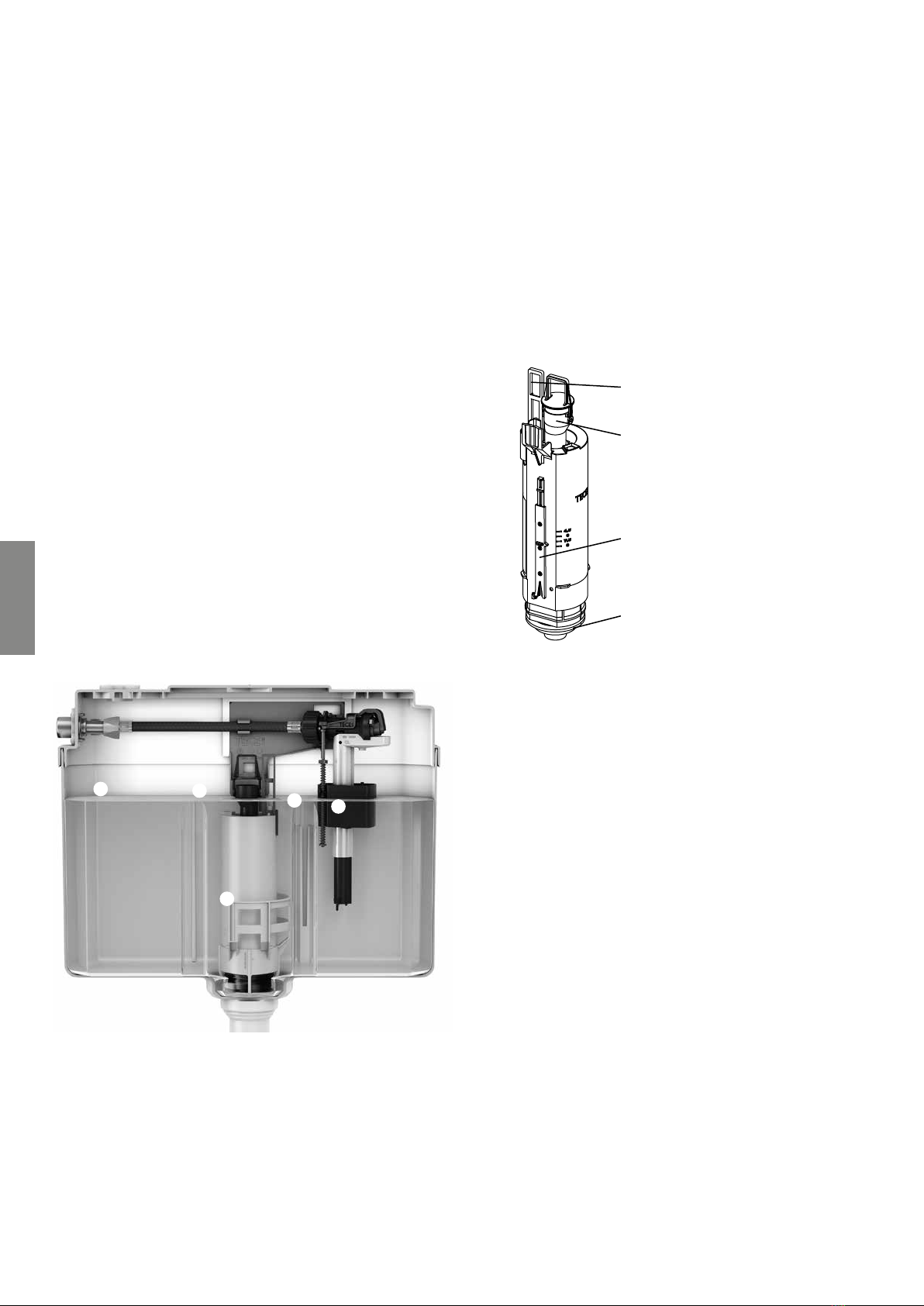

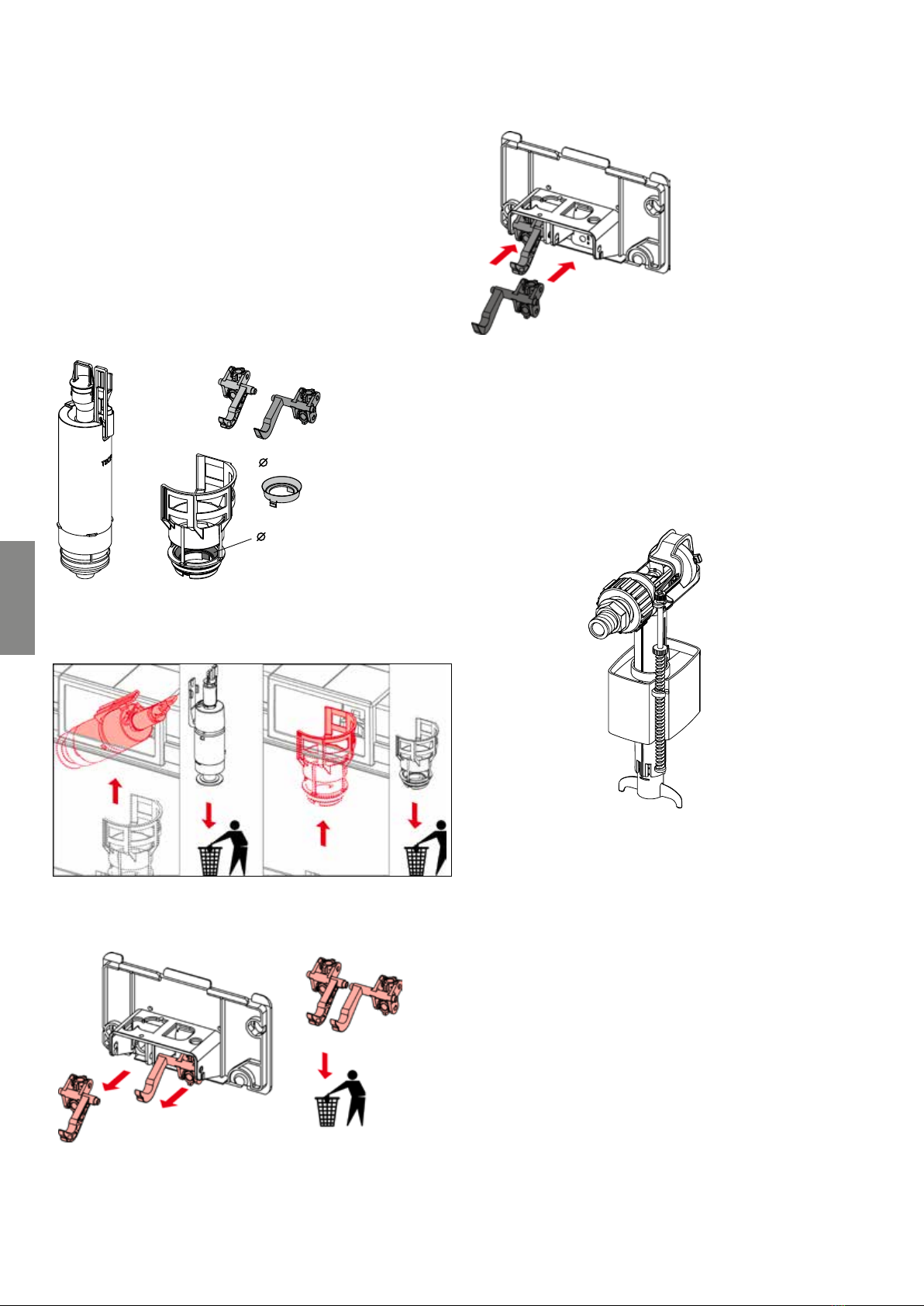

Flushing technology

6-18

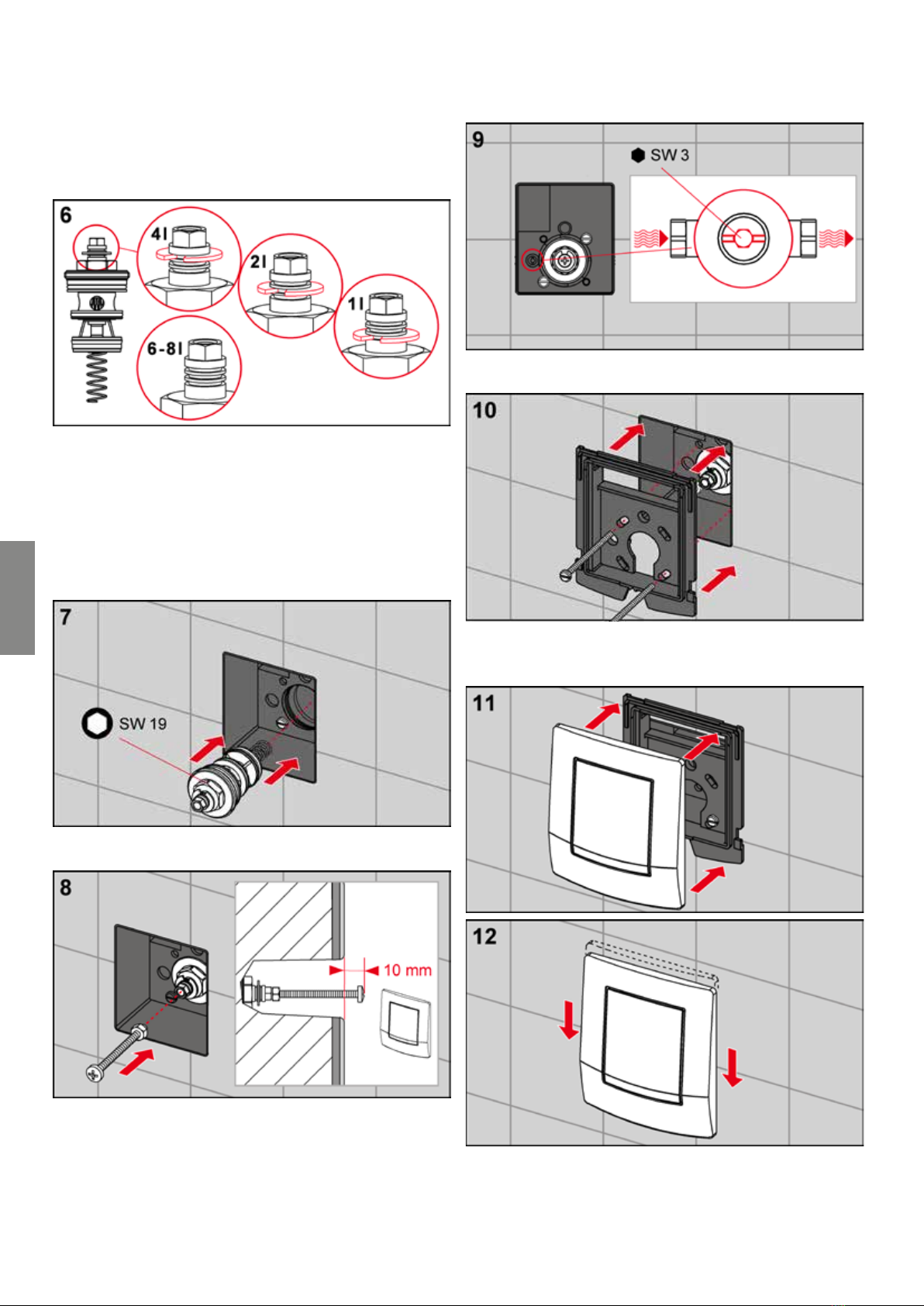

Programming the urinal infrared electronics

After installing the electrical supply, the electronics can be

programmed within one hour using the magnetic key sup-

plied. If you wish to change the program, you must inter-

rupt the power supply. Thanks to a memory chip, the last

program set always remains active even after a power cut.

Approximately five seconds after being connected to the

power supply, TECE electronics can be programmed in the

first minutes. Each configurable function is assigned a

position.

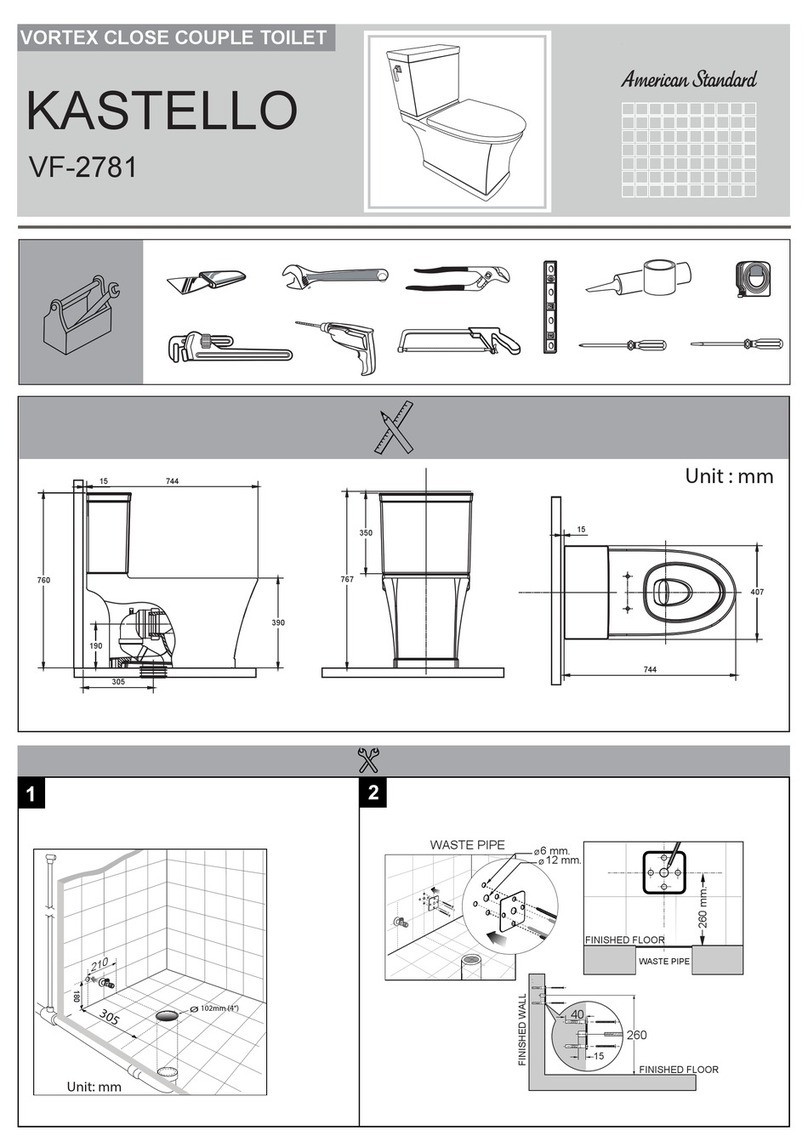

Position Function

1 Pause function “o”

2 Pause function “on”

3 Flush time 2 s

4 Flush time 2.5 s

5 Flush time 3 s

6 Flush time 3.5 s

7 Flush time 4 s

8 Flush time 5 s

9 Flush time 6 s

10 Flush time 8 s

11 Flush time 10 s

12 Pre-rinsing “o”

13 Pre-rinsing 0.5 s

14 Pre-rinsing 1 s

15 Pre-rinsing 2 s

16 Hygiene flush “o”

17 Hygiene flush 24 h

18 Hygiene flush 255 h

19 Sensor sensitivity “low”

... ...

23 Distance “standard”

24 Distance “short”

25 Distance “long”

... ...

28 Factory setting

29 Urinal covers “o”

30 Urinal covers “on”

= factory setting

Programming list for the urinal electronics

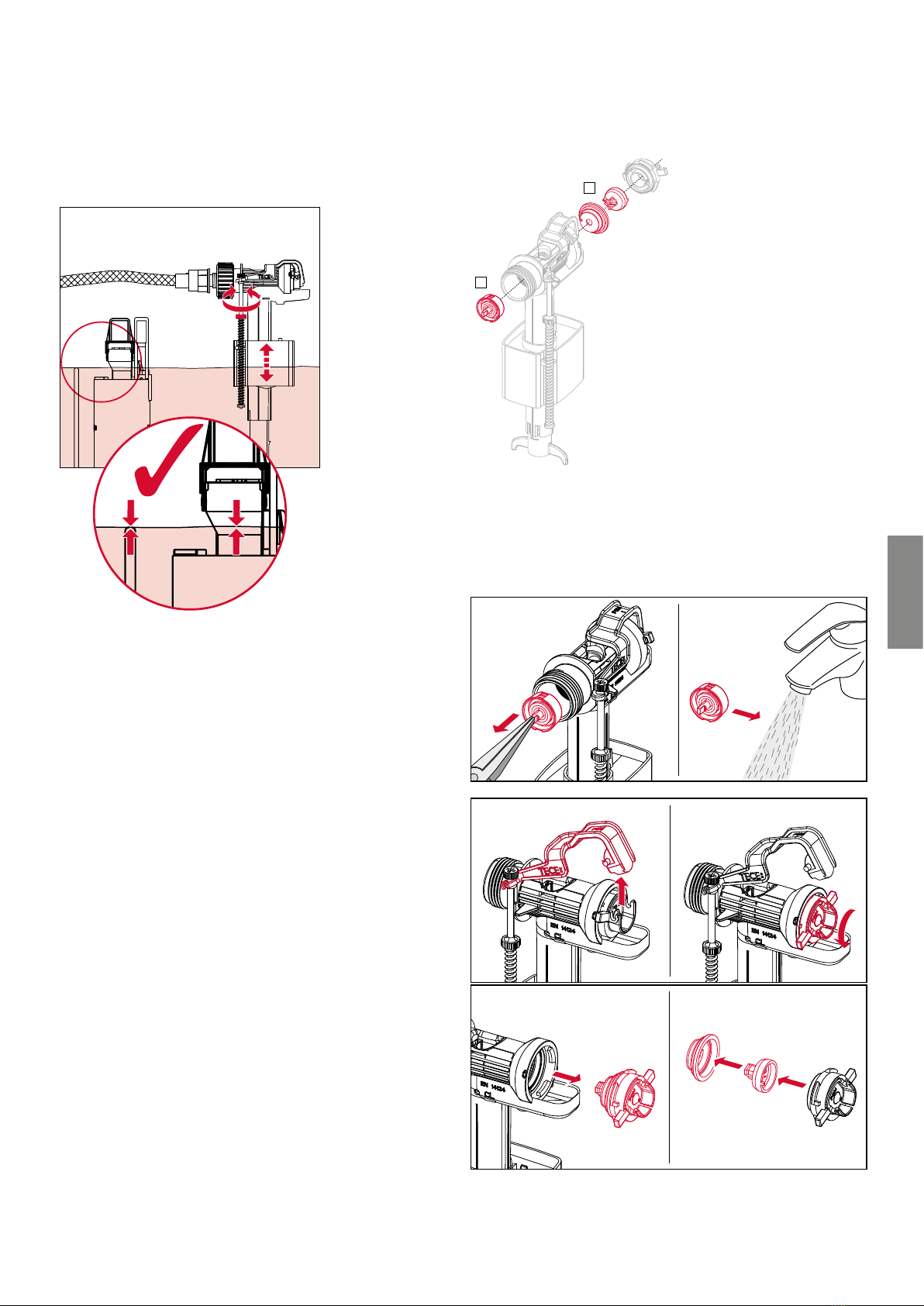

In programming mode, the electronics can be set with the

magnetic key. In standard mode, only the cleaning function

can be activated with this key.

• Cleaning function:

When cleaning the urinal, automatic flushing is generally

not required as the cleaning agent needs time to take

eect. For this reason, flushing can be delayed by

minutes.

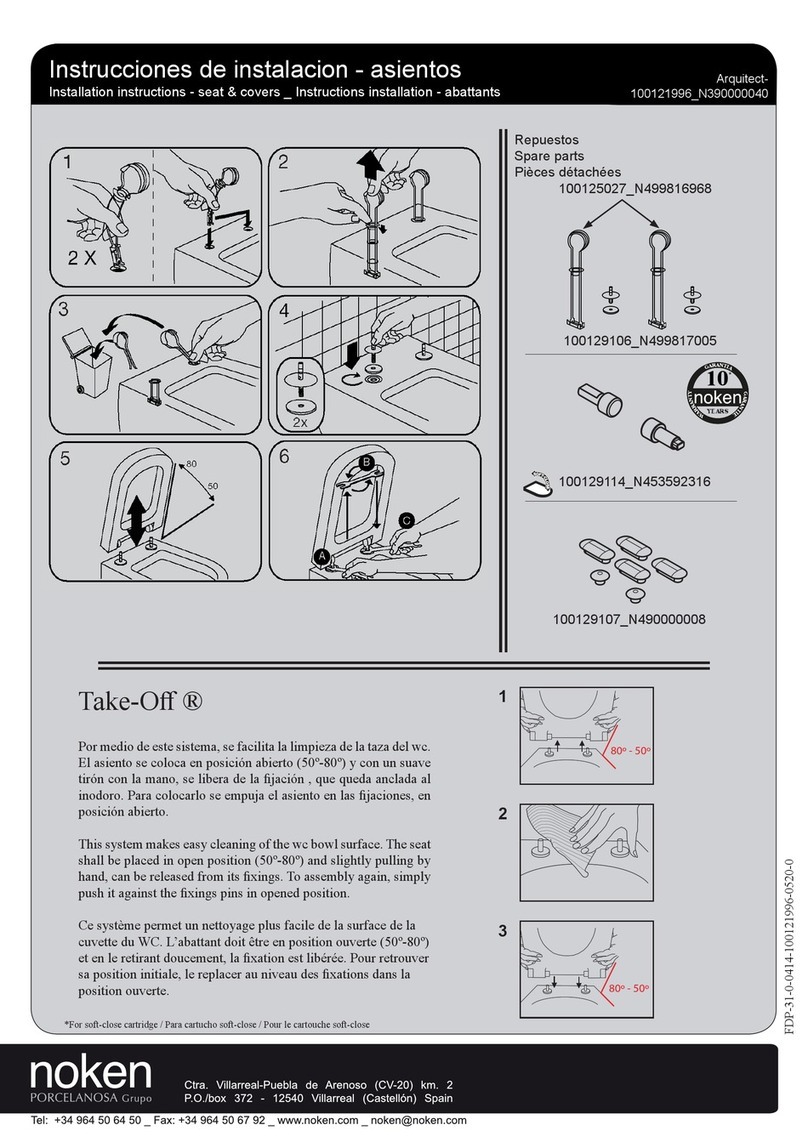

• Pre-flush (optional):

(Duration – seconds) Briefly humidifies the ceramic

before use, preventing adhesion of urine. Desired side

eect: The pre-flush stimulates the urge to urinate.

• Pause function (optional):

The volume of water is automatically reduced if the urinal

is flushed at intervals of less than two minutes. A clean-

ing flush takes place minutes after the last water-sav-

ing flush.

• Variable flush time:

(Duration – seconds) The flush volume can be

adapted to requirements throughout the flush time.

• Distance:

The modern autofocus sensor optical system operates

reliably in varying construction situations. Nevertheless,

the optical system's detection range can be changed on

extremely small or large urinal systems.

• Hygiene flush (optional):

If this function is activated, a regular clean flush prevents

the siphon from drying out and emitting unpleasant

smells, and also prevents residues from being deposited

(choice of or hours after the last flush).

• Siphon refill (optional):

Modern urinals generally suck the siphon contents

completely away and then refill enough water to fill the

siphon back up again. If this does not work, the refill

function of the TECE electronics can be activated. A

short flush impulse fills the siphon back up.

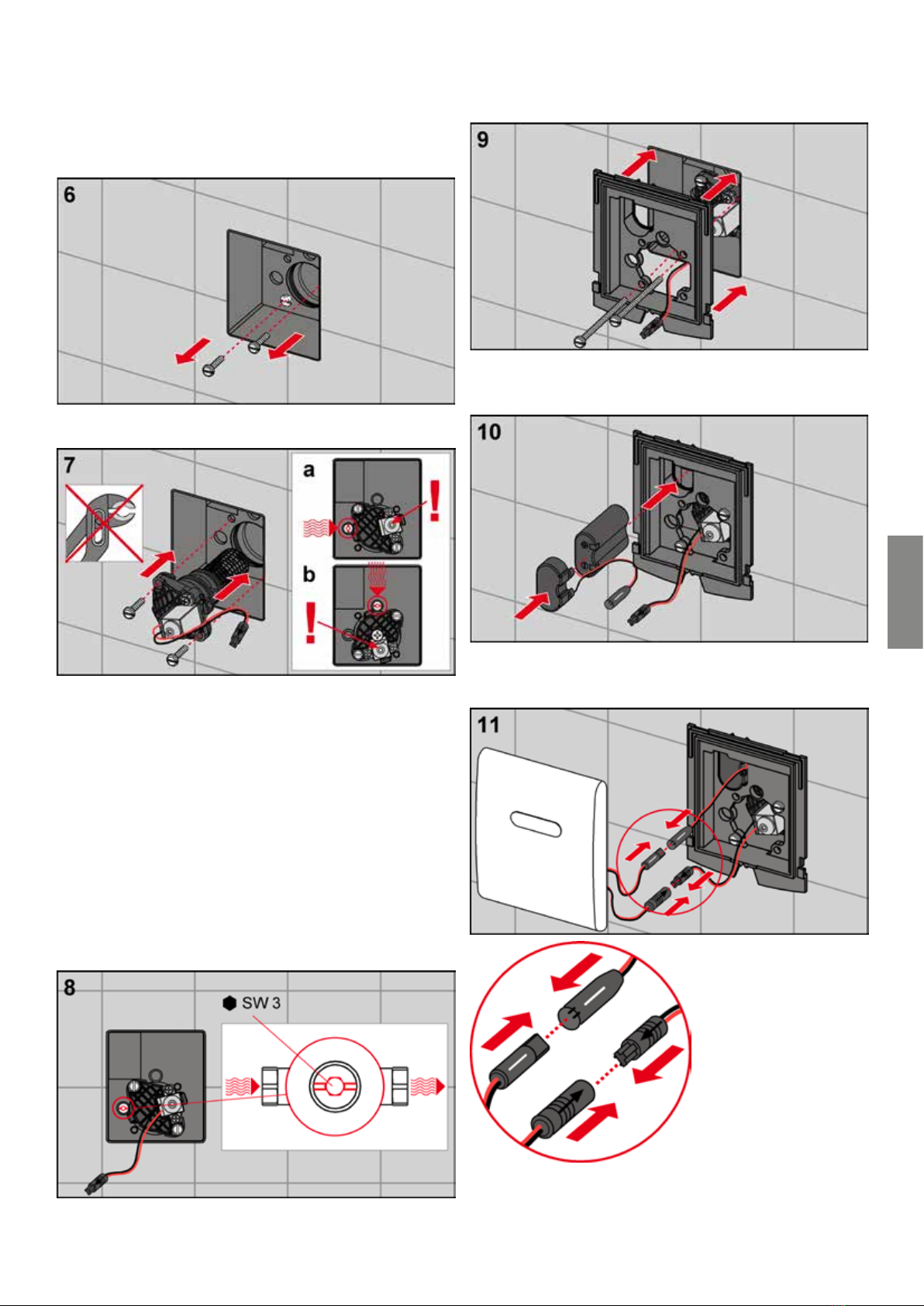

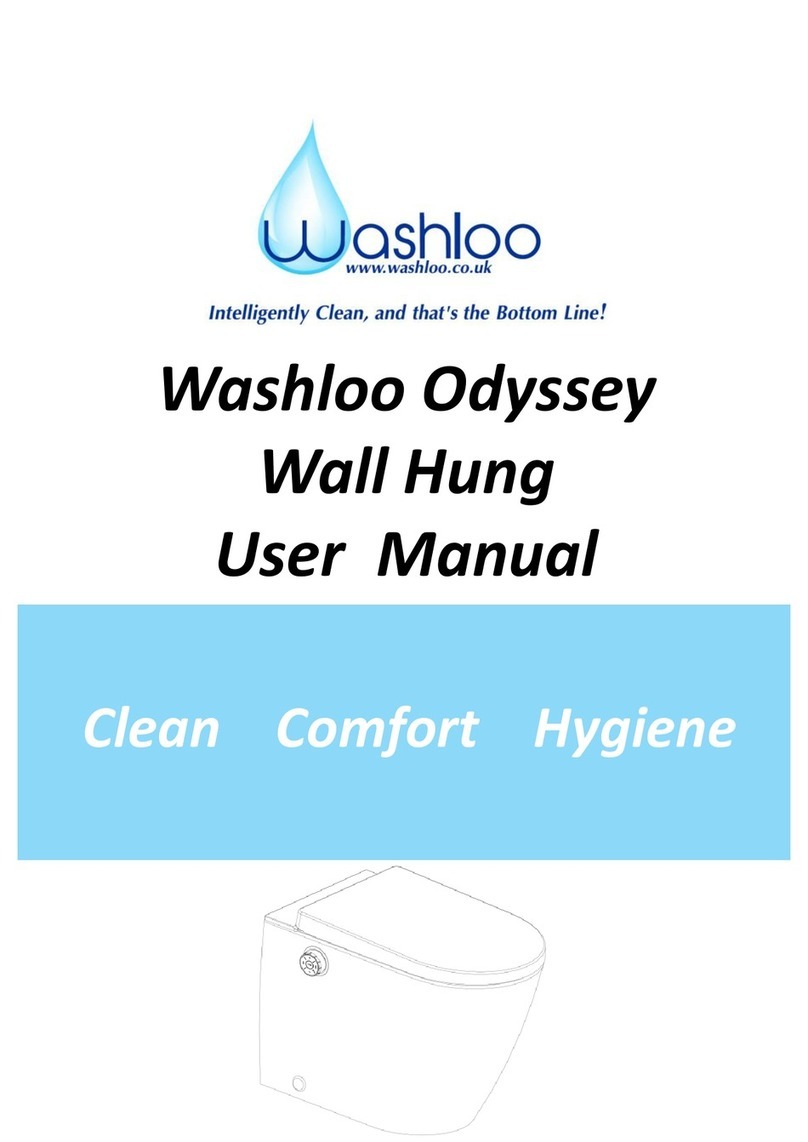

How to program the TECE electronics:

• Hold the programming key briefly

in front of the sensor window. The

programming mode starts with a

quick series of short beeps.

• After the start-up phase, a sequence of the same beeps

can be heard. Count the beeps until you reach your

desired function.

• Now remove the programming key. A long beep indi-

cates that the programming key has been removed.

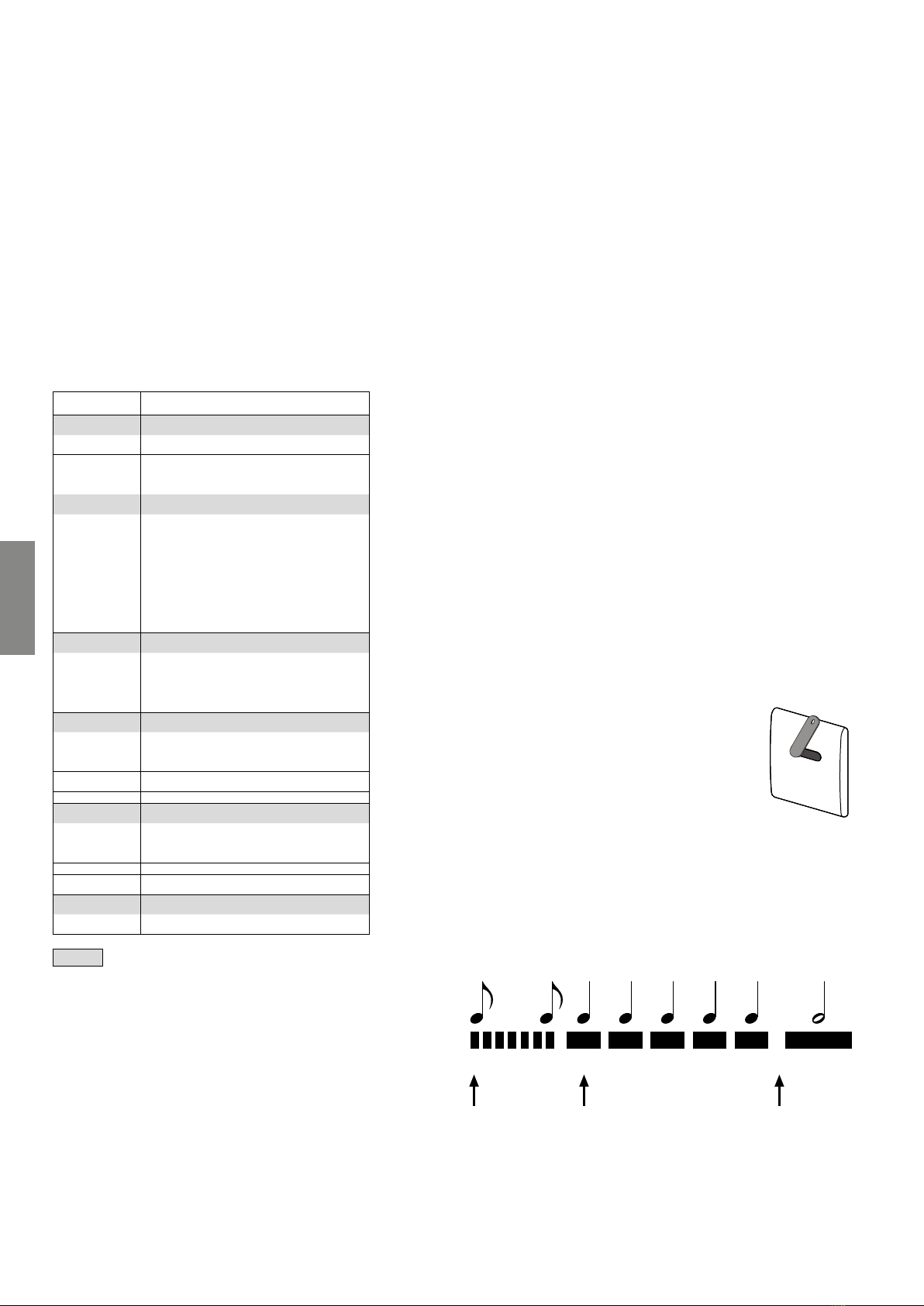

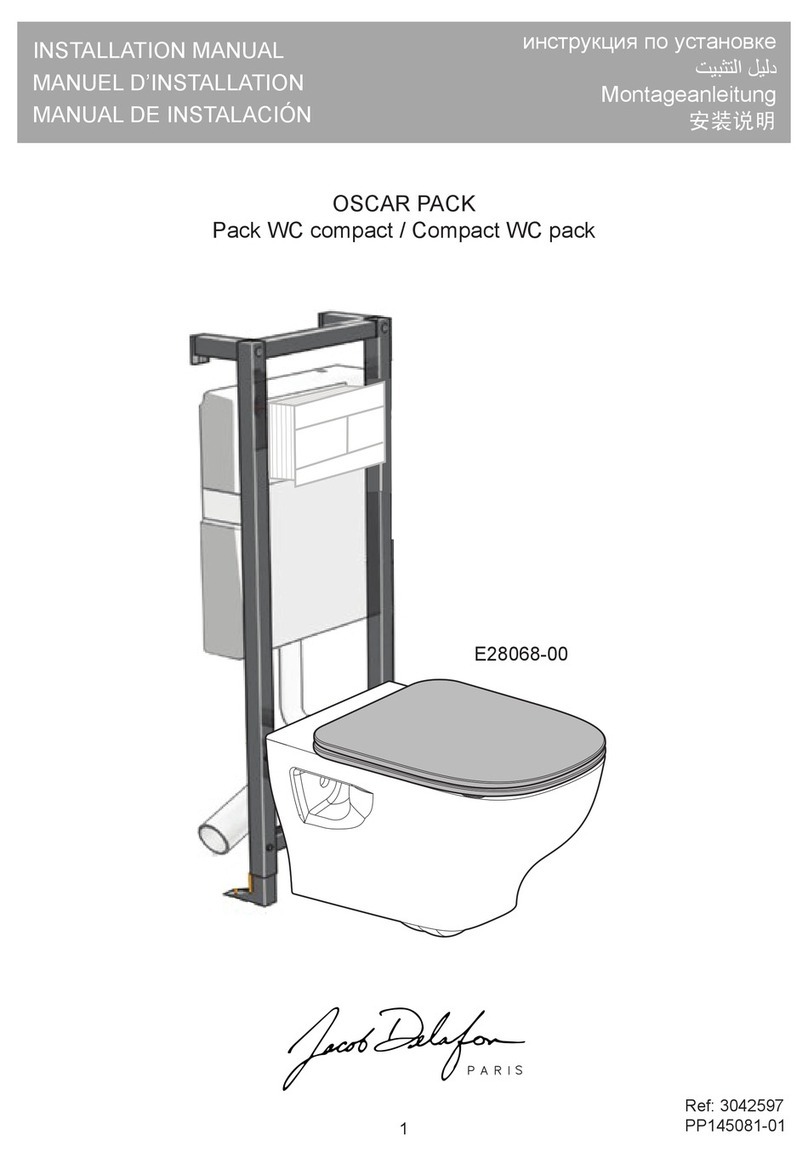

Example: Setting the flush time to three seconds

. . . .

Hold the programming

keybin front of the

sensor

Remove the key

Start 1 2 3 4 5 OK

Count the individual beeps

until the desired position is

reached

TECE flushing technology – U 1 urinal flush valve