Introduction 7

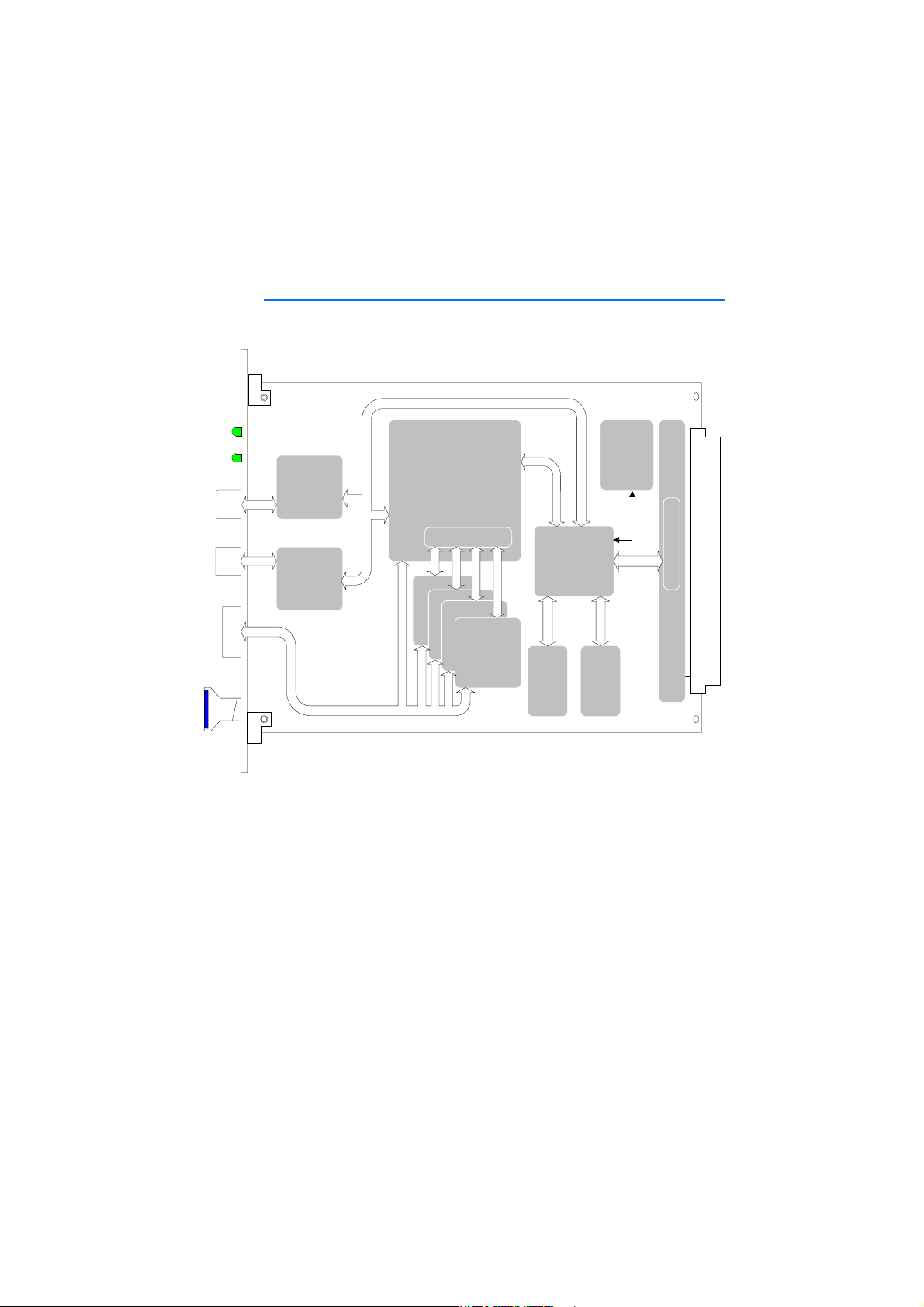

supplied externally or routed to the outside to synchronize I/O modules on

other carrier boards. The synchronization lines can also be stimulated from

within the simulation model.

CAN Interfaces

There are two identical CAN channels on the ES1651.1 Carrier Board for con-

necting the board to the CAN bus. The transceiver functionality is realized on

piggybacks so that, if necessary, different transceivers can be used than those

intended, i.e. than the PCA82C251 transceiver by Philips for high-speed CAN

applications 1and the MAX3055 transceiver by Maxim for low-speed CAN

applications2.

The ETAS PB1651CAN1 transceiver module is a combined high-speed/low-

speed CAN transceiver module3with galvanic isolation of the CAN channels.

Relays are used to toggle between high-speed and low-speed functionality.

The CAN controller functionality is realized in the MPC555 processor of the

board which has two CAN channels on board.

VMEbus Interface

The ES1651.1 Carrier Board has a VMEbus slave interface and reacts to ”A24

non privileged data access” accesses (VMEbus address modifier 39 hex).

The position of the 64-kByte VMEbus address space of the board can be set

either dynamically or statically. Data is exchanged with VMEbus master boards

via a 32-kByte DPRAM. The board can trigger interrupts at the VMEbus.

Inspection and Versioning Data

Inspection and versioning data of the board are stored in a serial non-volatile

data memory. PB1651CAN1 transceiver modules also have serial data memo-

ries for version and inspection data.

Processor

In addition to the CAN channels listed, the MPC555 processor of the board

also has a 448-kByte ROM memory which is large enough for program code

and data; this is why the optional external ROM memory is not assembled.

1. High-speed CAN systems (data rates between 125 kBaud and 1 MBaud) are

used e.g. for engine and transmission controls, ESP, ASR, ACC and ABS.

2. Low-speed CAN systems (data rates up to 125 kBaud) are used in the field

of convenience electronics.

3. The terms fault-tolerant CAN and low-speed CAN are synonymous.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com