Tormach 770M User manual

TECHNICAL DOCUMENT

Owner's Guide:

770M® Power

Drawbar

TD10541: Owner's Guide: 770M® Power Drawbar (0618A) Page 1 Specifications subject to change without notice.

©Tormach® 2018

1.1 PURPOSE

This document gives instructions on installing a 770M® Power

Drawbar.

1.2 PRODUCT INFORMATION

Product: Power Drawbar

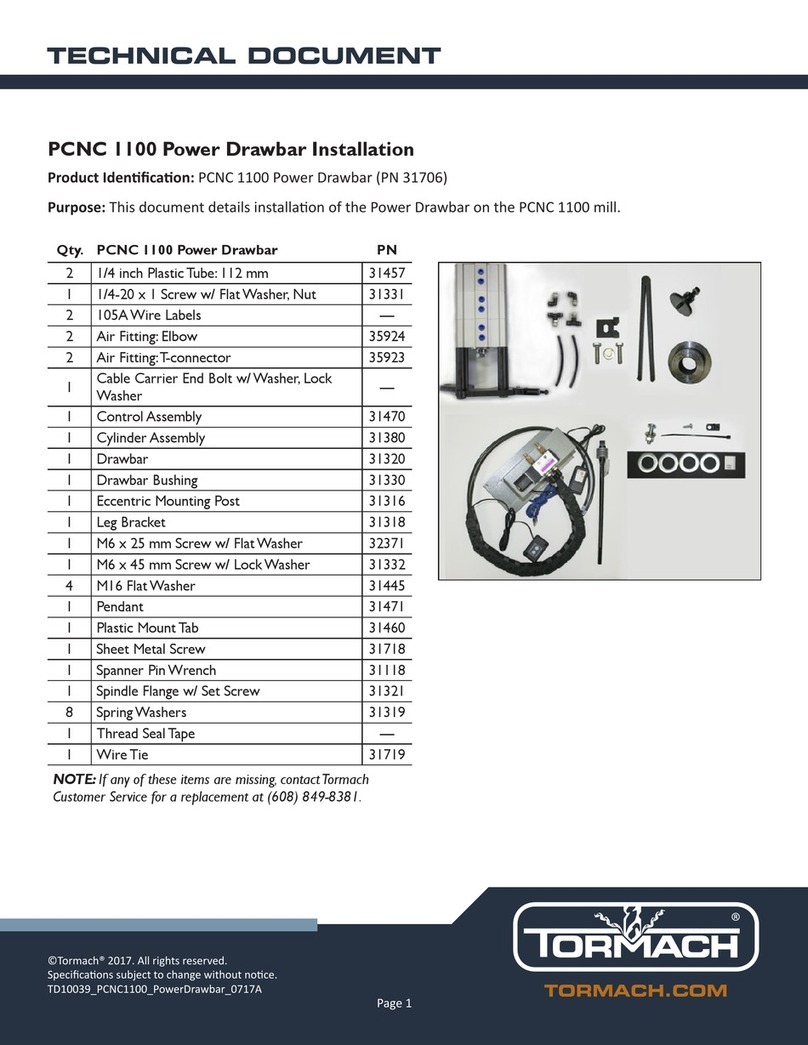

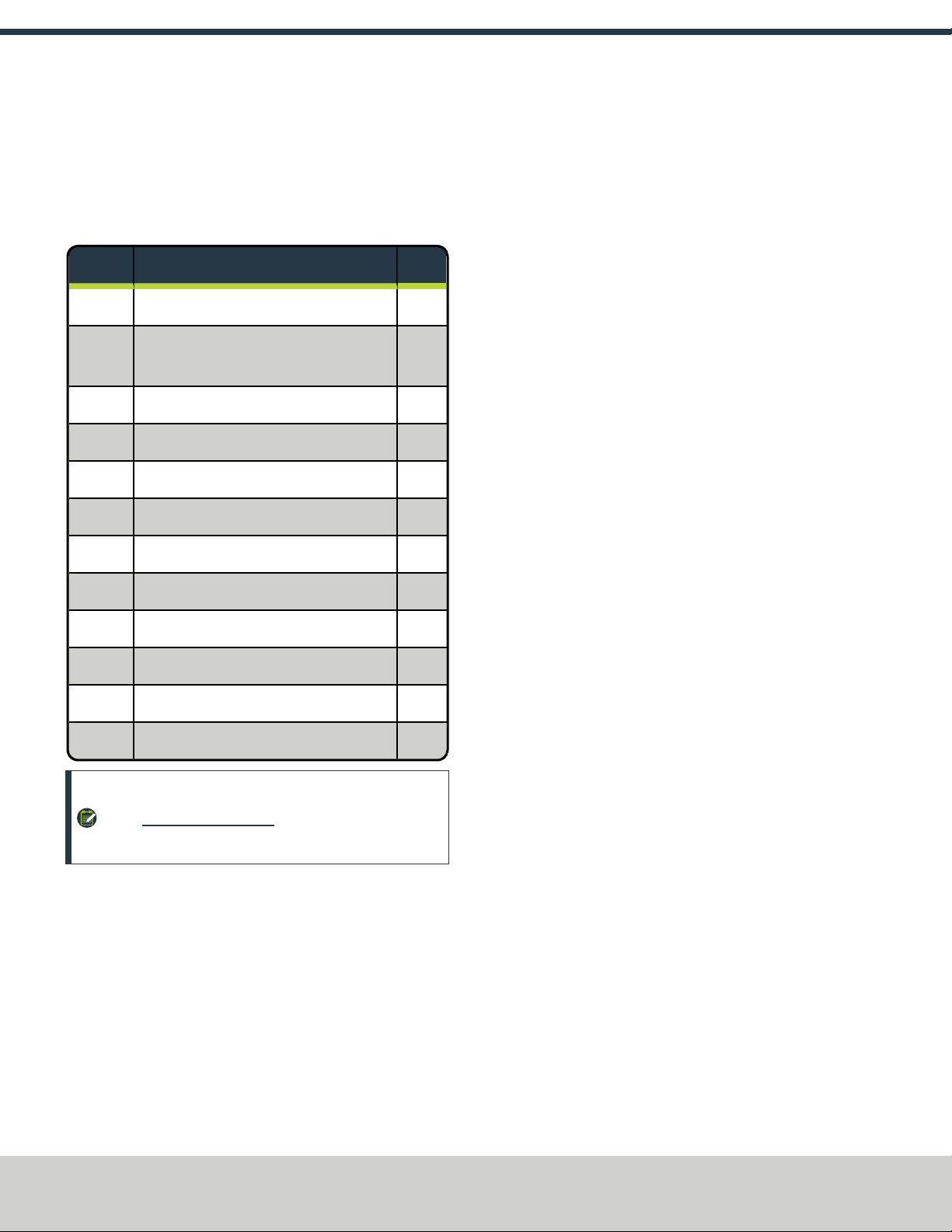

Quantity Description PN

1 1/4-inch Plastic Tube —

1 1/4-inch Push-to-Connect Air Fitting

Adapter

—

1 10 mm Shoulder Screw —

1 Anti-Seize 31273

1 Extend (Red) Air Line —

1 FRLFilter-Regulator-Lubricator 38829

1 Power Drawbar Button Assembly 38216

1 Power Drawbar Cylinder Assembly 37750

1 Quick-Release Pin —

1 Retract (White)Air Line —

8 Spring Washer —

4 Zip Tie 38436

NOTE: If any of these items are missing, we can help.

Email support@tormach.com to contact Tormach

Technical Support for guidance on how to proceed.

©Tormach® 2018

Specifications subject to change without notice.

Page 2 tormach.com

TD10541: Owner's Guide: 770M® Power Drawbar (0618A)

TECHNICAL DOCUMENT

2.1 SETTING UP THE POWER DRAWBAR

2.1.1 Required Tools

This procedure requires the following tools. Make sure that you

have them available before you begin.

lAdjustable wrench, two

lClean cloth

lMetric hex wrench set

lPaint pen

2.1.2 Air Requirements

The Power Drawbar uses compressed air to release tools held in

the spindle. You must make sure the site conforms to the

following air supply requirements.

lAir Pressure. Between 90 pounds per square inch (psi) and

120 psi (620 kPa - 825 kPa).

If the air supply is more than 120 psi (825 kPa), you must

use a regulator.

lDry Air. We recommend using a compressed air dryer,

desiccator, or filter between the air compressor and the

machine.

lLubricated Air. You must lubricate the air with air tool oil.

Use the FRLFilter-Regulator-Lubricator (PN 38829) or

similar for this purpose.

2.1.3 To Install the Power Drawbar

Installing the Power Drawbar varies if you have an (optional)

Automatic Tool Changer (ATC).

Power Drawbar Only

Installing the Power Drawbar involves the following steps.

Complete them in the order listed:

lStep 1: "Prepare the Machine" (below)

lStep 2: "Disassemble the Original Drawbar" (below)

lStep 3: "Assemble the Power Drawbar" (on the next page)

lStep 4: "Install the FRLFilter-Regulator-Lubricator" (page7)

lStep 5: "Set Up the FRLFilter-Regulator-Lubricator" (page7)

lStep 6: "Make Air Connections" (page8)

Power Drawbar and ATC

Installing the Power Drawbar and the ATC involves the following

steps. Complete them in the order listed:

lStep 1: "Prepare the Machine" (below)

lStep 2: "Disassemble the Original Drawbar" (below)

lStep 3: "Assemble the Power Drawbar" (on the next page)

lStep 4: "Install the FRLFilter-Regulator-Lubricator" (page7)

lStep 5: "Set Up the FRLFilter-Regulator-Lubricator" (page7)

lStep 6:Install the Automatic Tool Changer (ATC)

Prepare the Machine

1. If there is already a Tormach Tooling System® (TTS®) tool

holder in the spindle, remove it.

2. Make sure that you can access the inside of the spindle

cabinet: Jog the Z-axis down (-Z) until it is about six inches

from the machine table.

3. Power off the machine and the PathPilot® controller.

a. Push in the Emergency Stop button on the operator box,

which disables movement of the axes and the spindle.

b. From the PathPilot® interface, click Exit.

c. Turn the Main Disconnect switch to Off on the side of the

electrical cabinet.

Disassemble the Original Drawbar

CAUTION! Loose Objects Hazard: The original drawbar

contains spring-loaded hardware, which could quickly

become loose, causing serious injury. Before

disassembling the original drawbar, you must put on

safety eyewear that meets ANSI Z87+.

1. Put on eye protection.

2. Open the spindle door.

3. Use one hand to support the Tormach Tooling System®

(TTS®) collet, and use the other to turn and remove the

drawbar.

4. Set the collet and the drawbar aside.

©Tormach® 2018

Specifications subject to change without notice.

Page 3 tormach.com

TD10541: Owner's Guide: 770M® Power Drawbar (0618A)

TECHNICAL DOCUMENT

5. Use one hand to hold on to the spindle lock arm, and then

use a 5 mm hex wrench to remove the spindle lock arm

pivot screw.

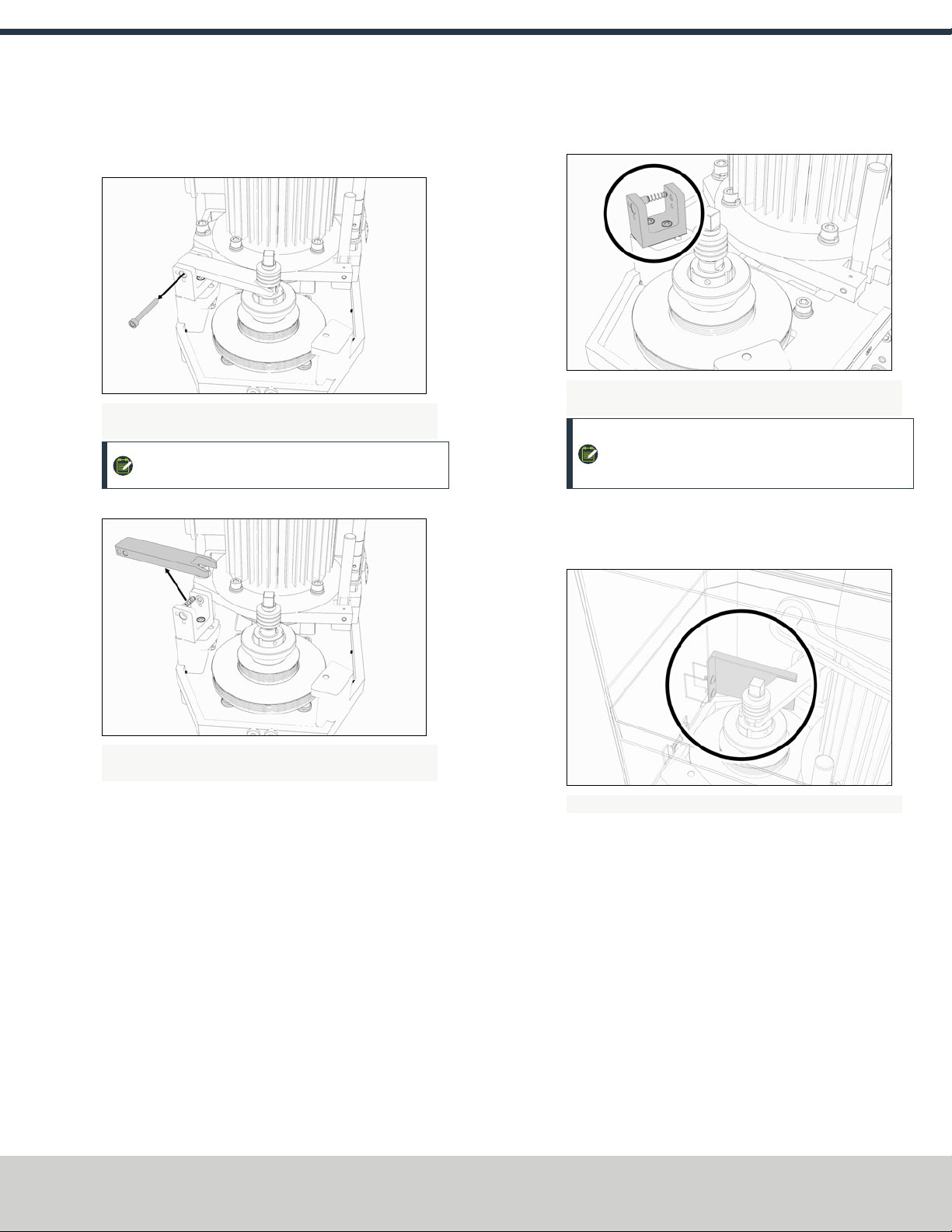

Figure 2-1: Spindle lock arm pivot screw removed from the

original drawbar assembly.

NOTE: The spindle lock arm assembly contains

spring-loaded hardware.

6. Carefully remove the spindle lock arm.

Figure 2-2: Spindle lock arm removed from the original

drawbar assembly.

7. Use a 5 mm hex wrench to remove the spindle lock base and

components.

Figure 2-3: Spindle lock base from the original drawbar

assembly.

NOTE: Keep all components for future use. The

drawbar, drawbar bushing, and spindle lock are all

required to operate without a Power Drawbar.

8. Use a clean cloth to wipe down all exposed drawbar

mounting surfaces inside the spindle motor cabinet.

9. Remove the spindle lock arm on the spindle door.

Figure 2-4: Spindle lock arm on the spindle door.

Assemble the Power Drawbar

1. Identify the drawbar that you set aside in "Disassemble the

Original Drawbar" (on the previous page).

2. Remove the drawbar bushing from the drawbar, and set it

aside.

3. Put Anti-Seize (provided) on the bottom of the drawbar

head.

4. Identify the eight spring washers provided.

©Tormach® 2018

Specifications subject to change without notice.

Page 4 tormach.com

TD10541: Owner's Guide: 770M® Power Drawbar (0618A)

TECHNICAL DOCUMENT

5. Move one spring washer on the drawbar, with the convex

side of the spring washer toward the drawbar head.

Figure 2-5: Example of moving the convex side of a spring

washer toward the drawbar head.

6. Move another spring washer on the drawbar, with the

concave side of the spring washer toward the concave side

of the spring washer from Step 5.

Figure 2-6: Example of moving the concave sides of two

spring washers together.

7. Put Anti-Seize on the edge of the contact surface between

the pair of spring washers that you put on the drawbar in

Step 5 and Step 6.

8. Repeat steps 5-7 for the remaining six spring washers. Make

sure that you put Anti-Seize on the spring washers at every

contact point.

9. Examine the stack of spring washers. Make sure that all

eight spring washers are installed on the drawbar and

arranged in four sets of opposing pairs.

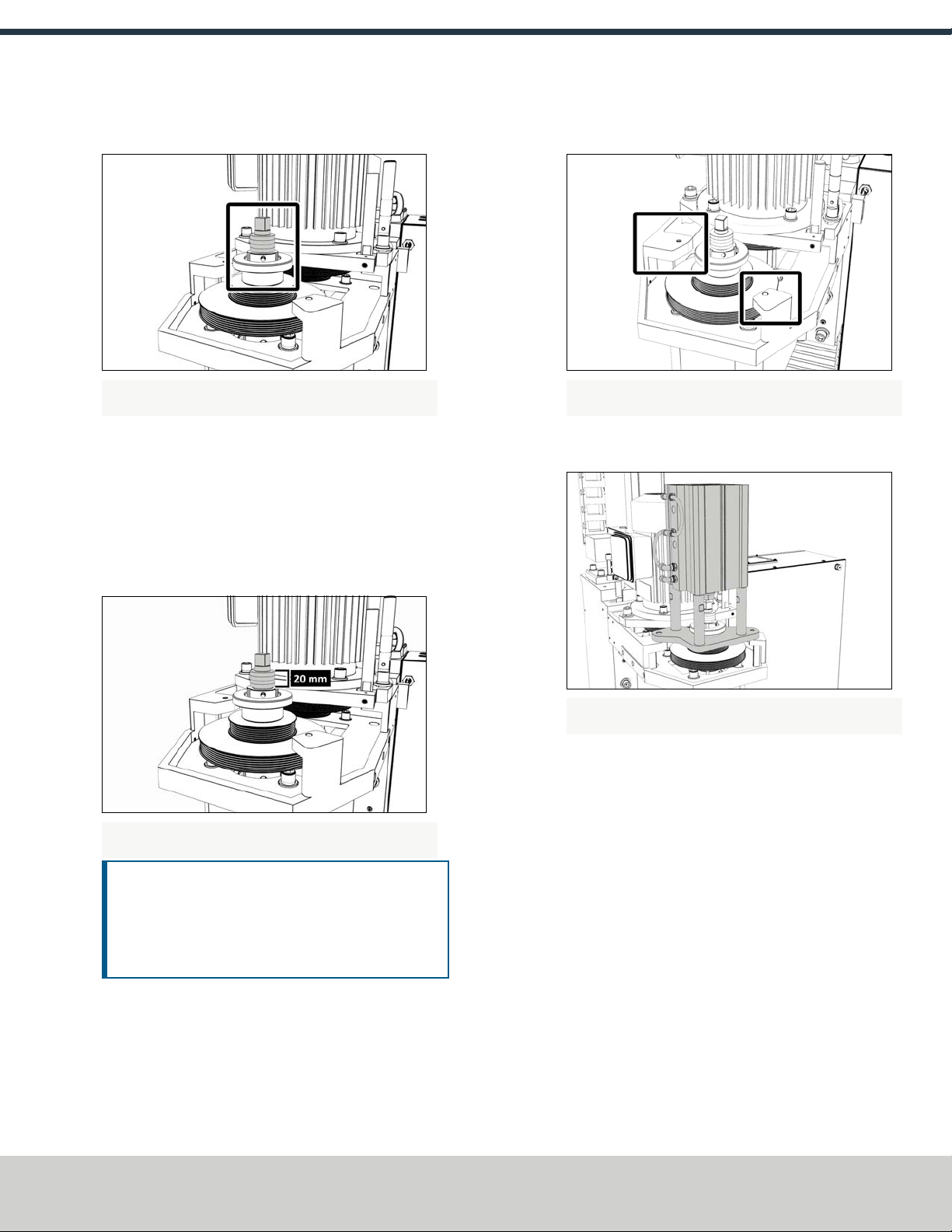

Figure 2-7: Example of all eight spring washers installed on

the drawbar.

10. Identify the drawbar bushing that you set aside in Step 2,

and reinstall it on the drawbar. Make sure that the smaller

diameter of the drawbar bushing is toward the bottom of

the drawbar.

11. Put Anti-Seize on the top of the drawbar bushing.

12. Put Anti-Seize on the bottom threads of the drawbar.

Figure 2-8: Example of the locations to apply Anti-Seize on a

drawbar assembly.

13. Put Anti-Seize on the outside taper of the Tormach Tooling

System® (TTS®) collet. Make sure that there is no Anti-Seize

on the inside of the collet.

14. Insert the drawbar assembly into the spindle.

©Tormach® 2018

Specifications subject to change without notice.

Page 5 tormach.com

TD10541: Owner's Guide: 770M® Power Drawbar (0618A)

TECHNICAL DOCUMENT

15. Use one hand to insert the collet into the spindle, and then

turn in the drawbar.

Figure 2-9: Drawbar assembly installed in the spindle motor

cabinet.

16. Hand tighten the drawbar.

17. Use one hand to insert an empty Tormach Tooling System®

(TTS®) tool holder into the collet, and then use an adjustable

wrench to tighten the collet into the drawbar.

18. Use two large, adjustable wrenches to tighten the Power

Drawbar until the spring washer stack is compressed to a

height of 20 mm.

Figure 2-10: Example of a correctly compressed spring

washer stack.

NOTICE! After the initial installation, you must

complete a final drawbar tension adjustment. For

more information, go to "Adjust the Drawbar Tension"

(page9). If you don't complete a drawbar tension

adjustment, there's a risk of tool pull-out.

19. Identify the Power Drawbar cylinder assembly provided.

20. Identify the Power Drawbar mounting surfaces inside of the

spindle motor cabinet as shown in the following image.

Figure 2-11: Power Drawbar mounting surfaces inside of the

spindle motor cabinet.

21. Put the Power Drawbar cylinder assembly on the mounting

surface.

Figure 2-12: Power Drawbar cylinder assembly inside of the

spindle motor cabinet.

22. Identify the 10 mm shoulder screw provided, and then put

anti-seize on its threads.

©Tormach® 2018

Specifications subject to change without notice.

Page 6 tormach.com

TD10541: Owner's Guide: 770M® Power Drawbar (0618A)

TECHNICAL DOCUMENT

23. Use a 5 mm hex wrench to install the 10 mm shoulder

screw on the Power Drawbar cylinder’s mount plate.

The unit is securely installed to the spindle head.

Figure 2-13: 10 mm shoulder screw installed on the Power

Drawbar cylinder's mount plate.

24. Identify the quick- release pin provided, and then insert it on

the Power Drawbar cylinder’s mount plate.

The quick-release pin allows the Power Drawbar cylinder to

pivot within the spindle motor cabinet.

Figure 2-14: Quick-release pin installed on the Power

Drawbar cylinder's mount plate.

NOTE: The Power Drawbar cylinder intentionally

floats.

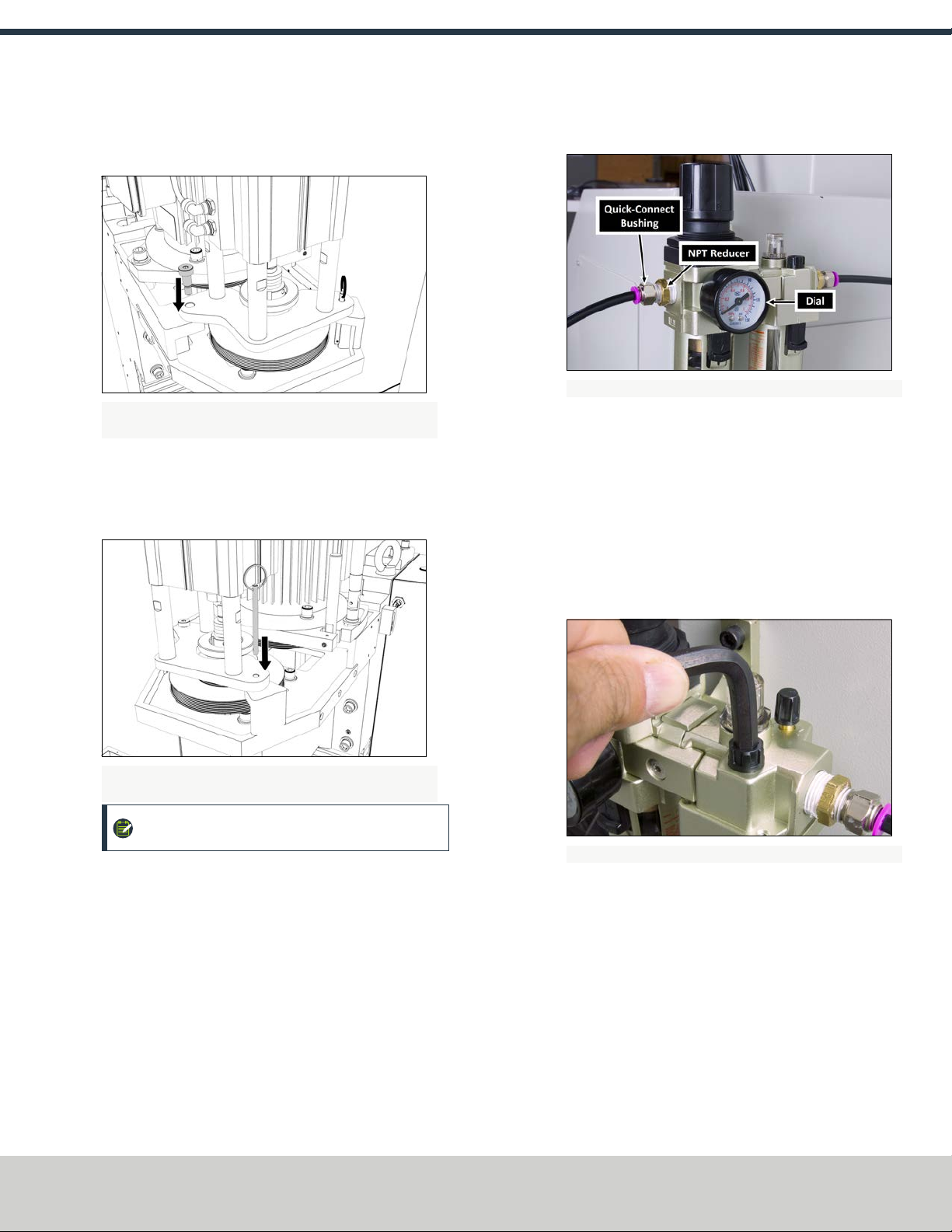

Install the FRLFilter-Regulator-Lubricator

1. Clean the FRL to make sure that it's free of dust.

2. Remove and discard the plastic inserts from the FRL.

3. Put two layers of thread seal tape on the threads of the dial.

4. Install the dial on the front of the FRL.

5. Install two quick-connect bushings into the two

NPTreducers.

6. Put two layers of thread seal tape on the threads of the NPT

reducers.

7. Install one NPT reducer into the valve housing on either side

of the FRL.

Figure 2-15: FRL installed on a mill's backsplash.

8. Determine the location to install the FRL.

9. Use the FRL bracket as a template to mark and drill two

holes.

10. Install the FRL bracket using your own hardware.

11. Connect the air lines to the quick-connect bushings that you

installed in Step 5.

Set Up the FRLFilter-Regulator-Lubricator

1. Use a hex wrench to open the fill port on the FRL.

Figure 2-16: Example of opening the fill port on an FRL.

2. Use a small funnel to fill the lubricator bowl with standard

air tool oil. Make sure that you only use oil that is

specifically designed for air tools.

3. Turn the adjustment knob halfway toward the +.

4. Flush all air bubbles from the system.

©Tormach® 2018

Specifications subject to change without notice.

Page 7 tormach.com

TD10541: Owner's Guide: 770M® Power Drawbar (0618A)

TECHNICAL DOCUMENT

5. Examine the sight window for air bubbles. When there are

no air bubbles in the sight window, and a drop of lubricant is

on the bottom of the stem, turn the adjustment knob one-

quarter back.

Figure 2-17: Components to flush the air from the FRL.

Make Air Connections

NOTE: If you have an (optional) Automatic Tool Changer

(ATC), install it now.

1. Identify the button box assembly provided.

2. Use a 3 mm hex wrench to remove the four M5 × 0.8 - 10

button head screws securing the cover to the button box,

and then remove the cover.

3. Use two M4 × 0.7 - 50 socket head cap screws to install the

button box base, standoffs, and button assembly to the mill

head.

Figure 2-18: Button box base installed on the mill head.

4. Remove and discard the shipping plugs on the Power

Drawbar.

5. Identify the Retract (white) air line provided, and then

connect one end to the Retract port on the Power Drawbar

button.

Figure 2-19: Example of the Power Drawbar air line routing.

6. Route the loose end of the Retract air line to the Power

Drawbar cylinder, and then connect it to the bottom-most

elbow fitting.

Figure 2-20: Retract fitting on the Power Drawbar cylinder.

7. Identify the Extend (red) air line provided, and then connect

one end to the Extend port on the Power Drawbar button.

8. Route the loose end of the Extend air line to the Power

Drawbar cylinder, and then connect it to the upper-most tee

fitting.

Figure 2-21: Extend fitting on the Power Drawbar cylinder.

©Tormach® 2018

Specifications subject to change without notice.

Page 8 tormach.com

TD10541: Owner's Guide: 770M® Power Drawbar (0618A)

TECHNICAL DOCUMENT

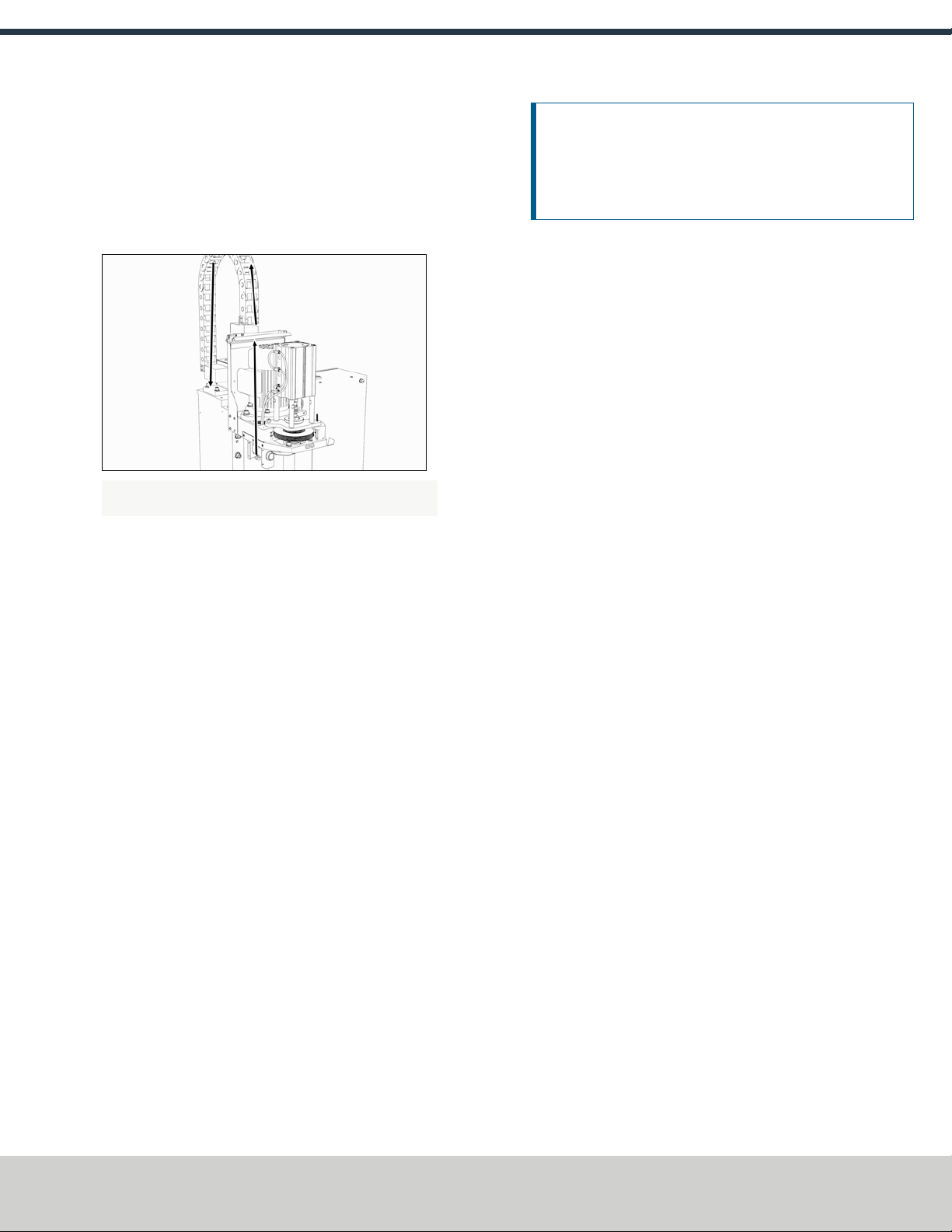

9. Use three cable ties to secure both air lines together.

10. Identify the 1/4-inch plastic tube provided, and then connect

one end to the Air Supply push-to-connect elbow on the

Power Drawbar button.

11. Route the loose end of the 1/4-inch plastic tube through the

energy chain and toward the FRL.

Figure 2-22: Example of the air line routing through the

energy chain.

12. Connect the 1/4-inch plastic tube to the Output port on the

FRL.

13. Identify the 1/4-inch plastic tube provided, and then connect

one end to the Input port on the FRL.

14. Identify the 1/4-inch push-connect air fitting adapter

provided, and then put it on the loose end of the 1/4-inch

plastic tube.

15. Route the 1/4-inch plastic tube to your shop's air supply and

connect it with the adapter.

16. Use a 3 mm hex wrench to reinstall the button box cover

with the screws that you set aside in Step 2.

2.1.4 To Adjust the Power Drawbar

After installing the Power Drawbar, you must adjust it. Complete

the following steps in the order listed:

lStep 1: "Adjust the Drawbar Tension" (below)

lStep 2: "Adjust the Initial Setup" (below)

Adjust the Drawbar Tension

The purpose of this adjustment is to set the highest possible

drawbar tension while still allowing the Power Drawbar cylinder to

release the tool. For more information, go to "About Drawbar

Tension" (below).

NOTICE! After the initial installation, you must examine the

drawbar tension weekly. During periods of heavy use,

examine the drawbar tension more frequently. If you don't,

there's a risk of tool pull-out.

To adjust the drawbar tension:

1. Install an empty Tormach Tooling System® (TTS®) tool

holder in the collet.

2. Use one hand to support the tool holder, and then push the

Release Tool button. Do one of the following:

lIf the tool holder releases: Use two adjustable wrenches

to tighten the Power Drawbar in quarter-turn increments

while pushing the Release Tool button after each turn.

Stop when the tool holder does not release.

lIf the tool holder does not release: Use two adjustable

wrenches to loosen the Power Drawbar in quarter-turn

increments while pushing the Release Tool button. Stop

when the tool holder releases.

3. Make a visual reference to help you set or adjust the

drawbar tension in the future: Use a paint pen to make a

witness mark on both the head of the drawbar and the end

of the spindle.

About Drawbar Tension

While machining, the Tormach Tooling System® (TTS®) collet

holds a Tormach Tooling System® (TTS®) tool holder in the spindle

by applying a clamping force to both the shank and the shoulder of

the tool. The tension force that is applied to the drawbar pulls the

Tormach Tooling System® (TTS®) collet into the spindle taper,

which then applies the clamping force to the Tormach Tooling

System® (TTS®) tool.

The force on the drawbar, known as the drawbar tension, is

applied differently depending on the tool changing method:

lWhen you change tools manually, the tension is applied

when you tighten the drawbar into the collet using a

wrench.

lWhen you change tools with the Power Drawbar, the tension

is applied by the compressed spring washers.

Adjust the Initial Setup

The purpose of this adjustment is to make sure that there is

enough clearance between the end of the drawbar and the Power

Drawbar cylinder.

©Tormach® 2018

Specifications subject to change without notice.

Page 9 tormach.com

TD10541: Owner's Guide: 770M® Power Drawbar (0618A)

TECHNICAL DOCUMENT

NOTICE! If you don't do this adjustment, there's a risk that

the drawbar can loosen, or that operations can be louder than

normal.

1. Examine the space between the hex head screw on the

Power Drawbar cylinder's rod and the top of the drawbar.

Figure 2-23: Example of a correctly spaced drawbar and

Power Drawbar cylinder.

2. Make sure that the gap is between 1 mm and 3 mm.

Depending on the size of the gap, do one of the following:

lIf the gap is between 1 mm and 3 mm, you have

completed adjusting the initial setup.

lIf the gap is less than 1 mm or greater than 3 mm, go to

Step 3.

3. Disconnect the shop's air supply from the Power Drawbar

button.

4. Pull out the quick-release pin.

5. Pivot the Power Drawbar cylinder assembly to the left so

that you can access the Power Drawbar cylinder's rod.

Figure 2-24: Power Drawbar cylinder pivoted to the left.

6. Use an adjustable wrench to remove the hex head screw on

the Power Drawbar cylinder’s rod.

Figure 2-25: Hex head screw on the Power Drawbar

cylinder's rod.

7. Remove the M16 washer from the Power Drawbar cylinder’s

rod, and set it aside.

Figure 2-26: M16 washer removed from the Power Drawbar

cylinder's rod.

8. Use an adjustable wrench to reinstall the hex head screw,

and then tighten it completely.

9. Pivot the Power Drawbar cylinder to the original location.

10. Push in the quick-release pin.

11. Reconnect the shop's air supply to the Power Drawbar

button.

12. Examine the space between the hex head screw on the

Power Drawbar cylinder’s rod and the top of the drawbar.

13. Makesure that the gap is between 1 mm and 3 mm.

Depending on the size of the gap, do one of the following:

lIf the gap is between 1 mm and 3 mm, go to "Operating

the Power Drawbar" (page12).

lIf the gap is less than 1 mm, go to Step 14.

14. Identify the three extra M16 flat washers provided.

©Tormach® 2018

Specifications subject to change without notice.

Page 10 tormach.com

TD10541: Owner's Guide: 770M® Power Drawbar (0618A)

TECHNICAL DOCUMENT

15. Put one M16 flat washer under each mounting post on the

Power Drawbar cylinder.

©Tormach® 2018

Specifications subject to change without notice.

Page 11 tormach.com

TD10541: Owner's Guide: 770M® Power Drawbar (0618A)

TECHNICAL DOCUMENT

3.1 OPERATING THE POWER DRAWBAR

The Power Drawbar is designed to provide more than sufficient

tool holding force to resist regular cutting loads. Machining

practices outside of these situations may result in tool holder pull-

out.

While operating the machine, avoid the following conditions:

lHigh chatter machining

lHigh cutter engagement (chip load) combined with high

helix angle cutter geometries

3.1.1 Change Tools with the Power Drawbar

WARNING! Ejection Hazard: Wait until the spindle is

completely stopped before pressing the Release Tool

button. Never press the Release Tool button while the

spindle is turning. Tooling can become a dangerous

projectile if it's released from a turning spindle.

1. With one hand on the Tormach Tooling System® (TTS®) tool

holder installed in the spindle, press and hold the Release

Tool button.

The Power Drawbar activates and releases the tool holder in

the spindle. Remove the tool from the spindle.

CAUTION! Pinch Hazard: Keep fingers clear of the

Tormach Tooling System® (TTS®) collet when

changing tools. Never put your fingers into an

unclamped Tormach Tooling System® (TTS®) collet.

If your fingers are in the Tormach Tooling System®

(TTS®) collet as it closes, it can crush or pinch your

fingers.

2. Insert a new tool holder.

3. Let go of the Release Tool button.

The Power Drawbar reverts to clamp mode and secures the

tool in the spindle.

NOTE: In the event of an air pressure loss, the

power drawbar reverts to clamp mode.

While the Power Drawbar is in clamp mode, make sure that

there's always a tool in the collet. Retracting the Power

Drawbar to clamp mode with no tool in the collet will

eventually fatigue the collet, and could shorten its service

life.

©Tormach® 2018

Specifications subject to change without notice.

Page 12 tormach.com

TD10541: Owner's Guide: 770M® Power Drawbar (0618A)

TECHNICAL DOCUMENT

4.1 MAINTAINING THE POWER DRAWBAR

Read the following sections to understand how to maintain the

Power Drawbar:

l"Examine Air Pressure" (below)

l"Lubricate the Power Drawbar" (below)

l"Examine Wear Items" (below)

4.1.1 Examine Air Pressure

Appropriate air supply helps with smooth actuation, and prevents

premature component failure. Examine the air to the Power

Drawbar for the following:

lMake sure that it's between 90 psi and 120 psi.

lMake sure that it's been lubricated with common air tool oil.

4.1.2 Lubricate the Power Drawbar

Every 5000 cycles (or six months — whichever comes first),

use Anti-Seize to lubricate the following parts on the Power

Drawbar:

oContact surfaces between spring washers

oEccentric pivot mount

oTop of the drawbar (below the drawbar flange and the

spring washers)

4.1.3 Examine Wear Items

Examine the following wear items regularly:

oSpring Washers. Inspect all spring washers once a month

for cracks. If they're damaged, replace them immediately

with the following item:

oPower Drawbar Spring Washer (PN 31319)

oTormach Tooling System® (TTS®) Collet and Drawbar.

Using the Power Drawbar may cause these items to wear

faster than with a manual drawbar. Inspect them

regularly, and immediately replace any damaged items

with the following:

oR8 Drawbar (PN 38793)

oPower Drawbar Alignment Bushing (PN 31330)

oTormach Tooling System® (TTS®) Adapter Collet: R8

(PN 35356)

oPower Drawbar Cylinder Rebuild Kit (PN 32093)

©Tormach® 2018

Specifications subject to change without notice.

Page 13 tormach.com

TD10541: Owner's Guide: 770M® Power Drawbar (0618A)

TECHNICAL DOCUMENT

Other manuals for 770M

2

Table of contents

Other Tormach Power Tools manuals