•

•

Wadkin

OPERATING

AND

MAINTENANCE

INSTRUCTIONS

INST

A L

LATION.

The machine Is despatched

from

the Works with

all

bright

surfaces

greased

to

prevent

rusting.

This

should

be

rem

oved by applying a cloth damped in paraffin

or

turpentine.

FOUNDATIONS.

If

the mill floor

consists

of

4" (100 mm)

solid

concrete

00

s

pecial

foundation

is

necessary.

Rag

type

foundation bolts i" (

16

mm)

diameter

should

be

used

to fix the machine to the floor, but

these

are

not supplied by Wadkin Ltd.

unless

specially

ordered

. The

outline

on page 4 gives

details

of

bolt

positions

and

cle

aran

ces

required.

Cut

6"

(150 mm) to

8"

(200 mm)

square

hates

in the conc

ret

e and run in

li

quid

cement

with bolts in position. The machine should be

carefully

levelled before fixing and again

after

final fixing to

ensure

that

no

d

isto

rtion

has taken place.

WIRING.

For

detailed cabling

Instructions

see

diagrams

of connections

on

pages

6

(motors

on

50

cycles)

and

19

(Motors on

60

c

ycles).

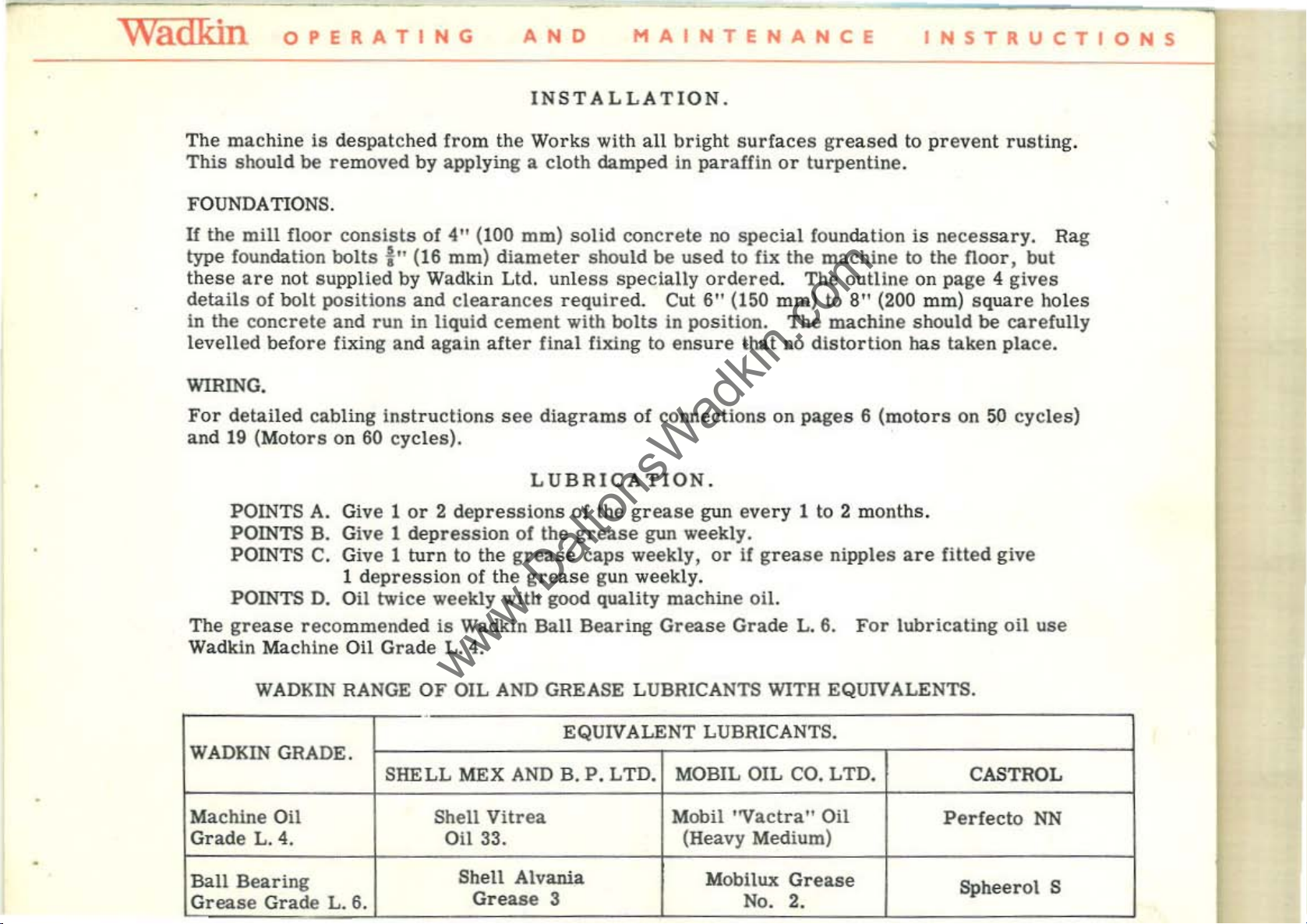

LUBRICATION.

POINTS

A.

Give 1

or

2

depressions

of the

grease

gun

every

1 to 2 months.

POINTS

B.

Give 1

depression

of

the

grease

gun weekly.

POINTS C. Give 1

turn

to the

grease

caps

weekly,

or

If

grease

nipples

are

fitted give

1

depression

of the

grease

gun weekly.

POINTS

D.

Oil twice weekly with good quality machine oil.

The

grease

rec

ommended

Is

Wadkin Ball

Bearing

Grease

Grade

L.

6.

For

lubr

icating

oil

use

Wadkin Machine Oil Grade L. 4.

WADKIN

RANGE

OF

OIL

AND

GREASE LUBRICANTS

WITH

EQUIVALENTS.

EQUIVALENT LUBRICANTS.

WADKIN

GRADE. SHELL

MEX

AND

B. P. LTD. MOBIL OIL

CO.

LTD. CASTROL

Machine Oil Shell

Vitrea

Mobil

"Vactra

·' Oil

Perfecto

NN

Grade

L.4

. Oil 33. (Heavy Medium)

Ball

Bearing

Shell Alvania MobUux

Greue

Spheerol S

Grease

Grade L. 6.

Greas

e 3 No.

2.