Torgun TB-20 User manual

2

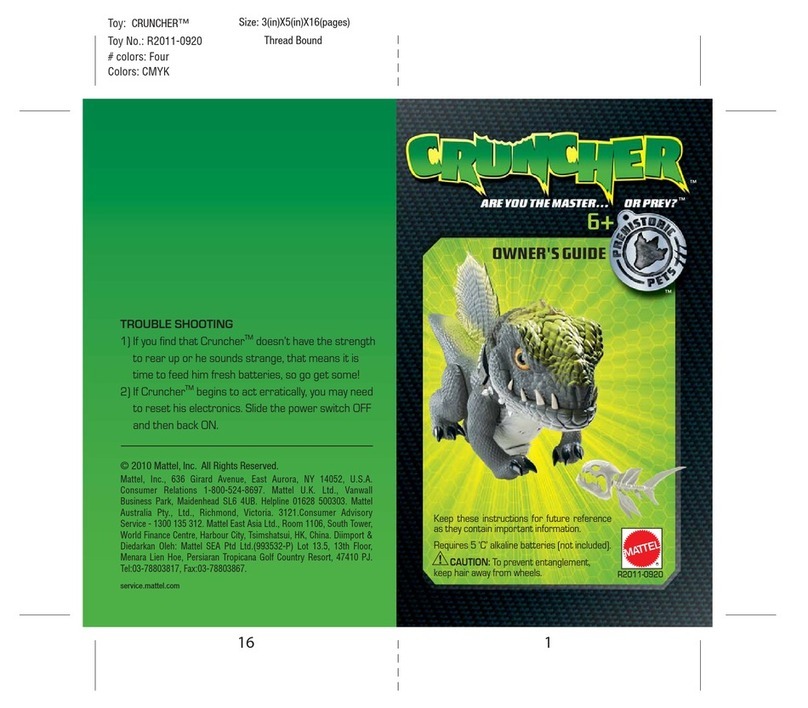

TB–20

INSTRUCTION MANUAL

RTF MODEL

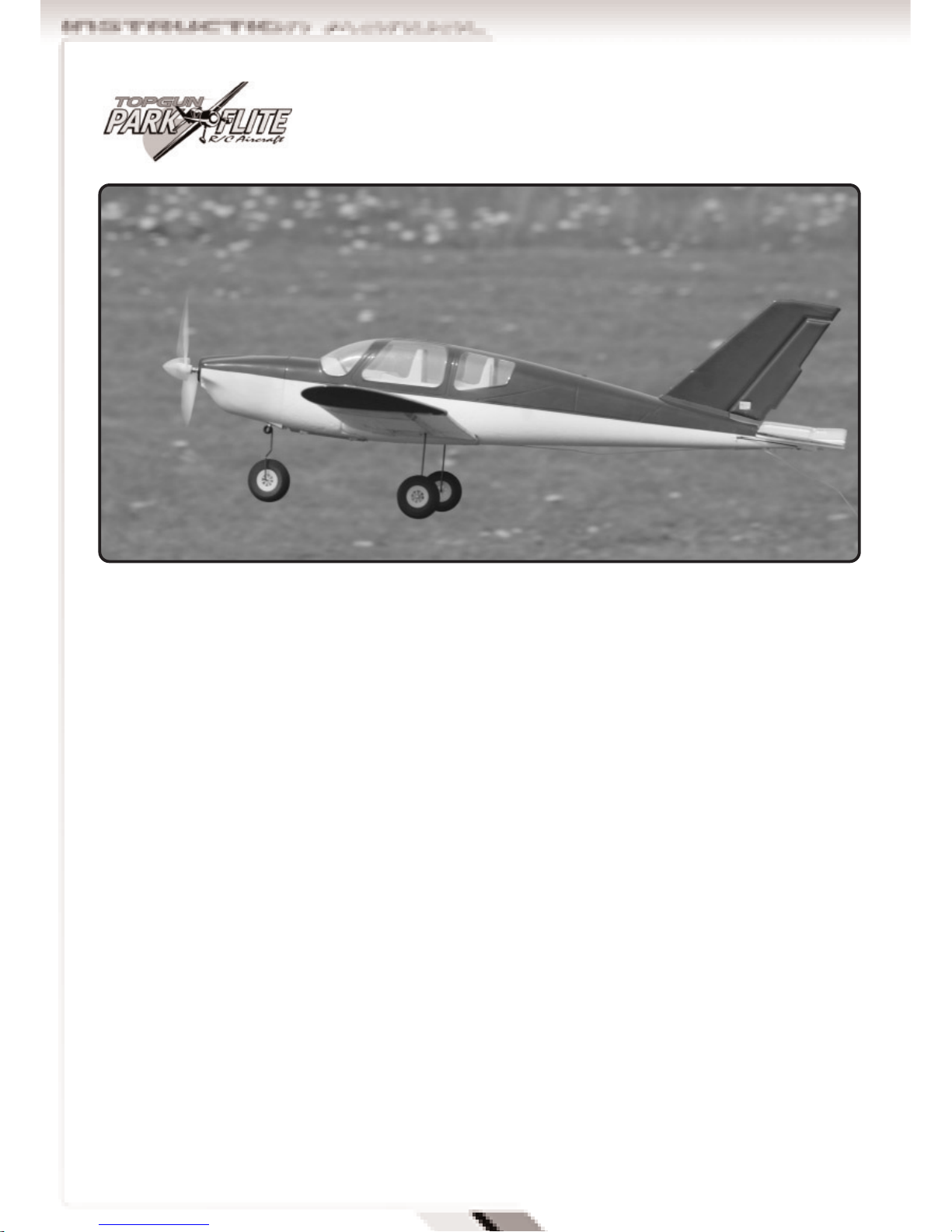

Top Gun Park Flite are proud to present this high

performance sport scale model of the Socata

Trinidad TB-20. We feel that this model emulates the

style, performance and character of its full size

counterpart.

Supplied as a Ready to Fly package with transmitter,

LiPo flight battery and charger, this model has been

designed with the utmost care and attention to detail

to produce a light weight, strong, and realistic looking

model aeroplane with excellent flying characteristics.

This model is a high performance miniature aircraft

that allows novice to intermediate model pilots to

perform both scale and aerobatic manoeuvers. The

light weight and large wing area allow the model to

fly extremely slowly, in a stable manner while still

maintaining full control.

These instructions assume a reasonable level of

competence for both building and flying and we

recommend that the model is flown at a recognised

club with frequency control measures and suitable

third party insurance.

The owner – pilot of this model should take note of

regulations, and local bylaws before flying this

aircraft.

Please take time to read through these instructions

before commencing assembly. We list operations in

order of works to reduce the risk of damage during

assembly.

Please read through the warnings before use.

A 7.4V 1800 mAh lithium polymer (LiPo) battery and

charger is included as part of this package and

these cells must be operated with care to prevent

the risk of fire.

LiPo Batteries are soft cased and can be easily

damaged by sharp items, puncturing of the soft

casing can cause fires and we recommend that they

are stored and handled carefully.

Use only a LiPo rated charger, set to a maximum of 2

cells (7.4v) and no more than 1 amp charge current.

Remove battery from the aircraft and charge on a

non flammable, non conductive surface

Due to continual and ongoing product development

the parts shown in the manual may differ from those

supplied.

Congratulations on purchasing the TB–20 RTF

3

Wing with ailerons connected to factory installed

servos

Fuselage with motor, Electronic Speed Control

(ESC) receiver, two quantity servo, and pushrods.

Fin and rudder assembly

Horizontal stabiliser (Tail plane) with elevator

Main undercarriage assembly mounting plate and

wheels

4 function fully proportional 35Mhz transmitter

Control horns and back plates for elevator and

rudder

Tube of adhesive

LiPo Battery 2 cell 7.4V 1800 mAh (12c)

LiPo charger and 12v power lead

Propellor –8” diameter x 6” pitch with spinner

Self adhesive decal sheet.

KIT CONTENTS AND DESCRIPTION

SPECIFICATIONS

Wing span 1040 mm (41”)

Length 795 mm (31.25”)

Wing Area 16.7 Dm? (257 sq inches)

Weight 585 g (20 Ounces)

Radio 4 function 35Mhz PPM

3 Qty micro servos

18 Amp brushless ESC

Motor Brushless out runner

]8” x 6” Propellor

7.4 v 1800mAh LiPo battery

4

SECTION 1: KIT CONTENTS AND

DESCRIPTION CONTINUED

FUSELAGE ASSEMBLY.

Supplied complete and ready for use with brushless

motor installed and connected to Electronic Speed

Control (ESC),

35mhz receiver pre-wired to ESC, rudder, and

elevator servos.

Elevator, rudder and steering push rods installed

Nose wheel and screw on retaining cap.

WING ASSEMBLY.

Supplied as two halves.

Each half includes fitted and hinged aileron,

aileron torque rods with control horn and main

undercarriage fixing plates.

Hardwood wing joiner.

WING FIXING HARDWARE

Leading edge fixing plate

5

Wing bolts 2 off

Aileron servo with loose servo arm and fixing

screw.

Two aileron pushrods with plastic snap link clevis

connectors.

Vertical and Horizontal Stabilisers

Vertical Stabiliser (Fin and rudder) with moulded in

hinges and fitted control horn.

Horizontal Stabiliser (tail plane and elevator) with

moulded in hinges and fitted control horn.

Main Undercarriage assemblies.

Two sets of lightweight wheels fixed onto wire

torque rod undercarriage.

Four clamp plates and 8 fixing screws for securing

to wing plates.

Steerable nose gear is pre fitted to fuselage.

BATTERY AND CHARGER

7.4V (2 cell) 1800mAh (C) LiPo Battery rated at 12C

max discharge.

12v DC input 0.8 Amp output balancing type fast

charger

12v crocodile clip connecting lead

8” diameter x 6” pitch moulded propellor.

6

Ensure text is on front face when mounting.

Moulded spinner

Adhesive

5ml tube of foam safe adhesive.

Note pierce end of tube with pin in screw on lid.

SECTION 2: BATTERY AND CHARGER

BATTERY AND CHARGER

The kit includes a high performance 7.4V (3 cell)

1800mAh LiPo Battery rated at 12C (21 amp) max

discharge.

This must be charged using the dedicated 12v DC

input 0.8 Amp output fast charger and connecting

lead.

Connect the crocodile lead connectors to a 12V DC

power source (a 12V car battery is ideal), ensuring

that correct polarity is observed. Red is positive (+)

and Black is Negative (-).

Connect the lead into the battery charger. And the

Red LED will illuminate.

Push the white balance

plug of the battery into

the matching charger

output socket to

commence charging.

The green LED

illuminates to confirm

charging and switches off when the charge is

complete

A full charge will take between 2 and 3 hours.

WARNING:

A lithium polymer (LiPo) battery and charger is

included as part of this package, these cells

must be operated with care to prevent the risk of

fire.

LiPo Batteries are soft cased and can be easily

damaged by sharp items, puncturing of the soft

casing can cause fires and we recommend that

they are stored and handled carefully.

Remove battery from the aircraft and charge on a

non flammable, non conductive surface

7

TRANSMITTER

The RIR 4EXA is a fully proportional 4 function

35Mhz transmitter

The transmitter is supplied in a Mode 2

configuration. Mode 2 is also known as Throttle

Left.

The left stick controls Throttle and rudder

movement.

The right stick controls aileron and elevator

movement.

Battery state is indicated by a bank of coloured

LED’s. With green for full and red for empty.

As soon as the indicator changes to amber the

model should be landed to allow battery

replacement.

A red LED indicates dangerously low voltage.

The model should be landed immediately to replace

batteries before all control is lost.

Frequency control is by removable crystal.

The transmitter frequency is identified on the

crystal holder located on the front of the

transmitter.

8 off AA size dry cells or high capacity Nimh

batteries must be inserted before operation.

Remove the rear cover and install batteries into the

battery tray as directed by the moulded in polarity

(+ & -) markings.

A small panel of five small slide switches is set on

the front panel of the transmitter.

Switches 1 to 4 are electronic servo reversing

switches and should be adjusted to give the correct

control surface deflections relative to stick

movements.

The mix switch activates a ch1-ch2 mix to give

elevon (2 servos both functioning as ailerons and

elevators) for delta winged aircraft

For the TB20 the mix switch must be in the ‘A-Nor’

position.

SECTION 3: ASSEMBLY

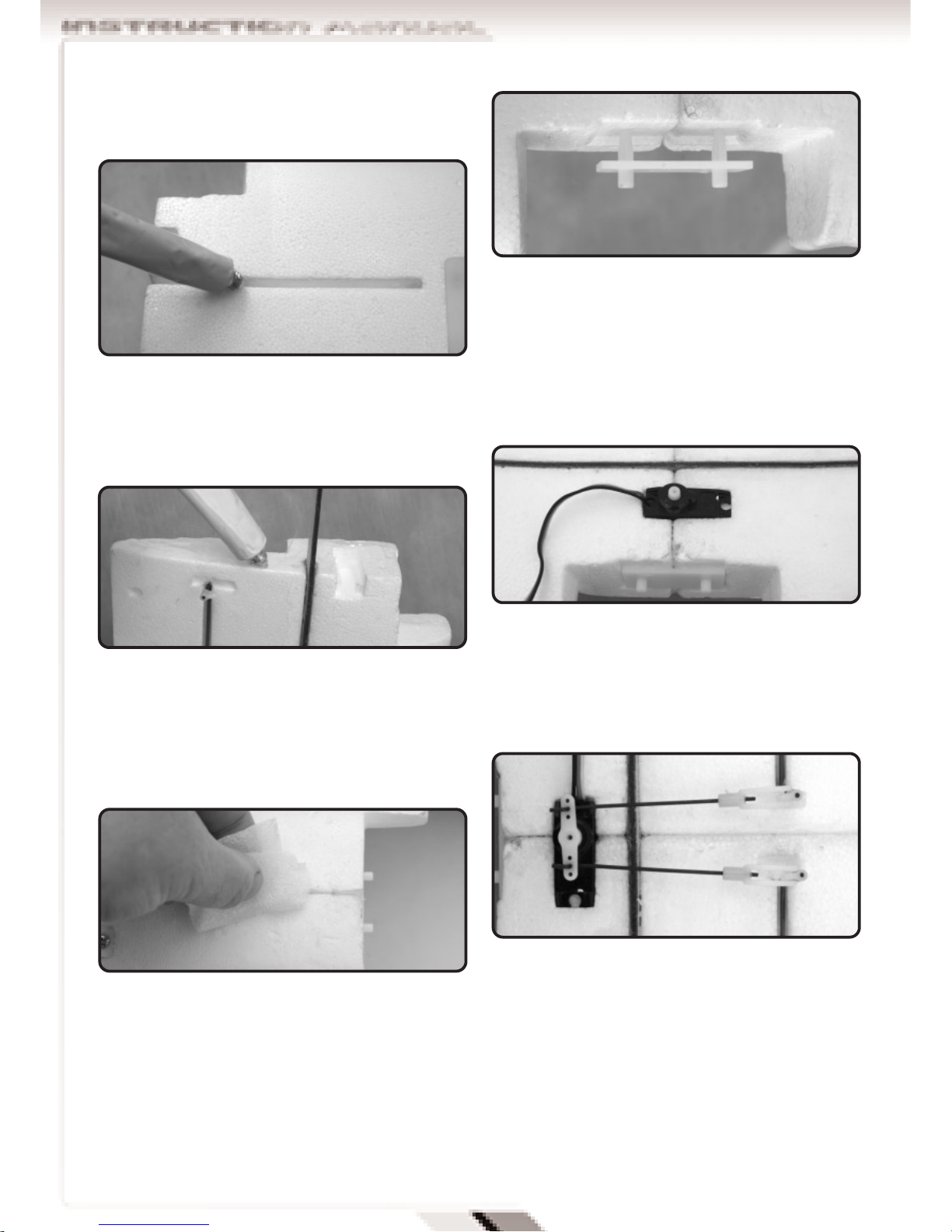

Locate the wing halves and wooden dihedral brace -

wing joiner.

Test fit the joiner in the slot formed in the wing and

dry fit the wings together.

8

Apply adhesive into the slot formed in one of the

wing halves and slide the wooden dihedral brace -

wing joiner firmly in position.

Ensure joiner is flush with top surface of wing. Wipe

off any excess adhesive and allow to dry.

Apply adhesive to the wing root and dihedral brace

slot in the remaining wing panel.

Slide the wooden dihedral brace - wing joiner in

position while butting the panels together.

Ensure that the wing halves are correctly aligned

with no visible gap and use tape or clips to hold in

place.

Wipe off any excess and adhesive allow to dry.

Locate the leading edge dowel plate and test fit in

the recess at the front of the wing.

When happy with location apply adhesive and press

firmly in place.

Locate the aileron servo with its pushrods and

connectors.

Apply a drop of adhesive to each side of the servo

and push into recess formed in wings.

The servo shaft should be central in the wing with

the lead exiting as shown

Connect the pushrods to the aileron control horns.

Push the servo arm onto the servo output shaft but

do not screw in place at this time.

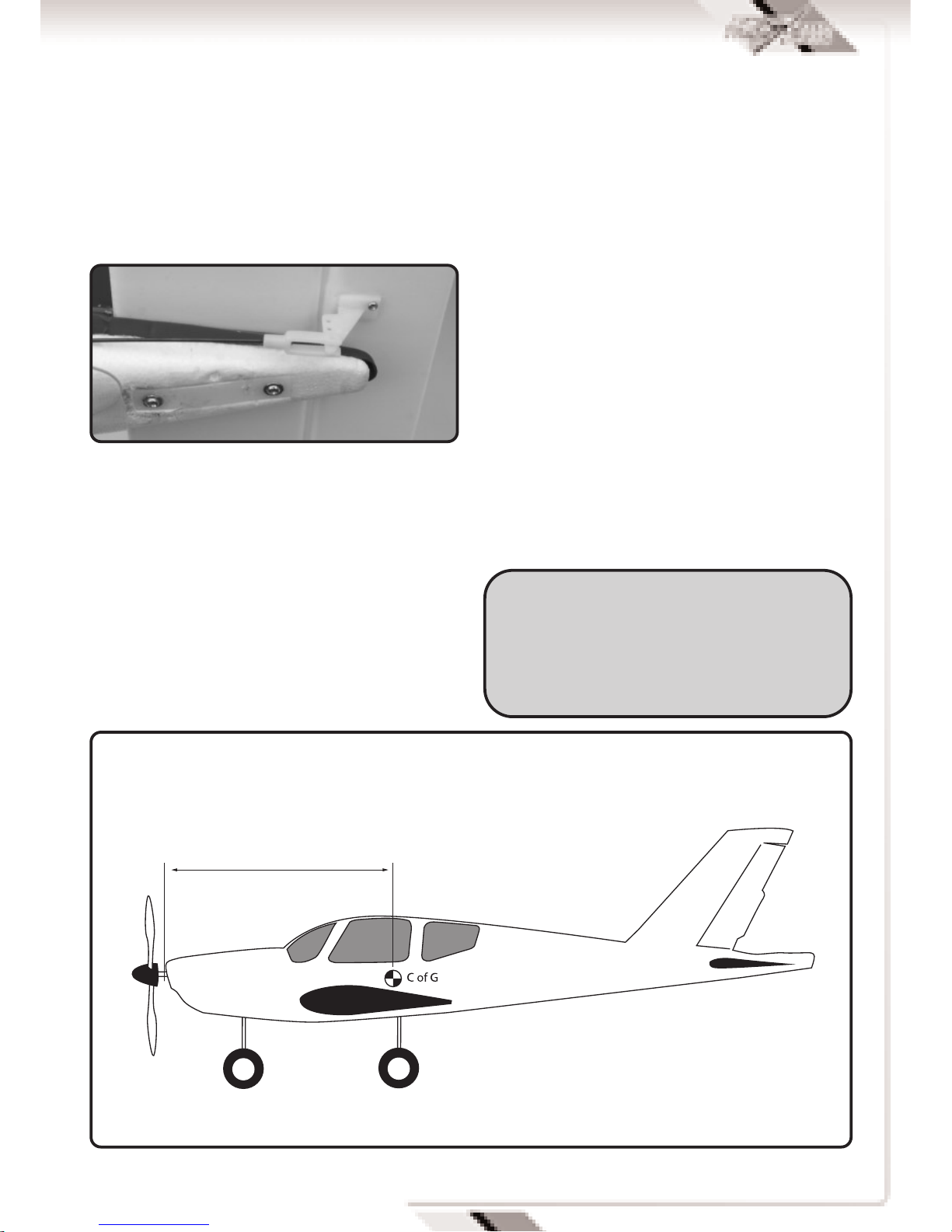

Locate the main undercarriage assemblies, saddle

plates and fixing screws.

Insert undercarriage into mounting plate and fix in

place with saddles and four self tapping screws.

Locate the fuselage, horizontal stabiliser and two

fixing screws.

Position over the tail plane seat and tighten screws

securely.

9

Locate the fin and rudder assembly and test fit in

the fin slot.

Apply adhesive into the fin slot and insert the fin.

Check that the fin is vertical and square to the

fuselage and tail plane and adjust if necessary.

Use a damp cloth to wipe off excess adhesive and

allow to dry

Slide the nose wheel in place and screw the

retaining cap onto the wire to secure.

Apply the self adhesive decals to the top surface of

the wing as shown.

The rear of the decal lines up with the trailing edge

and aileron cut out.

Locate the wing assembly and position it near the

wing seating area .

Take the plug on the aileron servo lead and push

plug into channel no 1 of the receiver.

Switch on the transmitter and centre the servo

trims.

Temporarily connect the battery and ESC leads

together and check that aileron servo arm is

central. Adjust if necessary and secure with screw.

Disconnect battery.

10

Push the wing firmly down onto its seat until wing

leading edge pegs locate into mounting plate.

Ensure that aileron wire is inside fuselage

Fit the wing fixing screws and tighten until The

wing is firmly seated.

Fix propellor to prop shaft using the M3 aluminium

spinner nut.

Note that washers are fitted to both sides of the

propellor.

The text on the propellor faces forward.

Push the spinner firmly in place.

Construction is now complete and the following

steps can be considered as part of the daily

assembly and rigging of the model.

SECTION 4: FINAL SET UP

Open the hinged battery bay door by turning the

catches.

Insert into the battery and ensure that battery and

ESC leads project out of the aperture.

Ensure that transmitter is switched on.

Connect the battery and ESC leads together and

close the battery cover using the catches to lock it

in place.

Uncoil the receiver aerial and fully extend to hang

off the rear of the aircraft.

Check that all controls operate in the correct

manner and that surfaces for aileron, elevator and

rudder are level.

Adjust surfaces if required by unclipping the

pushrod clevis connectors and winding in or out to

suit.

WARNING:

With the battery connected and the model

switched on the motor is now live. The Electronic

speed controller (ESC) will go through its start up

procedure and will emit a series of beeps while it

configures throttle positions. The motor could

start unexpectedly and we recommend that the

model is restrained and that the operator keeps

clear of the propellor during handling.

11

To adjust the ailerons and nose wheel steering it is

necessary to remove the wing.

loosen the clamp connector before adjusting the

pushrod location.

With the trims and wheel central re-tighten the

clamp connector.

Move transmitter sticks to ensure free movement of

the control surfaces.

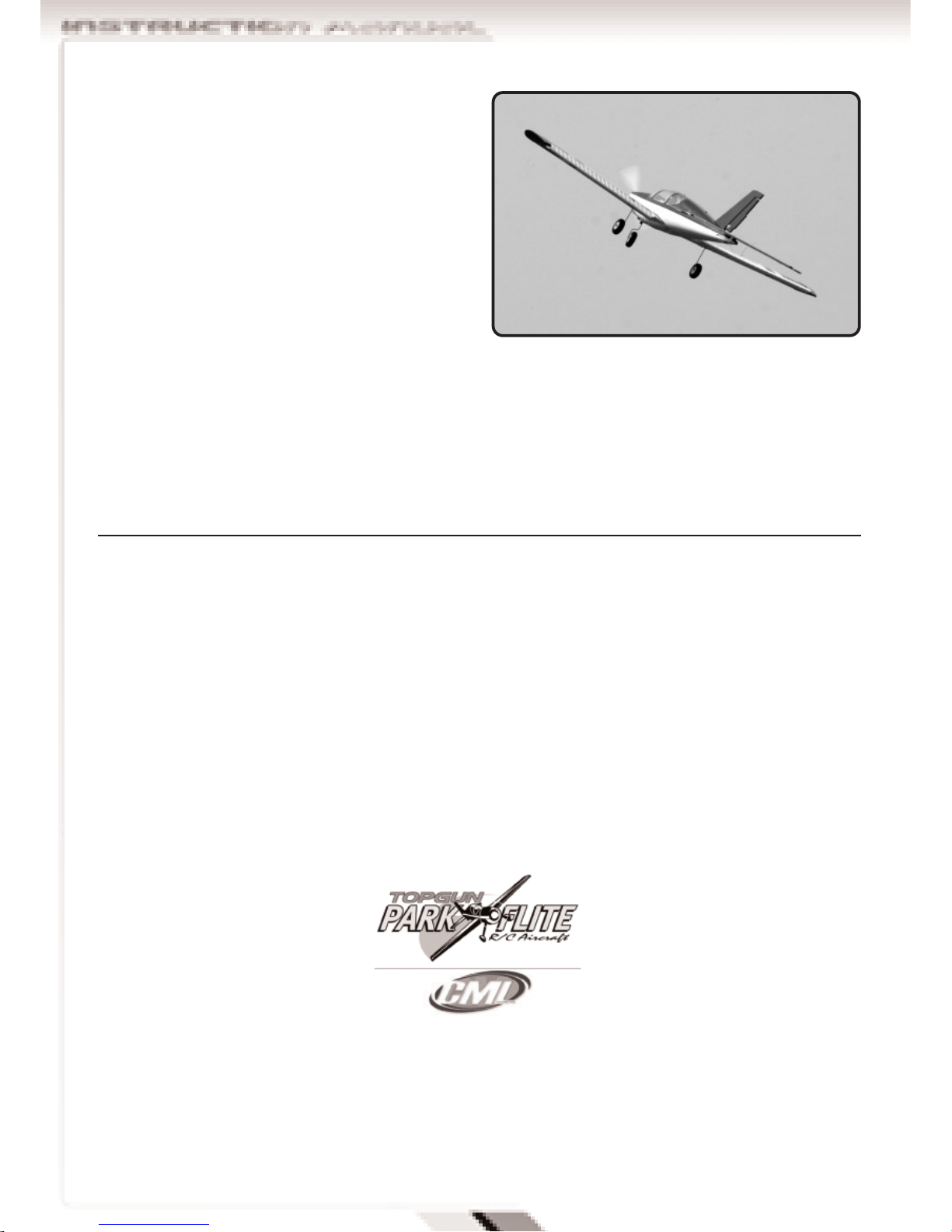

CHECK THE BALANCE.

The model should sit level or slightly nose down

when supported upside down from a point 50-54

mm from the wing leading edge. Add stick on lead

weights if necessary in order to achieve the correct

balance point.

DO NOT ATTEMPT TO FLY WITH A REARWARD

BALANCE POINT.

SECTION 5: FIRST FLIGHT

BEFORE THE TEST FLIGHT

On completion of the model take time to test rig the

model in the workshop several times.

Connect radio gear and double check that all

surfaces operate in the correct manner without

stalled servos.

Check for adequate range with and without motor

running.

If everything is okay, take it to the flying field and

rig it up again.

Always follow the frequency control procedures of

your local flying site and ensure that you have

adequate third party insurance cover.

Repeat the full pre flight inspection before flying.

WARNING:

Do not advance the throttle unless the model is

restrained. With the powerful motor-propellor

combination, the model will accelerate across a

smooth surface very quickly.

230mm

BALANCE POINT

12

FLYING

The TB20 is easily capable of 10 to 15 minute flight

times and can R.O.G (Rise Off Ground) from smooth

closely cut grass runways. It is aerobatic and able

to perform loops, rolls, and stall turns.

Due to its light weight it should not be flown in wind

greater than 10mph.

The use of rudder co-ordinated with aileron input

will produce smooth and scale like turns.

Control throws set during assembly will produce a

model capable of flying smooth scale like

performance and medium to high speed aerobatic

manoeuvers.

The control surface movements can be increased by

moving the clevis connectors nearer to the control

surfaces.

To reduce movements move the pushrod

connections nearer to the servo on the output arms

and further out along the control surfaces horns.

ENJOY YOURSELF BUT ALWAYS FLY SAFE!

TGP0155R TB20 EP Red Upper Fuselage

TGP0155B TB20 EP Blue Upper Fuselage

TGP0156 TB20 EP Lower Fuselage

TGP0157R TB20 EP Red Main Wing

TGP0157B TB20 EP Blue Main Wing

TGP0158R TB20 EP Red Wing Tips

TGP0158B TB20 EP Blue Wing Tips

TGP0159R TB20 EP Red Tail Wing Sets with

Vertical Tai /Horizontal Tail

TGP0159B TB20 EP Blue Tail Wing Sets with

Vertical Tai /Horizontal Tail

TGP0160R TB20 EP Red Front Nose Cowl

TGP0160B TB20 EP Blue Front Nose Cowl

TGP0161 TB20 EP Propeller 8x6

TGP0162 TB20 EP Spinner

TGP0163 TB20 EP Plastic Parts

TGP0164 TB20 EP Rear Landing Gear

TGP0165 TB20 EP Front Landing Gear

TGP0166 TB20 EP Aluminium Motor Frame

TGP0525 Top Gun Park-Flite 1800mAh 12c 7.4v

Lipo Battery (TB20)

TGP0534 Top Gun Park-Flite Bell 80w Outrunner

Brushless (TB20)

TGE0001 Etronix 8.4G Micro Servo

TGE0051 Etronix 25A Brushless Speed Control

DISTRIBUTORS OF QUALITY MODEL & HOBBY PRODUCTS

Saxon House, Saxon Business Park, Hanbury Road, Bromsgrove, Worcestershire. B60 4AD. England

Tel: +44 (0) 1527 575349 Fax: + 44 (0) 1527 570536

E-mail: [email protected]

Web site: www.cmldistribution.co.uk

TOP GUN PARKFLITE TB–20 SPARE PARTS LIST

Table of contents

Other Torgun Toy manuals

Popular Toy manuals by other brands

Mattel

Mattel N9795 instruction sheet

LEGO

LEGO Duplo Disney Junior Sofia the First 10822 Assembly manual

Faller

Faller 130232 manual

THE WORLD MODELS

THE WORLD MODELS Spot-On 50 instruction manual

Trends Audio

Trends Audio Peppa Pig Peppa’s Smart Tablet PP04 instruction manual

Fisher-Price

Fisher-Price 71922 instructions

Thames & Kosmos

Thames & Kosmos ANiMALS operating manual

Peg-Perego

Peg-Perego IMGIRE00 Series Instructions for use

Agora Models

Agora Models OPTIMUS PRIME Pack 02 Build instructions

Accucraft trains

Accucraft trains D&RGW C-25 2-8-0 instruction manual

goliath

goliath Star Wars Domino Express R2-D2 Dealer instructions

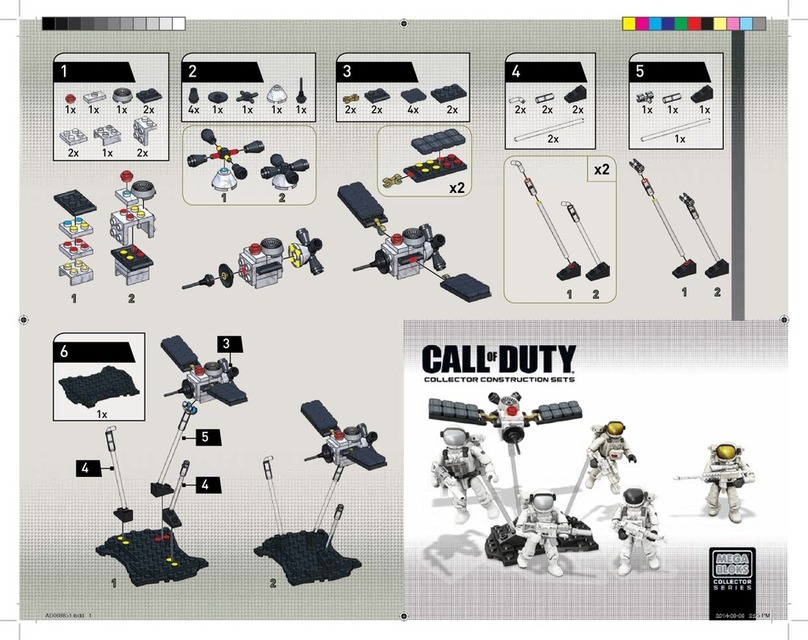

Mega Bloks

Mega Bloks Collector Series instructions