Tormach Collet Closer 5C Technical manual

Page 1

Tormach Inc.

1071 Uniek Drive, Waunakee, WI 53597

Phone: 608.849.8381 / Fax: 209.885.4534

©Tormach® 2014. All rights reserved.

Specicaons subject to change without noce.

TD10249_Collet_Closer_Install_0117A

Collet Closer Installation

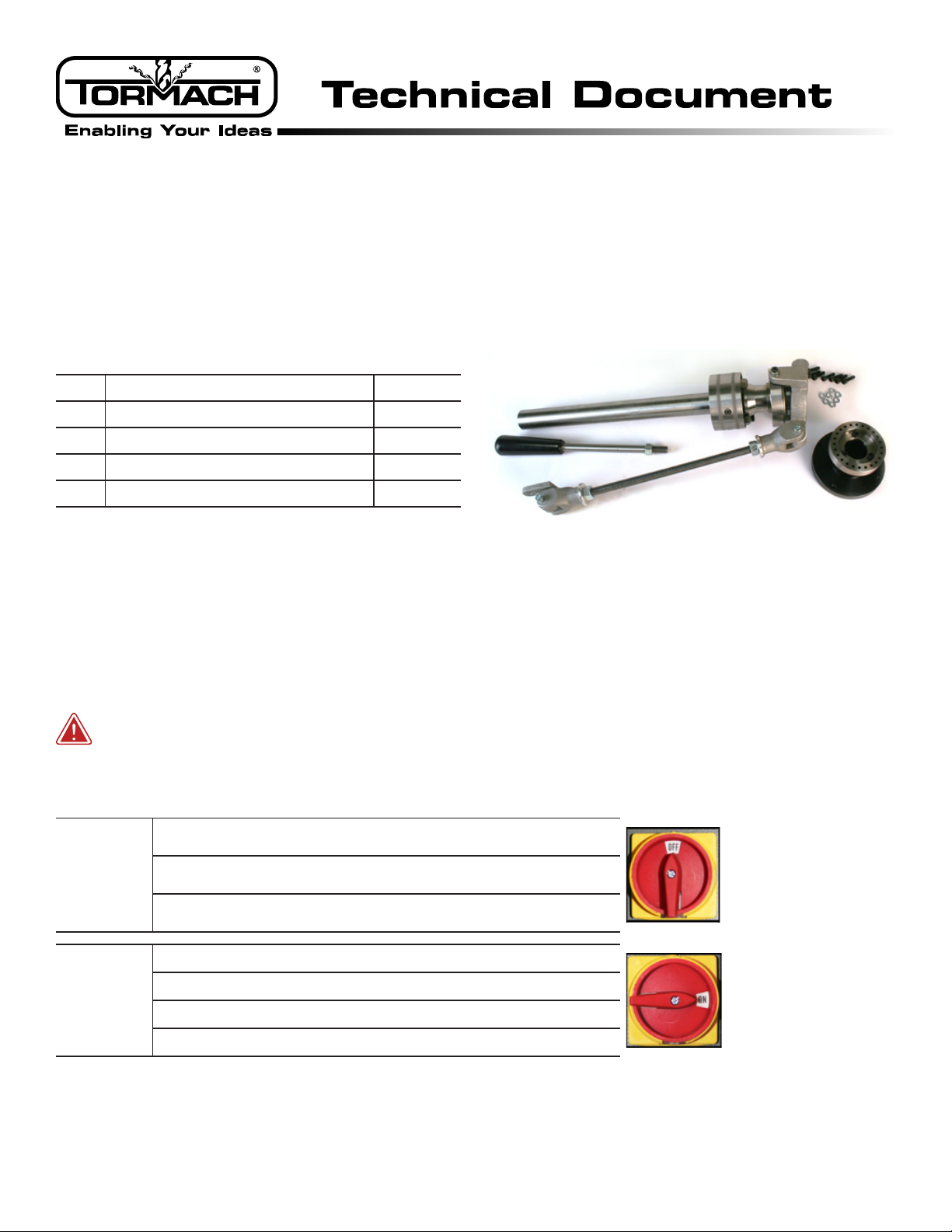

Product Idencaon: 5C Collet Closer (PN 33283)

Purpose: This document details the installaon and use of the collet closer on a 15L Slant-PRO lathe.

Qty.5C Collet Closer PN

1 Collet Closer —

1Index Ring/Adapter Assembly —

1 Collet Handle —

6 M6 Socket Head Cap Screw —

6M6 Lock Washer —

NOTE: If any of these items are missing, contact Tormach

Customer Service at (608) 849-8381 for a replacement.

Required Tools:

• .0005” Magnetic Dial Indicator (PN 31947) • Dead-blow hammer

• Bandsaw or hacksaw • Machinist’s stone or similar

WARNING! Electrical Shock Hazard: Be sure to power o machine before making any electrical

modicaons. Failure to do so may result in serious injury or death.

Power Off/On Procedure

Power Off

1. Push in red E-stop button

2. Click Exit on screen; when prompted click OK to power off

3.Turn Main Disconnect Off (see image at right)

Power On

1.Turn Main Disconnect On (see image at right)

2.After software loads, t

urn red E-stop clockwise to release

3. Press green Start button

4. Click Reset on screen

Page 2

Tormach Inc.

1071 Uniek Drive, Waunakee, WI 53597

Phone: 608.849.8381 / Fax: 209.885.4534

©Tormach® 2014. All rights reserved.

Specicaons subject to change without noce.

TD10249_Collet_Closer_Install_0117A

Installation

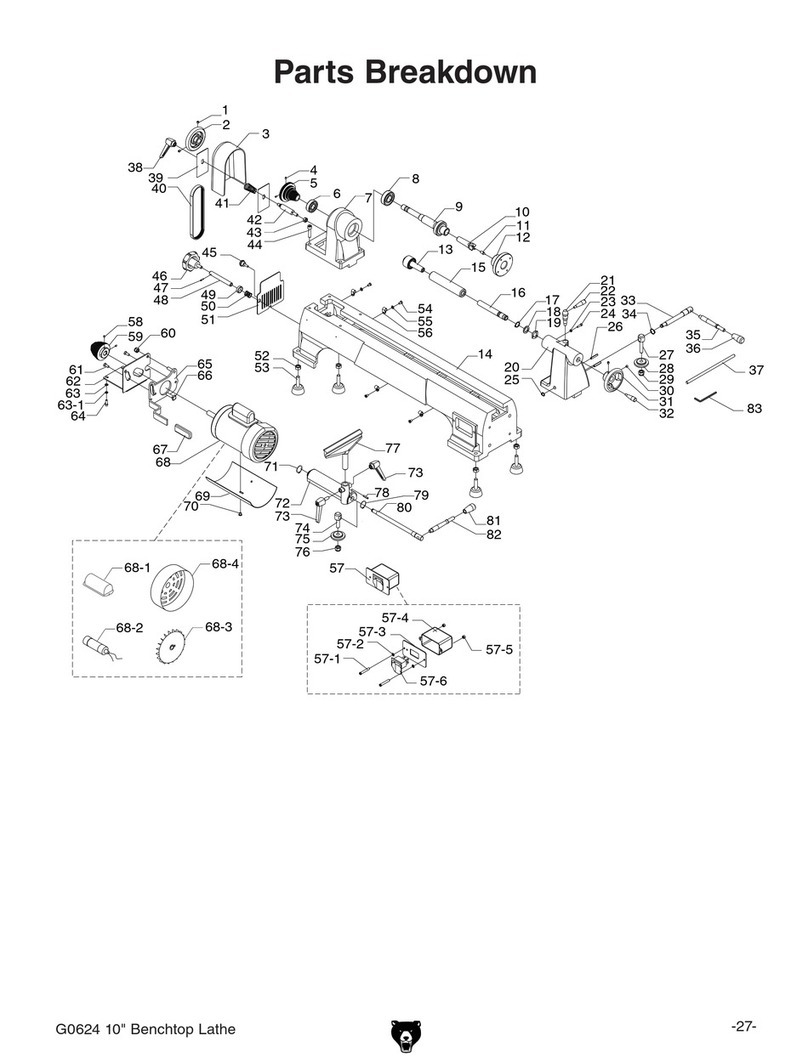

1. Remove four Phillips-head screws securing

panel to belt guard (see Figure 1); set aside for

future use.

2. Unscrew Power Connector from Rotary

Encoder (see Figure 2).

3. Loosen ve Phillips-head screws securing belt

guard cover to lathe; remove cover and set all

aside (see Figure 3).

Figure 1 Figure 2

Rotary Encoder

Power Connector

Figure 3

Page 3

Tormach Inc.

1071 Uniek Drive, Waunakee, WI 53597

Phone: 608.849.8381 / Fax: 209.885.4534

©Tormach® 2014. All rights reserved.

Specicaons subject to change without noce.

TD10249_Collet_Closer_Install_0117A

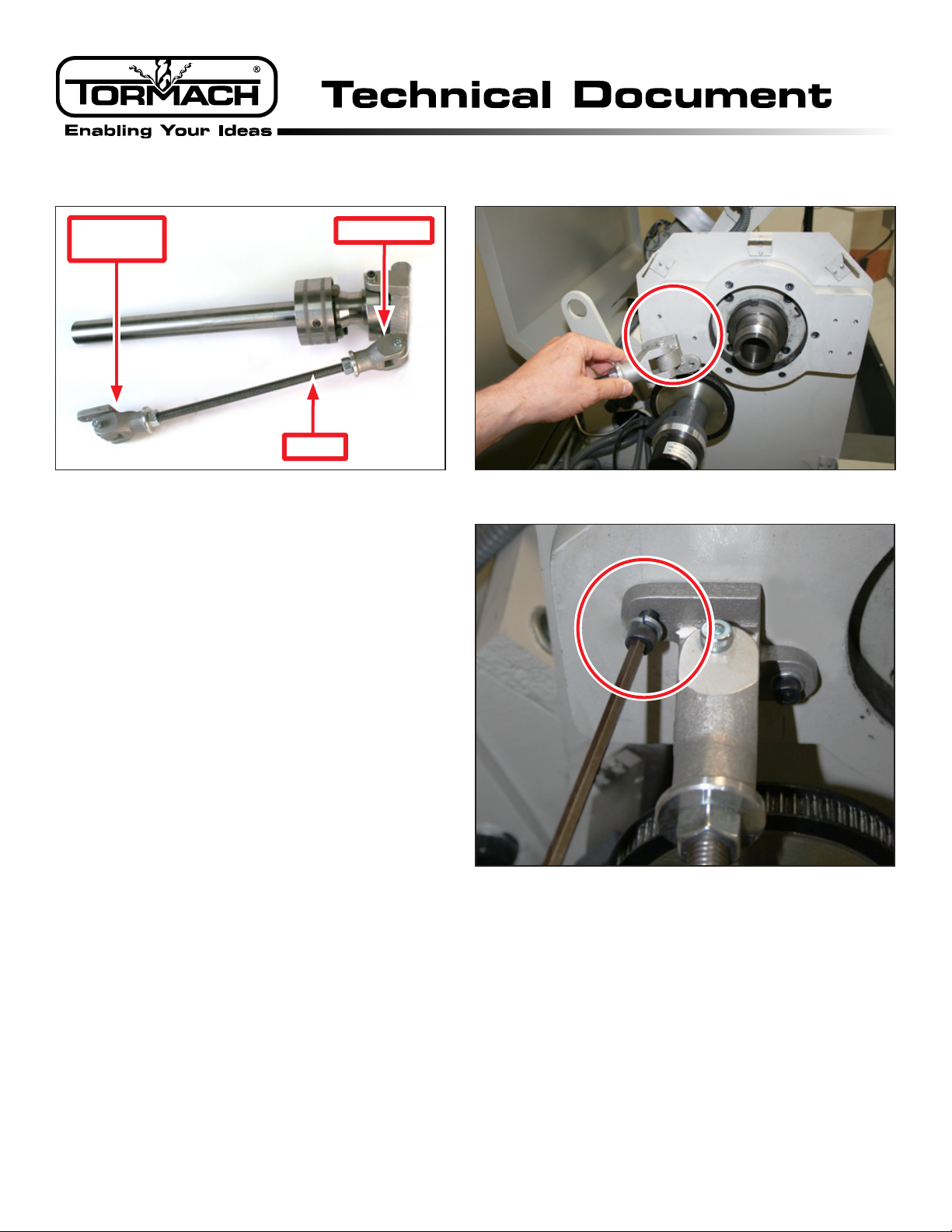

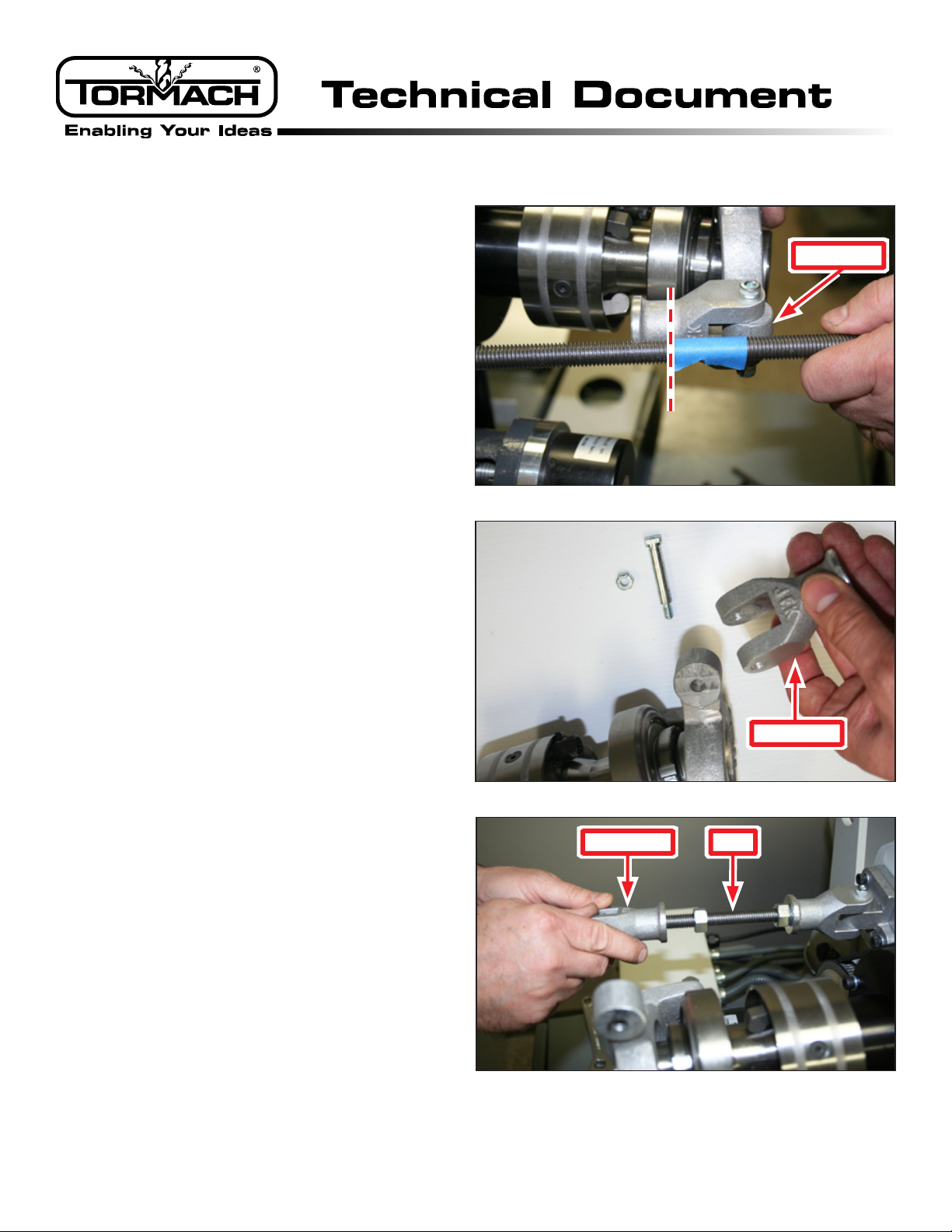

4. Unscrew Rod from Connector (see Figure 4) on

Collet Closer.

5. Locate two pilot holes on lathe to aach

Connector Bracket (see Figure 4 and Figure 5).

6. Using two M6 Socket Head Cap Screws and two

M6 Lock Washers, aach Connector Bracket to

lathe (see Figure 6).

Figure 4

Connector

Bracket

Connector

Rod

Figure 5

Figure 6

Page 4

Tormach Inc.

1071 Uniek Drive, Waunakee, WI 53597

Phone: 608.849.8381 / Fax: 209.885.4534

©Tormach® 2014. All rights reserved.

Specicaons subject to change without noce.

TD10249_Collet_Closer_Install_0117A

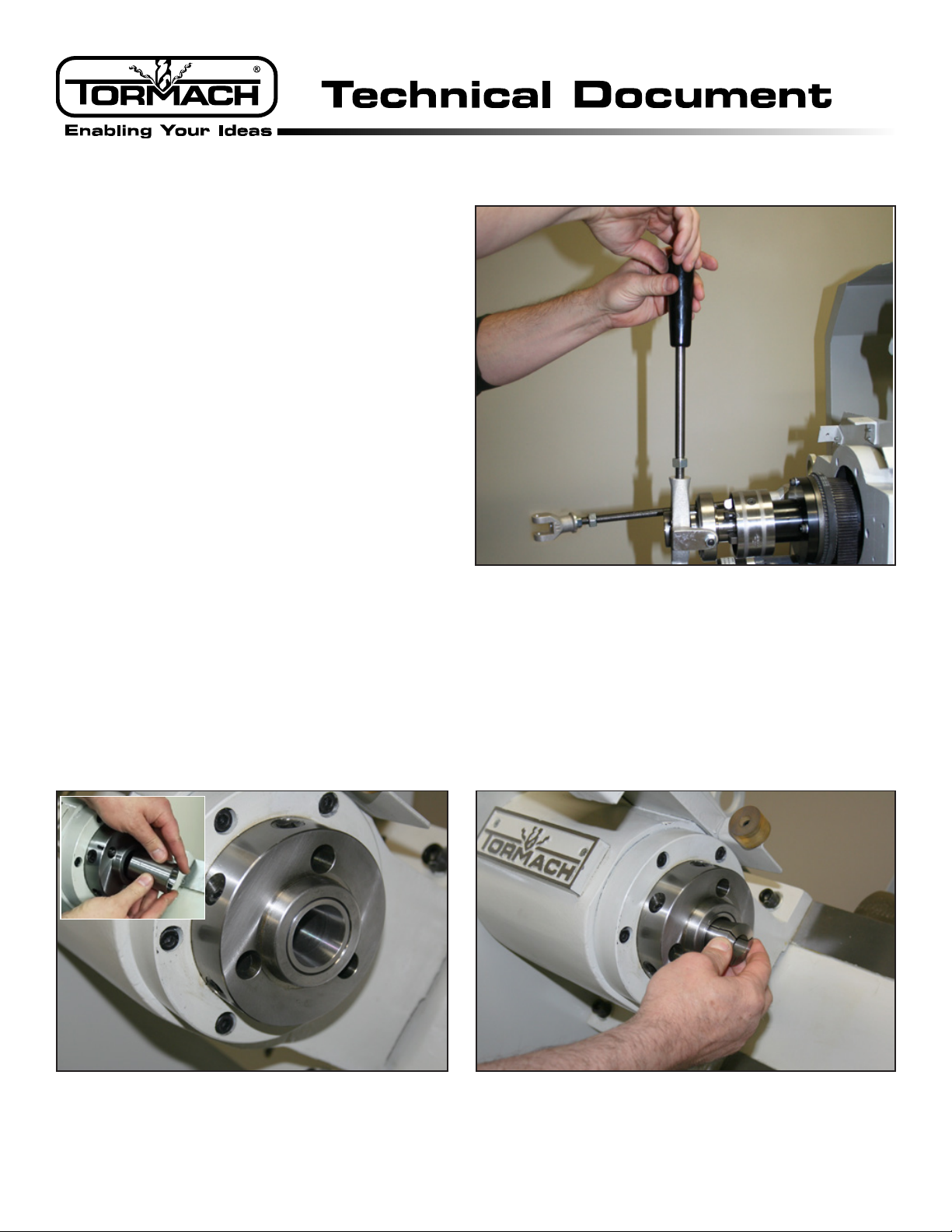

7. Using machinist’s stone or similar, lightly

stone the back of the Index Ring/Adapter

assembly and the face of the spindle pulley

(see Figure 7) to remove burrs. Presence of

burrs may cause runout.

8. Using four M6 Socket Head Cap Screws and four

M6 Lock Washers, aach Index Ring/Adapter

Assembly to spindle pulley (see Figure 8).

9. Aach .0005” magnec dial indicator to lathe

and posion indicator p against index ring

(see Figure 9).

Figure 8

Index Ring/

Adapter

Assembly

Figure 9

Figure 7

Deburr

Page 5

Tormach Inc.

1071 Uniek Drive, Waunakee, WI 53597

Phone: 608.849.8381 / Fax: 209.885.4534

©Tormach® 2014. All rights reserved.

Specicaons subject to change without noce.

TD10249_Collet_Closer_Install_0117A

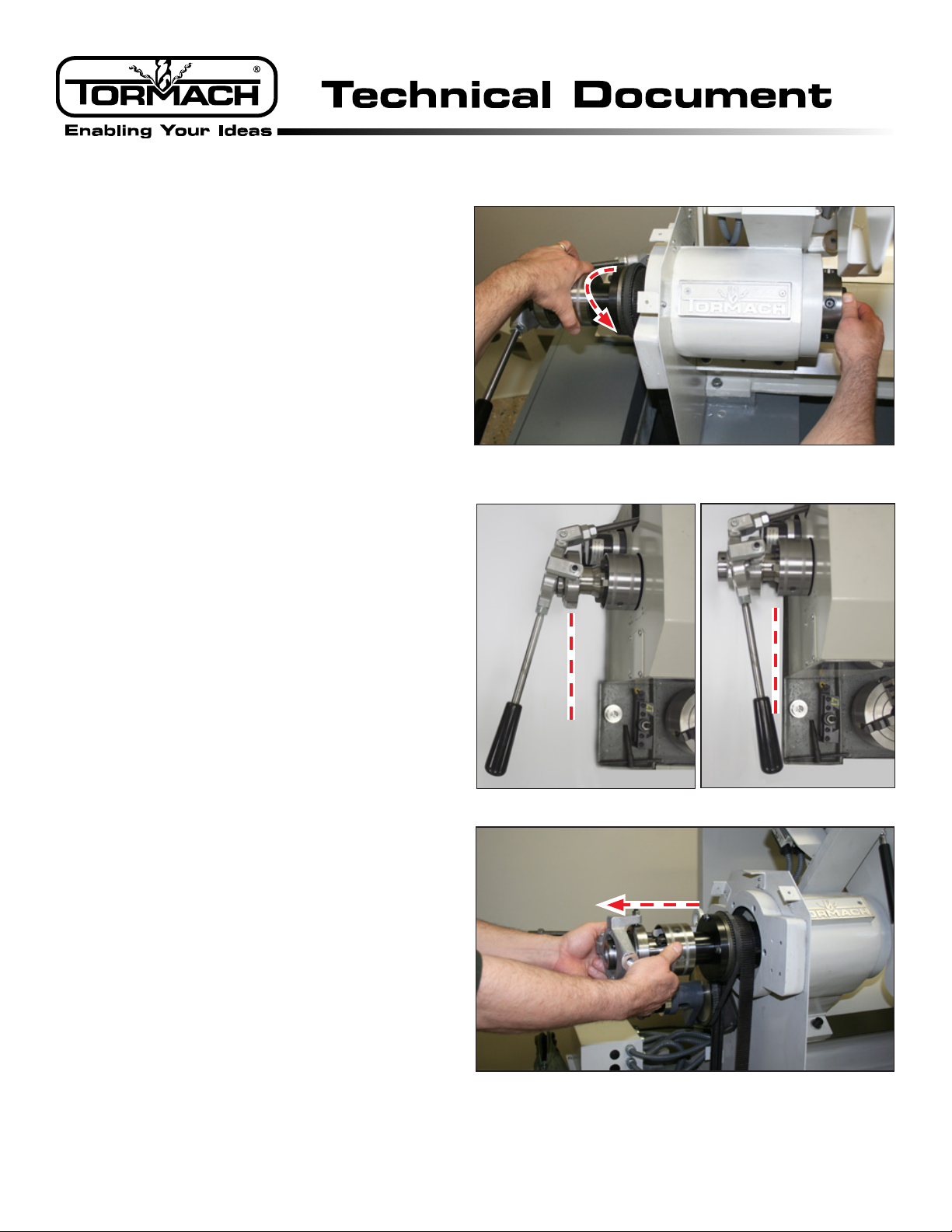

10. Slowly pull down on spindle belt to rotate index

ring (see Figure 10); complete one full cycle

and make note of reading on dial indicator.

Alignment should hold a total indicated runout

of 0.001” or beer.

11. If reading on indicator moves more than

0.001”, carefully loosen three socket head cap

screws on Index Ring and tap with a dead-blow

hammer to bring center in line with lathe’s

spindle bore (see Figure 11).

12. Repeat Step 10 and Step 11 unl alignment is

achieved.

13. Carefully ghten three socket head cap screws

on Index Ring.

14. Temporarily insert Collet Closer into lathe’s

spindle bore (see Figure 12).

Figure 11

Index

Ring

Figure 12

Figure 10

Page 6

Tormach Inc.

1071 Uniek Drive, Waunakee, WI 53597

Phone: 608.849.8381 / Fax: 209.885.4534

©Tormach® 2014. All rights reserved.

Specicaons subject to change without noce.

TD10249_Collet_Closer_Install_0117A

15. Posion rod next to Connector on Collet Closer;

esmate length of rod necessary for full range

of moon and mark with tape (see Figure 13).

NOTE: Required rod length varies; adjustments

may be necessary aer Collet Closer installaon is

complete.

16. Using a bandsaw or hacksaw, cut rod as

determined in Step 15.

17. Lightly stone newly-cut end of rod.

18. Remove Connector from Collet Closer by

removing nut and bolt (see Figure 14).

19. Screw Connector onto newly-cut end of Rod;

(see Figure 15) using nut, ghten securely.

Figure 13

Connector

Figure 14

Connector

Figure 15

Connector Rod

Page 7

Tormach Inc.

1071 Uniek Drive, Waunakee, WI 53597

Phone: 608.849.8381 / Fax: 209.885.4534

©Tormach® 2014. All rights reserved.

Specicaons subject to change without noce.

TD10249_Collet_Closer_Install_0117A

20. Screw Collet Handle into Collet Closer; ghten

securely (see Figure 16).

21. Re-aach Connector to Collet Closer with nut

and bolt set aside in Step 18; ghten securely.

NOTE: Connector should be able to move freely.

22. Ensure 5C insert (included with lathe) is inserted in spindle (see Figure 17 and inset).

23. Insert 5C collet (not included) into adapter and rotate to engage the collar’s internal pin with the groove

on the collet (see Figure 18).

Figure 16

Figure 17 Figure 18

Page 8

Tormach Inc.

1071 Uniek Drive, Waunakee, WI 53597

Phone: 608.849.8381 / Fax: 209.885.4534

©Tormach® 2014. All rights reserved.

Specicaons subject to change without noce.

TD10249_Collet_Closer_Install_0117A

24. Hold the collet sll in the spindle with one

hand; using the other hand, turn the Collet

Closer’s collar clockwise to thread it on to the

collet (see Figure 19).

25. Insert a piece of material into the collet and

turn the Collet Closer’s collar clockwise unl

desired tension is achieved on the workpiece.

IMPORTANT! Avoid excess tension on collet.

26. Move the collet handle back and forth between

the locked posion (away from the headstock)

and the released posion (toward the

headstock). Ensure handle is past centerline in

either posion (see Figure 20).

IMPORTANT! If collet handle is not past center

in the locked posion (see Figure 20), adjust

rod length unl proper alignment is achieved.

27. Temporarily remove Collet Closer from lathe

spindle assembly (see Figure 21).

28. Using ve Phillips-head screws, reaach Belt

Guard Cover to lathe.

29. Re-insert Collet Closer into lathe spindle

assembly.

30. Re-install power connector to rotary encoder.

Figure 20

Locked Released

Figure 21

Figure 19

Page 9

Tormach Inc.

1071 Uniek Drive, Waunakee, WI 53597

Phone: 608.849.8381 / Fax: 209.885.4534

©Tormach® 2014. All rights reserved.

Specicaons subject to change without noce.

TD10249_Collet_Closer_Install_0117A

31. Proceed to Operaon secon to idenfy any

adjustments required to operate the collet

closer. You have now completed the installaon

(see Figure 22).

Operation

1. With a piece of material inserted in the collet,

ensure the Collet Closer is in the released

posion (see Figure 20), with the collet handle

toward the headstock.

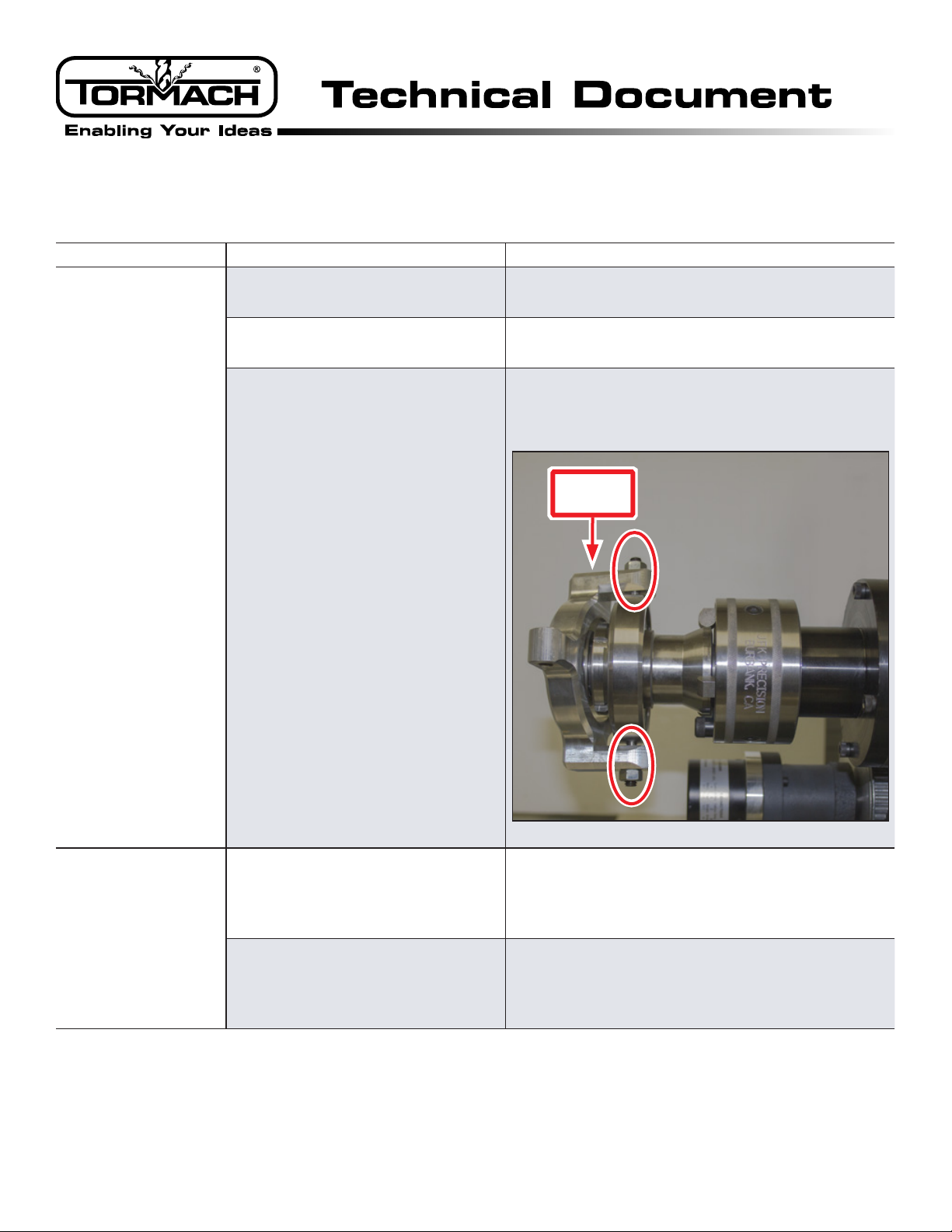

2. Idenfy Index Pin on Collet Closer’s index plate

(see Figure 23).

Figure 23

Figure 22

Page 10

Tormach Inc.

1071 Uniek Drive, Waunakee, WI 53597

Phone: 608.849.8381 / Fax: 209.885.4534

©Tormach® 2014. All rights reserved.

Specicaons subject to change without noce.

TD10249_Collet_Closer_Install_0117A

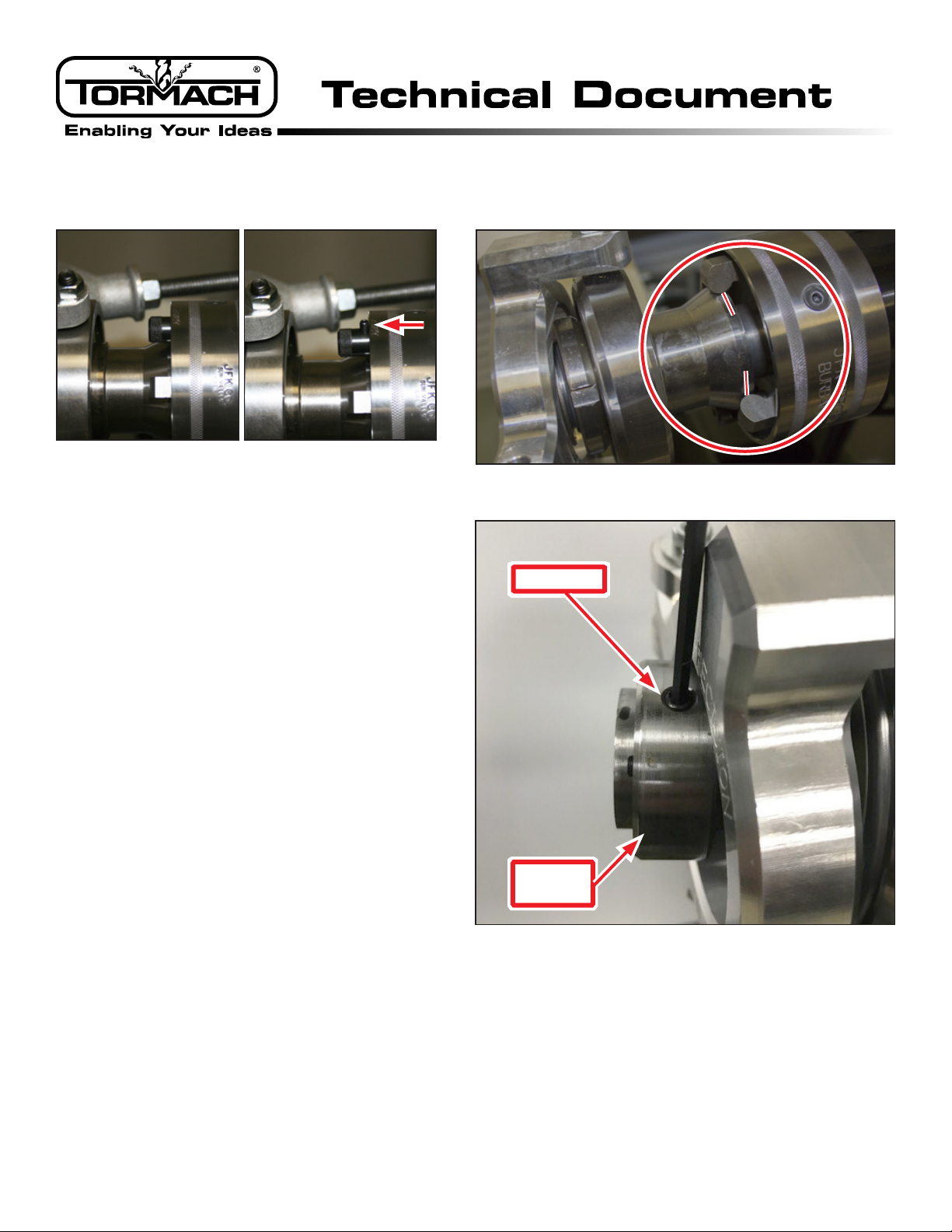

3. Ensure the index pin is in the Pin Out posion

(see Figure 24).

NOTE: When the pin is in, the collet closer is in run

mode. When the pin is out, the collet closer is in

adjust mode.

4. Move the collet handle to the locked posion

(away from the headstock); ensure cams are

centered on the hub as shown in Figure 25.

If the cams are not centered on the hub:

• Rotate Stop Collar to access Set Screw on

Collet Closer (Figure 26); loosen set screw.

• Slide unit forward or backward unl cams

rest in center of hub as shown in Figure 25.

• When adjustment is complete, re-ghten

set screw on Collet Closer’s hub.

5. Move the Index Pin to the Pin In posion (see

Figure 24) by twisng to release and allowing

it to enter the closest hole in the index plate.

NOTE: If necessary, turn the collar slightly to allow the index pin to seat completely.

6. With the Index Pin in the Pin In posion, the collet closer is in run mode. You have now adjusted the collet

closer for operaon.

Figure 25

Figure 26

Set Screw

Stop

Collar

Figure 24

Pin In Pin Out

Page 11

Tormach Inc.

1071 Uniek Drive, Waunakee, WI 53597

Phone: 608.849.8381 / Fax: 209.885.4534

©Tormach® 2014. All rights reserved.

Specicaons subject to change without noce.

TD10249_Collet_Closer_Install_0117A

Troubleshooting

Problem Possible Cause Discussion

Handle wobbles

Runout on Index Ring/Adapter Ensure both sides of Index Ring/Adapter assembly are

free of debris (see Figure 7).

Connector and/or connector bracket

is too loose or too tight

Adjust bolts on connector and connector bracket as

necessary (see Figure 14).

Handle casting is not centered

Loosen top and bottom height screw locknuts (see

Figure 27) on Handle Casting and adjust set screws

until it is centered.

Handle

Casting

Figure 27

Handle moves itself to

the released position

or

Index pin does not

engage in index ring

Cams are not centered on the hub

Loosen Set Screw on Stop Collar (see Figure 26) and

slide unit until cams rest in the center of the hub (see

Figure 25). Re-tighten Set Screw.

Threaded rod is too long

Ensure handle is past centerline when in the locked

position (see Figure 20). If not, make adjustments to

threaded rod length – either cut the rod or tighten it

further into connector and/or connector bracket.

This manual suits for next models

1

Table of contents

Other Tormach Lathe manuals