89

OPERATION MANUAL OPERATION MANUAL

WWW.THETOOLSHED.CO.NZWWW.THETOOLSHED.CO.NZ

SAFETY GUIDELINES

DANGER

GASOLINE AND GASOLINE VAPOURS

ARE HIGHLY FLAMMABLE AND

EXPLOSIVE. Fire or explosion can cause

severe burns or death.

Gasoline & Vapours When Adding or Removing

Gasoline

When Starting the Engine

• Gasoline is highly ammable and explosive.

• Gasoline can cause a re or explosion if

ignited.

• Gasoline is a liquid fuel, but its vapours can

ignite.

• Gasoline is a skin irritant and needs to be

cleaned up immediately if spilled on skin or

clothes.

• Gasoline has a distinctive odour; this will help

detect potential leaks quickly.

• In any petroleum gas re, you should not

attempt to extinguish the ames unless it

can be done in such a way by turning the

fuel supply valve OFF. This is because if a re

is extinguished and a supply of fuel is not

turned OFF, then an explosion hazard could

be created.

• Never ll the gas tank to capacity as gasoline

needs room to expand if temperature rises.

• Never use gasoline that is stale, contami-

nated, or mixed. Avoid getting contaminants,

dirt or water in the fuel tank.

• DO NOT light or smoke cigarettes.

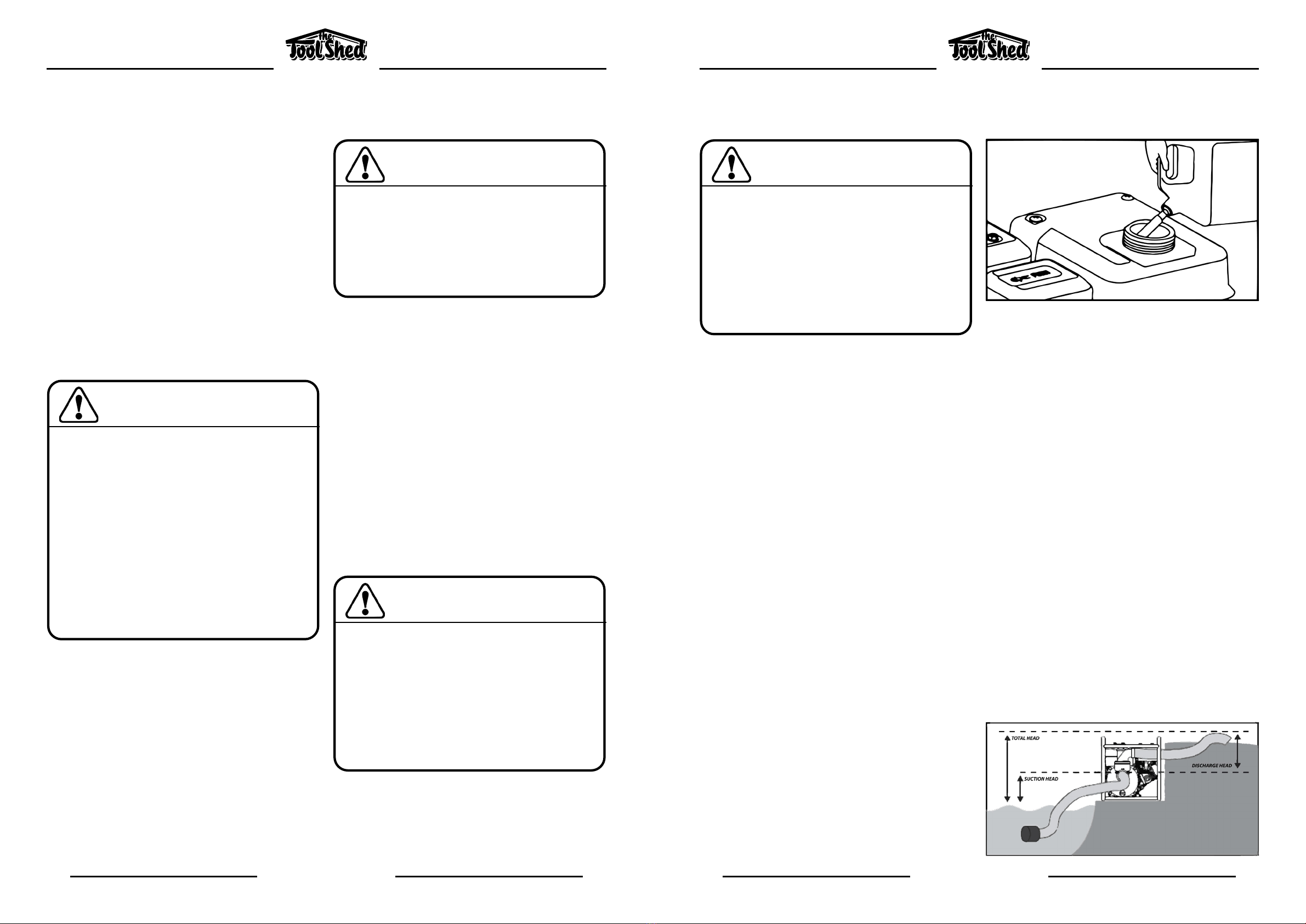

• Turn the engine o and let it cool for at least

two minutes before removing the gasoline

cap. Loosen the cap slowly to relieve pressure

in the tank.

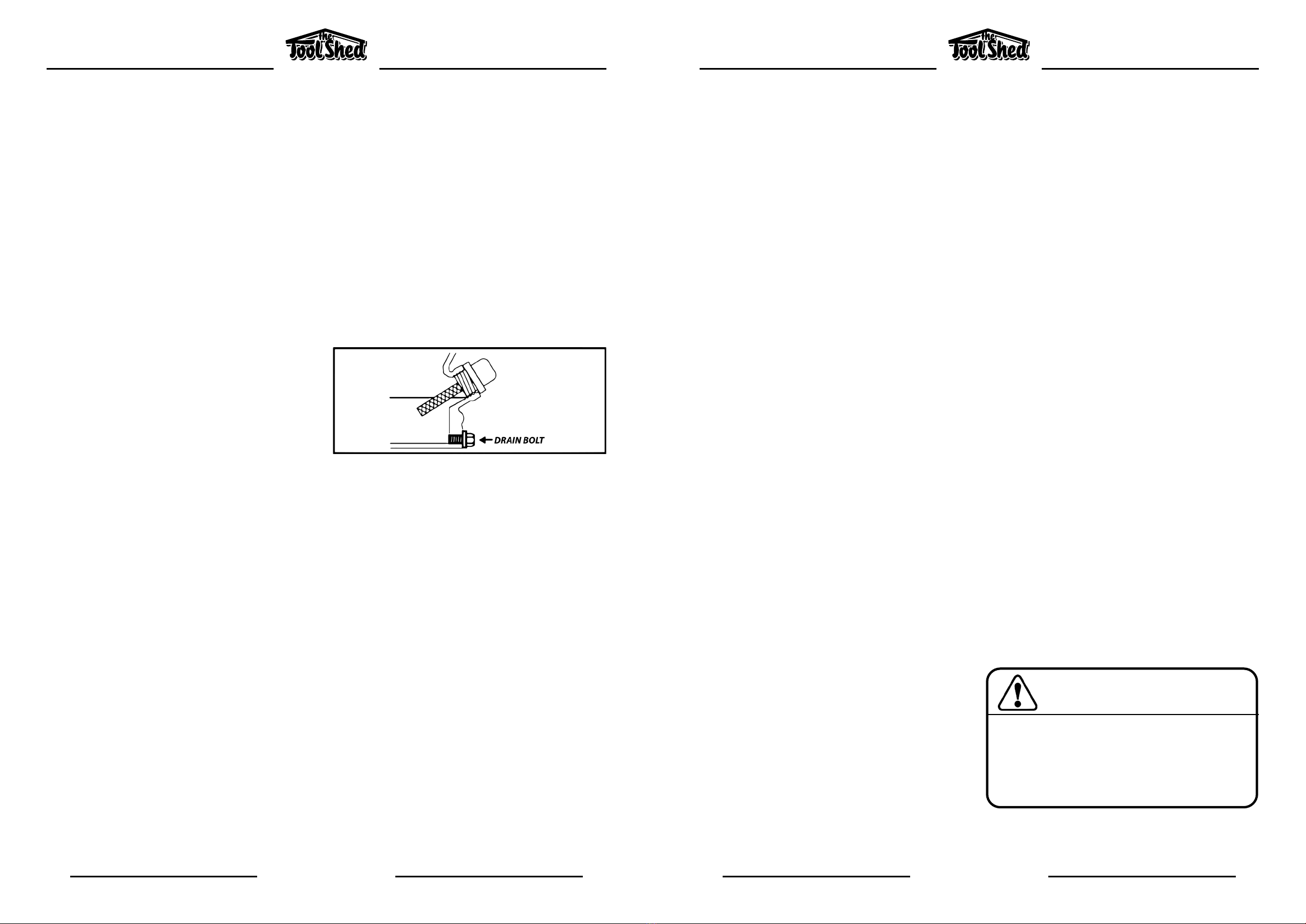

• Only ll or drain gasoline outdoors in a

well-ventilated area.

• DO NOT pump gasoline directly into the

engine at the gas station. Use an approved

container to transfer fuel to the engine.

• DO NOT overll the gasoline tank.

• Always keep gasoline away from sparks,

open ames, pilot lights, heat, and other

sources of ignition.

• DO NOT rell the fuel tank while the engine

is running or while the engine is still hot.

• When spills of fuel or oil occur, they must be

cleaned up immediately. Dispose of uids

and cleaning materials as per local regula-

tions.

• DO NOT attempt to start a damaged engine.

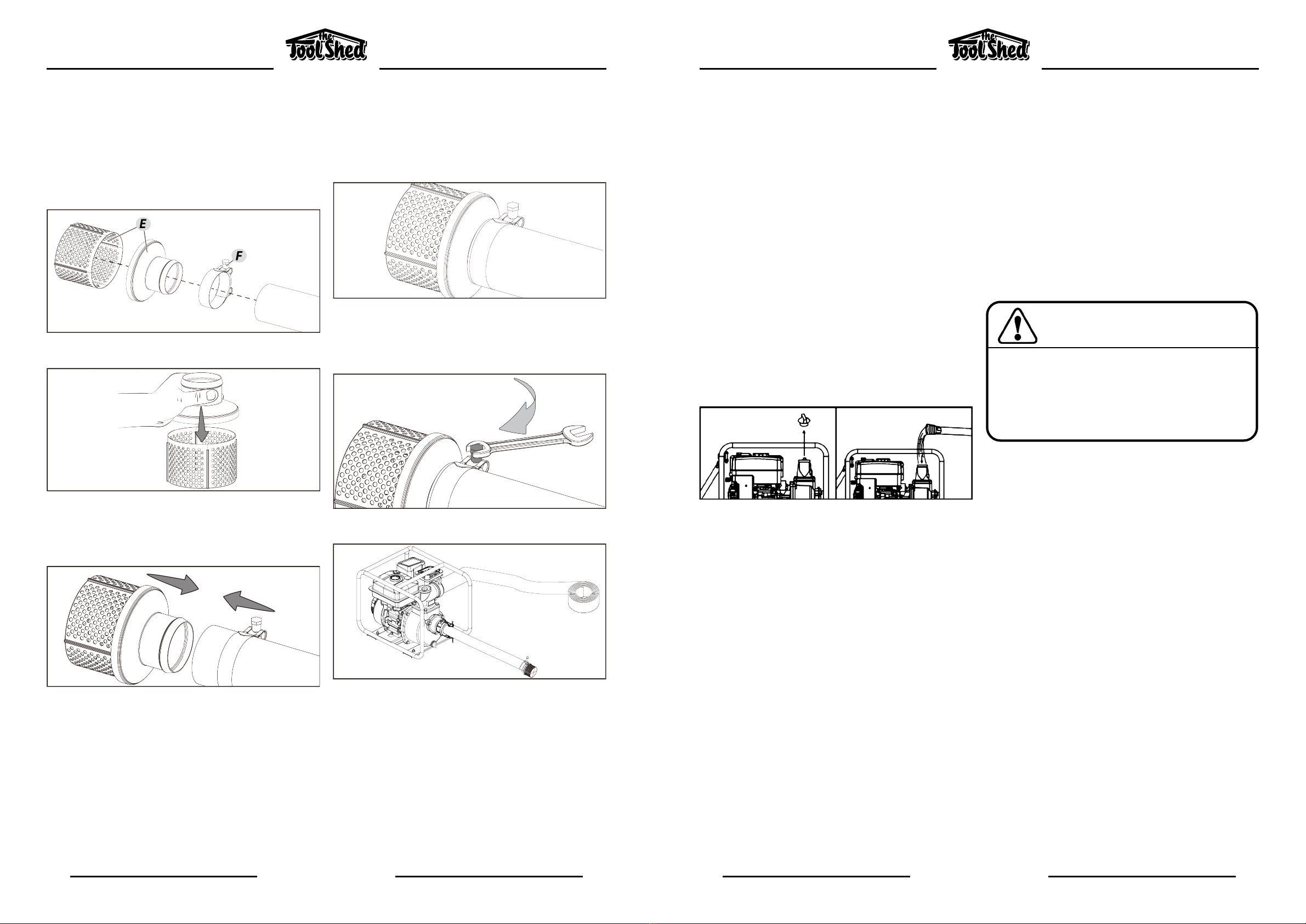

• Make certain that the gasoline cap, air lter,

spark plug, fuel lines, and exhaust system are

properly in place.

• Allow spilled gasoline to evaporate fully

before attempting to start the engine.

• Make certain that the water pump is resting

rmly on level ground.

• Spark from a removed spark plug wire can

result in re or electrical shock.

SAFETY GUIDELINES

Fuel & Engine Safety

Operate this machine outdoors only

in a well-ventilated area and point the

exhaust away from you.

WARNING

• DO NOT operate the machine inside any

building, including garages, basements,

crawlspaces and sheds, enclosures, or

compartments, including the storage

compartment of a recreational vehicle.

• DO NOT allow exhaust fumes to enter a

conned area through windows, doors,

vents, or other openings.

• NEVER use inside a home or garage, EVEN

IF doors and windows are open. ONLY use

OUTSIDE and far away from windows, doors,

and vents.

WARNING

Using an engine indoors CAN KILL YOU

IN MINUTES. Engine exhaust contains

Carbon Monoxide. This is a poison you

cannot see or smell.

• Engine exhaust contains carbon monoxide, a

colourless, odourless, poison gas. Breathing

carbon monoxide will cause nausea, dizzi-

ness, fainting or death. If you start to feel

dizzy or weak, get fresh air immediately.

Service

• Have your tools and machinery serviced

at The ToolShed with ToolShed replace-

ment parts. This will ensure that the safety

of the power tool or machine is maintained.

WARNING

The warnings and precautions

discussed in this manual cannot cover

all possible conditions and situations

that may occur. It must be understood

by the operator that common sense

and caution are factors which cannot

be built into this product, but must be

supplied by the operator.

WARNING

DO NOT immerse the water pump in

water.

• It is not possible to cover every conceivable

situation you can face. Always exercise care

and use your common sense. If you get into

a situation where you feel unsafe, stop and

seek expert advise. Contact your dealer,

service agent, or an experienced user. Do not

attempt any task you feel unsure of!

Always Use Common Sense