TorcUP EP500 Installation guide

OPERATION AND MAINTENANCE

MANUAL

Torque Wrench Power Pump

MODELS EP500, EP500-230V, EP1000, EP1000-Q, EP1000-230V, EP1000-Q-230V

EP500 AND EP1000

1025 Conroy Place, Easton PA 18040 * U.S.A.

Phone: +1 610-250-5800 * Fax:+1 610-250-2700

Toll Free: 1-888-TORCUP-1

Email: [email protected] * Website: www.torcup.com

Operational and Maintenance Manual for TorcUP

EP500 & EP1000 Torque Wrench Pump

TorcUP Inc. is not responsible for customer modication of tools for applications on

which TorcUP Inc. was not consulted.

IMPORTANT SAFETY INFORMATION ENCLOSED.

READ THIS MANUAL BEFORE OPERATING PUMP.

IT IS THE RESPONSIBILITY OF THE EMPLOYER TO PLACE THE INFORMATION IN THIS

MANUAL INTO THE HANDS OF THE OPERATOR.

FAILURE TO OBSERVE THE FOLLOWING WARNINGS COULD RESULT IN INJURY.

The use of other than genuine TorcUP replacement parts may result in safety

hazards, decreased tool performance, and increased maintenance, and may

invalidate all warranties. Repairs should be made only by authorized

personnel. Consult your nearest TorcUP Authorized Service Center.

Refer All Communications to the Nearest TorcUP Ofce or Distributor.

For Technical Support & Information Contact:

TorcUP Inc.

1025 Conroy Place, Easton, PA 18040 USA

Phone: +1 610-250-5800 Fax:+1 610-250-2700

email: [email protected]

CONTENTS

TorcUP has taken every care in preparing this Operational Manual that is intended as a technical guideline only. TorcUP

accepts no liability in relation to any use or reliance made of any information in this Operational Manual. All information,

illustrations and specications in this Operational Manual are based on the latest information available at the time of publica-

tion. The right is reserved to make changes at any time without notice. Equipment operators and installers shall be respon-

sible for ensuring that a safe working environment and safe systems of work are in place before operating the equipment.

Version 1: 2013 April

Category Page # Category Page #

Manual Index 1 Control Valves 8

General Warnings 2 Power Control Switches 8

Safe and Correct Use 3-5 Pressure Torque Setting 9

Warranty Statement 4 Completing the job 9

Working Pressure 5 Periodic Maintenance 9

Install Vent Plug 5 Oil Level 10

Adding Oil 5 Oil Intake Screen 10

General Safety 5 Oil Flushing 10

Technical Specications 6 Troubleshooting 11

Install Hydraulic Connections 6 EP1000 Parts Index 12

Electrical 7 EP500 Parts Index 23

Connecting Tools 7 Pendant 37

Initial Startup 7

Pump Mounting 8

EP500 EP1000

Shown with

optional quad kit

1/37

FAILURE TO OBSERVE THE FOLLOWING WARNINGS COULD RESULT IN INJURY

Do NOT exceed Maximum Pressure. See Torque Chart with Tool. Damage May Occur.

Always wear eye

protection

when

operating or

performing

maintenance

on this tool.

Always wear ear protection

when operating this tool. Do not carry

the tool

by the hose.

Keep body stance

balanced and rm.

Do not overreach

when operating this

tool.

USING THE TOOL

• Keep hands, loose clothing & long hair away from the reaction arm and working area during operation.

• This tool will exert a strong reaction force. Use proper mechanical support and correct reaction arm

positioning to control these forces. Do not position the reaction arm so that it tilts the tool off the axis of

the bolt and never use the swivel inlets as a reaction stop.

• Avoid sharp bends and kinks that will cause severe back-up pressure in hoses an lead to premature

hose failure.

• Use accessories recommended by TorcUP.

• Use only impact sockets and accessories. Do not use hand (chrome) sockets or accessories.

• Use only sockets and accessories that correctly t the bolt or nut and function without tilting the tool off

the axis of the bolt.

• This tool is not insulated against electric shock.

• This equipment must not be operated or serviced unless the operator read the operating instructions

and fully understands the purpose, consequences and procedure of each step.

Depending on the working environment your local health and safety regulations may require

you protective gear (i.e. Ear Protection, Safety Shoes, Hard Hat, Gloves, Coveralls, etc.) In

case external forces are exerted on the equipment, non-compliance with these regulations may

result in injury. EAR PROTECTION MUST BE WORN WHEN OPERATING THIS TOOL.

The Torque Reaction Arm must be

positioned against a positive stop.

Do not use the arm as a dead

handle. Take all precautions to

make certain the operator’s hand

cannot be pinched between the

arm and a solid object.

Do not use damaged,

frayed or deteriorated

hydraulic hoses

and ttings.

2/37

SAFE AND CORRECT USE

Operation of the Equipment in Accordance with Specied Use

1. Inspect, maintain, operate and install the tool in accordance with all applicable standards and

regulations (local, state, country, federal, etc.)

2. Do not remove any labels. Replace any damaged labels immediately.

3. Be sure all hoses and ttings are the correct size and tightly secured.

4. Do not use damaged, frayed or deteriorated hydraulic hoses and ttings. Do not paint hoses.

5. Do not lubricate tools with ammable or volatile liquids such as kerosene, diesel or jet fuel. Use

only TorcUP recommended lubricants.

6. Use only proper cleaning solvents to clean parts. Use only cleaning solvents which meet current

safety and health standards. Use cleaning solvents in a well ventilated area.

7. Keep work area clean, uncluttered, ventilated and illuminated.

Safety Information When Using The Tool

1. When wearing gloves always be sure that the gloves will not prevent the throttle mechanism from

being released.

2. Always wear eye protection when operating or performing maintenance on this tool.

3. Always wear hearing protection when operating this tool.

4. Always use personal protective equipment appropriate to the tool used and material worked.

This may include dust mask or other breathing apparatus, safety glasses, ear plugs, gloves,

apron, safety shoes, hard hat and other equipment.

5. Keep others a safe distance from your work area, or ensure they use appropriate personal

protective equipment.

6. Be aware of buried, hidden or other hazards in your work environment. Do not contact or dam-

age cords, conduits, pipes, or hoses that may contain electrical wires, explosive gases or harmful

liquids.

7. Keep hands, loose clothing, long hair and jewelry away from working end of tool.

8. Power tools can vibrate in use. Vibration, repetitive motions or uncomfortable positions may be

harmful to your hands and arms. Stop using any tool if discomfort, tingling feeling or pain occurs.

Seek medical advice before resuming.

9. Keep body stand balanced and rm. Do not overreach when operating this tool. Anticipate and

be alert for sudden changes in motion, reaction torques, or forces during start up and operation.

10. DO NOT USE THIS TOOL WHEN TIRED, UNDER THE INFLUENCE OF MEDICATION,

DRUGS OR ALCOHOL.

11. Never use a damaged or malfunctioning tool or accessory.

12. Do not modify the tools, safety devices or accessories.

13. Do not use this tool for purposes other than those recommended

14. Never exceed rated pressure of tool.

3/37

SAFE AND CORRECT USE

IMPORTANT - READ CAREFULLY

This manual contains important information for the correct installation, operation and maintenance of

this equipment. All persons involved in the installation, operation and maintenance of this equipment

must be thoroughly familiar with the contents of this manual. To safeguard against the possibility

of personal injury or property damage, follow the recommendations and instructions of this manual.

Keep this manual for reference.

WARRANTY STATEMENT

TorcUP products are warranted to be free of defects in materials and workmanship under normal use

for as long as the original purchaser owns them, subject to the guidelines and limitations listed. This

warranty does not cover: normal wear & tear, cosmetic items, abuse, overloading, alterations, im-

proper uid, or use in a manner for which they are not intended. If the customer believes a product is

defective, the product must be delivered, or shipped freight prepaid, to the nearest TorcUP Authorized

Service Center for evaluation and repair. This pump offers 13 month warranty.

RECEIVING INSTRUCTIONS

Important! Make sure to inspect all of the components for shipping damage. If damage is found, notify

carrier at once. Shipping damage will not be covered by warranty. The carrier is responsible for all

loss associated with shipping damage.

SAFETY

Make sure to read the instructions, warnings and precautions carefully. Follow any recommended

safety precautions to avoid personal injury or damage to the unit. TorcUP cannot be responsible for

any damage or injury from unsafe use, lack of maintenance or incorrect operation. In the event any

questions or concerns arise, contact TorcUP or a local representative for clarication.

The pump’s maximum working pressure is 10,000 PSI(700kg/cm2). Make sure that all hydraulic

equipment such as rams, hoses, etc. used with this pump are rated at 10,000 PSI (700kg/cm2)

operating pressure.

If you have never been trained on high-pressure hydraulic safety, consult your representative for a

free TorcUP Hydraulic Safety Course.

Failure to comply with the following cautions and warnings could cause equipment damage, property

damage or personal injury.

DANGER is only used when your action or lack of action may cause serious injury or even death.

WARNING indicates a potential danger that requires correct procedures or practices to avoid per-

sonal injury.

CAUTION is used to indicate correct operating or maintenance procedures and practices to prevent

damage to, or destruction of equipment, or other property.

4/37

WARNING: Wear proper personal protective gear when operating hydraulic equipment.

DANGER: To avoid personal injury, keep hands and feet away from work-piece during operation.

WARNING: Do not exceed equipment ratings. Overloading causes equipment failure and possible

personal injury. The pump tools are designed for a maximum pressure of 10,000 PSI (700kg/cm2).

Do not connect a jack or cylinder to a pump. Never set the relief valve to a higher pressure than the

maximum rated pressure of the pump. Higher settings may result in equipment damage and/or per-

sonal injury.

WARNING: The system operating pressure must not exceed the pressure rating of the lowest rated

component in the system. Install pressure gauges in the system to monitor operating pressure.

CAUTION: Avoid damaging hydraulic hose. Avoid sharp bends and kinks when routing hydraulic

hoses. Using a bent or kinked hose will cause severe back-pressure. Sharp bends and kinks will inter-

nally damage the hose, leading to premature hose failure. Do not drop heavy objects on hose. A sharp

impact may cause internal damage to hose wire strands. Applying pressure to a damaged hose may

cause it to rupture.

IMPORTANT: Do not lift hydraulic equipment by the hose or swivel couplers. Use the carrying handle

or other means of safe transport.

CAUTION: Keep hydraulic equipment away from ames and heat. Excessive heat will soften seals,

resulting in uid leaks. Heat also weakens hose materials. For optimum performance do not expose

equipment to temperatures of 65° C (170° F) or higher. Protect hoses and cylinders from weld spatter.

SAFE AND CORRECT USE

TECHNICAL SPECIFICATIONS

WORKING PRESSURE

The pump’s maximum working pressure is 10,000 PSI

(700kg/cm2). Make sure that all hydraulic equipment

such as tools, hoses, etc. used with this pump are

rated at 10,000 PSI (700kg/cm2) operating pressure.

INSTALL VENT PLUG

Remove shipping plug from reservoir and install

vent plug supplied with pump.

ADDING OIL

Remove oil ller cap and add TorcUP hydraulic oil

into reservoir. Oil level should not exceed 1” from

the reservoir cover. Oil should be ISO 32 or 46

weight.

*As a “rule of thumb” oil should be lled about an inch below the

top of the reservoir when the unit is powered down and all

connected tools or cylinders are retracted.

EP500 EP1000

5/37

LUBRICATION

TECHNICAL SPECIFICATIONS

INSTALL HYDRAULIC CONNECTIONS

Use only tools, hoses and accessories rated at 10,000 PSI

(700kg/cm2). Remove the shipping plugs from the ports

to connect your coupling(s) or hose(s) to manifold. Use

1.5 wraps of Teon tape (or suitable thread sealant) on all

threads, leaving the rst complete thread free of tape to

ensure no foreign matter enters the hydraulic circuit.

When making connections with quick disconnect couplings,

make sure the couplings are fully engaged. Threaded connec-

tions such as ttings, gauges, etc. must be securely tightened

and leak free.

EP500

EP1000

6/37

TECHNICAL SPECIFICATIONS

Loose or improperly threaded ttings can be potentially dangerous if pressurized;

however, severe over tightening can cause premature thread failure. Fittings need

to be tightened secure & leak free. Never hold or stand directly in line with any

hydraulic connections while pressurizing. Never grab, touch or in any way come in

contact with a hydraulic pressure leak. Escaping oil can penetrate the skin and a

serious injury can result.

CAUTION: Do not subject the hose to potential hazards such as sharp surfaces, extreme heat or

heavy impact. Do not allow the hose to kink or twist. Inspect each hose for wear before it is used.

ELECTRICAL

Check for proper electrical supply before connecting. Be sure the electrical connection is grounded.

Check that your power supply agrees with the motor nameplate and/or TorcUP model decal.

NOTE: MOTOR MAY SPARK. DO NOT OPERATE IN AN EXPLOSIVE ATMOSPHERE OR IN THE

PRESENCE OF CONDUCTIVE LIQUIDS.

1. Do not use a power or extension cord that is damaged or has exposed wires.

2. All single phase motors come equipped with a three prong grounding type plug to t the proper

grounded type electrical outlet. Do not use a two prong ungrounded extension cord as the

pump’s motor must be grounded.

CONNECTING HYDRAULIC TOOLS

Use only tools, hoses and accessories rated at 10,000 PSI (700kg/cm2). When making connections

with quick disconnect couplings, make sure the couplings are fully engaged. Threaded connections

such as ttings, gauges, etc. must be securely tightened and leak free. Use 1.5 wraps of Teon tape (or

suitable thread sealant) on all threads, leaving the rst complete thread free of tape to ensure no foreign

matter enters the hydraulic circuit.

STARTING THE PUMP FOR THE FIRST TIME

1. Check for any leaks, repair as needed.

2. When rst plugged in the solenoid makes 4 “clicks” relieving any pressure still in the system.

When the button to turn off the pump is pressed it goes through the same sequence for the

same reason. It is then safe to remove tool and hoses.

3. Shift pendant to the advance position to advance tool and release to retract tool. Look for

movement in tool, check for any leaks, repair as needed.

CAUTION: Never operate the pump without tool movement for more than 1 minute. Leaving the valve

in the advance or retract position without the tool’s piston rod moving will overheat the oil.

CAUTION: Never disconnect or connect any hydraulic hoses or ttings without rst unloading the tool,

then unplug the electrical cord of the pump. Open manual relief valve to assure that the system has

been depressurized.

7/37

TECHNICAL SPECIFICATIONS

PUMP MOUNTING

Refer to the chart for mounting dimensions to

secure the pump to a xed surface.

1 gal.

(4L)

1.5 gal.

(6L)

2.5 gal.

(10L)

5 gal

(20L)

A 11 15.13 17 19.6

B 0.56 1.68 2.75 4.69

C 0.56 3.57 4.37 5.03

D 1.16 1.43 1.93 2.93

E 8.19 9.75 9.75 11.75

F 1/4-2unc 1/4-2unc 1/4-2unc 1/4-2unc

(4 places) (4 places) (4 places) (4 places)

CONTROL VALVES

2-Postion – 4 Way Solenoid Valve for

Hydraulic Torque Wrenches.

To Advance......depress the Advance Switch

To Retract.........release advance switch to Retract Tool.

2 Position

-

4 Way Solenoid

POWER CONTROL SWITCHES

Remote pendant.

Congured with motor control pendant:

Press UP or Down

To Turn Pump Off

Press UP or Down

To Turn On Pump

NOTE: In the event multiple buttons are

depressed for longer than 5 seconds,

the unit is programmed to shut down.

To restart, you will need to depress

the motor “ ON” to continue, or unplug/

replug the unit into power supply, then

depress the motor “ ON” to continue.

8/37

OPERATION PROCEDURES

PRESSURE TORQUE SETTING

1. See torque wrench instructions for amount of pressure required

to produce desired torque.

2. Loosen lock nut and back out relief valve to prevent unintended

pressure builds up.

3. Turn pump on. Press and hold the “ADVANCE” switch, and read

pressure gauge.

4. While holding the switch, turn relief valve in (clockwise)

to increase pressure or out (counter-clockwise)

to decrease maximum pressure. Repeat until

correct pressure is obtained.

5. Tighten lock nut on the relief valve to maintain setting.

6. Run pump several times to test this setting before

setting tool on the nut.

AFTER COMPLETING THE JOB

Before disconnecting hoses, ttings, etc., rst be sure the tool is unloaded and retracted, then unplug

the power cord. The pump is designed to cycle the valve upon powering off to release pressure.

PERIODIC MAINTENANCE

Completely change the hydraulic oil and clean the intake screen and magnet (located in the reservoir)

twice a year. If equipped, change the external oil lter twice a year (Use TorcUP oil only, Model # AO1,

1 gallon). Change the oil more frequently when used in extremely dusty areas or when the oil has been

overheated. Using oil other than TorcUP Brand may void the pump’s warranty.

The following conditions require more frequent oil changes.

•Rigorous duty, where oil temperature may reach 150˚ F.

•High humidity environment and extreme changes in temperature that can result in condensation

inside the reservoir.

•Dirty or dusty environments that may contaminate the oil.

•Frequent connection and disconnection of hydraulic hoses and components.

Make these adjustments BEFORE putting torque wrench on nut or bolt

head. The pump pressure setting may be above the pressure needed

to provide the required torque for your application.

Exceeding required torque will cause equipment damage and may lead

to serious personal injury.

The electrical power cord must be disconnected from electrical outlets

before performing maintenance or repair procedures.

9/37

MAINTAIN OIL LEVEL

Check hydraulic oil level every 30 hours of operation (sight gauge should be completely covered in

oil when all tools are retracted. Add TorcUP oil (Model # AO1 – 1 gallon) when necessary. Oil level

should be no more than 1” from top of reservoir plate – with cylinders retracted and motor off.

CLEAN OIL INTAKE SCREEN ONCE A YEAR

Loosen and remove reservoir plate bolts. Lift pump unit off the reservoir, being careful not to damage

the gasket.

Applies to 1, 1.5, 2, 2.5 gallon reservoirs:

Remove the ve allen socket head cap screws, securing the screen to the 1st stage gear pump. Care

should be taken not to remove the center plate and gears. Remove and clean with nonammable

solvent, blow dry clean. Reinstall in reverse order and torque bolts to 75 inch pounds. Keep the motor

and pump as clean as possible.

Applies to the 5 and 10 gallon reservoirs:

Unscrew screen from bottom of pump unit and clean

with nonammable solvent. Blow dry and reassemble.

Keep areas around pump unobstructed to provide good

air ow around the motor and pump. Keep the motor

and pump as clean as possible.

FLUSH THE PUMP

If you suspect your pump has been contaminated or

discover sludge or other deposits on internal

components, you should thoroughly ush the pump.

Remove the old oil from the reservoir, then thoroughly

clean the reservoir and rell with a clean, nonammable

ushing oil. Reassemble the pump and motor to the

reservoir.

Run the pump in no load condition for 1 or 2 minutes maximum. Unplug the pump and remove the

motor and pump assembly again. Now drain the ushing oil and re-clean the inside of the reservoir.

(Make sure ushing uid is also drained from pump assembly). Reassemble the pump and rell the

reservoir with TorcUP hydraulic oil and reassemble the pump.

OPERATION PROCEDURES

10/37

TROUBLESHOOTING

PROBLEM CAUSE-SOLUTION

Sporadic Tool Action: • Air in the hydraulic system. Bleed the hydraulic circuit.

• Check reservoir oil level.

Motor Will Not Start: • Be sure power cord is not damaged.

• Check for tripped circuit breaker; be sure breaker is of

adequate size.

• Have motor checked for proper operation.

• Have qualied electrician inspect for loose or faulty wiring or

switch.

.

Noisy Operation: • Air in system.

• Be sure the oil reservoir is lled to normal level.

• Check all points where air might leak into system.

• Clogged or blocked intake screen.

Pump Oil is Over Heating: • Inspect for high pressure leakage at the pump (leaking at

plug or relief valve).

• Oil level is low. Fill reservoir to normal level, or retrot the

pump with larger reservoir or heat exchanger.

Pump Runs But Will Not Pump Oil: • Pump is not primed. Run pump a few minutes tipping from

side to side.

• Inspect to make sure that external adjustable relief valve is

set properly.

• Defective control valve, take to nearest TorcUP Authorized

Service Center for repair.

• Incorrect motor rotation, take to nearest TorcUP Authorized

Service Center for repair.

• Check to make sure the intake screen is not clogged. Clean

if needed.

• Check oil reservoir is low. Fill as needed.

• Oil viscosity is too high. Replace with TorcUP oil.

11/37

PARTS INDEX

How to Identify Parts for Your Model.

MODEL NUMBER & DATE CODE LOCATION

For example, the date code and serial number

J = October

07 = Year 2007

42 = Week number in year

J 07 42

A B C D E F G H I J K L

1 2 3 4 5 6 7 8 9 10 11 12

How to Identify Parts

for Your Model.

EP1000 Torque Wrench

Power Pump

MODEL NUMBER & DATE CODE LOCATION

MODEL DECAL

PLACEMENT

DATE CODE COVER PLATE

STAMPING LOCATION

12/37

COMMON COMPONENTS

Common components

used in pumps

EP1000 Torque Wrench

Power Pump

NOTE: This illustration is for reference

only. The appearance of your unit

Note: This illustration is for reference only. The appearance of your unit may differ from unit shown.

EP1000

13/37

COMMON COMPONENTS

EP1000

Common components

used in pumps

EP1000 Torque Wrench

Power Pump

NOTES : REBUILD KIT ( * = COMPONENTS) -- PART # 54488

ITEM # DESCRIPTION PART # PART # QTY. ITEM # DESCRIPTION PART # PART # QTY.

02 PUMP ASM. 1.00 29 HEAVY HEX JAM NUT 1/4-20 69234 69234 2.00

03 RESERVOIR 1.00 30 BHCS 10-24 x 3/8 LG 69236 69236 4.00

04 RESERVOIR GASKET 1.00 30 BHCS 10-24 x 3/8 LG 69236 69236 4.00

05 BREATHER VENT 3/8" NPT 46348 46348 1.00 35 DECAL 5.71" x 1.15" 46355 46355 2.00

06 PIPE PLUG 1/4" W/ COATING 46510 46510 1.00 37 QUICK DISCON. FLAG BLUE 44491 44491 2.00

07 SAE #12 HEX PLUG WITH PT 46118 46118 1.00 42 HOLE PLUG 1/4" 46405 46405 4.00

08 HHCS 1/4-20 X .75 PLT 65891 65891 14.00 43 SPACER 1" 69353 69759 2.00

09 SEALING WASHER 65892 65892 14.00 44 HHCS 1/4-20 X 1.50 84417 87260 2.00

10 G5 RESERVOIR DECAL 46052 46052 2.00 45 WASHER 1/4" SS 88429 88429 2.00

11 LABEL SAFE USE ELEC 68068 68068 1.00 46 COIL 115V WITH DIN CONNECTOR 46294 46324 1.00

12 BLANK DECAL 3 X 4 87305 87305 1.00 52 SIGHT GAUGE 46009 46009 1.00

13 MANIFOLD ASM. 1.00 57 1/4 IN NIPPLE 4100067 4100067 1.00

14 VALVE GASKET 69242 69242 1.00 58 1/4" NIPPLE CT210 CT210 1.00

15 SHCS 3/8-16 X 2 3/4 99921 99921 3.00 59 1/4" SELF-LOCKING COUPLER 45765 45765 1.00

16 ADAPTER ASSY. 68963 68963 1.00 62 GAUGE SHROUD ASSEMBLY 46474 46474 1.00

17 HEX PIPE PLUG 3/8" W/ COATING 46513 46513 1.00 68 VELCRO STRAP 1x14 46310 46310 1.00

19 VALVE ASM. 2P/4W 1.00 70 GASKET-MOTOR 1.00

20 SHCS 3/8-16 X 3 1/2 88363 88363 4.00 71 PUMP GASKET G5 1.00

21 LOCK WASHER 3/8 93943 93943 2.00 73 COVER PLATE 1.00

21 LOCK WASHER 3/8 93943 93943 4.00 74 PIN,DOWEL 3/16 1" LONG 69026 69026 1.00

22 ROLL PIN 1/8 X 3/8 LG 561604 561604 1.00 75 SHCS 3/8-16 X 1 93594 93594 2.00

24 MAGNET 66021 66021 1.00 76 1 1/2HP, PM MOTOR 68376 68403 1.00

25 MOTOR SHROUD W/ HANDLE 45534 45534 1.00 78 FHCS 1/4-28 x 0.50 LONG 46279 46279 4.00

27 DECAL OVERLAY 46539 46539 1.00

28 BRACKET ASM - CIRCUIT BOARD 1.00

SEE PAGE 21-22

*

*

SEE PAGE 23

SEE PAGE 19

SEE PAGE 16

SEE PAGE 23

*

SEE PAGE 20

15

14/37

COMMON COMPONENTS

Common components

used in pumps

EP1000 Torque Wrench

Power Pump 230v

NOTE: This illustration is for reference

only. The appearance of your unit

16

EP1000

15/37

SUB PUMP ASSEMBLY

(46335) PUMP ASM.

EP1000

16/37

(46335) PUMP ASM.

SUB PUMP ASSEMBLY

EP1000

Sub Pump Assembly

EP1000 Torque Wrench

Power Pump

(46335) PUMP ASM.

ITEM # DESCRIPTION PART # QTY.

01 PUMP BODY G5 45750 1.00

02 BEARING ROLLER 5/8x13/16x5/8 WIDE 68360 1.00

03 THRUST BEARING 66033 1.00

04 THRUST WASHER 66474 2.00

05 ECCENTRIC SHAFT ASM 5/8" G5 SEE PAGE 18 1.00

06 THRUST BEARING 66106 1.00

07 THRUST WASHER 66108 2.00

08 ECCENTRIC SHAFT ADAPTER G5 45908 1.00

09 O-RING 1 3/4 X 1 7/8 * 1.00

10 RETAINING RING 68978 1.00

11 POW'R BUD DUMP PLUG 43283 1.00

12 O-RING 3/16X5/16 * 3.00

13 BACKUP WASHER 56080087 1.00

14 MALE TEE 1/8" PIPE TO 1/4" TUBE 45426 1.00

15 PIPE PLUG 1/4" FLUSH W/ COATING 46509 1.00

16 UNLOADING PISTON ASSEMBLY SEE PAGE 18 2.00

17 MALE ELBOW 1/4" TUBE 1/4" PIPE 45929 1.00

18 BALL 1/8" 90906 3.00

19 G3 PISTON BLOCK TUBE 45420 1.00

20 OUTLET TUBE PISTON BLOCK 45815 1.00

21 BALL 5/16" 91701 3.00

22 UNLOADING SPRING 43671 1.00

23 ADJUSTING SCREW G5 45903 1.00

24 O-RING 5/8X3/4 URETH * 1.00

25 PIPE PLUG FLUSH 1/16 W/ COATING 40049 7.00

26 WEAR PLATE G5 45909 1.00

27 BOTTOM PLATE 9/32" G5 45900 1.00

28 GEAR PUMP 0.281 45824 2.00

29 SHAFT-IDLER 68850 1.00

30 SCREEN * 1.00

31 TUBE-GUIDE .11 68894 2.00

32 SHCS 1/4-28 X 1 3/4 68255 5.00

33 PLATE-SCREEN MTG. 68927 1.00

34 MALE ELBOW 1/8 PIPE 69354 1.00

35 SPRING 68225 2.00

36 ROLL PIN 1/8 X 3/4 LONG 97782 1.00

37 BALL STOP G5 45904 2.00

38 GASKET 29/64 X 5/8 * 2.00

39 SPRING CAP UNLOADING VALVE 43673 1.00

41 TUBE RETURN 68569 1.00

43 BEARING ROLLER 1 1/4x1 1/2x3/4 WIDE 66030 1.00

44 BEARING ROLLER 1/2x11/16x1/2 WIDE 68891 3.00

45 RING-RETAINING 68892 1.00

46 PIPE PLUG 1/8" FLUSH W/ COATING 46508 1.00

47 CART REL. VAL. ASSEMBLY 66220 1.00

48 SHAFT SEAL G5 * 1.00

49 PISTON BLOCK ASM. 0.255 G5 SEE PAGE 18 2.00

50 SHCS 5/16-24 X 1.75 69392 8.00

REBUILD KIT ( * = COMPONENTS) -- PART # 54488

17/37

(46336) PISTON BLK ASM.

(43766) UNLOADING PISTON ASM.

ITEM # DESCRITPION PART # QTY.

01 UNLOAD PISTON 43765 1.00

02 O RING 1/4X3/8 1.00

03 BACK-UP WASHER TEF 43768 1.00

04 DOWEL PIN 1/8X3/4 LG 43686 1.00

(45820) ECCEMTRIC SHAFT ASM.

ITEM # DESCRIPTION PART # QTY.

01 ECCENTRIC SHAFT 5/8" 45819 1.00

02 ECCENTRIC RING 45907 1.00

03 ROLL BEARING 1 1/8x1 3/8x3/4 WIDE 45926 1.00

04 RETAINING RING EXTERNAL 1 1/8" 45931 1.00

05 THRUST WASHER 68026 2.00

ITEM # DESCRIPTION PART # QTY.

01 GEN II PISTON BLOCK 45539 1.00

02 BALL 1/8" 90906 2.00

03 SPRING 66042 1.00

04 BALL STOP 68810 1.00

05 BALL RETAINER 66043 1.00

06 INTAKE SEAT 66046 1.00

07 GASKET 25/64X19/32 1.00

08 PLUG PISTON BLOCK 68825 1.00

09 GASKET 29/64 X 5/8 1.00

10 ADAPTOR .255 DIA. 68909 1.00

11 SPRING, PISTON 68340 1.00

12 PISTON .255 DIA. 68222 1.00

*

*

*

REBUILD KIT ( * = COMPONENTS) -- PART # 54488

SUB PUMP ASSEMBLY

EP1000

(45820) ECCENTRIC SHAFT ASM.

(46336) PISTON BLK ASM.

(43766) UNLOADING PISTON ASM.

18/37

VALVE SUB ASSEMBLY

Valve Sub Assemblies

(46291) 3 & 4 WAY SOLENOID VALVE 115V. / 230V.

PACKING KIT 3 & 4 WAY SOLENOID VALVE

(* = COMPONENTS) -- PART #54491

ITEM # DESCRIPTION PART # QTY.

01 BODY-VALVE 68708 1.00

02 SLIDER ADV/RET ONLY 44328 1.00

03 BALL 3/16" 90548 4.00

04 SET SCREW 1/4-28 X 1/4 CUP 40254 4.00

06 O-RING 7/32X11/32 * 3.00

07 BACK UP WASHER * 3.00

08 SHEAR SEAL 68383 3.00

09 SPRING 68384 3.00

10 O-RING 2 5/8 X 2 3/4 * 1.00

11 BEARING ROLLER 5/16x1/2x5/16 WIDE 68385 4.00

12 PIN BEARING 68390 2.00

13 PIPE PLUG FLUSH 1/16 W/ COATING 40049 1.00

14 SHCS #10-32 X 1" LG PLATED 68264 2.00

15 VALVE TOP PLATE MACHINED 46272 1.00

17 O-RING 3/16X5/16 * 1.00

19 VALVE PLUG 2 POSITION SLIDER 46271 1.00

26 O-RING SAE PORT #10 * 2.00

27 SPRING 68711 1.00

29 SPACER VALVE SLIDER 46418 1.00

31 O-RING 5/16X7/16 URE * 4.00

32 PUSHER-SOLENOID 68729 1.00

EP1000

19/37

This manual suits for next models

1

Table of contents

Other TorcUP Water Pump manuals

Popular Water Pump manuals by other brands

ProMinent

ProMinent Vario Series operating instructions

Sunpole

Sunpole MAGNUS VSG-6000 user manual

Franklin Electric

Franklin Electric E Series owner's manual

samhydraulik

samhydraulik H1V 2NC Operator's manual

MasterCraft

MasterCraft 312222-01 owner's manual

Tecnosystemi

Tecnosystemi smart clima 12170027 Manual for installation

EYELA

EYELA MP-2000 instruction manual

Grundfos

Grundfos PACOpaQ Installation and operating instruction manual

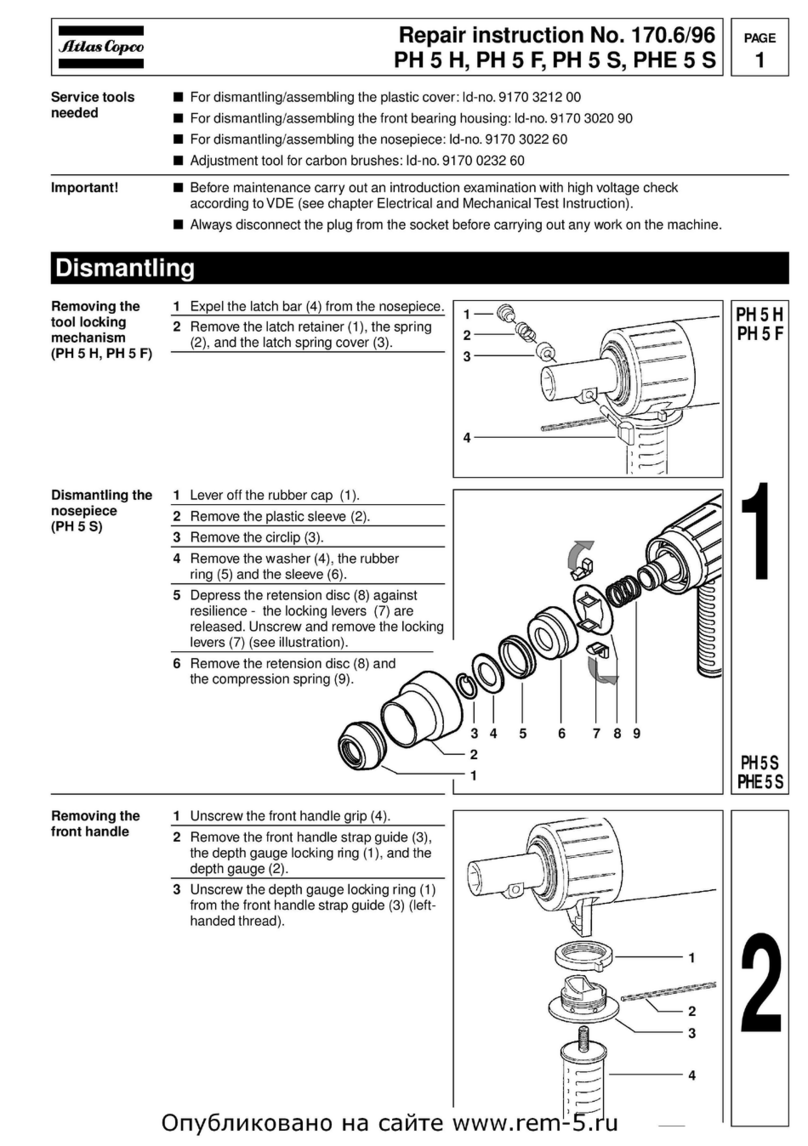

Atlas Copco

Atlas Copco PH 5 H Repair instructions

OTC Tools

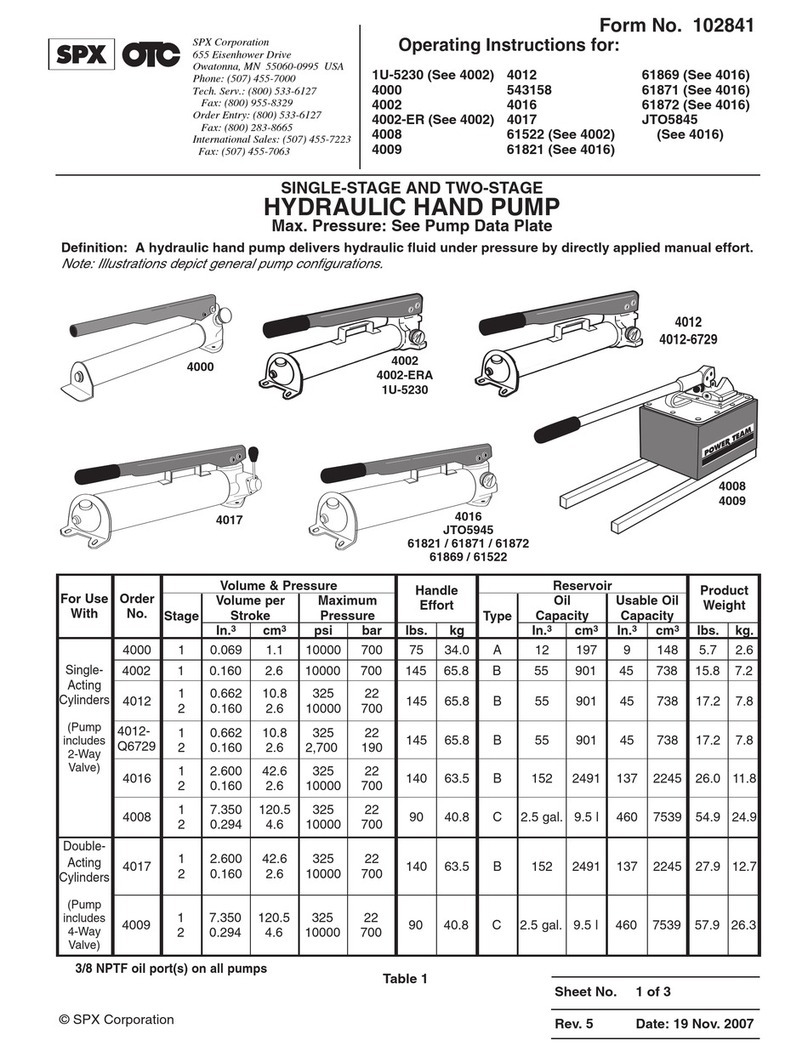

OTC Tools 1U-5230 operating instructions

Unibloc-Pump

Unibloc-Pump LABTOP 200 Series Operation and service manual

Könner & Söhnen

Könner & Söhnen KS 50 Operation manual