Toradex Colibri Guide

Colibri Computer Module

Carrier Board Design Guide

Colibri Carrier Board Design Guide

Toradex AG l Altsagenstrasse 5 l 6048 Horw l Switzerland l +41 41 500 48 00 l www.toradex.com l info@toradex.com

Page | 2

Issued by:

Toradex

Document Type:

Carrier Board Design Guide

Purpose:

This document is a guideline for developing a carrier board that confirms to the specifications

for the Colibri Computer Module

Document

Version:

1.7

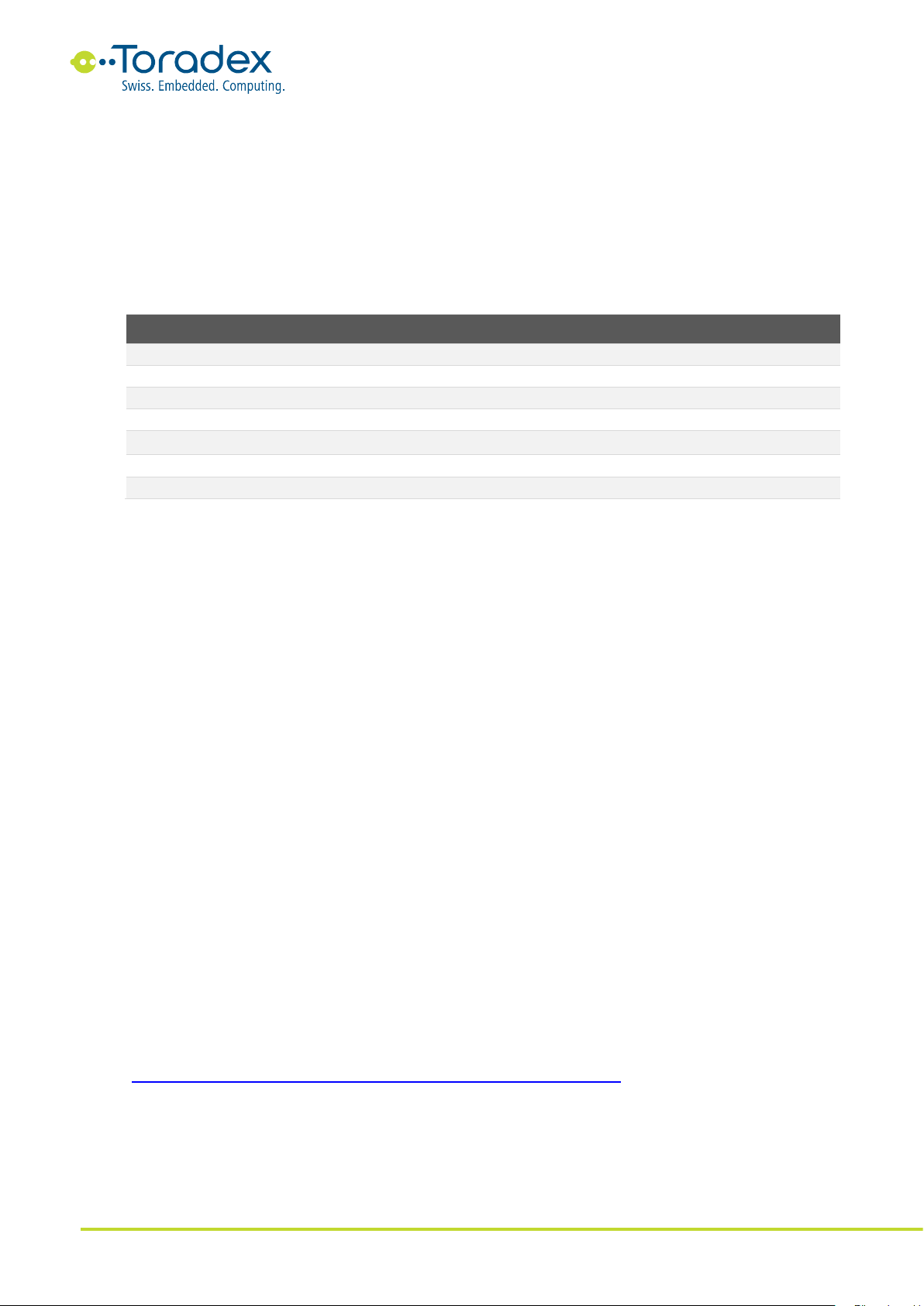

Revision History

Date

Version

Remarks

13 Apr 2015

V1.0

Initial Release: Preliminary Version

28 Sept 2015

V1.1

Correct figure 3 and figure 4 in section 2.3.2 (positive and negative USB

signals were swapped in schematics)

22 Oct 2015

V1.2

Corrections in figure 4 in section 2.3.2 (pull up resistor of USB_OC# and

pull-down of USBH_EN where swapped)

Correction in typical pull-up value for I2C in section 2.9

15 Jun 2016

V1.3

Add section 2.1.4 "Pin Reset State"

Section 2.16: Updated information to the input voltage range

Section 2.17: Add a note to the usage of PXA270

Section 0: insert information to nVDD_FAULT, nGPIO_RESET, and

nBATT_SENSE

Section 3.6: Add information to bulk capacitors.

06 Apr 2017

V1.4

Section 2.2, Ethernet: Minor correction in figure 2

Section 2.5, HDMI/DVI: Correction in figure 12 (differential pair

impedance value)

All reference schematic images: Cosmetic update.

Section 1.2, Section 4 & Section 5: Updated web-links

14 Dec 2018

V1.5

Section 2.2.2: Add recommendation for ESD protection diodes

Section 2.3.1: Add note regarding default polarity of USB_H_PWR_EN

Section 2.3.2: Add USB OTG reference schematic

Section 2.3.2: Remove 15k pull down on USB data signals

Section 2.3.2.3: Change to the active low version of the power switch

(TPS2042 instead of TPS2052)

Section 2.15.3: Update recommendation for unused touch signals

Section 2.16.1: Correct pin numbers

05-Feb 2021

V1.6

Section 2.3.2.2: Update figure 4

Section 3.7: Add backfeeding recommendations

Colibri Carrier Board Design Guide

Toradex AG l Altsagenstrasse 5 l 6048 Horw l Switzerland l +41 41 500 48 00 l www.toradex.com l info@toradex.com

Page | 3

30-Apr 2021

V1.7

Section 2.19: Add module recovery description.

Section 3: Clarify module power requirement for supply design

Section 4.5: Add JTAG test pad description.

Minor changes

Colibri Carrier Board Design Guide

Toradex AG l Altsagenstrasse 5 l 6048 Horw l Switzerland l +41 41 500 48 00 l www.toradex.com l info@toradex.com

Page | 4

1Introduction................................................................................................................... 6

1.1 Overview............................................................................................................................. 6

1.2 Additional Documents .......................................................................................................... 6

1.2.1 Layout Design Guide.................................................................................................6

1.2.2 Colibri Module Datasheets.........................................................................................6

1.2.3 Toradex Developer Center.........................................................................................6

1.2.4 Colibri Evaluation Board Schematics ..........................................................................6

1.2.5 Pinout Designer ........................................................................................................7

1.3 Abbreviations....................................................................................................................... 7

2Interfaces...................................................................................................................... 9

2.1 Architecture......................................................................................................................... 9

2.1.1 Standard Interfaces...................................................................................................9

2.1.2 Interfaces on Alternative Functions.............................................................................9

2.1.3 Pin Numbering ........................................................................................................10

2.1.4 Pin Reset State.......................................................................................................10

2.2 Ethernet............................................................................................................................ 11

2.2.1 Ethernet Signals......................................................................................................11

2.2.2 Reference Schematics.............................................................................................11

2.2.3 Unused Ethernet Signals Termination.......................................................................12

2.3 USB.................................................................................................................................. 12

2.3.1 USB Signals ...........................................................................................................12

2.3.2 Reference Schematics.............................................................................................13

2.3.3 Unused USB Signal Termination ..............................................................................14

2.4 Parallel RGB LCD Interface................................................................................................ 14

2.4.1 Parallel RGB LCD Signals .......................................................................................15

2.4.2 Reference Schematics.............................................................................................15

2.4.3 Unused Parallel RGB Interface Signal Termination....................................................18

2.5 HDMI/DVI.......................................................................................................................... 18

2.5.1 HDMI/DVI Signals ...................................................................................................19

2.5.2 Reference Schematics.............................................................................................19

2.5.3 Unused HDMI/DVI Signal Termination......................................................................21

2.6 Analog VGA ...................................................................................................................... 22

2.6.1 VGA Signals ...........................................................................................................22

2.6.2 Reference Schematics.............................................................................................22

2.6.3 Unused VGA Interface Signal Termination................................................................23

2.7 Parallel Camera Interface................................................................................................... 23

2.7.1 Parallel Camera Signals ..........................................................................................23

2.7.2 Unused Parallel Camera Interface Signal Termination ...............................................24

2.8 SD/MMC/SDIO .................................................................................................................. 24

2.8.1 SD/MMC/SDIO Signals............................................................................................24

2.8.2 Reference Schematics.............................................................................................25

2.8.3 Unused SD/MMC/SDIO Interface Signal Termination.................................................25

2.9 I2C.................................................................................................................................... 25

2.9.1 I2C Signals..............................................................................................................25

2.9.2 Real-Time Clock (RTC) recommendation..................................................................25

2.9.3 Unused I2C Signal Termination.................................................................................26

2.10 UART................................................................................................................................ 26

2.10.1 UART Signals......................................................................................................26

2.10.2 Reference Schematics .........................................................................................27

2.10.3 Unused UART Signal Termination.........................................................................28

2.11 SPI ................................................................................................................................... 29

2.11.1 SPI Signals..........................................................................................................29

2.11.2 Unused SPI Signal Termination ............................................................................29

2.12 CAN.................................................................................................................................. 29

2.12.1 Reference Schematics .........................................................................................29

Colibri Carrier Board Design Guide

Toradex AG l Altsagenstrasse 5 l 6048 Horw l Switzerland l +41 41 500 48 00 l www.toradex.com l info@toradex.com

Page | 5

2.13 PWM................................................................................................................................. 30

2.13.1 PWM Signals.......................................................................................................30

2.13.2 Reference Schematics .........................................................................................30

2.13.3 Unused PWM Signal Termination..........................................................................30

2.14 Analog Audio..................................................................................................................... 31

2.14.1 Analog Audio Signals ...........................................................................................31

2.14.2 Reference Schematics .........................................................................................31

2.14.3 Unused Analog Audio Signal Termination..............................................................32

2.15 Touch Panel Interface ........................................................................................................ 33

2.15.1 Resistive Touch Signals .......................................................................................33

2.15.2 Reference Schematics .........................................................................................33

2.15.3 Unused Touch Panel Interface Signal Termination .................................................33

2.16 Analog Inputs .................................................................................................................... 34

2.16.1 Analog Input Signals ............................................................................................34

2.16.2 Unused Analog Inputs Signal Termination .............................................................34

2.17 Parallel Memory Bus (External Memory Bus)....................................................................... 34

2.17.1 Memory Bus Signals ............................................................................................34

2.17.2 Unused Memory Bus Signals Termination .............................................................36

2.18 GPIO ................................................................................................................................ 36

2.18.1 Preferred GPIO Signals........................................................................................36

2.18.2 Unused GPIO Termination....................................................................................36

2.19 Module Recovery............................................................................................................... 37

3Power Management....................................................................................................... 38

3.1 Power Supply Design......................................................................................................... 38

3.2 Power Signals ................................................................................................................... 38

3.2.1 Digital Supply Signals..............................................................................................38

3.2.2 Analog Supply Signals.............................................................................................38

3.2.3 Power Management Signals ....................................................................................39

3.3 Power Block Diagram......................................................................................................... 39

3.4 Power States..................................................................................................................... 41

3.5 Power-Up Sequence.......................................................................................................... 41

3.6 Reference Schematics ....................................................................................................... 42

3.7 Backfeeding ...................................................................................................................... 44

3.7.1 Introduction.............................................................................................................44

3.7.2 What is Backfeeding................................................................................................44

3.7.3 Potential Issues Caused by Backfeeding...................................................................46

3.7.4 Identify Backfeeding Issues......................................................................................47

3.7.5 Backfeeding Prevention...........................................................................................50

4Mechanical and Thermal Consideration ........................................................................... 60

4.1 Module Connector.............................................................................................................. 60

4.2 Fixation of the Module........................................................................................................ 60

4.3 Thermal Solution................................................................................................................ 62

4.4 Module Size ...................................................................................................................... 62

4.5 JTAG Test Pads ................................................................................................................ 63

5Appendix A –Physical Pin Definition and Location ............................................................ 64

Colibri Carrier Board Design Guide

Toradex AG l Altsagenstrasse 5 l 6048 Horw l Switzerland l +41 41 500 48 00 l www.toradex.com l info@toradex.com

Page | 6

1 Introduction

1.1 Overview

This document guides the development of a customized carrier board for the Colibri computer

module. It describes the different interfaces and contains reference schematics. This document

reflects only the standardized primary function of the Colibri modules. The alternative functions are

not guaranteed to be compatible between different Colibri modules. These interfaces are described

in the datasheet of each computer module. Some Colibri modules do not feature the complete set

of standard interfaces. Therefore, it is strongly recommended to read the datasheets of the

modules that are intended to be used with the carrier board.

Some of the Colibri computer module interfaces, such as High-Speed USB and Ethernet, require

special layout considerations regarding trace impedance and length matching. Please carefully

read the Toradex Layout Design Guide for additional information related to the routing of these

interfaces.

1.2 Additional Documents

1.2.1 Layout Design Guide

This document contains layout requirement specifications for the high-speed signals and avoids

problems related to the layout.

http://developer.toradex.com/carrier-board-design/carrier-board-design-guides

1.2.2 Colibri Module Datasheets

There is a datasheet available for every Colibri module. Amongst other things, this document

describes the type-specific interfaces and the alternative function of the pins. Before starting the

development of a customized carrier board, please check this document to determine whether the

required interfaces are available on the selected modules.

https://www.toradex.com/computer-on-modules/colibri-arm-family

1.2.3 Toradex Developer Center

You can find a lot of additional information at the Toradex Developer Center, which is updated

with the latest product support information regularly.

Please note that the Developer Center is common for all Toradex products. You should always

check to ensure if the information is valid or relevant for the specific Colibri modules.

http://www.developer.toradex.com

1.2.4 Colibri Evaluation Board Schematics

We provide the complete schematics plus the Altium project file for the Colibri Evaluation Board for

free. This is a great help when designing your own Carrier Board.

http://developer.toradex.com/products/colibri-evaluation-board

Colibri Carrier Board Design Guide

Toradex AG l Altsagenstrasse 5 l 6048 Horw l Switzerland l +41 41 500 48 00 l www.toradex.com l info@toradex.com

Page | 7

1.2.5 Pinout Designer

This is an interactive and helpful tool for configuring the pin muxing of the Colibri and Apalis

modules. It can be beneficial in custom carrier board development for Toradex modules and for

checking the compatibility of existing carrier boards with our modules.

http://developer.toradex.com/carrier-board-design/pinout-designer-tool

1.3 Abbreviations

Abbreviation

Explanation

ADC

Analog to Digital Converter

AGND

Analog Ground - separate ground for analog signals

Auto-MDIX

Automatically Medium Dependent Interface Crossing - a PHY with Auto-MDIX it can detect whether RX

and TX need to be crossed (MDI or MDIX)

CAD

Computer-Aided Design –in this document it is referred to PCB Layout tools

CAN

Controller Area Network - a bus that is manly used in the automotive and industrial environment

CDMA

Code Division Multiplex Access - abbreviation often used for a mobile phone standard for data

communication

CEC

Consumer Electronic Control - HDMI feature that allows controlling CEC compatible devices

CPU

Central Processor Unit

CSI

Camera Serial Interface

DAC

Digital to Analog Converter

DDC

Display Data Channel - interface for reading out the capability of a monitor. In this document DDC2B

(based on I2C) is always meant

DRC

Design Rule Check - a tool for checking whether all design rules are satisfied in a CAD tool

DSI

Display Serial Interface

DVI

Digital Visual Interface - digital signals are electrically compatible with HDMI

DVI-A

Digital Visual Interface Analog only - signals are compatible with VGA

DVI-D

Digital Visual Interface Digital only - signals are electrically compatible with HDMI

DVI-I

Digital Visual Interface Integrated - combines digital and analog video signals in one connector

EDA

Electronic Design Automation - software for schematic capture and PCB layout (CAD or ECAD)

EDID

Extended Display Identification Data - timing setting information provided by the display in a PROM

EMI

Electromagnetic Interference - high-frequency disturbances

eMMC

Embedded Multi Media Card - flash memory combined with MMC interface controller in a BGA package,

used as internal flash memory

ESD

Electrostatic Discharge - high voltage spike or spark that can damage electrostatic- sensitive devices

FPD-Link

Flat Panel Display Link - high-speed serial interface for liquid crystal displays. In this document, it is also

called the LVDS interface.

GBE

Gigabit Ethernet - Ethernet interface with a maximum data rate of 1000Mbit/s

GND

Ground

GPIO

General Purpose Input/Output pin that can be configured to be either an input or output

GSM

Global System for Mobile Communications

HDA

High Definition Audio (HD Audio) - a digital audio interface between CPU and audio codec

HDCP

High-Bandwidth Digital Content Protection - copy protection system that is used by HDMI beside others

HDMI

High-Definition Multimedia Interface - combines audio and video signal for connecting monitors, TV sets

or Projectors, electrical compatible with DVI-D

I2C

Inter-Integrated Circuit - two-wire interface for connecting low-speed peripherals

I2S

Integrated Interchip Sound - serial bus for connecting PCM audio data between two devices

IrDA

Infrared Data Association - infrared interface for connecting peripherals

JTAG

Joint Test Action Group - widely used debug interface

LCD

Liquid Crystal Display

LSB

Least Significant Bit

LVDS

Low-Voltage Differential Signaling - electrical interface standard that can transport very high-speed

signals over twisted-pair cables. Many standard interfaces like PCIe or SATA use this interface standard.

Colibri Carrier Board Design Guide

Toradex AG l Altsagenstrasse 5 l 6048 Horw l Switzerland l +41 41 500 48 00 l www.toradex.com l info@toradex.com

Page | 8

Abbreviation

Explanation

Since the first successful application was the Flat Panel Display Link, LVDS has become synonymous

with this interface. In this document, the term LVDS is used for the FPD-Link interface.

MIPI

Mobile Industry Processor Interface Alliance

MDI

Medium Dependent Interface - a physical interface between Ethernet PHY and cable connector

MDIX

Medium Dependent Interface Crossed - an MDI interface with crossed RX and TX interfaces

mini PCIe

PCI Express Mini Card - card form factor for internal peripherals. The interface features PCIe and USB

2.0 connectivity

MMC

MultiMediaCard - flash memory card

MSB

Most Significant Bit

mSATA

Mini-SATA - a standardized form factor for small solid-state drive, similar dimensions as mini PCIe

N/A

Not Available

N/C

Not Connected

OD

Open-Drain

OTG

USB On-The-Go - a USB host interface that can also act as a USB client when connected to another host

interface

OWR

One Wire (1-Wire) - a low-speed interface that needs just one data wire plus ground

PCB

Printed Circuit Board

PCI

Peripheral Component Interconnect - parallel computer expansion bus for connecting peripherals

PCIe

PCI Express - high-speed serial computer expansion bus, replaces the PCI bus

PCM

Pulse-Code Modulation - digital representation of analog signals and a standard interface for digital audio

PD

Pull Down Resistor

PHY

Physical Layer of the OSI model

PMIC

Power Management IC - integrated circuit that manages amongst others the power sequence of a system

PU

Pull-up Resistor

PWM

Pulse-Width Modulation

RGB

Red Green Blue - color channels in standard display interfaces

RJ45

Registered Jack - common name for the 8P8C modular connector that is used for Ethernet wiring

RS232

Single-ended serial port interface

RS422

Differential signaling serial port interface - full-duplex

RS485

Differential signaling serial port interface - half-duplex, multi-drop configuration possible

R-UIM

Removable User Identity Module - identifications card for CDMA phones and networks, an extension of

the GSM SIM card

S/PDIF

Sony/Philips Digital Interconnect Format - optical or coaxial interface for audio signals

SATA

Serial ATA, high-speed differential signaling interface for hard drives and SSD

SD

Secure Digital - flash memory card

SDIO

Secure Digital Input Output - an external bus for peripherals that uses the SD interface

SIM

Subscriber Identification Module - identification card for GSM phones

SMBus

System Management Bus (SMB) - a two-wire bus based on the I2C specifications, used mainly in x86

design for system management.

SoC

System on a Chip - IC which integrates the main component of a computer on a single chip

SO-DIMM

Small Outline Dual Inline Memory Module - form factor for mobile RAM modules, the Colibri module uses

the SO-DIMM (DDR, 2.5V variant) connector as the primary interface

SPI

Serial Peripheral Interface Bus - synchronous four-wire full-duplex bus for peripherals

TIM

Thermal Interface Material - thermal conductive material between CPU and heat spreader or heat sink

TMDS

Transition-Minimized Differential Signaling - serial high-speed transmitting technology that is used by DVI

and HDMI

TVS Diode

Transient-Voltage-Suppression Diode - diode that is used to protect interfaces against voltage spikes

UART

Universal Asynchronous Receiver/Transmitter - serial interface, in combination with a transceiver an

RS232, RS422, RS485, IrDA, or similar interface can be achieved

USB

Universal Serial Bus - serial interface for internal and external peripherals

VCC

Positive supply voltage

VGA

Video Graphics Array - analog video interface for monitors

Table 1: Abbreviations

Colibri Carrier Board Design Guide

Toradex AG l Altsagenstrasse 5 l 6048 Horw l Switzerland l +41 41 500 48 00 l www.toradex.com l info@toradex.com

Page | 9

2 Interfaces

2.1 Architecture

2.1.1 Standard Interfaces

The Colibri module family's standard interfaces intend to provide electrical and functional

compatibility between module family members. The table below shows an overview of the

standard interfaces that are provided by a Colibri module. The "GPIO Capable" column indicates

whether the assigned pins intend to be also used as GPIOs. "Yes" and "No" are self-Explanatory.

"Optional" indicates that it may be possible for some modules, but not all.

The "Standard" column indicates the number of interfaces that the specification allows for the

standard pinout. Customers should consult the datasheet for specific Colibri module variants to

check which of the interfaces are available for that module.

Description

Standard

Note

GPIO

Capable

4/5 Wire Resistive Touch

1

Touch wiper shared with analog input 4

No

Analog Inputs

4

Minimum 8-bit resolution, 0-3.3V nominal range

No

Analog Audio

1

Line in L&R, Microphone in, Headphone out L&R

No

Fast Ethernet

1

No

HDMI (TDMS)

1

Located on a dedicated FFC connector

(availability depending on Module)

No

I2C

1

Additional dedicated DDC available on FFC connector

Yes

Parallel Camera

1

8-bit BT.656 (other modes may be available)

Yes

Parallel LCD

1

18-bit resolution (additional bits may be available)

Yes

Parallel Memory Bus

1

Supported bus width depends on Module

Optional

PWM

4

Yes

SDIO

1

4 bit

Yes

SPI

1

Yes

UART

3

1x Full Featured, 1x CTS/RTS, 1x RXD/TXD only

Yes

USB

2

1x shared host/client, 1x host only

No

VGA

1

Located on a dedicated FFC connector

(availability depending on Module)

No

Table 2: Standard Interfaces

2.1.2 Interfaces on Alternative Functions

Many SoC pins can be used for more than one function. This allows the modules to provide many

additional interfaces to the standard set. For example, in the Colibri standard, there is only one SPI

interface listed. Nevertheless, some modules can provide up to 6 SPI interfaces.

Please note that there are a few restrictions on using the interfaces provided as alternative

functions of the pins. There is limited compatibility between their availability at different modules.

For a design to be compatible with a wide range of Colibri modules, it is recommended to use the

standard interfaces mainly. The various pins can be used for only one function simultaneously.

The configuration of the alternative function interfaces can be pretty complex. Toradex provides a

powerful tool that helps the development engineer to resolve pin muxing conflicts. The tool is

called Pinout Designer. It reduces the complexity of this critical task. More information, including its

download link, can be found here:

http://developer.toradex.com/carrier-board-design/pinout-designer-tool

Colibri Carrier Board Design Guide

Toradex AG l Altsagenstrasse 5 l 6048 Horw l Switzerland l +41 41 500 48 00 l www.toradex.com l info@toradex.com

Page | 10

The interfaces on the alternative functions are not described in this document since they differ

between the modules. Information related to these functions can be found in the datasheets of the

modules.

2.1.3 Pin Numbering

The diagrams in the figures below show the pin numbering schema on both sides of the module.

The schema is equal to the JEDEC MO-224 DDR SO-DIMM standard. The odd pin numbers are

located on the top side of the module.

Figure 1: Colibri Module Pin Numbering Schema

2.1.4 Pin Reset State

The datasheets of the Colibri module provide information about the default reset status of the IO

pins. Please be aware that the pin reset status is only guaranteed during the release of the reset

signal. Some of the modules switch the IO bank voltages to follow the power-up sequence of the

SoC. This means the IO pins can have an undefined state between applying the main power to the

module until the nRESET_OUT is released. For carrier board designs that do not allow undefined

pin states, it is recommended to ensure that the peripheral devices are not powered before the

nRESET_OUT is released. Another solution can be gating the related IO signals with the

nRESET_OUT signal.

Pin1 Pin47Pin39 Pin199

Pin2 Pin42Pin40 Pin200

Colibri Carrier Board Design Guide

Toradex AG l Altsagenstrasse 5 l 6048 Horw l Switzerland l +41 41 500 48 00 l www.toradex.com l info@toradex.com

Page | 11

2.2 Ethernet

The Colibri module standard features a fast 10/100Mbit Ethernet (10/100Base-TX) interface port.

The required center tap circuit can differ between the modules. Different assembly options might

be needed for supporting the complete Colibri module family. Some modules support Auto MDIX,

which means they can swap the transmitting with the receiving lanes. Read the corresponding

datasheet of the module for more information about the availability of the Auto MDIX function.

2.2.1 Ethernet Signals

Colibri

Pin

Colibri

Signal Name

I/O

Type

Power

Rail

Description

189

ETH_1_TXO+

I

Analog

100BASE-TX: Transmit + (Auto MDIX: Receive +)

187

ETH_1_TXO-

I

Analog

100BASE-TX: Transmit - (Auto MDIX: Receive -)

195

ETH_1_RXI+

O

Analog

100BASE-TX: Receive + (Auto MDIX: Transmit +)

193

ETH_1_RXI-

O

Analog

100BASE-TX: Receive - (Auto MDIX: Transmit -)

191

AGND_LAN

Ethernet ground, on some modules connected to common GND

183

ETH_1_LINK_AKT

O

CMOS

3.3V

LED indication output for link activity on the Ethernet port

185

ETH_1_SPEED100

O

CMOS

3.3V

LED indication output for 100Mbit/s

Table 3: Ethernet Signals

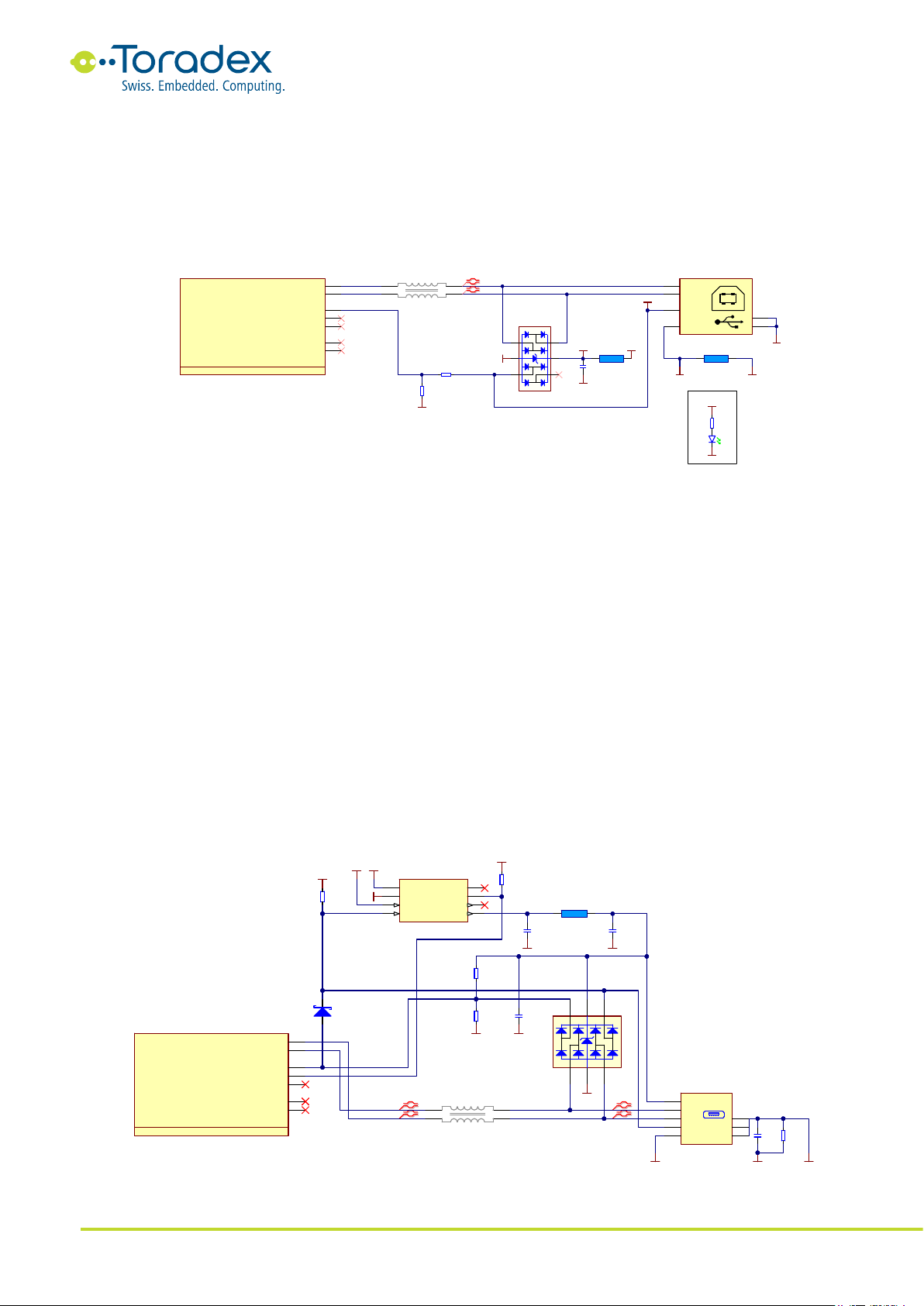

2.2.2 Reference Schematics

Ethernet connectors with integrated magnetics are preferable. If a design with external magnetics

is chosen, additional care must be taken to route the signals between the magnetics and Ethernet

connector.

The LED output signals ETH_1_LINK_AKT and ETH_1_SPEED100 can be connected directly to the

LED of the Ethernet jack with suitable serial resistors. There is no need for additional buffering if

the current drawn does not exceeds 10mA.

The Fast Ethernet interface uses the ETH_1_TXO as transmitting lanes and the ETH_1_RXI as

receiving lane. If the Ethernet PHY features Auto-MDIX, the signal lanes RX and TX could be

swapped. We strongly recommend not swapping the RX and TX lanes to keep the compatibility with

all Colibri modules.

The required center tap circuit depends on the supported modules. Currently, the Ethernet

controller on the PXA270 module is the only one that requires a different center tap circuit since it

does not support Auto-MDIX. All the other currently available modules feature a current control

PHY that requires a 3.3V supply at the center tap of the RX and TX lanes. Since all the Ethernet PHY

manufacturers are tending to change from current mode to voltage mode, which requires leaving

the center tab pins of the magnetics unconnected, we recommend adding additional 0R resistors

into the center tab lines. This ensures that the carrier board design is ready for any future Colibri

module with voltage-mode PHY.

The magnetics provide a certain ESD protection which is sufficient for many designs. However,

especially in Power over Ethernet (PoE) systems, additional transient voltage suppressor diodes

(TVS) are highly recommended between the module and the magnetics. More information can be

found in the following application note from Microchip:

http://ww1.microchip.com/downloads/en/AppNotes/00002157B.pdf

Colibri Carrier Board Design Guide

Toradex AG l Altsagenstrasse 5 l 6048 Horw l Switzerland l +41 41 500 48 00 l www.toradex.com l info@toradex.com

Page | 12

Figure 2: Fast Ethernet with Integrated Magnetics Reference Schematic

2.2.3 Unused Ethernet Signals Termination

All unused Ethernet signals can be left unconnected.

2.3 USB

The Colibri modules feature two USB interfaces. One of the two USB interfaces can be configured

to be used as either the host or client. The other interface can only be used as a host. Some of the

Colibri modules use the USB client port for debugging and recovery purposes. Therefore, it is

recommended to have the interface accessible even for carrier board designs that do not need any

USB ports.

2.3.1 USB Signals

Colibri

Pin

Colibri

Signal Name

I/O

Type

Power

Rail

Description

139

USB_H_DP

I/O

USB

3.3V

Positive Differential Signal for USB Host port

141

USB_H_DM

I/O

USB

3.3V

Negative Differential Signal for USB Host port

143

USB_C_DP

I/O

USB

3.3V

Positive Differential Signal for the shared USB Host / Client port

145

USB_C_DM

I/O

USB

3.3V

Negative Differential Signal for the shared USB Host / Client port

Table 4: USB Data Signals

If you use the USB Host function, you need to generate the 5V USB supply voltage on your carrier

board. The Colibri modules provide two optional signals for USB power supply control (PWR_EN

and OC). We recommend using the following pins to ensure the best possible compatibility.

However, the use of these signals is not mandatory, and other GPIOs may be used instead.

In the USB client mode, an additional signal is required that detects whether the client is connected

to a host interface (VBUS_DETECT). Please note that this pin is only 3.3V tolerant. Therefore, an

additional logic level shifter (the simplest solution is a voltage divider) is required.

Colibri

Pin

Colibri

Signal Name

I/O

Type

Power

Rail

Description

129

USB_H_PWR_EN

O

CMOS

3.3V

This pin enables the external USB voltage supply. By default, this

pin is active low.

131

USB_H_OC

I

CMOS

3.3V

USB overcurrent, this pin can signal an overcurrent condition in the

USB supply

137

USB_C_VBUS_DETECT

I

CMOS

3.3V

Use this pin to detect if VBUS is present (5V USB supply). Please

note that this pin is only 3.3V tolerant

Table 5: USB Control Signals

ETH_LINK_ACT

ETH_SPEED

ETH_TX 0_N

ETH_TX 0_P

ETHERNET[0..5]

50R

R20

50R

R21

100nF

16VC45

GND

50R

R22

50R

R23

100nF

16VC46

GND

ETH_RX I_P

ETH_RX I_N

C44

100nF

16V

GND

ETH_AVCC

3.3V

3.3V

2A

220R@ 100MHz

L10

47uF

6.3V

+

C4 8

47uF

6.3V

+

C49

3.3V ETH_AVCC

GND

150 RR25

150RR24

J00- 0065N L

TD +

1

TD -

2

CT_TX D

4

CT_RX D

5

RD +

3

RD -

6

LED_Left_ A

9

LED_Left_ C

10

LED_R ight_ C

11 LED_R ight_ A

12 SHIELD S1

SHIELD S2

NC 7

CHS GND 8

X17

ETH_LINK_ACT

ETH_SPEED

ETH_TX0_N

ETH_TX0_P

ETH_RXI_N

ETH_RXI_P

1473005 -1

ETH_LINK_ACT 183

ETH_SPEED 185

ETH_TX0-

ETH_TX0+ 189

ETH_RXI- 193

ETH_RXI+ 195

ETH_GND 191

Colibri -Ethernet

2of 16

X1B

SHIELD

Ethernet Connector

ETH_CT_TX

ETH_CT_RX

GND

GND

0R

R10

C47

100nF

16V

GND

0R

R11

0R

R12

NA

PXA2700RNA0R

ModuleR12R11R10

All except PXA2700RNA 0R

Reserved for future modulesNA NANA (Integrated Magnetics)

187

Colibri Carrier Board Design Guide

Toradex AG l Altsagenstrasse 5 l 6048 Horw l Switzerland l +41 41 500 48 00 l www.toradex.com l info@toradex.com

Page | 13

2.3.2 Reference Schematics

2.3.2.1 USB 2.0 Client Schematic Example

The differential USB data signals require a common mode choke to be placed. Make sure that the

selected choke is certified for USB 2.0 High Speed. The same is also required for the TVS diodes.

The VBUS_DETECT signal is only 3.3V tolerant on the Colibri module. The simplest solution is to

use a voltage divider.

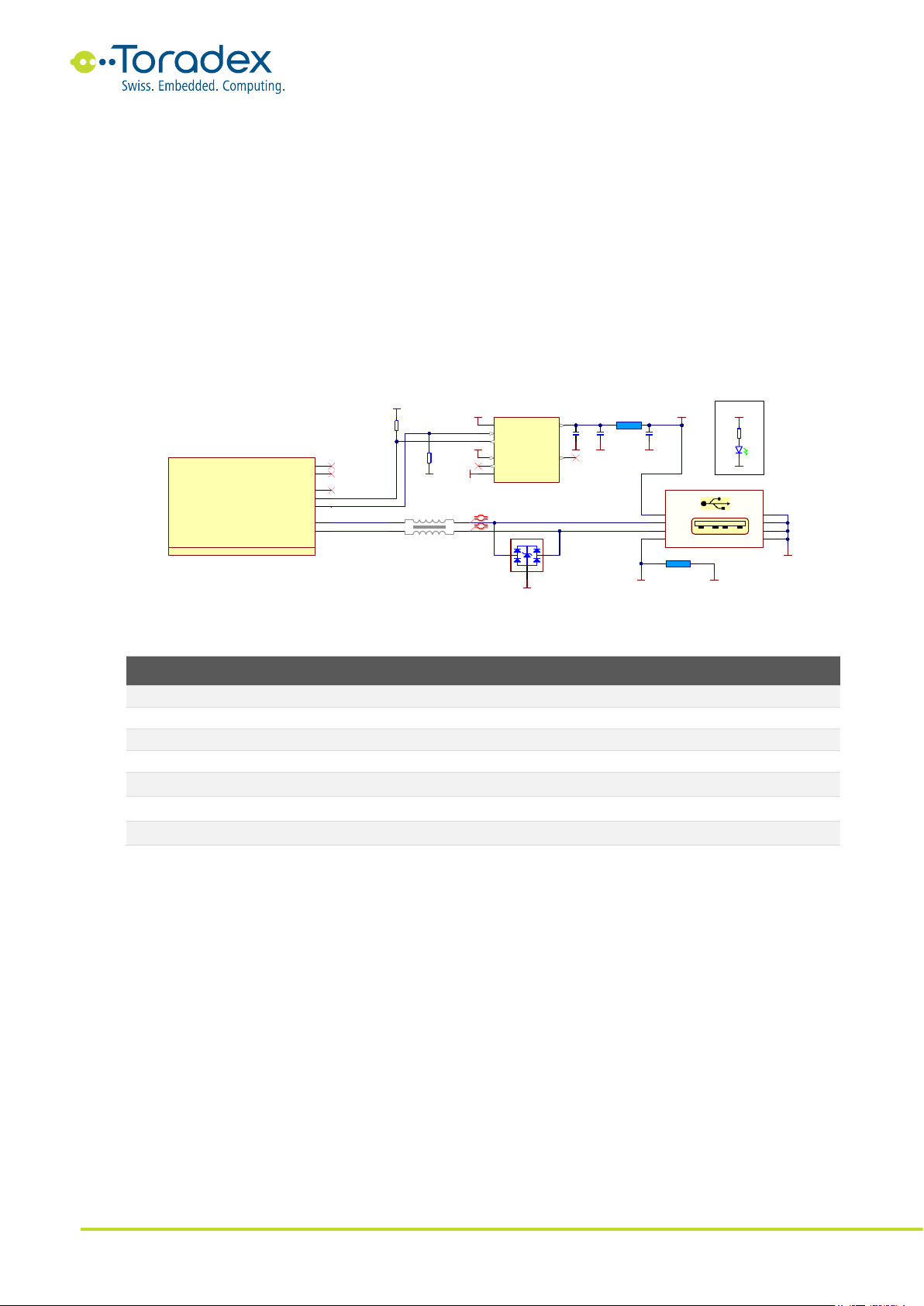

Figure 3: USB 2.0 Client Reference Schematic

2.3.2.2 USB 2.0 OTG Schematic Example

The Colibri standard does not support the full USB OTG function. However, it is possible to

implement a circuit on the carrier board that allows changing the role from host to client

depending on the level of the ID pin of a Micro-AB jack. The reference schematic differs from other

USB OTG solutions since the module itself does not directly use the ID pin to detect whether the

port is supposed to be set in client or host mode. The pin is indirectly used.

If no cable is plugged into the Micro-AB jack, the port is configured to host mode, and the 5V

power output (VCC_USB2 in the schematic below) is disabled. If a Micro-B is plugged in (ID pin is

floating on such plugs), the VCC_USB2 comes from the cable since the system gets plugged into a

host. With the help of the voltage divider, the USB_C_DET signal gets around 3.3V. This signalizes

the module that it has been connected to a host and needs to switch to client mode.

If a Micro-A connector is inserted, the ID pin gets shorted to the ground. This ID pin enables the

output of the TPS2042 power switch. This voltage on the VCC_USB2 rail is used to power any client

device connected to the port. Additionally, the ID pin keeps the USB_C_DET signal low over a

diode, even though the VCC_USB2 rail goes to 5V. This makes sure the module remains in host

mode to be able to communicate with the client device that is plugged in.

Figure 4: USB 2.0 OTG Reference Schematic

GND

2A

220R@100MHz

L1

90R@100MHz

1

2 3

4

L2

USBO1_D_N

USBO1_D_P USBO1_D_CON_N

USBO1_D_CON_P

330R

R3

GND

GREEN

LED1

SHIELD

VCC_USBO1

VCC_USBO1

GND_USBO1

Optional

USBO1_VBUS

RCLAMP0504S

1

2

3 4

5

6

D1

4A

39R@100MHz

L3

100nF

C1

SHIELD

5V_ESD

SHIELD

5V

VCC

1

D-

2

D+

3

GND

4S1

S2

61729-0010BLF

X2

1473005-1

USBH_P 139

USBH_N 141

USBC_P 143

USBC_N 145

PIN_131/USB_OC 131

PIN_137/USBC_CABLEDET 137

PIN_129/USB_P_EN 129

Colibri - USB

3 of 16

X1C

560R

R73

R74

1K

GND

GND

5V R50

100K

3.3V

USBC_P

USBC_N

GND

90R@100MHz

1

2 3

4

L15

220R@100MHz

2A

L18

100nF

16V

C43

GND

3.3V

USB_ID

R61

100K

TPS2042BD

GND

1V_IN

2

EN_1#

3

EN_2#

4

OC_2# 5

OUT_2 6

OUT_1 7

OC_1# 8

IC1

RCLAMP0504S

1

2

34

5

6

D11

100nF

16V

C104

560R

R115

R116

1K

GND

GND

GND

USB_ID

1473005-1

USBH_P 139

USBH_N 141

USBC_P 143

USBC_N 145

PIN_131/USB_OC 131

PIN_137/USBC_CABLEDET 137

PIN_129/USB_P_EN 129

Colibri - USB

3 of 16

X1C

USB_CLIENT_N

USB Host / Client

Micro-AB type

22uF

10V

C42

GND

VBUS

USB_CLIENT_P

BAT54C

D12B

ZX62-AB-5PA(31)

VCC

1

D-

2

D+

3

ID

4

GND

5

S1

S3

S2

X12

Alternative part for connector X12:

-TE/Tyco,1981584-1

CHASSIS_GND

1nF

2KV

C129 R37

1M

GND

USB_OC

USB_ID

USB_C_DET

3.3V

VBUS

USB_OC

Colibri Carrier Board Design Guide

Toradex AG l Altsagenstrasse 5 l 6048 Horw l Switzerland l +41 41 500 48 00 l www.toradex.com l info@toradex.com

Page | 14

2.3.2.3 USB 2.0 Host Connector Schematic Example

The carrier board needs to provide 5V USB bus power on the USB host jacks. According to the USB

2.0 specifications, the maximum current drawn per port is limited by 500mA. The bus power needs

to be in the range of 4.75V to 5.25V measured at the USB host jack for any load current from 0mA

to 500mA. To ensure that an out-of-spec device or a defective device is not damaging the 5V

power rail on the carrier board, adding a current limiting IC is recommended. This device detects

an overcurrent situation and switches off the corresponding USB bus power. The overcurrent signal

(USB_H_OC) is used to notify the host controller about the occurrence of an overcurrent shutdown

event.

The inrush current needs to be taken into account while designing the USB bus power. USB devices

are allowed to have a maximum input capacitor at the bus power of 10µF. The maximum inrush

charge is limited to 50µC. This means that the power rail at the USB host jack needs to be tolerant

of this inrush current. A good approach is to place a large capacitor (e.g., 100µF) at the rail.

Figure 5: USB 2.0 Host Reference Schematic

2.3.3 Unused USB Signal Termination

Colibri

Pin

Colibri

Signal Name

Recommended Termination

139

USB_H_DP

Leave NC if not used

141

USB_H_DM

Leave NC if not used

143

USB_C_DP

Leave NC if not used

145

USB_C_DM

Leave NC if not used

129

USB_H_PWR_EN

Leave NC if not used

131

USB_H_OC

Add pull-up resistor or disable the overcurrent function in software

137

USB_C_VBUS_DETECT

Leave NC if not used

Table 6: Unused USB Signals Termination

2.4 Parallel RGB LCD Interface

The Colibri modules feature one parallel RGB LCD interface as the primary display interface. As

standard, the Colibri modules feature an interface with 18-bit color depth. Some modules support

a color depth of 16-bit or 24-bit. Unfortunately, the color mapping of these modes can be different

between the modules. Therefore, Toradex recommends using the interface in the 18-bit color

mode for the best compatibility between all Colibri modules. Dithering can help to reduce the

visible color banding of gradients in lower color depth systems. Consider using 18-bit color

mapping with enabled dithering instead of 24-bit mapping. Carefully check which modules support

color dithering.

2A

220R@100MHz

L3 1nF

50V

C3

GND_USBH

100nF

16V

C1

GND

100uF

10V

+

C2

GND

GND

2A

220R@100MHz

L2

90R@100MHz

1

2 3

4

L1

USBH2_D_N

USBH2_D_P USBH2_D_CON_N

USBH2_D_CON_P

330R

R1

GND

GREEN

LED1

TPD2EUSB30DRTR

12 D+D-

D2

GND

SHIELD

VCC_USBH VCC_USBH

USBH_OC#

USBH_EN#

GND_USBH

Optional

USBH_OC#

USBH_EN#

GND

5V

VCC

1

D-

2

D+

3

GND

4

292303-1

S1

S2

S3

S4

X2

R2

100K

3.3V

R3

100K

GND

1473005-1

USBH_P 139

USBH_N 141

USBC_P 143

USBC_N 145

PIN_131/USB_OC 131

PIN_137/USBC_CABLEDET 137

PIN_129/USB_P_EN 129

Colibri - USB

3 of 16

X1C

TPS2042BD

GND

1

V_IN

2

EN_1#

3

EN_2#

4

OC_2#

5OUT_2 6

OUT_1 7

OC_1#

8

IC?

3.3V

Colibri Carrier Board Design Guide

Toradex AG l Altsagenstrasse 5 l 6048 Horw l Switzerland l +41 41 500 48 00 l www.toradex.com l info@toradex.com

Page | 15

2.4.1 Parallel RGB LCD Signals

Colibri

Pin

Colibri

Signal Name

I/O

Type

Power

Rail

Description

52

LCD_1_18bit_R0

O

CMOS

3.3V

Red LCD data signals (LSB: 0, MSB: 5)

54

LCD_1_18bit_R1

O

CMOS

3.3V

66

LCD_1_18bit_R2

O

CMOS

3.3V

64

LCD_1_18bit_R3

O

CMOS

3.3V

57

LCD_1_18bit_R4

O

CMOS

3.3V

61

LCD_1_18bit_R5

O

CMOS

3.3V

80

LCD_1_18bit_G0

O

CMOS

3.3V

Green LCD data signals (LSB: 0, MSB: 5)

46

LCD_1_18bit_G1

O

CMOS

3.3V

62

LCD_1_18bit_G2

O

CMOS

3.3V

48

LCD_1_18bit_G3

O

CMOS

3.3V

74

LCD_1_18bit_G4

O

CMOS

3.3V

50

LCD_1_18bit_G5

O

CMOS

3.3V

76

LCD_1_18bit_B0

O

CMOS

3.3V

Blue LCD data signals (LSB: 0, MSB: 5)

70

LCD_1_18bit_B1

O

CMOS

3.3V

60

LCD_1_18bit_B2

O

CMOS

3.3V

58

LCD_1_18bit_B3

O

CMOS

3.3V

78

LCD_1_18bit_B4

O

CMOS

3.3V

72

LCD_1_18bit_B5

O

CMOS

3.3V

44

LCD_1_18bit_DE

O

CMOS

3.3V

Data Enable (other names: Output Enable)

56

LCD_1_18bit_PCLK

O

CMOS

3.3V

Pixel Clock (other names: Dot Clock, L_PCLK_WR)

68

LCD_1_18bit_HSYNC

O

CMOS

3.3V

Horizontal Sync (other names: Line Clock, L_LCKL_A0)

82

LCD_1_18bit_VSYNC

O

CMOS

3.3V

Vertical Sync (other names: Frame Clock, L_FCLK)

Table 7: Parallel RGB LCD Signals

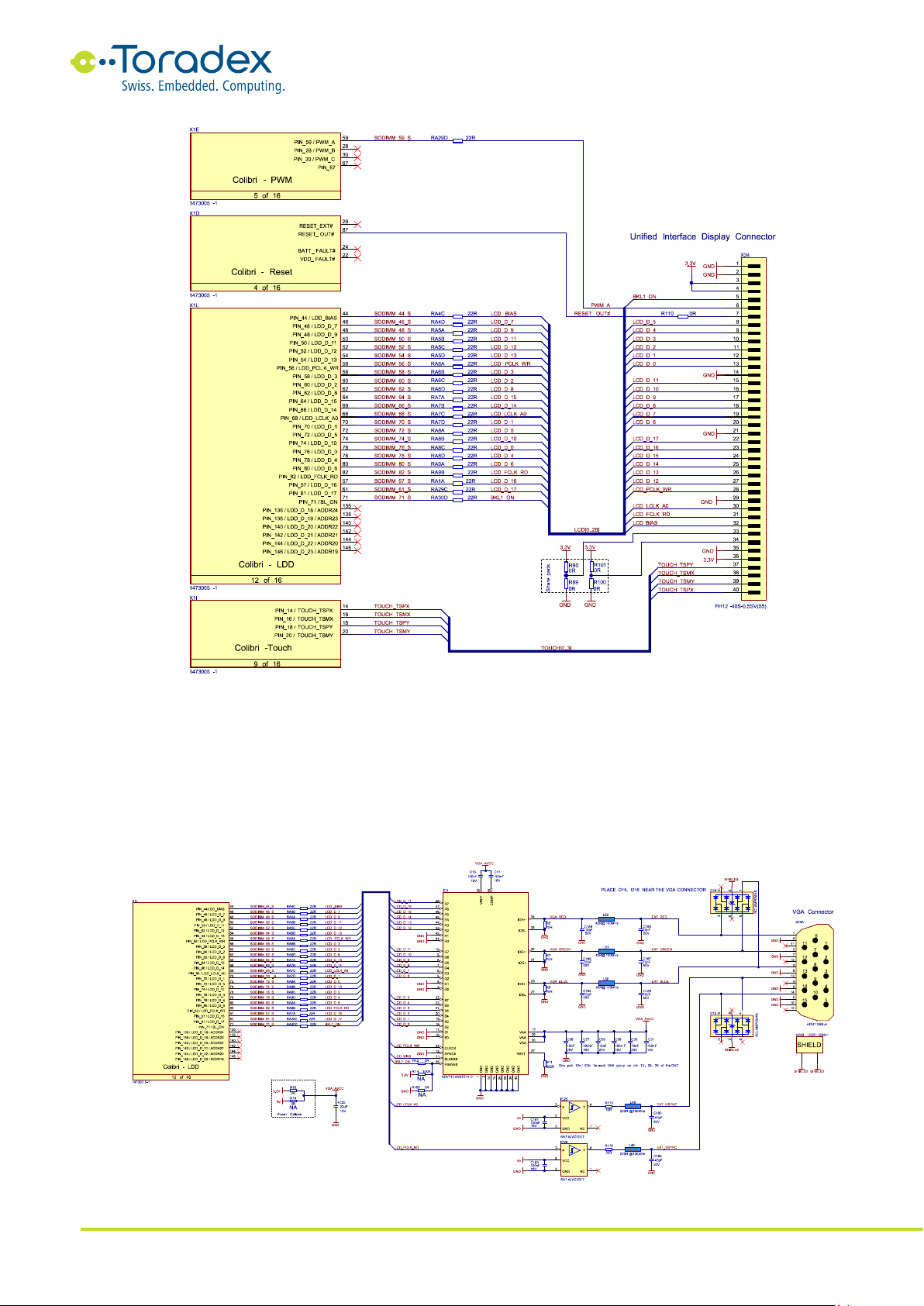

2.4.2 Reference Schematics

2.4.2.1 18-bit Display Schematic Example

The parallel RGB interface can cause problems in passing the electromagnetic radiation tests when

used with high pixel clock frequency, especially if a display is connected over long flat flex cables.

The reduction of radiation needs to be taken into account. Keep the flat flex cables as short as

possible. Series resistors in the data lines reduce the slew rate of the signals, which reduces the

radiation problem but can introduce signal quality and timing problems. The serial resistor value is

a trade-off between electromagnetic radiation reduction and signal quality. A good starting value

is 22Ω.

Colibri Carrier Board Design Guide

Toradex AG l Altsagenstrasse 5 l 6048 Horw l Switzerland l +41 41 500 48 00 l www.toradex.com l info@toradex.com

Page | 16

Figure 6: 18bit Parallel RGB Display Reference Schematic

2.4.2.2 VGA DAC Schematic Example

A few Colibri modules feature a dedicated VGA interface on an FFC connector. Nevertheless,

adding a parallel RGB to VGA converter is recommended if a VGA interface is needed, which is

compatible with all modules. Since only the 18-bit color depth is compatible between the different

modules, it is recommended to use this mode even if the DAC is capable of 24-bit.

Figure 7: VGA DAC Reference Schematic

Colibri Carrier Board Design Guide

Toradex AG l Altsagenstrasse 5 l 6048 Horw l Switzerland l +41 41 500 48 00 l www.toradex.com l info@toradex.com

Page | 17

2.4.2.3 LVDS Transmitter Schematic Example

Since the electromagnetic radiation of the parallel RGB interface is not easy to handle, it is

recommended to attach liquid crystal displays with high resolutions by using an LVDS interface.

LVDS also reduces problems associated with long cables. The Colibri standard does not feature a

dedicated LVDS LCD interface. Nevertheless, a parallel RGB to LVDS transmitter can be placed on

the carrier board to get an LVDS interface.

Since there are different LVDS color mapping available, check with your display vendor how the

RGB signals need to be connected to the transmitter in order to be compatible.

Figure 8: LVDS Transmitter Reference Schematic

18-bit Color Mapping

The color mapping for the 18-bit LVDS interface is standardized and is shown in the following

picture:

Figure 9: 18-bit LVDS Color Mapping

LVDS1_A_CLK+

LVDS1_B_CLK+

LVDS1_A_TX0+/-

LVDS1_B_TX0+/-

LVDS1_A_TX1+/-

LVDS1_B_TX1+/-

LVDS1_A_TX2+/-

LVDS1_B_TX2+/-

Previous Cycle Current Cycle Next Cycle

G0 R5 R4 R3 R2 R1 R0

B1 B0 G5 G4 G3 G2 G1

DE VSYNC HSYNC B5 B4 B3 B2

Colibri Carrier Board Design Guide

Toradex AG l Altsagenstrasse 5 l 6048 Horw l Switzerland l +41 41 500 48 00 l www.toradex.com l info@toradex.com

Page | 18

24-bit JEIDA Color Mapping

The JEIDA color mapping is compatible with the 18bit LVDS interface. Therefore, the mapping is

sometimes also called "24bit / 18bit Compatible Color Mapping". The signal names of the color

bits are renamed (e.g., the 18bit R5 is renamed to 24bit R7), but the MSB position is kept the

same. The additional least significant bits R0, R1, G0, G1, B0, and B1 are located at the additional

fourth LVDS data pair.

Figure 10: 24-bit JEIDA LVDS Color Mapping

24-bit VESA Color Mapping

Most of the 24bit LVDS displays follow the VESA Color mapping. The VESA color mapping does not

rename the signal bits. This means that the MSB position is changed since they are available at the

additional data pair. Therefore, the VESA color mapping is not compatible with the 18bit interface.

Figure 11: 24-bit VESA LVDS Color Mapping

2.4.3 Unused Parallel RGB Interface Signal Termination

All unused parallel RGB interface signals can be left unconnected.

2.5 HDMI/DVI

The HDMI and DVI interface uses a TMDS compatible physical link to transfer video and optional

audio data. While electrically, HDMI and DVI are similar, but there can be a few differences in

their protocols. HDMI is the DVI successor and specifies the additional transport for audio data and

content protection (HDCP). As HDMI is backward compatible, HDMI devices (monitor, television

set, and others) work with DVI signals. Forward compatibility is not guaranteed. Not all DVI

displays accept the HDMI protocol or are HDCP compatible. Please read the datasheet of the

Colibri modules for more information about the provided HDMI and DVI protocols.

The HDMI and DVI interface define different connectors. There are passive adapters available in

both types. Please be advised that HDMI and HDCP are required to be licensed. The HDMI/DVI

signals are available on a dedicated FFC connector. Check carefully to confirm which modules

provide the interface.

LVDS1_A_CLK+

LVDS1_B_CLK+

LVDS1_A_TX0+/-

LVDS1_B_TX0+/-

LVDS1_A_TX1+/-

LVDS1_B_TX1+/-

LVDS1_A_TX2+/-

LVDS1_B_TX2+/-

LVDS1_A_TX3+/-

LVDS1_B_TX3+/-

Previous Cycle Current Cycle Next Cycle

G2 R7 R6 R5 R4 R3 R2

B3 B2 G7 G6 G5 G4 G3

DE VSYNC HSYNC B7 B6 B5 B4

N/A B1 B0 G1 G0 R1 R0

LVDS1_A_CLK+

LVDS1_B_CLK+

LVDS1_A_TX0+/-

LVDS1_B_TX0+/-

LVDS1_A_TX1+/-

LVDS1_B_TX1+/-

LVDS1_A_TX2+/-

LVDS1_B_TX2+/-

LVDS1_A_TX3+/-

LVDS1_B_TX3+/-

Previous Cycle Current Cycle Next Cycle

G0 R5 R4 R3 R2 R1 R0

B1 B0 G5 G4 G3 G2 G1

DE VSYNC HSYNC B5 B4 B3 B2

N/A B7 B6 G7 G6 R7 R6

Colibri Carrier Board Design Guide

Toradex AG l Altsagenstrasse 5 l 6048 Horw l Switzerland l +41 41 500 48 00 l www.toradex.com l info@toradex.com

Page | 19

2.5.1 HDMI/DVI Signals

Colibri

FFC Pin

Colibri

Signal Name

I/O

Type

Power

Rail

Description

2

HDMI_1_CLK_P

O

TDMS

HDMI/DVI differential clock positive

3

HDMI_1_CLK_N

O

TDMS

HDMI/DVI differential clock negative

5

HDMI_1_DATA0_P

O

TDMS

HDMI/DVI differential data lane 0 positive

6

HDMI_1_DATA0_N

O

TDMS

HDMI/DVI differential data lane 0 negative

8

HDMI_1_DATA1_P

O

TDMS

HDMI/DVI differential data lane 1 positive

9

HDMI_1_DATA1_N

O

TDMS

HDMI/DVI differential data lane 1 negative

11

HDMI_1_DATA2_P

O

TDMS

HDMI/DVI differential data lane 2 positive

12

HDMI_1_DATA2_N

O

TDMS

HDMI/DVI differential data lane 2 negative

14

HDMI_1_HPD

I

CMOS

3.3V

Hot-plug detect

16

HDMI_DDC_SDA

I/O

OD

3.3V

I2C interface for reading the extended display identification data (EDID)

over DDC.

15

HDMI_DDC_SCL

O

OD

3.3V

Table 8: HDMI/DVI Signals

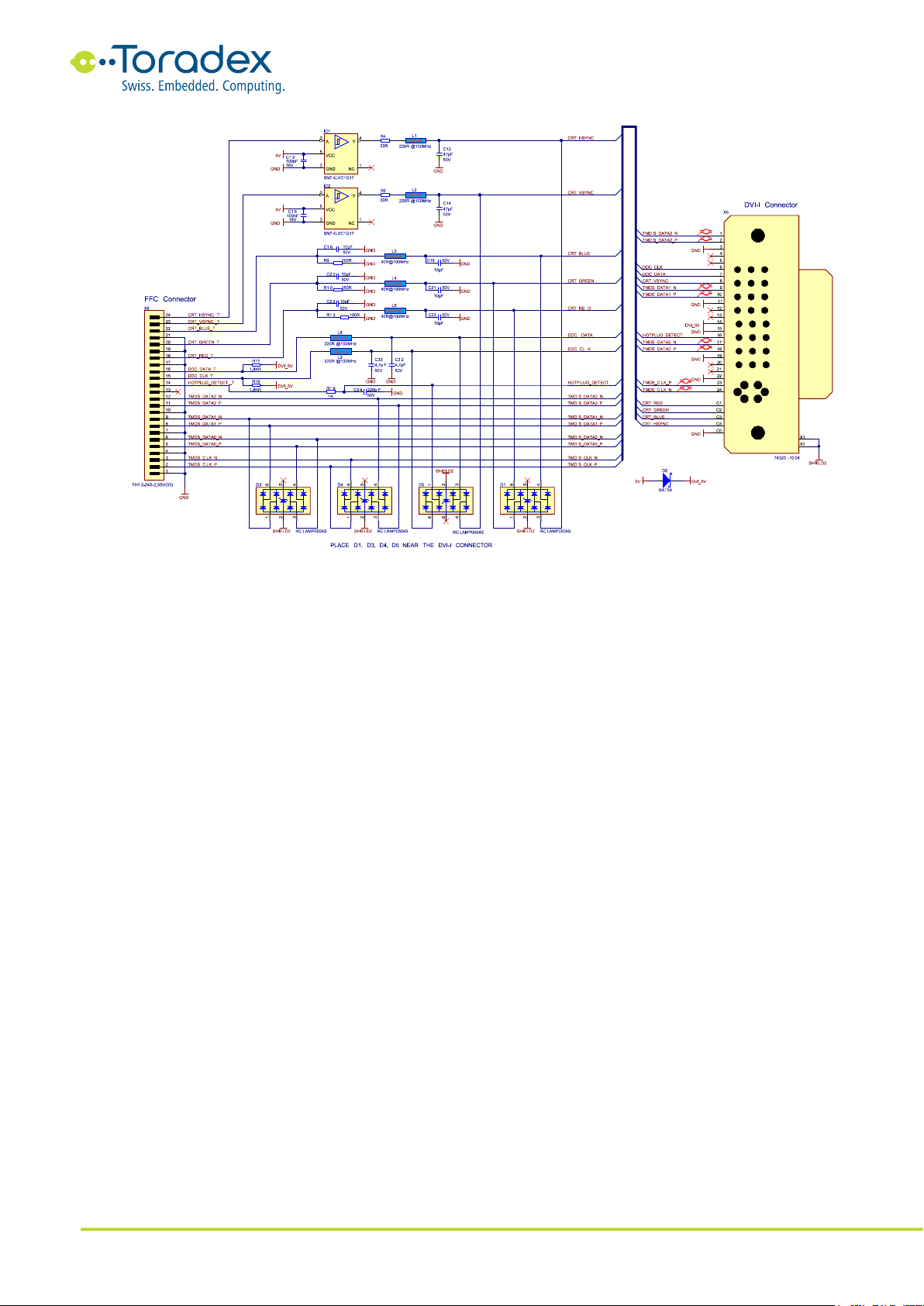

2.5.2 Reference Schematics

2.5.2.1 DVI Schematic Example

There are different configurations of DVI connectors available. The DVI-D (digital) contains only the

native DVI signals. The DVI-A (analog) provides no DVI signals. Only the analog VGA signals are

provided. The DVI-I (integrated) combines the digital DVI signals and the analog VGA signals. For

the DVI-A and DVI-I, there are passive adapters available for the D-SUB VGA connector. There is

only one DDC channel available on the DVI-I interface. Therefore, the connector is not designed to

use both links (DVI and VGA) contemporaneously. Nevertheless, there are Y-cables available that

provide a DVI and VGA output contemporaneously. Such cables are not standardized and usually

provide the DDC only on the DVI or VGA output. Please be aware of the DDC when using such a

Y-cable.

The following schematic example shows a DVI-I implementation. It can also be used as an example

for a DVI-D design. Just remove the analog VGA signals. The sync signals for the VGA signals need

to be level shifted from 3.3V to 5V. The same is necessary for the DDC signals. The TDMS signals

need to be ESD protected by using diodes. The schematic example shows a discrete solution for the

level shifting and protection. There are also integrated solutions available.

Colibri Carrier Board Design Guide

Toradex AG l Altsagenstrasse 5 l 6048 Horw l Switzerland l +41 41 500 48 00 l www.toradex.com l info@toradex.com

Page | 20

Figure 12: DVI-I Reference Schematic

2.5.2.2 HDMI Schematic Example

The HDMI connector does not feature an Analog VGA interface, but an optional Consumer

Electronics Control (CEC) interface is available on the connector. The location of the CEC signal is

not standardized on the Colibri modules. Check the datasheet of the modules for more

information on the position of the signal. The CEC is a single-wire interface used to control

consumer audio and video devices such as television sets or AV receivers. There are many different

CEC trade names (VIERA Link, Anynet+, EasyLink, Aquos Link, BRAVIA Link, and others.). The CEC

is a 3.3V interface. Nevertheless, it is recommended to add a level shifter from the internal 3.3V

logic level. This eliminates problems with displays that pull-up the signal to other voltage levels.

The I2C signals for the DDC and the hotplug detection (HPD) need to be shifted to/from the 5V

logic level of the HDMI to the Colibri level of 3.3V. The HPD has a 100kΩpull-down resistor

already on the baseboard

Table of contents

Other Toradex Carrier Board manuals