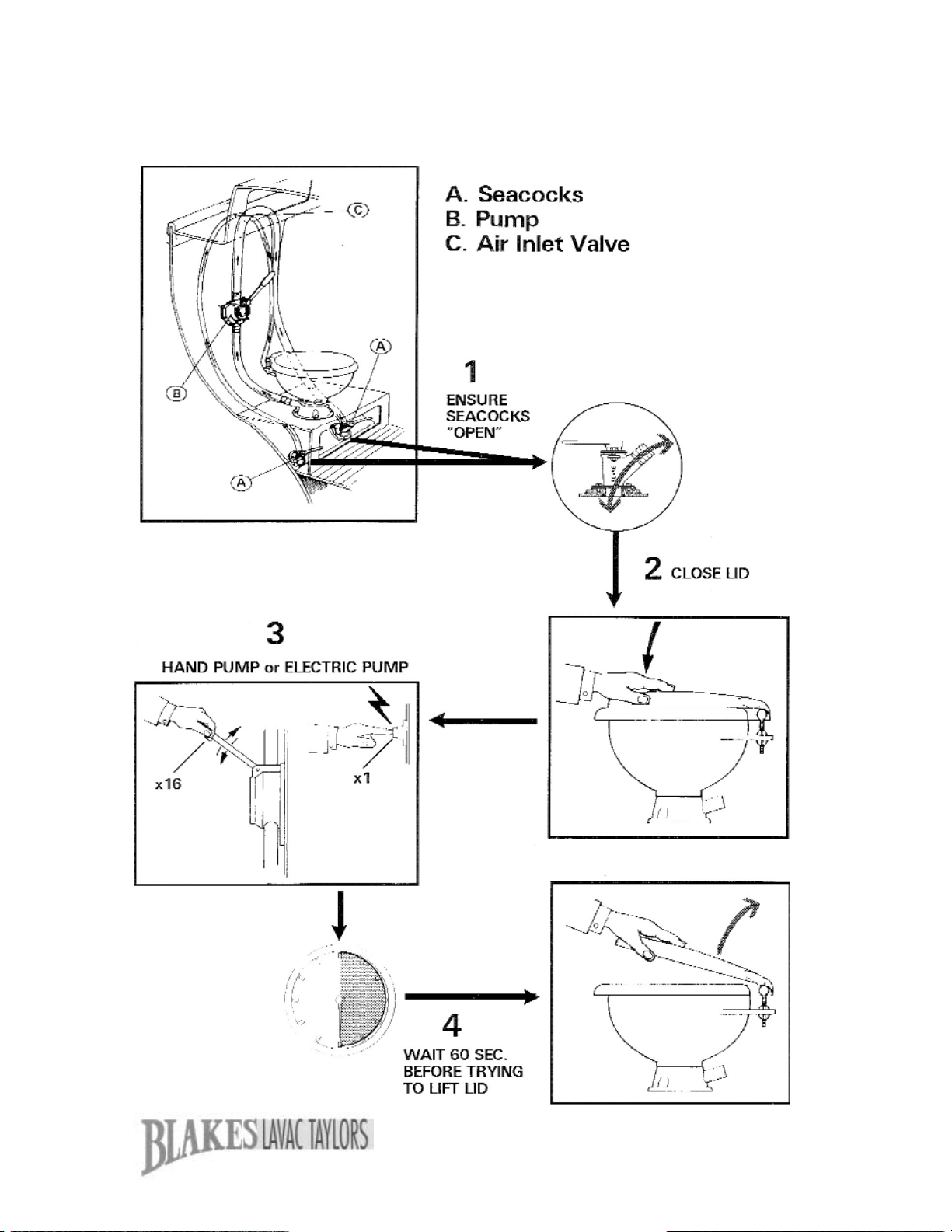

The Lavac is one of the most simple to

operate marine toilets available. After use,

the seat and lid are closed and the pump is

then operated for 14-16 strokes (For full

instructions see page 21). As waste is

pumped out, the bowl is sealed causing a

vacuum which draws in the flushing water.

It’s as simple as that!

Within this handbook you will find informa-

tion and practical help on installing, running

and maintaining your Lavac. If you require

any further help or advice, please contact

us either by:

Telephone: +44 (0)1489 580580

Fax: +44 (0)1489 580581

E-mail: info@blakes-lavac-taylors.co.uk

or by writing to:

Blakes Lavac Taylors

13 Harvey Crescent

Warsash

Southampton

SO31 9TA

United Kingdom

Over many years we have taken advice from

sailors around the world concerning their

requirements for marine equipment and our

current range is a result of this ongoing com-

mitment. If you have any comments or help-

ful hints that you would like to share with us,

we would be very pleased to hear from you.

Installation kit provided with your lavac

All Lavac marine toilets are provided wit the

following parts for installation.

zPump – Hand (T/A: On Bulkhead; U/D:

Behind Bulkhead) or Electric (12 volt DC

or 24 volt DC, including wiring loom, time

switch, fuse and fuse holder)

zPlastic Bleed Plugs (Spares No.

TLZ9251)

zSelf adhesive operating instructions

zOwners Handbook.

Because the nature of an installation varies

from owner to owner, certain components

are easier to source locally. We therefore

feel it is best for you to purchase the follow-

ing separately, depending on your require-

ments.

z4 x 6mm (¼“) diameter Stainless Steel

securing bolts or screws for base

z4 x 6mm (¼“) diameter Stainless Steel

securing bolts or screws for pump

zReinforced sanitation grade hose –

length dependant on installation:

19mm (¾“) bore for inlet

38mm (1½“)bore hose for outlet

zHose clips

3

The Lavac System

General

The well known Lavac system is unique

and probably the only single action, above

or below water line, marine WC.

The Lavac has a china pan and is available

as either hand or electrically operated. On

the electric models 12 or 24V DC can be

supplied.

To flush simply close the lid and operate a

single pump. Pressure is reduced in the

bowl as waste goes out and flushing water

is drawn in. A small air bleed valve in the

inlet pipe prevents siphoning.

The particularly hygienic operation and

quietness are characteristics which in

themselves make Lavac a popular choice

for discerning owners. Simplicity of opera-

tion, robustness and reliability are further

important features.

By using a diverter valve the Lavac’s pump

can also be used for other pumping opera-

tions, such as shower tray discharge, bilge

pumping or discharge of the holding tank

(see page 20).

Because legislation is now prohibiting over-

board discharge from toilets, or at least

making it impractical, this edition of the

Lavac owners handbook now gives guid-

ance on holding tanks (see pages 18).

Features

zEasy and versatile in installation.

zCan be mounted under bunk or locker

and pulled out for use.

zPump, separate from bowl, can be

mounted in most convenient position

(above bowl consistent with instructions).

For installation behind bulkhead, a spe-

cial hand pump option is available (see

illustration on p.9).

zParticularly quiet and hygienic in opera-

tion.

zPump can also empty holding tanks, be

used as a bilge pump and/or shower

tray discharge pump.

zAny type of paper can be used,

although tissue is recommended.

zVirtually no maintenance.

zQuick release pump cover for easy

access.

zSingle action operation.

zExceptionally sturdy and durable.

zFull flow valve system.

zLow water usage.

zRemote holding tank installation (if cho-

sen).

zA water seal is the only certain and

complete way of preventing odour from

the waste pipe and/or holding tank.

Electric – Extra Features

zOnly marine toilet to offer manual back-

up with electric version

(see page 17).

zExtremely quiet in operation.

zFully marinised, automatic, adjustable

time switch

4

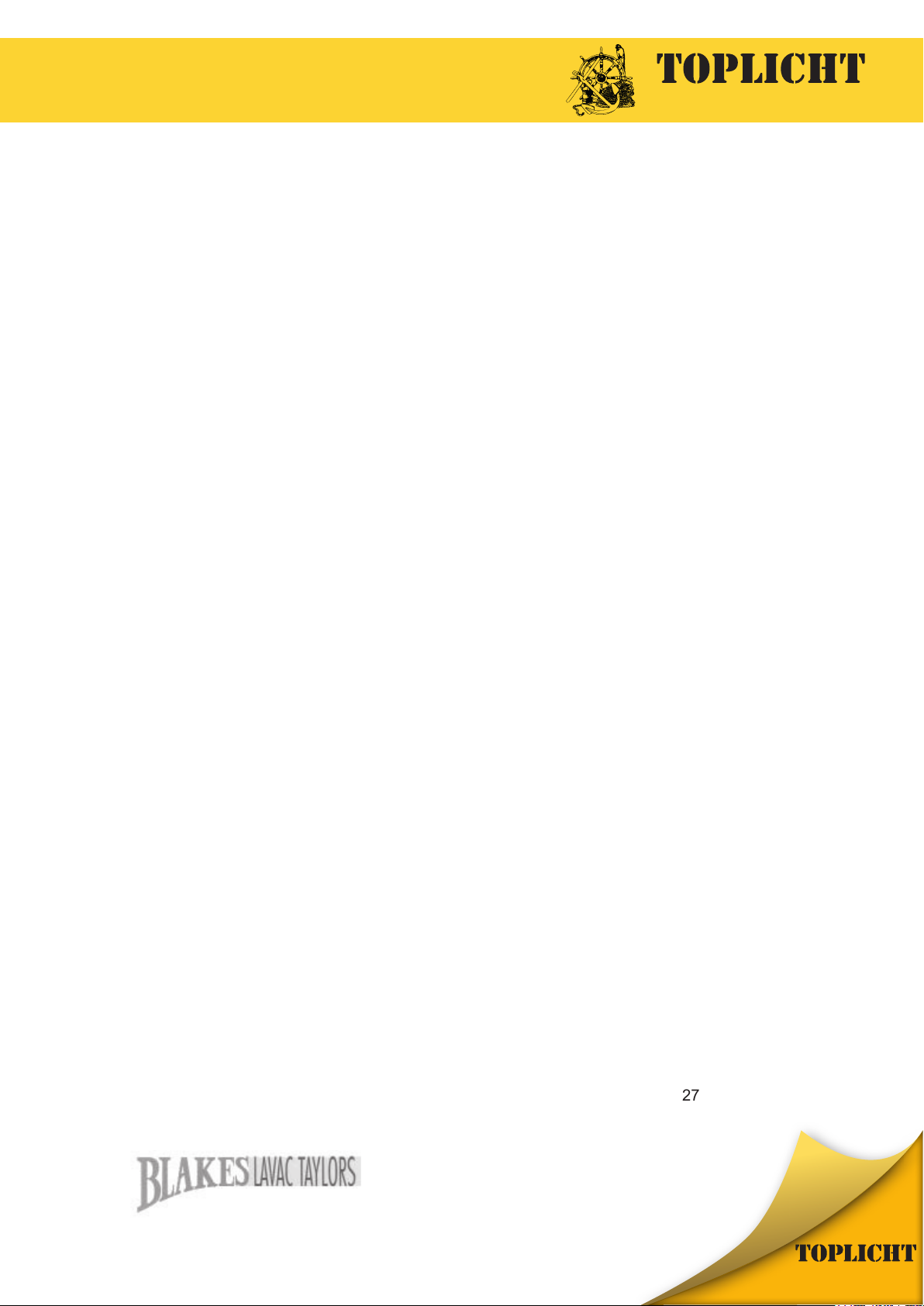

Exploded diagram of the Lavac Zenith

PRODUCT UPDATE

New Thermo-set seal (11) introduced July 1993

with no joins or weld points. Cross-section

below showing longer sealing lip conforms bet-

ter to contact surface (seat or bowl) for

improved vacuum.

PRODUCT UPDATE

New white rubber washer for dome nut.

5

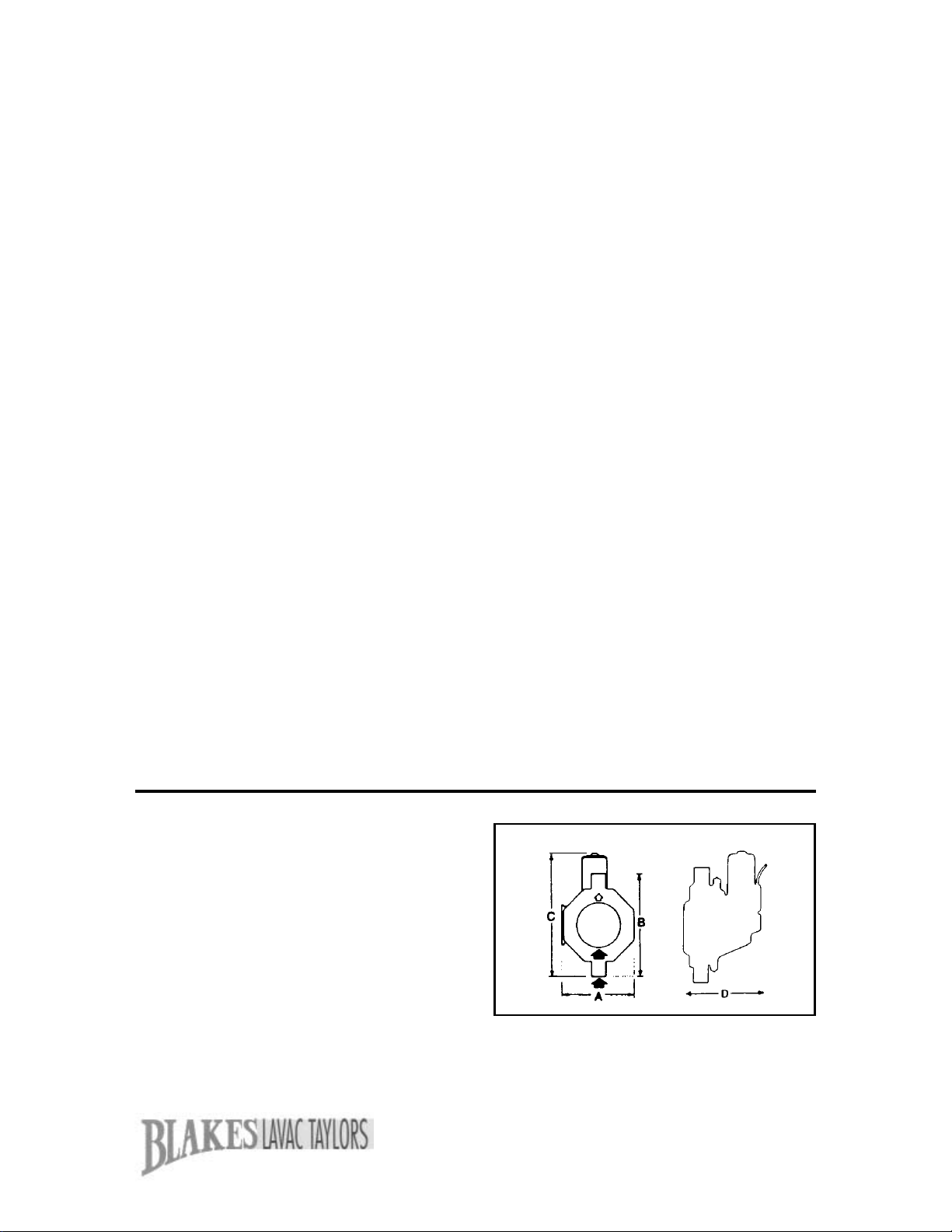

Dimensions and specifications

Lavac Zenith toilet

zBowl – vitreous china for easy

cleaning and durability

zPedestal – injection mould uPVC.

Outlet can be set to either side or rear

of toilet.

zSeat and Lid – special purpose

plastic mouldings.

zHinge assembly – injection moulded

acetal. Stainless steel hinge pin.

zToilet connections –

Inlet 19mm (¾“) bore hose.

Discharge 38mm (1½“) bore hose.

Dimensions:

A - 185mm (7.3”) C - 368mm (14.5”)

B - 290mm (11.4”) D - 410mm (16.2”)

Lavac Zenith

Zenith Components

Diagram No Part No Description

1 TBB7215 x 4 M6 Nuts

2 TLZ9021 x 4 Pan bolt washers - small

TLZ9022 x 4 Pan bolt washers - large

3 TLZ9022 x 4 M6 x 35 Pan bolt

4 TLZ9005 Pedestral base

5 TLZ9010 Pan base joint

6, 7, 8, 9 TLZ9031 Spigot assembly

10 TLZ9025 Zenith pan

11 TLZ9065 x 2 Seals for seat and lid

12 TLZ9070 Zenith seat

13 TLZ9075 Zenith lid

14 TLZ9405 Zenith hinge pin

15(x2), 16(x2) TLZ9056 Hinge set

17(x4), 17a(x2)

Lavac Zenith - Accessories

Part No Description

TLZ9096 Clip for pump handle (38)

TLZ9310 Diverter (two-way) valve

TLZ9460 Bulkhead plate and shroud for U/D pump

6

Exploded diagram of the Lavac Popular

7

Dimensions and specifications

Lavac Popular toilet

zBowl – vitreous china for easy

cleaning and durability

zPedestal – injection mould uPVC.

Outlet can be set to either side or rear

of toilet.

zSeat and Lid – special purpose

plastic mouldings.

zHinge assembly – injection moulded

acetal.

zToilet connections –

Inlet 19mm (¾“) bore hose.

Discharge 38mm (1½“) bore hose.

Dimensions:

A - 185mm (7.3”) C - 343mm (13.5”)

B - 352mm (13.9”) D - 416mm (16.4”)

Lavac Popular

Popular Components

Diagram No Part No Description

4 TLZ9005 Pedestal base

5 TLZ9010 Pan base joint

51 TLZ8015 x 4 M6 x 50 Pan bolt

TLZ8010 x 4 Plastic covers

TLZ8022 x 4 Plastic washer

TLZ8021 x 4 Stainless steel washer

TLZ8020 x 4 M6 nuts

52 TLZ8025 Popular pan

53 TLZ8031 Popular inlet spigot

54L, 54R. 55(x2) TLZ8056 Hinge set

56 TLZ8065 Popular seat seal

57 TLZ8066 Popular lid seal

58 TLZ8070 Popular seat

59 TLZ8075 Popular lid

Lavac Popular - Accessories

Part No Description

TLZ9096 Clip for pump handle (38)

TLZ9310 Diverter (two-way) valve

TLZ9460 Bulkhead plate and shroud for U/D pump

8

Note:

Bulkhead plate and shroud for the

U/D pump (makes a neat, flush

installation – Spares No: TLZ9460,

see installation diagram on p.15).

U/D Pump

Handle Position T/A Pump

Handle Position

Exploded diagram of Hand Pump

9

Dimensions and specifications

Hand Pump

zDiaphragm type

zInjection moulded plastic body

zStainless steel fastenings and handle

zAll rubber components of oil resistant

nitrile

Lavac Zenith & Popular Hand Pump

Components

Diagram No Part No Description

20 TLZ9110 Diaphragm

21 TLZ9175 x 8 2BA x 1” Bolts

TLZ9181 x 8 2BA nuts

22H TLZ9330 Inlet valve - hand

TLZ9335 Inlet valve plate

23 TLZ9320 Front cover

24 TLZ9325 Front cover seal

25 TLZ9125 Eye bolt nut

26 TLZ9100 Top cover complete with valves

27 TLZ9340 Outlet valve

28 TLZ9345 x 2 Outlet valve screws - long

TLZ9350 x 2 Outlet valve screws - short

29 TLZ9115 x 2 Diaphragm plates

30 TLZ9120 Eye bolt

35 N/A Not available as spares item

36 TLZ9406 Rocker arm hinge pin

TLZ9408 x 2 Circlips (rocker arm pin)

37 TLZ9450 U/D Rocker arm

38 TLZ9265 Pump handle

39 TLZ9455 T/A Rocker arm

Hand pump

Dimensions:

A - 170mm (6.6”) C - 140mm (5.5”)

B - 200mm (7.9”)

10

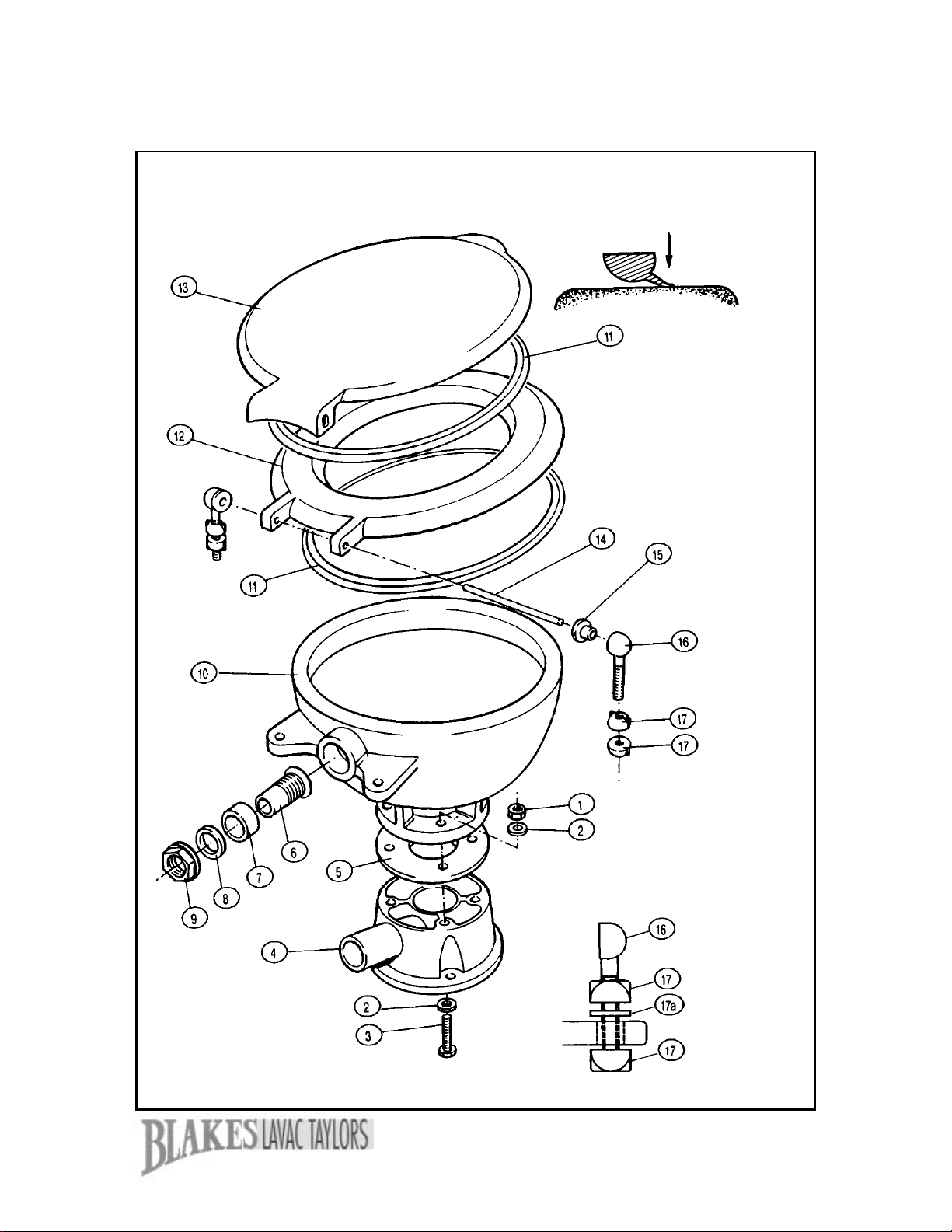

Exploded diagram of the electric pump – 12&24 Volt

11

Dimensions and specifications

Electric pump

zDiaphragm type 12V or 24V DC

zInjection moulded plastic body

zAlloy crancase

zStainless steel crank mechanism with

plain bearing

zConsumption 5 amps at 12v under

load. - 5 amp fuse supplied

zWeight 4Kg

zFlow / delivery rate 6 gal per min

Lavac Zenith & Popular Electric Pump

Components

Diagram No Part No Description

20 TLZ9110 Diaphragm

21 TLZ9175 x 8 2BA x 1” Bolts

TLZ9181 x 8 2BA nuts

22H TLZ9330 Inlet valve - hand

TLZ9335 Inlet valve plate

23 TLZ9320 Front cover

24 TLZ9325 Front cover seal

25 TLZ9125 Eye bolt nut

26 TLZ9100 Top cover complete with valves

27 TLZ9340 Outlet valve

28 TLZ9345 x 2 Outlet valve screws - long

TLZ9350 x 2 Outlet valve screws - short

29 TLZ9115 x 2 Diaphragm plates

30 TLZ9120 Eye bolt

33 TLZ9421 Crank assembly

60 TLZ9290 12V Motor

TLZ9295 24V Motor

61 TLZ9185 x 4 M5 x 22mm bolts

62 TLZ9156 Crank case

Electric pump

Dimensions:

A - 178mm (7”) C - 278mm (11”)

B - 223mm (8.8”) D - 225mm (10”)

12

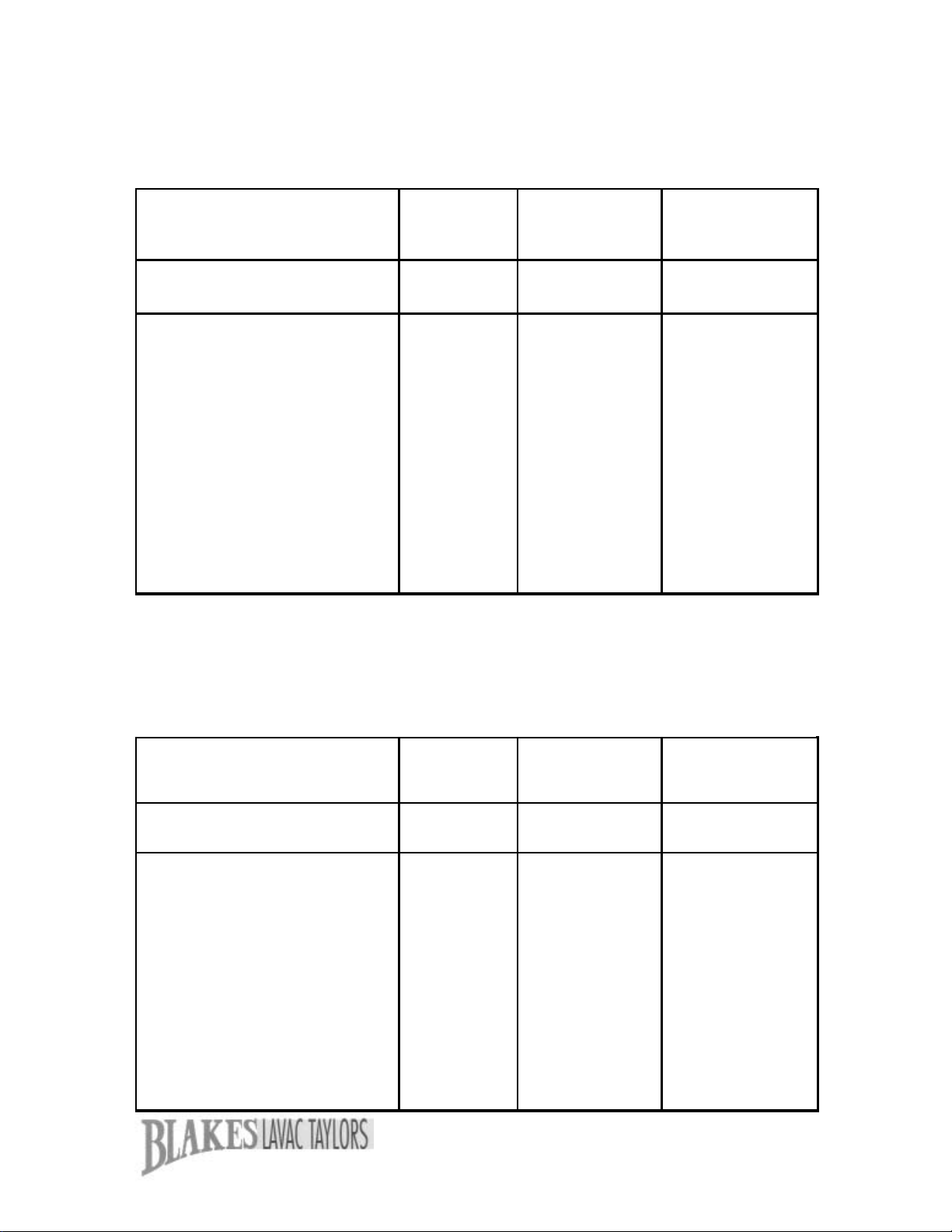

Lavac Zenith

Description Part No Hand pump kit 12 or 24V electric

pump kit

TLZ0954 TLZ0952

Hand pump spares kit

Electric pump spares kit

Pan base gasket (5)

Sealing washer for inlet spigot (7)

Rubber washer (17a)

Hinge bush (15)

Seal for seat and lid (11)

Handbook

TLZ0951

TLZ0956

TLZ9010

TLZ9035

TLZ9054

TLZ9060

TLZ9065

TLZLIT

1

-

1

1

2

2

2

1

-

1

1

1

2

2

2

1

Zenith spares kits

Lavac Popular

Description Part No Hand pump kit 12 or 24V electric

pump kit

TLZ0854 TLZ0852

Hand pump spares kit

Electric pump spares kit

Pan base gasket (5)

Hinge pad (55)

Seal for seat (56)

Seal for lid (57)

Handbook

TLZ0951

TLZ0956

TLZ9010

TLZ8061

TLZ8065

TLZ8066

TLZLIT

1

-

1

2

1

1

1

-

1

1

2

1

1

1

Popular spares kits

13

Lavac operation

14

Installation – seacocks

Siting and installing the seacocks

Having chosen the type of inlet and

discharge seacocks required for

your particular needs, they should

be mounted in the hull. We recom-

mend Blakes Seacocks for use with

our marine toilets. The inlet is

19mm (¾“) and the outlet is 38mm

(1½“).

The inlet seacock should be about

460mm (18“) below the water line

and forward of the discharge sea-

cock. On a sailing vessel, the dis-

tance below the water line may

have to be more to allow for heel-

ing. The discharge seacock should

also be below the water line but

need not be as deep as the inlet.

The location of both seacocks should

be convenient for attaching piping to

and from the toilet and easily acces-

sible for turning off. Ensure that they

are positioned to accept the hoses

before drilling the holes to accept the

fixing bolts.

Fitting the seacocks to the boat.

For fibre-glass boats (Glass

Reinforced Plastic) we recommend

the fitting of a wooden pad, bonded

to the hull, slightly greater in diame-

ter than the seacock flange and

13mm to 19mm (½“ to ¾“) thick(see

fig. 1). To ensure watertight joints on

Fig. 1

¾“ INLET SEACOCK WITH STRAINER

CHAMFER

EDGE

WOODEN

PAD

GRP

HULL

GRP hulls, a small amount of under-

water sealing compound should be

put between the inside skin and this

pad and also under the seacock

flange

For wooden hulls, ensure that

drilling is carried out in the centre of

a hull plank.

For steel hulls. (see fig. 2, the sea-

cocks must not under any circum-

stances be bolted directly onto the

hull. They should be isolated with a

gasket and studded with stainless

steel fittings. This is to prevent elec-

trolytic action.

For aluminium (alloy) hulls, special

aluminium seacocks should be used.

Plastic seacocks are often used but

are not recommended by Lloyds

because of the possibility of melting

in the event of a fire.

Seacock spigots should be cut off to

suit the outside of the hull. The inlet

seacock should be flush with the out-

side of the hull and a strainer fitted.

Similarly the discharge seacock

should protrude to enable it to take

the discharge plate.

Fig. 2

RUBBER or

NEOPRENE

STUD

STEEL HULL

PAD WELDED

TO HULL

15

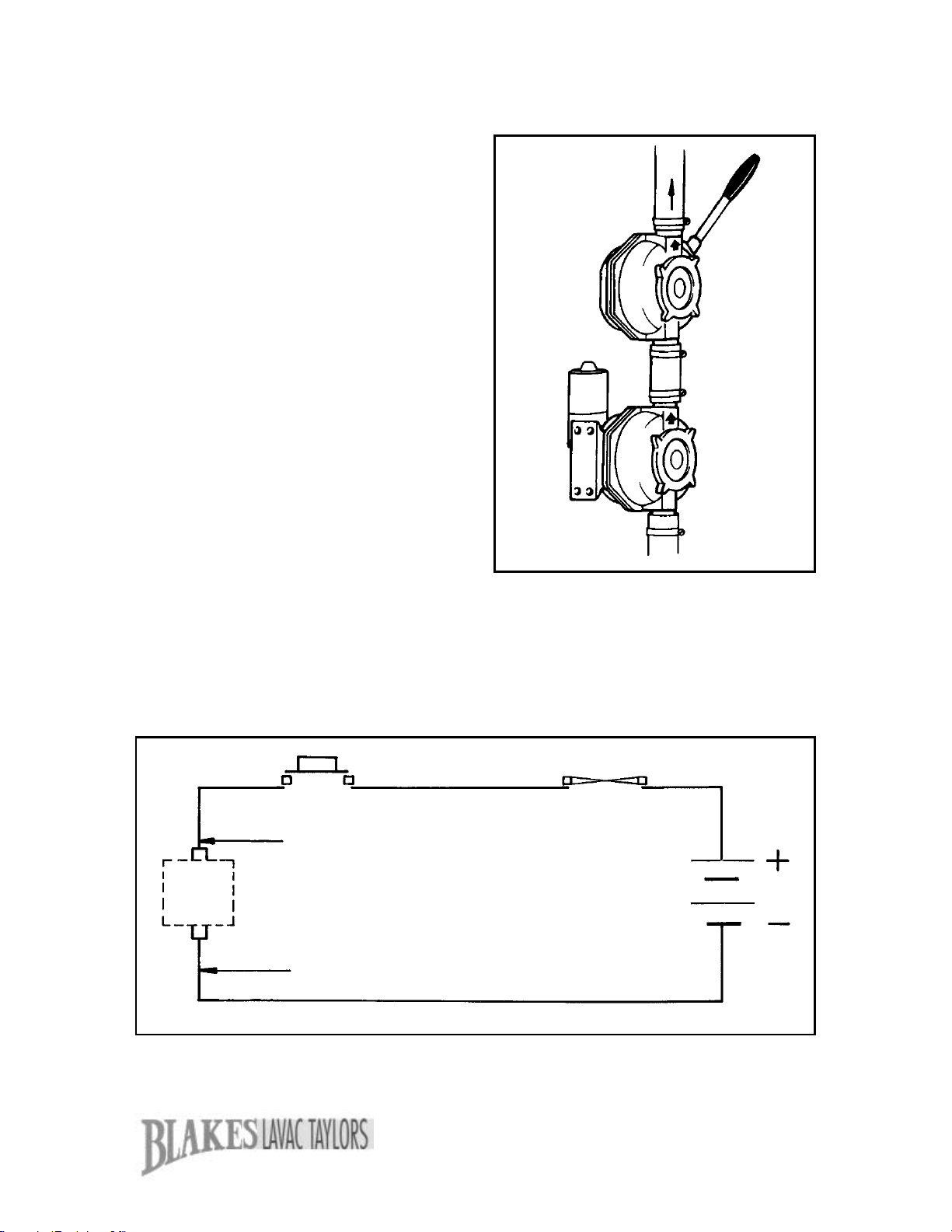

Lavac Installation

Summary

1. INLET SEACOCK

Should be mounted forward of the

discharge to avoid recirculating

waste. We recommend the use of

Blakes seacocks.

2. PUMP (Hand or Electric)

Diagram on the right shows a U/D

hand pump installation with U/D

pump plate and shroud. The pump

(hand or electric) must be mounted

so that the water flow is vertically

upwards through the pump as

shown. The bottom of the pump

must not be mounted at a lower

level than the top of the bowl.

3. AIR BLEED VALVE

A simple plastic plug with a hole

drilled into it. The plug allows air

into the system, preventing siphon-

ing and releasing the vacuum when

pumping stops. The size of the hole

in this valve controls the level of

water remaining in the bowl. Two

valves with different sized holes are

provided (Spares No. TLZ9251 –

the larger the hole, the less water

remains in the bowl.

4. DISCHARGE SEACOCK

5. BOWL

The outlet at the rear of the bowl

can be positioned to the left, right or

centre. This can be very helpful for

difficult installations.

6. U/D PUMP

Makes a neat, flush installation.

7. HANDLE CUP

Typical installation

Siting and installing the Lavac

1. The Lavac base should be

mounted on a hardwood or fibre

glass platform approximately 32mm

(¼“) thick. A template should be

used for drilling the holes necessary

in the platform.

2. Securing bolts 6mm (¼“) should

be used to hold down the toilet. Do

not fix the toilet at this point. It is

advisable to wait until the hoses are

fixed and installation checked.

3. We recommend the use of rein-

forced sanitation grade hose for the

Lavac installation. Avoid sharp

angled or acute bends in either the

16

Lavac Installation Handle position (angle of operation) and/or outlet

direction can be varied by rotating pump body

(26) relative to back cover (35) (See exploded

diagram p.8).

If back cover (35) is rotated ensure air bleed hole

in back cover is re-drilled at lowest point.

DIRECTION OF

OUTLET

therefore all hose clips must be

tight.

8. An important part of the Lavac

installation is the air bleed valve

which has to be located at the top

of the loop of the inlet pipe. Drill a

5mm (1/18”)diameter hole at the

top of the curve of the inlet pipe If

the top of the inlet pipe is in a

clothing locker, ensure that the

clothes do not obstruct the air

bleed valve. Similarly, if the hose

is hard up below the deck, drill the

hole slightly to one side at the top

of the loop. For installations on or

above the water line, insert the

white plastic bleed plug.

For installations below the water

line, use the black plastic plug.

(Set of bleed plugs TLZ9251).

9. Attach the self-adhesive oper-

ating instructions to the bulkhead

near the pump. We recommend

that a suitable rubber stop is

placed on the bulkhead behind the

Lavac unit to avoid possible dam-

age to the lid when opened.

inlet and, particularly, the outlet

hoses. If it is completely unavoid-

able to use right angled fittings in

the outlet hose, then rigid plastic fit-

tings should be used having an

inside radius of not less than 31mm

(2“). Do not use sharp angled

plumbers fittings which can easily

cause a blockage.

4. Establish a position for the pump

where the pump inlet is no lower

than the bowl top.

5. Bolt or screw the pump in posi-

tion using 6mm (¼“) diameter bolts

or screws ensuring that the flow

arrow on the pump is vertically up

or certainly not more than 45° from

the vertical.

IF THE PUMP IS MOUNTED IN

ANY OTHER WAY THE INSTALLA-

TION WILL BE INEFFICIENT IN

OPERATION AS THE INLET VALVE

CANNOT SEAL EFFECTIVELY.

6. Cut the 38mm (1½“) diameter

outlet hose to the lengths required.

Be sure to allow enough hose from

the top of the pump to take the loop

above the waterline at maximum

heel of the boat. For motor vessels

this is high enough at maximum

angle of roll. Attach the two cut

lengths of hose from the bowl to the

bottom (inlet) of the pump and from

the top of the pump (outlet) to the

outlet seacock.

7. Connect the 19mm (¾“) bore

inlet hose to the bowl inlet, having

allowed for a loop similar to the outlet

(see point 6) and attach the inlet

hose to the inlet seacock.

PEASE NOTE: It is absolutely

essential that all joints are 100%

sealed. No air leakage is permissible

17

Lavac Electric pump Installation

1. Connect up wiring as indicated in the

diagram. The time switch should be

mounted through the bulkhead so that

only the front flange with push button and

shroud are visible to the user. Use only

stainless steel screws.

2. The time switch is set for 30-45 sec-

onds. If you wish to adjust the operating

time (inlet pipe length will vary between

installations), turn the small screw in the

centre of the back of the switch very

slightly in a clockwise direction to length-

en the time and anti-clockwise to reduce

it (time switch is adjustable between

approx 1 second and 10 minutes).

3. Ensure when mounting the pump

that the flow arrows are facing upwards.

Do not mount in a horizontal position.

Also ensure that the pump is no lower

than the top of the bowl.

4. WARNING. Do not operate the

switch while using the toilet. As a precau-

tion, mount the switch in such a position

that children cannot reach it until after

use.

The Electric Lavac can be fitted with

a standby manual pump to provide

emergency back up. It is easy to

upgrade existing hand toilets to elec-

tric or add a standby pump to elec-

tric toilets.

BLACK or BLUE LEAD

RED or BROWN LEAD

TERMINAL BLOCK

ON PUMP MOTOR

12 OR 24 VOLT

BATTERY

(OR DC SUPPLY)

5 AMP FUSE

+ HOLDER

MINIMUM WIRE SIZE 30/.25 (30 STRANDS/0.25mm)

PUSH-BUTTON

TIME SWITCH

(Loom) {Black/Blue - Black/Blue}(Pump)

Red/Brown - Red/Brown

18

Holding Tanks – General

Options

Recirculating pump out – often used

for a conversion installation where

the toilet compartment is sufficiently

roomy. The holding tank is usually

integrated with the toilet head, but

with the Lavac used in a recirculat-

ing system the holding tank can be

remote.

Fresh Water Flush with Pump-Out

Holding Tank – probably the most

acceptable system to the user.

Allows for a larger tank installation,

as the tank can be positioned any-

where in relation to the toilet head.

Holding Tank Capacity

If sink and shower waste is also

being contained the holding tank

must be substantially larger. Used

with care, a shower will require

about three gallons each time it is

used. Obviously both sink and

shower waste quantities depend

entirely on how the facilities are

used, as well as the frequency of

use. The size of a holding tank is

entirely dependent on the berth/size

of the boat and anticipated duration

between pump-outs. A holding tank

can never be too large but it can

easily be inconveniently small.

Restriction on size depends on

available space for installation and

effect on the boats trim. The follow-

ing formula will provide an approxi-

mate guide to the minimum size of

tank which is acceptable:

zBerths x days between pump-out

x Y = gallons capacity of tank.

zFor recirculating systems factor Y

=0.5

zFor fresh water flush systems factor

Y = 2.5

These calculations assume low water

use toilets are being used.

Materials

If a holding tank system is being

considered, some careful thought

must be given to the design and

construction of the tank. Four

materials are commonly used for

holding tank construction,

polypropylene, glass fibre, stain-

less steel and galvanised steel.

Polypropylene – the smooth inter-

nal and external finish of this

material has the benefit of prevent-

ing matter from adhering to the

walls of the tank and at the same

time presenting a clean, trim

appearance.

Glass Fibre – provides consider-

able flexibility in design and is

easy to alter during or after instal-

lation, should the need arise.

Stainless Steel – is strong and

resistant to corrosion but is expen-

sive, in both material and con-

struction.

Galvanised Steel – provides the

cheapest solution but is not totally

corrosion resistant. Once corrosion

starts it spreads rapidly.

Flexible Tanks

Flexible tanks are very easy to

install in retrofit situations. Ideal on

craft where holding facility is sel-

dom used, but two points should

be considered carefully:

(i) If the boat is likely to encounter

much sea movement then flexible

tanks are prone to wear and chaffe

(ii)some materials, although fluid-

tight, will omit odour and a suitable

grade flexible tank must be used.

19

Holding Tanks – Lavac

Economy of Flushing Water

Economy of flushing water is a valu-

able Lavac characteristic for holding

tank installations. This is also impor-

tant when flushing water is being

drawn from the craft’s own water tank.

Using the on-board fresh water supply

for flushing should be seriously con-

sidered. It prevents scaling in the sys-

tem from salt water and dirty/oily water

entering the bowl. The Lavac uses

approximately only 3 pints of flushing

water per operation. With the electric

Lavac, the quantity of flushing water

can be controlled accurately by the

time switch. This may be helpful for

owners frequently entertaining visitors

inexperienced on boats. Two time

switches can be used if a long and

short flush option is thought worth

while.

Flexibility

Lavac provides the facility to site

tanks anywhere in the boat. Therefore,

as well as making maximum use of

the tank capacity, because of the

economy of flushing water used, the

holding tank can be housed where

space is less critical, allowing a larger

tank to be installed than is possible

with some other systems. With the

Lavac system it is practical to install a

high tank. Why not consider, for exam-

ple, a full height floor to roof bulkhead

tank? (This can be in conjunction with

either sea water or fresh water flush

systems).

Diverted Pump Action

In conjuction with a two-way valve, it

can carry out other tasks. See figs 2, 3

and 4 on pages 21 and 22. Fig. 5

shows how this saves the cost of a

separate pump and hull fitting.

Ideal for Recirculating System

Although the Lavac has ideal features

for fresh water flushing systems, in

extreme circumstances it may be pre-

ferred to minimise the holding tank

size and operate a recirculating sys-

tem. Lavac, incorporating a sealed

seat and lid to the bowl, reduces

odour considerably below levels

encountered with other recirculating

toilet systems. If the Lavac is being

used on a recirculating principle, the

flushing water pick up pipe, in the

holding tank, must be surrounded by a

fine aluminium or brass gauze filter.

Vacuum Fragments Waste

The vacuum fragments waste as it

passes through the base opening.

Solid matter will remain in suspension

in the tank, thus allowing more effi-

cient tank emptying. This eliminates

the need for a macerator. Macerators

are best avoided if possible because

their mechanically operated cutting

blades can be jammed with even small

objects. Macerators are also very

noisy!

20

Holding Tank Plumbing

Key Points

zFor all systems where pump-out

via deck fitting, or via seacock,

is not required either can be

omitted.

zIf Holding Tank is above the

waterline no pump is required

for discharge to sea, i.e. open

seacock to drain, close to hold.

(Also open seacock to allow dis-

charge to sea via the tank,

direct from toilet. Tank outlet

must be installed at bottom of

tank and fall continuously to

seacock).

zWhen inlet or Outlet Hoses are

plumbed overboard, to a below-

waterline position, they must be

looped above the waterline to

prevent siphoning (If toilet is

below the waterline).

zBall Check Valve for ¾“ bore hose

(only required if draw is more than

36“ below toilet) or vented loop

required if toilet is below waterline.

Useful statistics

zOne cubic foot contains 6 gallons.

zOne gallon contains 1/6cubic feet.

zOne gallon of water weighs 10 lbs.

Fig. 1

Suggested Systems

1 - For craft permanently on

waters where overbard discharge

is prohibited. This is a basic sys-

tem. Use of a dock side marina

pump out station is used or a DIY

outboard pump can also discharge

the holding tank.

A Toilet discharge flow

B Pump-out flow to quay

C Discharge to sea

1. Vent/breather pipe connect to 1”

ID hose

2. Microvent filter (see p.20)

3. Rinse-out facility connect to ID

hose

4. Ball check valve or vented loop.

5. Seacock

Pump-out deck fitting

Vented Loop

‘T’ Connection

Lavac Pump. Hand

and/or Electric

Self pump-out

inboard pump

Hand or

Electric

Flush

water

intake

B/C

HOLDING TANK

LAVAC

TOILET

This manual suits for next models

2

Table of contents

Other Toplicht Toilet manuals

Popular Toilet manuals by other brands

Kohler

Kohler Sterling Windham 402015 manual

Invacare

Invacare H304 Finesse user manual

Vetus

Vetus HATO212B Installation instructions and operation manual

SUNWIND

SUNWIND El-dorado 720100 user manual

Villeroy & Boch

Villeroy & Boch 9M77C1 quick start guide

Kohler

Kohler JULY S-TRAP K-28866T-S quick start guide