C-25 Live Steam

Preparing the engine

A steam-locomotive engineer goes

through a lighting-up ritual every time

the engine is to be run. It is good to

follow the same routine each time so

that nothing is overlooked.

1. Oil all external moving parts of the

engine, including wheel bearings, with

a high grade, lightweight machine oil

like 3-in-1. Be sure to oil all parts of the

drive train.A little oil is all that’s neces-

sary.

2. Place the engine on track.

3. The adjustable lubricator located

in the cab ensures the cylinders and

valves are properly lubricated inside.

The adjustable lubricator valve handle

should be open at least two full turns

when the engine is breaking in. The

break in period should be approx. two

hours. If you notice excessive oil use

after that period of time then close the

valve to one full turn.

As the steam passes through it, a

small amount will condense into

water. This water will sink to the bot-

tom of the lubricator, forcing a similar

quantity of oil into the steam line and

thus to the cylinders.

5

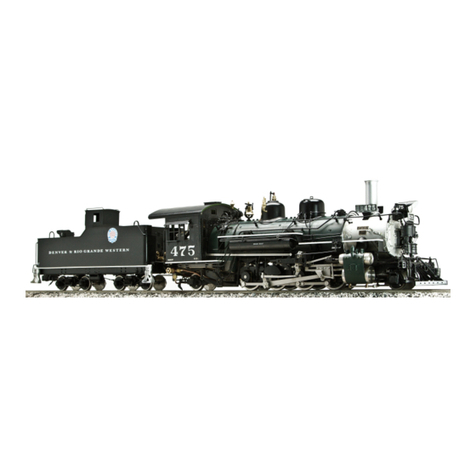

Gas line to locomotive

Water line to locomotive

Water filler plugLubricator

Water level gauge

Pressure gauge

Throttle

C-25 Live Steam

Remove the lubricator cap and draw

out any water from previous run with

a syringe. Use only proper steam cyl-

inder oil. Fill the lubricator, but leave

a small air space between the oil and

the cap.

4. Unscrew the filler plug and fill the

boiler to the top with water then pull

out 30 ml with large syringe. Use only

distilled water in your engine’s boiler.

Tap water contains minerals that will

leach out and ultimately affect the per-

formance of the engine.

5. Finally, add fuel. Your C-25 burns

butane gas. The gas tank is located

in the tender beneath the front hatch.

Butane gas can be purchased at the

grocery store or at a tobacconist’s as

cigarette-lighter refills. These come

with a nipple suitable for the filler valve

on the C-25’s gas tank. (Butane can

also be purchased in larger containers

at camping-supply stores, but these

cans will require a special adapter for

filling the engine’s tank.) Simply press

the nozzle of the butane canister hard

onto the filler valve atop the tank,

making sure that the control valve is

closed. You will hear the gas transfer-

ring and will see a little gas bleeding

out of the valve. When the tank is full,

the gas will begin to splutter and much

more gas will escape the valve. When

the gas tank is full you are ready to fire

up the engine. Add 1” to 2” of water to

the rear tank. This will keep the tank

warm and the gas pressure up!

Firing up

Make sure the throttle is closed. The

engine’s burner resides at the back

of the flue inside the boiler. Open the

hinged smokebox door at the front of

the engine and you’ll be able to see

the flue. To light up, strike a match

and hold it at the open smokebox door

while simultaneously opening the gas

valve in the tender very slowly until the

gas ignites. You should hear the gas

coming into the burner. Opening the

valve too wide or too fast may blow

out the flame or cause the fire to burn

in the smokebox.

The fire should flash back into the

back of the flue with a quiet “pop”. If

it wants to burn in the smokebox or

in the forward part of the flue, slowly

close the gas valve until it flashes back

to the burner. Don’t let the fire burn in

the smokebox - your engine will not

run as it should and may be damaged.

The fire should burn under the burner

in a crescent-shaped flame, which

should be clearly visible through the

smokebox door. The flame should be

bright blue and should burn steadily.

If it sputters or looks yellow or green,

adjust the gas valve accordingly. The

object is to run the burner at the low-

est setting possible to operate the en-

gine, thereby increasing the efficiency

of the engine and the duration of the

run. You’ll get the hang of this with

practice.

6