Topward 8112 User manual

INSTRUCTION

MANUAL

DIGITAL

FUNCTION

GENERATOR

MODEL:

8112

if.

To

pwa

rd

TABLE

of

CONTENTS

Picture

of

Model

8112

.....................................

Introduction..................................................

Before

we

Begin..........Q....................................

Front

Panel

of

the

Model

8112

.......................w.....

Front

Panel

Description.......................................

Operating

Instructions........................................

8

Operating

Cautions............................................1D

Theory

of

Operation...........................................11

Calibration...................................................1a

Troubleshooting...............................................16

Adjustfient

Location...........................................20

Block

Diagram.................................................21

Circuit

Diagram...............................................22

Component

Layout..............................................26

Specifications................................................2?

U'TJ-‘bJN‘

part5

List-cotton...onto..-ole-InInca-Ilse.-liooooooco-ogunooozg

PICTURE

of

MODEL

8112

x‘

\\

\

\R

>

INTRODUCTION

The

Topward

8112

is

a

portable,

bench

type

multi-purpose

digital

function

generator/counter

capable

of

producing

5

different

waveforms.

These

are

Sine,

Square,

Triangle,

Pulse

and

Ramp.

The

model

8112

features:

Adjustable

frequency

range

from

0.1

Hz

to

2

MHz

in

7

ranges,

variable

output

amplitude

from

5

mV

to

20

Vp-p,

variable

symmetry/duty

cycle

from

5%

to

95%

in

the

Ramp/Pulse

mode,

continuous

or

externally

controlled

outputs,

DC

offset

between

—10

V

to

+10

U

can

be

added

to

all

output

waveforms,

inverted

and

attenuated

output,

built-in

100

MHz

frequency

counter

with

25

mV

input

sensitivity.

-

2 _

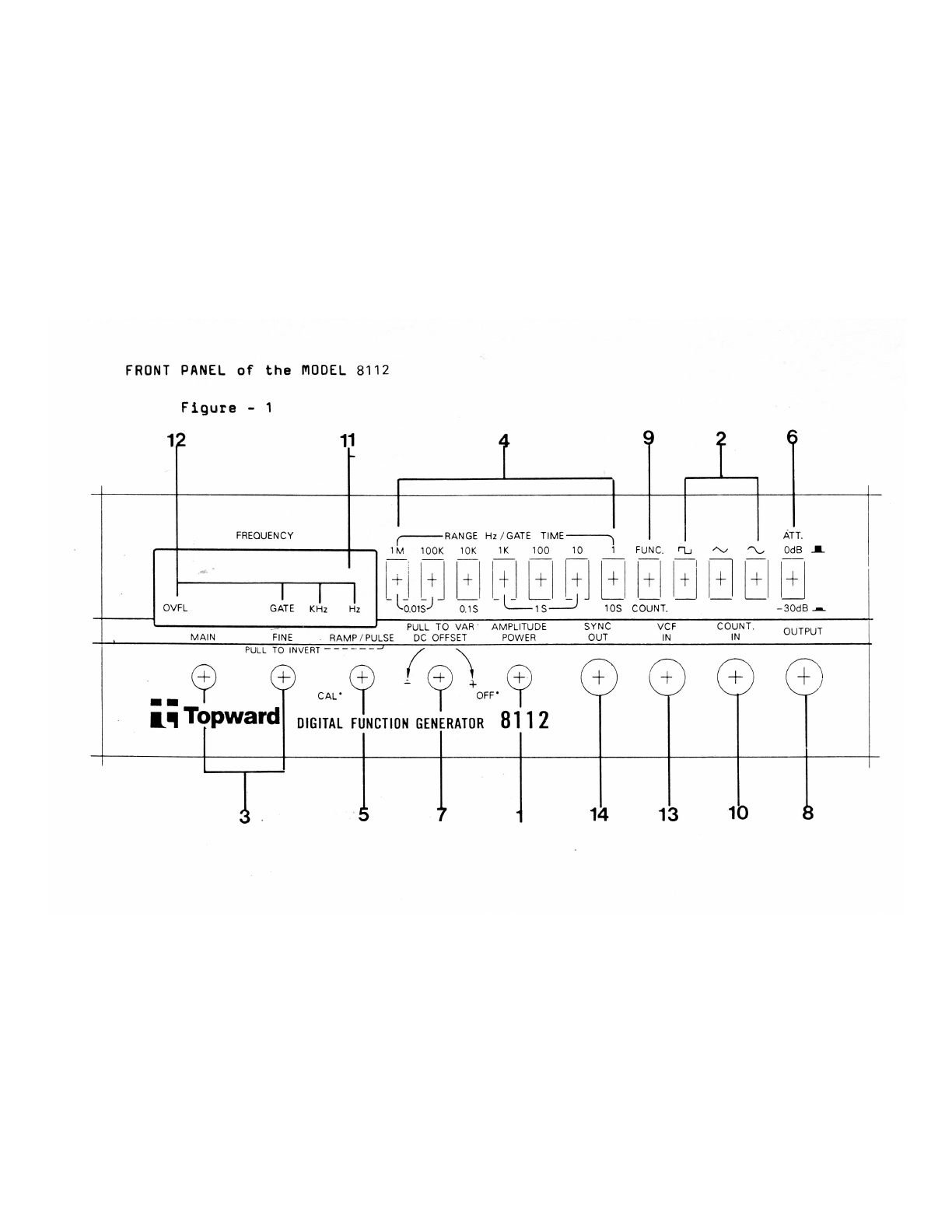

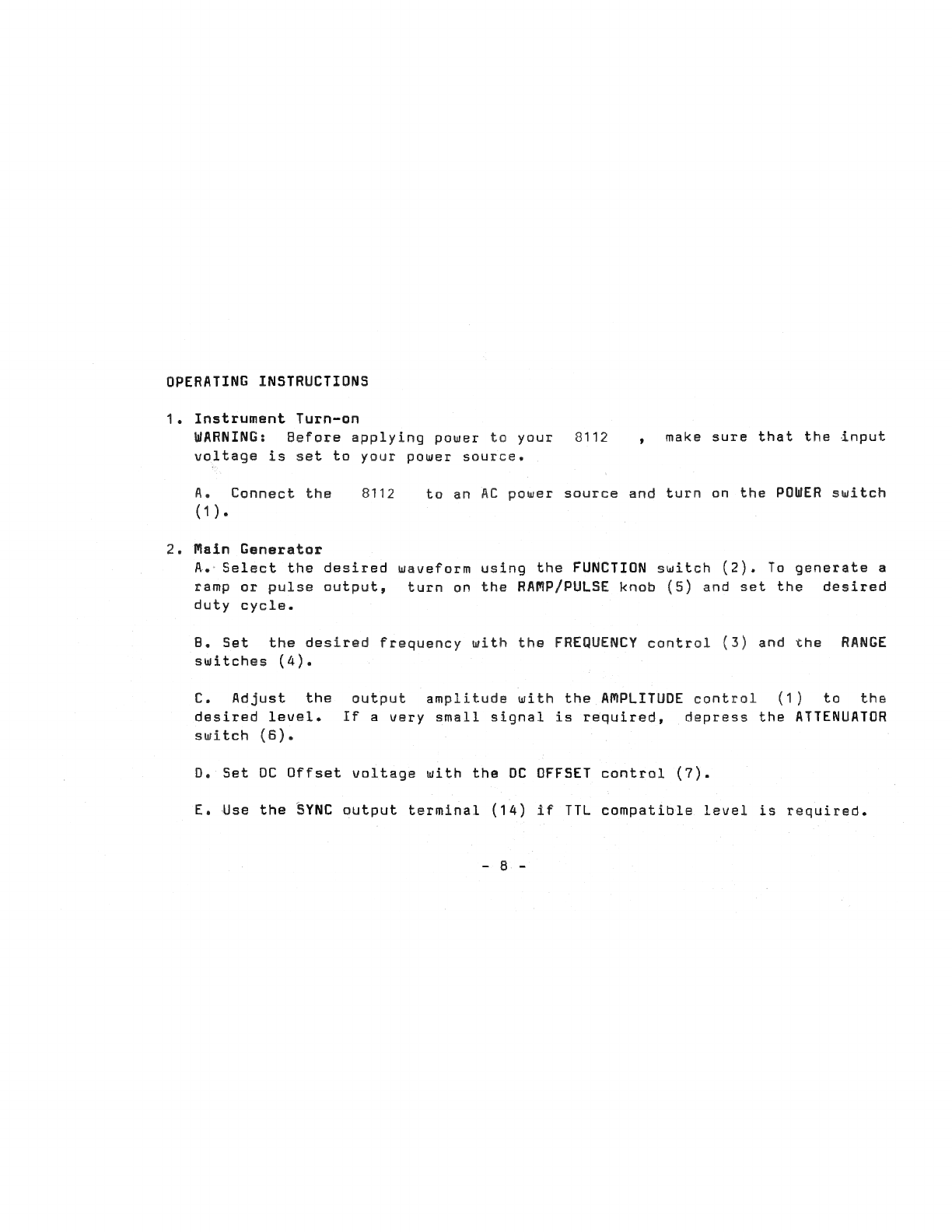

FRONT

PANEL

of

the

MODEL

8112

Figure

—

1

12

11

T

9

FREQUENCY

RANGE

Hz/GATE

THME

ATT

1M

TOOK

10K

1K

100

10

EU__N_C

m

N

%

OdB..I.

‘

__

LIEII+IEI_

I+RLIIfl

I

[TIMI]

JET”

OVFL

GATE

KHz

Hz

QJOTS

0

IS

108

COUNT.

~30dB

.-.

fl.

PULL

TO

VAR

AMPLITUDE

SYNC

VICF

COUNT.

OUTPUT

MAIN

FINE

.

RAMP/PULSE

DC

OFFSET

POWER

OUT

IN

PULL

TO

INVERT

"

‘‘‘‘‘

.C‘P

Q“

I

l!

Topward

DIGITAL

FUNCTION

GENERATOR

81

12

+

[NW

@®@@

h

13

1O

FRONT

PANEL

DESCRIPTION

The

following

is

an

explanation

of

the

function

of

the

front

panel

controls

and

connectors.

Please

refer

to

Figure

1

for

location

of

each

control/connector.

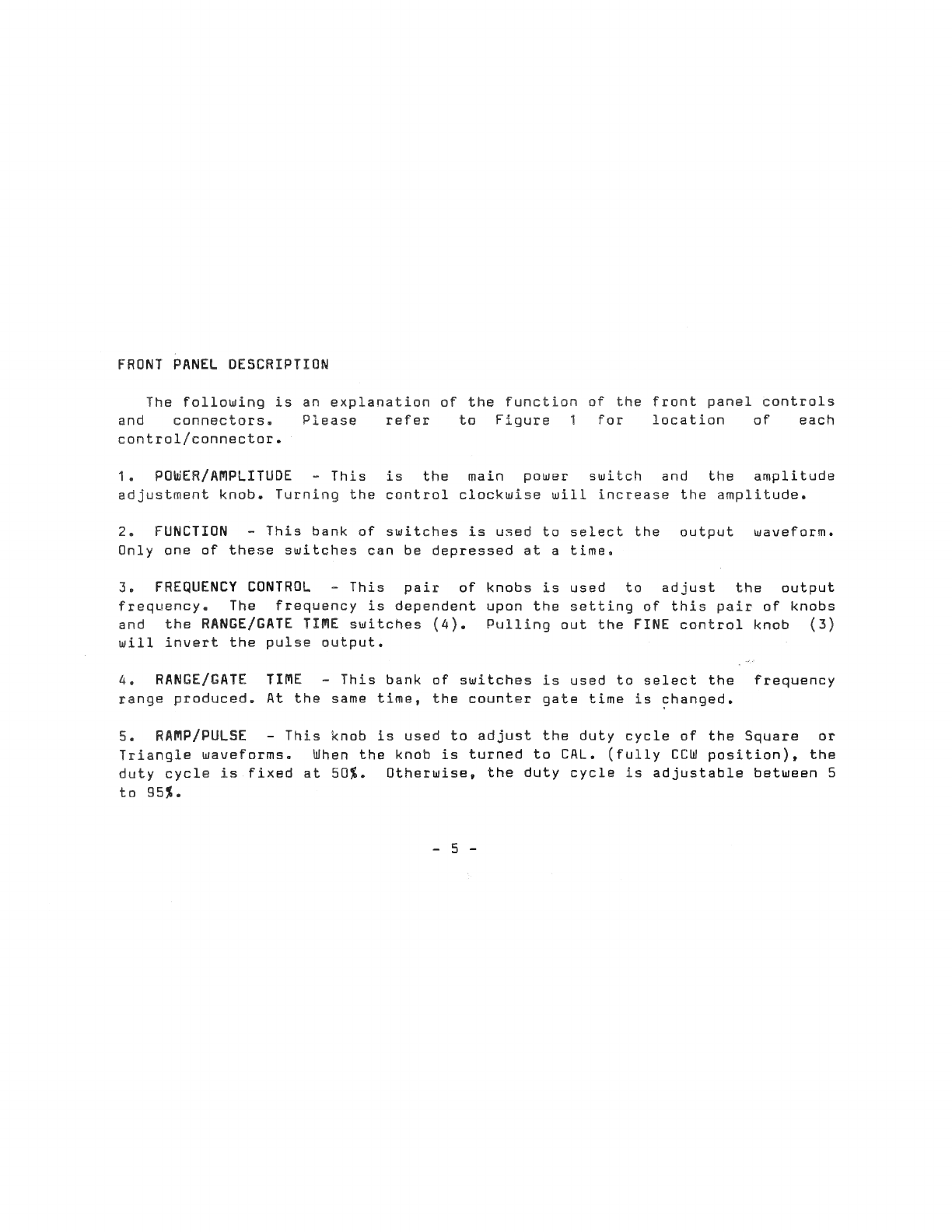

1.

POWER/AMPLITUDE

“

This

is

the

main

power

switch

and

the

amplitude

adjustment

knob.

Turning

the

control

clockwise

will

increase

the

amplitude.

2.

FUNCTION

-

This

bank

of

switches

is

used

to

select

the

output

waveform.

Only

one

of

these

switches

can

be

depressed

at

a

time.

3.

FREQUENCY

CONTROL

_

This

pair

of

knobs

is

used

to

adjust

the

output

frequency.

The

frequency

is

dependent

upon

the

setting

of

this

pair

of

knobs

and

the

RANGE/GATE

TIME

switches

(4).

Pulling

out

the

FINE

control

knob

(3)

will

invert

the

pulse

output.

a.

RANGE/GATE

TIME

-

This

bank

of

switches

is

used

to

select

the

frequency

range

produced.

At

the

same

time,

the

counter

gate

time

is

changed.

5.

RAMP/PULSE

-

This

knob

is

used

to

adjust

the

duty

cycle

of

the

Square

or

Triangle

waveforms.

when

the

knob

is

turned

to

CAL.

(fully

CCN

position),

the

duty

cycle

is

fixed

at

50%.

Otherwise,

the

duty

cycle

is

adjustable

between

5

to

95%.

_

5

-

FRONT

PANEL

DESCRIPTION

The

following

is

an

explanation

of

the

function

of

the

front

panel

controls

and

connectors.

lease

refer

to

Figure

1

for

location

of

each

control/connector.

1.

POWER/AMPLITUDE

n

This

is

the

main

power

switch

and

the

amplitude

adjustment

knob.

Turning

the

control

clockwise

will

increase

the

amplitude.

2.

FUNCTION

—

This

bank

of

switches

is

used

to

select

the

output

waveform.

Only

one

of

these

switches

can

be

depressed

at

a

time.

3.

FREQUENCY

CONTROL

—

This

pair

of

knobs

is

used

to

adjust

the

output

frequency.

The

frequency

is

dependent

upon

the

setting

of

this

pair

of

knobs

and

the

RANGE/GATE

TIME

switches

(4).

Pulling

out the

FINE

control

knob

(3)

will

invert

the

pulse

output.

a.

RANGE/GATE

TIME

-

This

bank

of

switches

is

used

to

select

the

frequency

range

produced.

At

the

same

time,

the

counter

gate

time

is

changed.

5.

RAMP/PULSE

-

This

knob

is

used

to

adjust

the

duty

cycle

of

the

Square

or

Triangle

waveforms.

when

the

knob

is

turned

to

EAL.

(fully

new

position),

the

duty

cycle

is

fixed

at

50%.

Otherwise,

the

duty

cycle

is

adjustable

between

5

to

95$.

_

5

-

B.

ATTENUATOR

—

when

this

push

button

is

out,

the

output/input

signal

is

unchanged.

If

the

switch

is

depressed,

the

Output/Input

signal

is

reduced

by

30

dB

(Generator

output

/

Counter

input).

7.

DC

OFFSET

-

This

knob

allows

a

variable

DC

voltage

between

~1O

V

to

+10

V

to

be

added

to

the

output

signal.

Note

that

the

knob

has

to

be

pulled

out

for

the

offset

to

affect

the

signal.

When

the

control

is

pushed

in,

no

offset

voltage

is

added.

8.

OUTPUT

—

This

connector

provides

the

output

signal

for

all

waveforms.

9.

FUNC/CDUNT

-

When

the

switch

is

out,

the

8

digits

DISPLAY

(11)

shows

the

generator

frequency.

When

the

switch

is

in,

the

DISPLAY

(11)

shows

the

input

frequency

of

counter.

10.

COUNTER

IN

-

This

is

the

input

connector

for

the

1OOMH2

frequency

counter.

FUNC/COUNT

switch

(9)

must

be

depressed.

11.

FREQUENCY

DISPLAY

-

This

is

a 6

digits

LED

display

that

shows

the

output

frequency

of

the

main

generator

or

the

input

frequency

of

the

counter.

12.

INDICATORS

-

OVFL,

GATE,

KHz,

Hz

LEDs

enunciate

frequency

overflow,

gate

time

and

frequency

units

in

KHz,

Hz.

-

5

_

B.

ATTENUATDR

—

When

this

push

button

is

out,

the

output/input

signal

is

unchanged.

If

the

switch

is

depressed,

the

Output/Input

signal

is

reduced

by

30

dB

(Generator

output

/

Counter

input).

7.

DC

OFFSET

-

This

knob

allows

a

variable

DC

voltage

between

~10

V

to

+10

V

to

be

added

to

the

output

signal.

Note

that

the

knob

has

to

be

pulled

out

for

the

offset

to

affect

the

signal.

When

the

control

is

pushed

in,

no

offset

voltage

is

added.

8.

DUTPUT

-

This

connector

provides

the

output

signal

for

all

waveforms.

9.

FUNC/CDUNT

—

When

the

switch

is

out,

the

5

digits

DISPLAY

(11)

shows

the

generator

frequency.

When

the

switch

is

in,

the

DISPLAY

(11)

shows

the

input

frequency

of

counter.

10.

COUNTER

IN

-

This

is

the

input

connector

for

the

1DDNH2

frequency

counter.

FUNC/CDUNT

switch

(9)

must

be

depressed.

11.

FREQUENCY

DISPLAY

-

This

is

a

6

digits

LED

display

that

shows

the

output

frequency

of

the

main

generator

or

the

input

frequency

of

the

counter.

12.

INDICATORS

—

DVFL,

GATE,

KHz,

Hz

LEDs

enunciate

frequency

overflow,

gate

time

and

frequency

units

in

KHz,

Hz.

13.

VCF

IN

-

This

input

is

used

to

modulate

the

main

frequency

to

1000:1

with

an

external

source

of

0

—

SVDC.

14.

SYNC

OUT

-

This

connector

supplies

a

TTL

compatible

output

signal

which

is

unaffected

by

either

the

FUNCTION

(2)

or

AMPLITUDE

(1)

controls.

The

output

frequency

is

the

same

as

that

of

OUTPUT

signal

(8).

13.

VCF

IN

-

This

input

is

used

to

modulate

the

main

frequency

to

1ODD:1

with

an

external

source

of

0

—

SVDC.

14.

SYNC

OUT

-

This

connector

supplies

a

TTL

compatible

output

signal

which

is

unaffected

by

either

the

FUNCTION

(2)

or

AMPLITUDE

(1)

controls.

The

output

frequency

is

the

same

as

that

of

OUTPUT

signal

(8).

_

7

-

OPERATING

INSTRUCTIONS

1.

2.

Instrument

Turn-on

UARNING:

Before

applying

power

to

your

8112

,

make

sure

that

the

input

voltage

is

set

to

your

power

source.

A.

Connect

the

8112

to

an

AC

power

source

and

turn

on

the

POWER

switch

(1).

Main

Generator

A.

Select

the

desired

waveform

using

the

FUNCTION

switch

(2).

To

generate

a

ramp

or

pulse

output,

turn

on

the

RAMP/PULSE

knob

(5)

and

set

the

desired

duty

cycle.

B.

Set

the

desired

Frequency

with

the

FREQUENCY

control

(3)

and

the

RANGE

switches

(4).

C.

Adjust

the

output

amplitude

with

the

AMPLITUDE

control

(1)

to

the

desired

level.

If

a

very

small

signal

is

required,

depress

the

ATTENUATDR

switch

(6).

D.

Set

DC

Offset

voltage

with

the

DC

OFFSET

control

(7).

E.

Use

the

SYNC

output

terminal

(14)

if

TTL

compatible

level

is

required.

OPERATING

INSTRUCTIONS

1.

2.

Instrument

Turn—on

WARNING:

Before

applying

power

to

your

8112

,

make

sure

that

the

input

voltage

is

set

to

your

power

source.

A.

Connect

the

8112

to

an

AC

power

source

and

turn

on

the

POWER

switch

(1)-

Main

Generator

A.

Select

the

desired

waveform

using

the

FUNCTION

switch

(2).

To

generate

a

ramp

or

pulse

output,

turn

on

the

RAMP/PULSE

knob

(5)

and

set

the

desired

duty

cycle.

8.

Set

the

desired

frequency

with

the

FREQUENCY

control

(3)

and

the

RANGE

switches

(4).

C.

Adjust

the

output

amplitude

with

the

AMPLITUDE

control

(1)

to

the

desired

level.

If

a

very

small

signal

is

required,

depress

the

ATTENUATUR

Smitch

(B)

o

D.

Set

DC

Offset

voltage

with

the

DC

OFFSET

control

(7).

E.

Use

the

SYNC

output

terminal

(14)

if

TTL

compatible

level

is

required.

F.

Pull

out

the

INVERT

switch

(3)

to

introduce

a

180

degree

phase

shift.

Voltage

Controlled

Frequency

A.

Supply

a

trim

voltage

between

0

and

5

VDC

to

the

VCF

IN

terminal

(13).

The

main

frequency

will

be

varied

over

1DUU:1.

Frequency

Counter

A.

Push

in

the

FUND/COUNT

switch

(9).

8.

Apply

input

signal

to

COUNT

IN

(10).

C.

Select

GATE

TIME

(4)

for

best

resolution.

0.

Use

ATTANUATDR

(6)

for

large

input

signal

to

avoid

damage

instrument.

-

g

-

to

the

F.

Pull

out

the

INVERT

switch

(3)

to

introduce

a

180

degree

phase

shift.

Voltage

Controlled

Frequency

A.

Supply

a

trim

voltage

between

0

and

5

VDC

to

the

VCF

IN

terminal

(13).

The

main

frequency

will

be

varied

over

1000:1.

Frequency

Counter

A.

Push

in

the

FUND/COUNT

switch

(9).

3.

Apply

input

signal

to

COUNT

IN

(10).

C.

Select

GATE

TIME

(4)

for

best

resolution.

D.

Use

ATTANUATUR

(B)

for

large

input

signal

to

avoid

damage

to

the

instrument.

OPERATING

CAUTIDNS

To

assure

operation

within

the

published

specifications,

allow

the

unit

to

warm

up

and

stabilize

for

at

least

20

minutes.

Failure

to

observe

the

operating

procedure

listed

below

will

damage

to

the

unit

and

void

your

warranty.

Do

not

supply

more

than

10

Volts

(

AC

+

DC

)

into;

Output

terminal

(8)

VCF

IN

terminal

(13)

SYNC

terminal

(14)

_

10

-

result

in

TFB~8111

OPERATING

CAUTIDNS

To

assure

operation

within

the

published

specifications.

allow

the

unit

to

warm

up

and

stabilize

for

at

least

20

minutes.

Failure

to

observe

the

operating

procedure

listed

below

will

result

in

damage

to

the

unit

and

void

your

warranty.

TFG-8111

Do

not

supply

more

than

10

Volts

(

AC

+

DC

)

into:

Output

terminal

(8)

VCF

IN

terminal

(13)

SYNC

terminal

(1h)

_

10

_

THEORY

OF

OPERATION

Counter

Section

1.

Counter

Amplifier

(refer

to

circuit

diagram

sheet

1)

A.

The

buffer

amplifier

(03

and

04)

make

up

the

impedance

buffer

circuit.

B.

USA-U58

form

a

secondary

high

voltage

gain

stage.

05

and

05

form

a

level

shifter.

Counter

Control

Circuit

(refer

to

circuit

diagram

sheet

4)

A.

U14

(72160)

is

a

single

chip

counter

IC.

U13

and

CREE-ERAS

form

a

gate

time

selecting

circuit.

8.

CRaa—CRSA

form

a

decimal

point

selecting

circuit

and

H2,

KHz

indicating

circuit.

C.

U15A-U160

form

a

generator

frequency

display

/

counter

input

frequency

display

selecting

circuit.

D.

U1:

is

a

divide~by~ten

IC,

use

for

the

high

frequency

input

measurement.

Generator

Section

1.

Tuning

Amplifier,

Summing

Amplifier

and

Constant

Current

Source

(refer

to

circuit

diagram

sheet

2)

_

11

_

A.

The

tuning

amplifier

is

a

non-inverting

input

amplifier

(UBA),

providing

a

fixed

voltage

for

frequency

control

MAIN

and

FINE

(3).

U88

is

a

voltage

buffer

IE,

buffering

the

variable

control

voltage

of

frequency

control

MAIN

and

FINE

(3).

B.

The

summing

amplifier

(U6

and

Q?)

sums

each

current

from

the

VCF

input

and

the

tuning

amplifier

output.

The

output

voltage

of

the

amplifier

is

a

weighted

average

of

the

input

signal

voltages.

The

frequency

control

MAIN

.

and

FINE

(3)

varies

the

amount

of

voltage

which

determines

the

generator

output

frequency.

C.

U?

and

Q8

generate

equalizing

positive

and

negative

voltages

for

the

current

source

circuit.

The

current

source

circuit

includes

positive

current

source

(U9

and

09)

and

negative

current

source

(U10

and

Q10).

The

positive

and

negative

current

values

are

determined

by

frequency

control

MAIN

and

FINE

(3).

Triangle

Generator

and

Comparator

(refer

to

circuit

diagram

sheet

2)

The

triangle

waveform

from

the

triangle

generator

is

apply

to

the

voltage

comparator

which

acts

as

an

amplitude

limiter.

As

the

triangle

waveform

alternately

crosses

the

upper

and

lower

switching

levels

(refer

to

R47-R50)

of

the

limiter

input,

a

square

wave

is

generated

at

the

output

of

the

voltage

comparator

(U11).

The

square

is

feedback

to

the

triangle

generator

where

it

controls

the

charge

/

discharge

cycle

of

the

triangle

output.

-

12

-

A.

The

tuning

amplifier

is

a

non-inverting

input

amplifier

(UBA),

providing

a

fixed

voltage

for

frequency

control

MAIN

and

FINE

(3).

USE

is

a

voltage

buffer

IE,

buffering

the

variable

control

voltage

of

frequency

control

MAIN

and

FINE

(3).

B.

The

summing

amplifier

(U6

and

a?)

sums

each

current

from

the

VCF

input

and

the

tuning

amplifier

output.

The

output

voltage

of

the

amplifier

is

a

weighted

average

of

the

input

signal

voltages.

The

frequency

control

MAIN

,

and

FINE

(3)

varies

the

amount

of

voltage

which

determines

the

generator

output

frequency.

E.

U7

and

Q8

generate

equalizing

positive

and

negative

voltages

for

the

current

source

circuit.

The

current

source

circuit

includes

positive

current

source

(U9

and

D9)

and

negative

current

source

(U10

and

010).

The

positive

and

negative

current

values

are

determined

by

frequency

control

MAIN

and

FINE

(3).

Triangle

Generator

and

Comparator

(refer

to

circuit

diagram

sheet

2)

The

triangle

waveform

from

the

triangle

generator

is

apply

to

the

voltage

comparator

which

acts

as

an

amplitude

limiter.

As

the

triangle

waveform

alternately

crosses

the

upper

and

lower

switching

levels

(refer

to

R47—R50)

of

the

limiter

input,

a

square

wave

is

generated

at

the

output

of

the

voltage

comparator

(U11).

The

square

is

feedback

to

the

triangle

generator

where

it

controls

the

charge

/

discharge

cycle

of

the

triangle

output.

_

12

-

3.

Sine

Shaper

and

PRE-Amplifier

(refer

to

circuit

diagram

sheet

3)

A.

'To

obtain

a

sine

wave.

The

triangle

wave

is

shaped

by

a

diode

network

(CR16

-

CR31),

in

the

sine

snapper.

There

are

four—stage

diodes

network

serves

as

a

non-linear

load

which

varies

the

attenuation

of

the

input

triangle

according

to

its

level.

B.

The

PRE-Amplifier

is

a

non-inverting

closed

loop

amplifier.

Q15

and

Q16

form

the

differential

input

stage

that

provides

DC

stability.

Q17

forms

the

second

gain

stage.

Q18

and

019

are

the

output

buffer

circuit.

4.

Output

Amplifier

(refer

to

circuit

diagram

sheet

3)

The

output

amplifier

works

the

same

manner

as

PRE-Amplifier,

and

provides

a

50

ohms

low

output

impedance

for

OUTPUT

terminal

(8).

-13-

3.

4.

Sins

Shaper

and

PRE-Amplifier

(refer

to

circuit

diagram

sheét

3)

A.

‘To

obtain

a

sine

wave.

The

triangle

wave

is

shaped

by

a

diode

network

(CR1B

-

CR31),

in

the

sine

shapper.

There

are

four—stage

diodes

network

serves

as

a

non-linear

load

which

varies

the

attenuation

of

the

input

triangle

according

to

its

level.

B.

The

DRE-Amplifier

is

a

non-inverting

closed

loop

amplifier.

Q15

and

Q15

form

the

differential

input

stage

that

provides

DC

stability.

017

forms

the

second

gain

stage.

018

and

019

are

the

output

buffer

circuit.

Output

Amplifier

(refer

to

circuit

diagram

sheet

3)

The

output

amplifier

works

the

same

manner

as

DRE-Amplifier,

and

provides

a

50

ohms

low

output

impedance

for

OUTPUT

terminal

(8).

_

13

-

CALIBRATION

CAUTIDNS:

Services

performed

by

unauthorized

person

will

void

your

warranty.

To

assure

the

most

stable

operation

possible,

your

Model

8112

should

be

periodically

adjusted.

To

perform

the

following

adjustment

procedures,

you

will

need

a

Phillips

screwdriver,

Timer/Counter,

Voltmeter,

an

Oscilloscope

(SDMHz

minimum),

Distortion

meter,

and

high

frequency

(up

to

1ODNH2)

signal

generator.

Calibration

be

performed

under

liboratory

conditions

having

an

ambient

temperature

of

18°

to

28°c(62°

to

82°F),

and

relative

humidity

of

less

then

80%.

As

you

perform

this

procedure,

please

refer

to

the

adjustment

location

drawing.

1.

Set

the

8112

controls

as

follows:

RANGE

(a)

............................

1K

FUNCTION

(2)

.........................

Av

DC

OFFSET

(7)

........................

OFF

AMPLITUDE

(1)

........................

cm

(Max.)

RAMP/PULSE

(s)

.......................

cum

(CAL)

FREQUENCY

NAIN

&

FINE

(3)

............

cw

(Max.)

2.

Connector

OUTPUT

(8)

on

Counter

1202

(or

equivalent),

adjust

R127

(ZNHz

ADJ)

to

display

2.3KH2

i

SUHz.

-

14

-

CALIBRATION

CAUTIUNS:

Services

performed

by

unauthorized

person

will

void

your

warranty.

To

assure

the

most

stable

operation

possible,

your

Model

8112

should

be

periodically

adjusted.

To

perform

the

following

adjustment

procedures,

you

will

need

a

Phillips

screwdriver,

Timer/Counter,

Voltmeter,

an

Oscilloscope

(SUMHz

minimum),

Distortion

meter,

and

high

frequency

(up

to

1DOMH2)

signal

generator.

Calibration

be

performed

under

liboratory

conditions

having

an

ambient

temperature

of

1a“

to

28“r(62“

to

82°F),

and

relative

humidity

of

less

then

80%.

As

you

perform

this

procedure,

please

refer

to

the

adjustment

locatidn

drawing.

1.

Set

the

8112

controls

as

follows:

RANGE

(a)

............................

1K

FUNCTION

(2)

.........................

AV

0:

OFFSET

(7)

........................

DFF

AMPLITUDE

(1)

........................

cw

(Max.)

RAMP/PULSE

(5)

.......................

cow

(CAL)

FREQUENCY

MAIN

&

FINE

(3)

............

cw

(Max.)

2.

Connector

OUTPUT

(8)

on

Counter

1202

(or

equivalent),

adjust

R127

(ZMHz

ADJ)

to

display

2.3KHZ

:

SUHZ.

-

14

-

3.

Select

RANGE(4)

to

1

K

and

FUNCTION

(2)

to

SINE.

Set

the

FREQUENCY

MAIN

&

FINE

(3)

to

read

1KHz

on

1202

.

Connect

the

OUTPUT

(8)

to

a

distortion

meter

TDA-71O

(or

equivalent).

Adjust

R13O

(SINE

DIST1),

R131

(SINE

DISTZ)

for

minimum

distortion.

4.

Select

FUNCTION

(2)

to

TRIANGLE.

Turn

the

AMPLITUDE

(1)

to

mid

location.

Connect

the

output

to

an

voltmeter.

Adjust

R135

(PA

DC)

to

be

DC

:

10mV.

Turn

the

AMPLITUDE

(1)

to

maximum

location.

Connect

the

OUTPUT

(8)

to

an

oscilloscope.

Adjust

R134

(TRI

ANPL)

to

let

the

Vp-p

of

triangle

wave

be

20.8V

1"

0.2V.

5.

Select

FUNCTION

(2)

to

SINE.

Adjust

R132

(SINE

DC)

to

let

DC

offset

be

DC

OV

i

10mV.

Adjust

R133

(SINE

AMPL)

to

let

the

Vp—p

of

sine

wave

be

20.8V

1

0.2V.

5.

Select

FUNCTION

(2)

to

SQUARE.

Adjust

R128

to

let

the

upper

level

of

square

wave

be

+10.4V

i

O.1V.

Adjust

R129

to

let

the

lower

level

of

square

wave

be

-10.4V

1

O.1V.

7.

Press

the

FUNC/COUNT

switch

(9)

in.

Connect

a

1OMHz

1

1PPM

standard

frequency

to

the

COUNTER

input

(10).

Adjust

trimmer

capacitor

C2

until

the

display

reads

000.000

KHZ

1

1

digits

(Hz).

(with

DVFL

LED

lit).

Set

the

RANGE

switch

(4)

to

1

MHz.

Apply

a

100MHz

SOmV

signal

to

COUNT

input

(10).

Adjust

trimmer

resistor

R126

to

let

the

display

be

stable.

_

15

_

3.

Select

RANGE(4)

to

1

K

and

FUNCTION

(2)

to

SINE.

Set

the

FREQUENCY

nAIu

&

FINE

(3)

to

read

1KHz

on

1202

.

Connect

the

OUTPUT

(8)

to

a

distortion

meter

TBA-710

(or

equivalent).

Adjust

R130

(SINE

DIST1).

R131

(SINE

DISTZ)

for

minimum

distortion.

h.

Select

FUNCTION

(2)

to

TRIANGLE.

Turn

the

AMPLITUDE

(1)

to

mid

location.

Connect

the

output

to

an

voltmeter.

Adjust

R135

(PA

DC)

to

be

DC

1

10mV.

Turn

the

AMPLITUDE

(1)

to

maximum

location.

Connect

the

OUTPUT

(8)

to

an

oscilloscope.

Adjust

R134

(TRI

AMPL)

to

let

the

Vp-p

of

triangle

wave

be

20.3V

3

0.2V.

5.

Select

FUNCTION

(2)

to

SINE.

Adjust

R132

(SINE

DC)

t0

let

DC

offset

be

DC

0V

1

10mV.

Adjust

R133

(SINE

AMPL)

to

let

the

Vp-p

of

sine

wave

be

20.8V

i

0.2V.

5.

Select

FUNCTION

(2)

to

SQUARE.

Adjust

R128

to

let

the

upper

level

of

square

wave

be

+10.4U

1

0.1V.

Adjust

R129

to

let

the

lower

level

of

square

wave

be

-10.4V

3

0.1V.

7.

Press

the

FUNC/COUNT

switch

(9)

in.

Connect

a

1ONHz

1

1PPM

standard

frequency

to

the

COUNTER

input

(10).

Adjust

trimmer

capacitor

C2

until

the

display

reads

000.000

KHz

1

1

digits

(Hz).

(with

OVFL

LED

lit).

Set

the

RANGE

switch

(a)

to

1

MHZ.

Apply

a

100MHz

SOmV

signal

to

COUNT

input

(10).

Adjust

trimmer

resistor

R125

to

let

the

display

be

stable.

_

15

_

TROUBLESHOOTING

If

ybu

are

experiencing

trouble

with

your

Model

8112

Digital

Function

Generator,

follow

the

procedures

below

to

find

and

correct

the

problem.

1.

Power

Supply

A.

Varify

that

the

voltage

selector

switch

(

S1

)

is

set

correctly

(115V

or

230V)

for

your

available

power.

8.

Turn

the

POWER

(1)

on

and

using

an

voltmeter

measure

the

voltages

at

the

following

points:

”3

pin

1

00.000.00.00.

+

9V

:

10%

U1

pin

1

.............

+23v

1

10%

Q1

Collector..........

~23V

:

10$

If

not,

check

and

repair

the

components

from

the

line

cord

to

test

points.

C.

Measure

the

voltages

at

the

fOllowing

points:

U3

pin

3

...........

+

5V

i

5%

U1

pin

3

...........

+15U

i

5%

O1

Emitter

..........

~15V

i

5%

02

Emitter

..........

—

5V

1

5%

_

15

-

TROUBLESHOOTING

If

ybu

are

experiencing

trouble

with

your

Model

8112

Digital

Function

Generator,

follow

the

procedures

below

to

find

and

correct

the

problem.

1.

Power

Supply

A.

Verify

that

the

voltage

selector

switch

(

S1

)

is

set

correctly

(115V

or

230V)

for

your

available

power.

8.

Turn

the

POWER

(1)

on

and

using

an

voltmeter

measure

the

voltages

at

the

following

points:

U3

pin1.............

+9V11US

U1

pin

1

.............

+23V

1

10%

Q1

Collector-oonoooool

'23V

i

10‘

If

not.

check

and

repair

the

components

from

the

line

cord

to

test

points.

C.

Measure

the

voltages

at

the

following

points:

U3

pin

3

...........

+

5v

1

5%

U1

pin

3

...........

+15V

1

5%

O1

Emitter

..........

~15V

i

5%

OZ

Emitter

..........

-

5V

1

5%

_

15

_

U2

pin

3

...........

+

5V

1

5%

If

not,

check

and

repair

the

components

of

U1, U2,

U3, U4,

01

and

02.

2.

Counter

Amplifier

Set

the

RANGE

switch

(4)

to

1M.

Push

FUNC/CUUNT

(9)

in

and

the

DISPLAY

(11)

will

blank

out.

Apply

a

1MHz

25mV

signal

to

COUNTER

INPUT

(10).

Using

an

oscilloscope,

trace

this

signal

at

the

following

points:

03

source

...............

1

MHz

.......”\J

SSmVp-p

i

20%

04

collector

............

1

MHz

.......’\J

150mVp-p

i

20%

05

pin

7

1

MHz

Wm

750mVp-p

:

20%

pin

2

................

1

MHZ

.......J—L

1

Vp—p

i

20%

pin15

1

MHz

.......n

1Vp-p

i

20%

05

collector

1

MHz

.......n

1.8

Vp-p

1

20%

U16

pin

3

1

MHz

.......n

1.8

Vp—p

1.20%

pin1

1

MHz

.......n

3

Vp-p

i

20%

pin

4

................

1

MHz

......._F1

3.5

Vp-p

i

20%

If

not,

check

and

repair

the

components

of

03,

04.

05,

06

and

U16.

3.

Counter

Control

Circuit

Refer

to

circuit

diagram

sheet

a.

The

counters

gate

time

were

selected

by

RANGE/BATE

switches

(a).

If

there

occurrs

functional

error,

check

and

repair

U13,

U14

or

nearby

components.

-

17

_

02

pin

3

+

5V

1

5%

If

not,

check

and

repair

the

components

of

U1,

U2,

2.

Counter

Amplifier

U3,

U4,

Q1

and

02.

Set

the

RANGE

switch

(4)

to

1M.

Push

FUNC/CUUNT

(9)

in

and

the

DISPLAY

(11)

1MH2

25mV

signal

to

COUNTER

INPUT

(10).

oscilloscope,

trace

this

signal

at

the

following

points:

will

blank

out.

Apply

a

03

source

04

collector

............

U5

pin

7

pin

2

pin15

RDOOIIOIIIIIIIOO

IIOIIIIIOOCOOIOI

OIOCOOI'ICVOIII.

QB

collector

ICICIOIOOOIQ

U16

pin

3

pin

1

pin

4

caoovcoucoovulol

If

not,

check

and

repair

the

components

3.

Counter

Control

Circuit

Refer

to

circuit

diagram

sheet

a.

1

1

1

1

1

1

1

1

1

of

03,

MHz

MHz

MHZ

MHz

MHz

MHz

MHz

MHz

MHz

.......F\,

55mVp—p

......."b

1SDmVp-p

.......”w

750mVp~p

.......11.

1

Up-p

........Fl

1

Vp—p

.......J_L

1.8

Vp—p

.......J_L

1.8

Vp—p

.......,F1

3

Vp—p

......._F1

3.5

Vp—p

04,

U5,

US

and

U18.

The

counters

gate

time

were

selected

by

RANGE/GATE

switches

(a).

check

and

repair

U13,

occurws

functional

error,

_

17

_

U14

01‘

U

I+|+g+l+l+x+l+|+l+

sing

an

20%

20%

20%

20%

207:.

20%

20%

20%

20%

If

there

nearby

components.

4.

Tuning

Amplifier

and

Constant

Current

Source

A.

Turn

the

frequency

control

MAIN

and

FINE

(3)

to

CCU

Check

the

voltage

ratings

of

the

following

points:

U8

pin?

U8

pin1

U7

pin3

U9

pin2

U10

pin2

.................

+1UV

.................

0V

.................

-15V

.................

+15V

ooooooooooooooooo

‘15"

8.

Turn

the

frequency

control

MAIN

and

FINE

Check

the

voltage

ratings

of

the

following

points:

UB

pin?

U8

pin1

U7

pin}

U9

pin2

U10

pin2

.................

+10V

.................

+10V

.................

-

5V

.................

+

5V

0.000.000.0000...

-

5"

If

not,

check

and

repair

the

components

of

and

Q10.

5.

Triangle

Buffer

and

Comparator

Set

the

RANGE

switch

(A)

to

1

KHz.

Turn

the

AMPLITUDE

(1)

to

CU

location.

i

10%

1

1DmV

(equals

to

(equals

to

(equals

to

(minimum)

position.

-Vcc)

+Vcc)

-Vcc)

(3)

to

cw

(maximum)

position.

10%

10%

101

10$

10%

l+|+|+l+l+

U8,

US,

07,

U7,

08,

U9,

U10,

09

4.

Tuning

Amplifier

and

Constant

Current

Source

A.

Turn

the

frequency

control

MAIN

and

FINE

(3)

to

CCU

(minimum)

position.

Check

the

voltage

ratings

of

the

following

points:

U8

pin?

U8

pin1

U7

pin3

U9

pin2

U10

pin2

B.

Turn

the

frequency

control

MAIN

and

+1UV

0V

-15V

+15V

—15V

.i...............

oocoaoo-Ioconcco-

pea-ooooo-uo'uoon-

IOOIIIICIOCCOOOCO

FINE

1

10%

i

1UmV

(equals

to

—Vcc)

(equals

to

+Vcc)

(equals

to

~Vcc)

(3)

to

CU

(maximum)

position.

Check

the

voltage

ratings

of

the

following

points:

ue

pin?

U8

pin1

U7

pin3

U9

pinZ

U10

pinz

If

not,

check

and

repair

the

components

and

Q10.

5.

Set

+1UV

+10V

—

5V

+

5V

-

5V

leoeoolooeoonooou

ole-conno-eluoool

nooooeoooooooooeo

IOIOIoIoo'Iooeell

of

Triangle

Buffer

and

Comparator

the

RANGE

switch

(4)

to

1

KHz.

_

18

_

l+|+t+l+i+

us,

101

10%

10%

105

101

U6,

U7,

U7,

08,

U9,

U10,

D9

Turn

the

AMPLITUDE

(1)

to

CU

location.

Check

and

be

sure

that

the

waveform

and

voltage

of

the

following

points:

013

Base

0000.00.00.00...

Av

ZVP-P

i

10%

,‘

U11

pin4

oooooooooooaoooo

I1

4.5Vp-p

i

10%

i

10%

ping

OOOOQGOOOODOEIOO

f1

3-5Vp”p

If

not,

check

and

repair

Q11,

Q13,

Q14

and.U11.

6.

Sine

Shape:

and

PRE

Amplifier

Check

and

be

sure

that

the

waveform

and

voltage

of

the

following

points:

Tp1

oooooooooooooooooooooo

AV

2Vp"p

:

10%

Q15

Base

0000006000069...

AU

UoBVp‘p

i

10%

R87

(eaCh

SidE)

00000-0...

AU

2Vp~p

:

10%

If

not,

check

and

repair

CR16

to

CR31

or

Q15

to

019.

7.

Power

Amplifier

Set

the

FUNCTION

switch

(2)

to

sine

wave.

Check

and

be

sure

the

waveform

and

voltage

of

the

following

points:

020

Base

ooooooooooooonoo‘fik,'

2Vp“p

:

10x

R103

(eaCh

Side)

.....a...

“V

ZUoBUp‘p

:

10%

If

not,

check

and

repair

020

to

024.

_

1g

_

Check

and

be

sure

that

the

waveform

and

voltage

of

the

following

points:

Q13

Base

ODDCIIIIIIIIOOODN

ZVp—pi'IUx

U11

pin4

concoucoooaavuoaJ—‘L

4.5Vp—p11DX

1

10%

pins

oooaasuonlnc;loo

I1

3.5Up-p

If

not,

check

and

repair

Q11,

Q13,

Q14

and

U11.

6.

Sins

Shepar

and

PRE

Amplifier

Check

and

be

sure

that

the

waveform

and

voltage

of

the

following

points:

TP1

onloooaoolI-ouaouaoooo

AV

2Vp‘p

:

10%

015

Base

.o.o..n.....a...”\JU.5Vp—p310%

R87

(Each

Side)

IOOIOIIOI.

nu

2Vp*p

i

10%

If

not.

check

and

repair

CR1B

to

CR31

or

G15

to

019.

7.

Power

Amplifier

Set

the

FUNCTION

switch

(2)

to

sine

wave.

Check

and

be

sure

the

waveform

and

voltage

of

the

following

points:

10%

10%

020

Base

CIIDDOOOIOOI‘IIOIN"

2Vp—p

R103

(each

side)

.........

av

20.8Vp-p

|+

1+

If

not,

check

and

repair

020

to

024.

_

1g

_

Table of contents

Popular Test Equipment manuals by other brands

Unit

Unit UT-P35 instruction manual

AutoTest

AutoTest AUTOSTOP Micro Plus user manual

Kyoritsu Electrical Instruments Works, Ltd.

Kyoritsu Electrical Instruments Works, Ltd. 4200 instruction manual

Unit

Unit UTD1025CL manual

Serveredge

Serveredge TRCER-CAB instruction manual

U.S. General

U.S. General 65928 Set up and operating instructions