Contents

Introduction.................................................................2

Safety...........................................................................4

SafeOperatingPractices.......................................4

ToroRidingMowerSafety....................................6

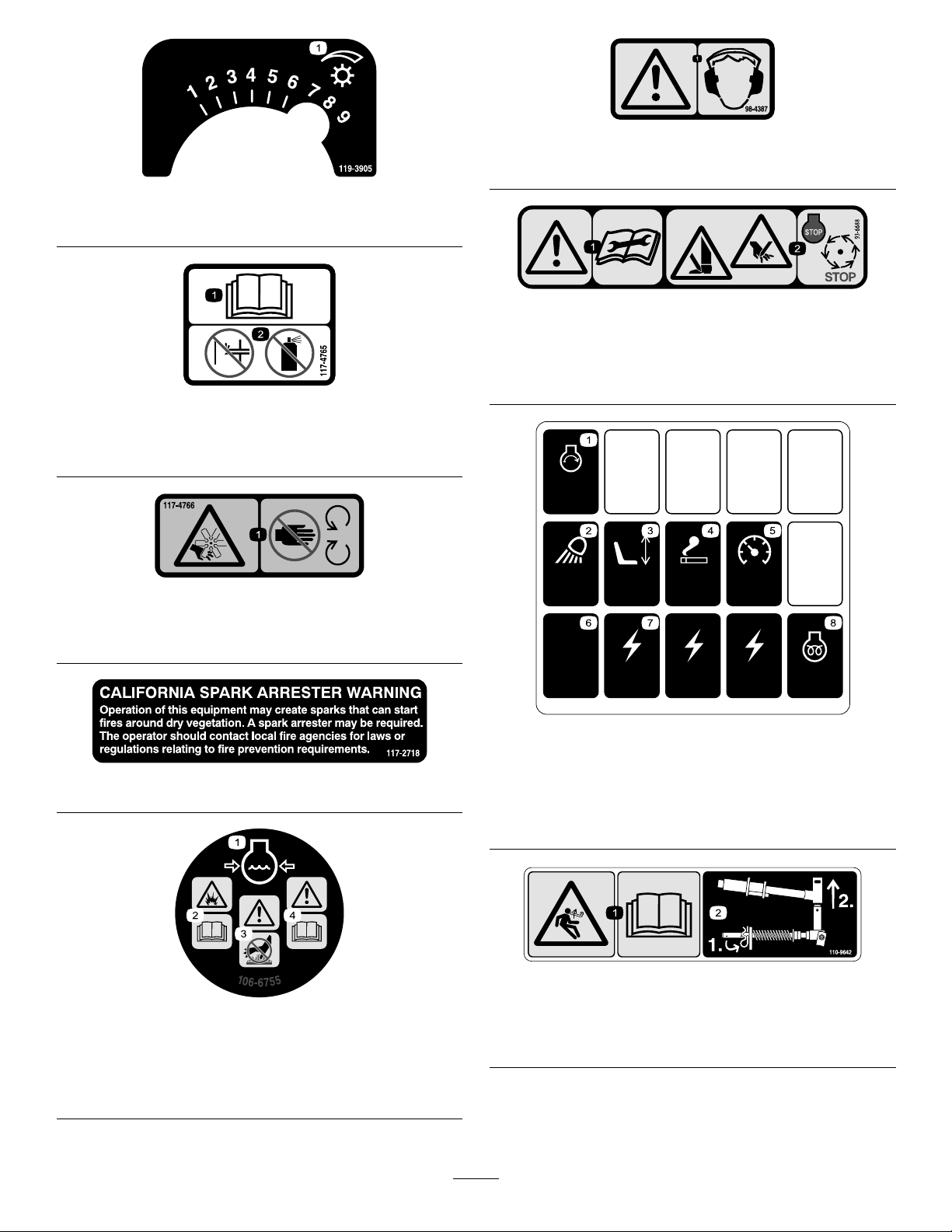

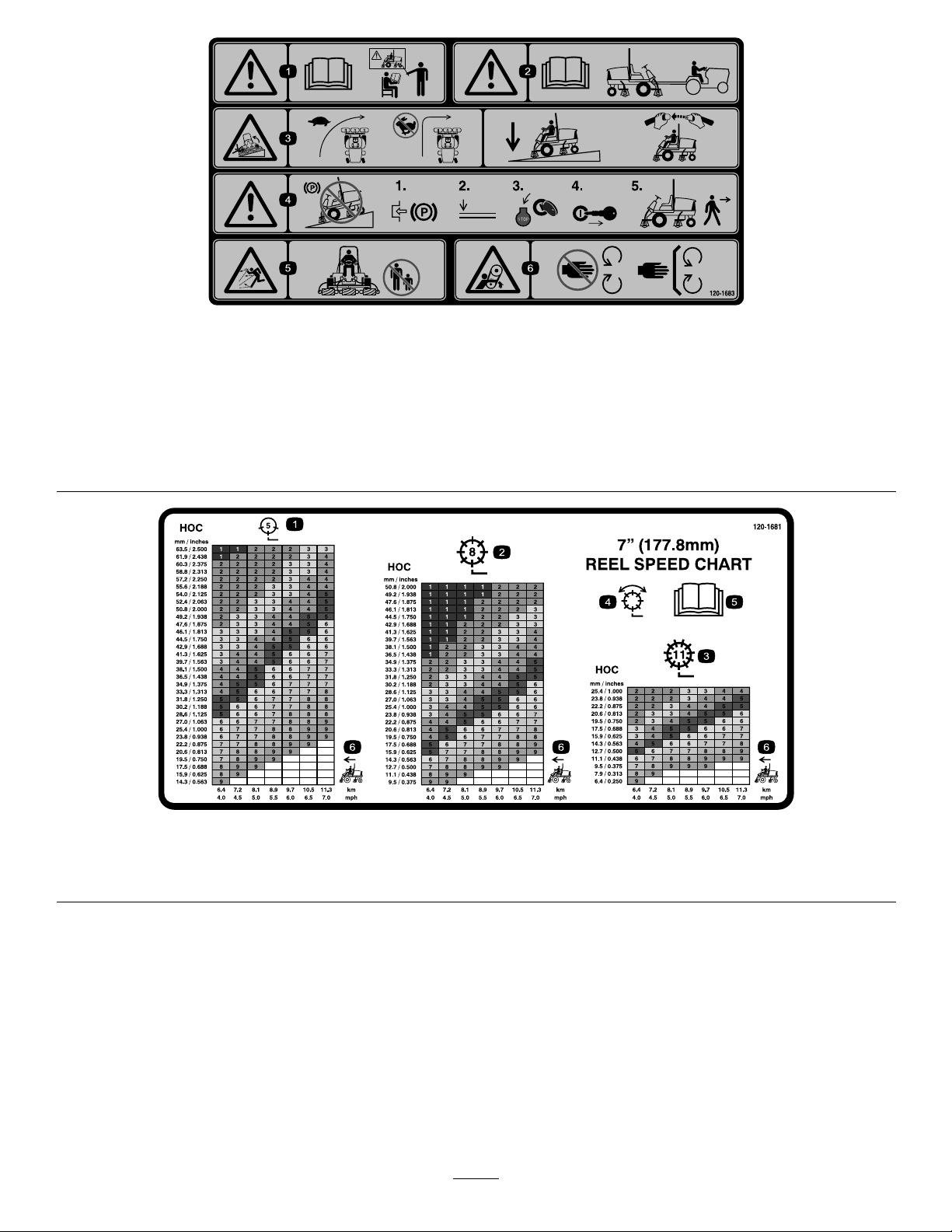

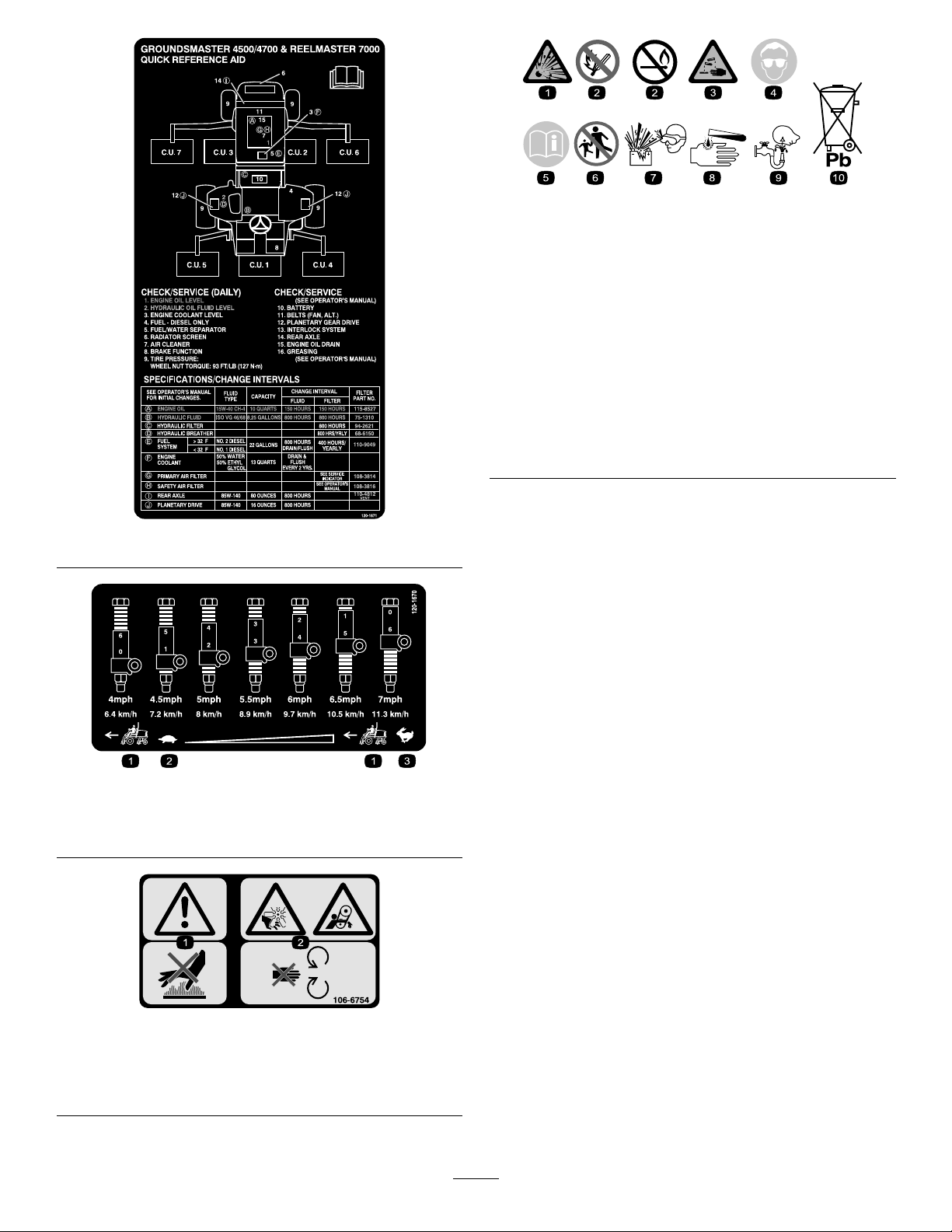

SafetyandInstructionalDecals.............................7

Setup.........................................................................11

1AdjustingtheSupportRollers...........................12

2InstallingtheCuttingUnits..............................12

3AdjustingtheTurfCompensation

Spring............................................................15

4UsingtheCuttingUnitKickstand.....................16

5GreasingtheMachine......................................16

6CheckingFluidLevels......................................17

ProductOverview......................................................17

Controls.............................................................17

Specications.....................................................21

TractionUnitSpecications................................21

Attachments/Accessories...................................21

Operation...................................................................22

CheckingtheEngineOilLevel............................22

CheckingtheCoolingSystem..............................23

FillingtheFuelTank...........................................23

CheckingtheHydraulicFluidLevel.....................25

CheckingtheTirePressure.................................26

StartingandStoppingtheEngine........................26

CheckingtheInterlockSwitches.........................26

SettingtheReelSpeed.........................................27

AdjustingtheLiftArmCounterbalance...............28

AdjustingtheLiftArmTurnAround

Position..........................................................28

PushingorTowingtheMachine..........................29

JackingPoints.....................................................29

TieDowns.........................................................29

UnderstandingtheDiagnosticLight....................29

DiagnosticAceDisplay.......................................30

CheckingtheInterlockSwitches.........................30

OperatingCharacteristics...................................31

EngineCoolingFanOperation...........................32

OperatingTips...................................................32

Maintenance...............................................................33

RecommendedMaintenanceSchedule(s)................33

DailyMaintenanceChecklist...............................34

ServiceIntervalChart.........................................35

PremaintenanceProcedures....................................36

RemovingtheHood...........................................36

Lubrication.............................................................36

GreasingtheBearingsandBushings....................36

EngineMaintenance...............................................38

ServicingtheAirCleaner....................................38

ServicingtheEngineOilandFilter......................39

AdjustingtheThrottle........................................39

FuelSystemMaintenance.......................................40

FuelTank...........................................................40

FuelLinesandConnections................................40

ServicingtheWaterSeparator.............................40

FuelPickupTubeScreen....................................40

BleedingAirfromtheInjectors...........................41

ElectricalSystemMaintenance................................41

ChargingandConnectingtheBattery..................41

BatteryCare.......................................................42

Fuses..................................................................43

DriveSystemMaintenance.....................................44

CheckingtheTorqueoftheWheel

Nuts...............................................................44

CheckingthePlanetaryGearDrive

Oil..................................................................44

ChangingthePlanetaryGearDrive

Oil..................................................................44

CheckingtheRearAxleLubricant.......................45

ChangingtheRearAxleLubricant.......................45

AdjustingtheTractionDriveforNeutral.............46

CheckingtheRearWheelToe-In.........................46

CoolingSystemMaintenance..................................47

ServicingtheEngineCoolingSystem..................47

BrakeMaintenance.................................................48

AdjustingtheServiceBrakes...............................48

BeltMaintenance....................................................48

ServicingtheAlternatorBelt...............................48

HydraulicSystemMaintenance...............................49

ChangingtheHydraulicFluid.............................49

ReplacingtheHydraulicFilters...........................49

CheckingtheHydraulicLinesandHoses.............50

CuttingUnitMaintenance.......................................50

BacklappingtheCuttingUnits............................50

Cleaning.................................................................51

ServicingtheSparkArrestorMufer...................51

Storage.......................................................................52

Engine...............................................................52

TractionUnit......................................................52

Schematics.................................................................53

3