Safety

Hazardcontrolandaccidentpreventionaredependent

upontheawareness,concern,andpropertraining

ofthepersonnelinvolvedintheoperation,transport,

maintenance,andstorageofthemachine.Improper

useormaintenanceofthemachinecanresultininjury

ordeath.Toreducethepotentialforinjuryordeath,

complywiththefollowingsafetyinstructions.

•Read,understand,andfollowallinstructionsinthe

tractionunitandcuttingunitOperator’sManualsbefore

operatingthecuttingunit.

•Neverallowchildrentooperatethetractionunitor

cuttingunits.Donotallowadultstooperatetractionunit

orcuttingunitswithoutproperinstruction.Onlytrained

operatorswhohavereadthismanualshouldoperatethe

tractionunitorcuttingunits.

•Neveroperatethecuttingunitswhenundertheinuence

ofdrugsoralcohol.

•Keepallshieldsandsafetydevicesinplace.Ifashield,

safetydeviceordecalisillegibleordamaged,repairor

replaceitbeforeoperationiscommenced.Alsotighten

anyloosenuts,bolts,andscrewstoensurecuttingunitis

insafeoperatingcondition.

•Alwayswearsubstantialshoes.Donotoperatecutting

unitswhilewearingsandals,tennisshoes,sneakers,or

shorts.Also,donotwearloosettingclothingwhich

couldgetcaughtinmovingparts.Alwayswearlongpants

andsubstantialshoes.Wearingsafetyglasses,safetyshoes,

andahelmetisadvisableandrequiredbysomelocal

ordinancesandinsuranceregulations.

•Removealldebrisorotherobjectsthatmightbepicked

upandthrownbythecuttingunitreelblades.Keepall

bystandersawayfromtheworkingarea.

•Ifthecuttingbladesstrikeasolidobjectortheunit

vibratesabnormally,stopandshuttheengineoff.Check

thecuttingunitsfordamagedparts.Repairanydamage

beforerestartingandoperatingthecuttingunits.

•Lowerthecuttingunitstothegroundandremovekey

fromignitionswitchwhenevermachineisleftunattended.

•Ensurethatthecuttingunitsareinsafeoperating

conditionbykeepingnuts,bolts,andscrewstight.

•Removethekeyfromtheignitionswitchtoprevent

accidentalstartingoftheenginewhenservicing,adjusting,

orstoringthemachine.

•Performonlythosemaintenanceinstructionsdescribedin

thismanual.Ifmajorrepairsareeverneededorassistance

isdesired,contactanAuthorizedToroDistributor.

•Toensureoptimumperformanceandsafety,always

purchasegenuineTororeplacementpartsandaccessories.

Neveruse"will-t"replacementpartsand

accessoriesmadebyothermanufacturers.Lookfor

theTorologotoensuregenuineness.Usingunapproved

replacementpartsandaccessoriescouldvoidthewarranty

ofTheToroCompany.

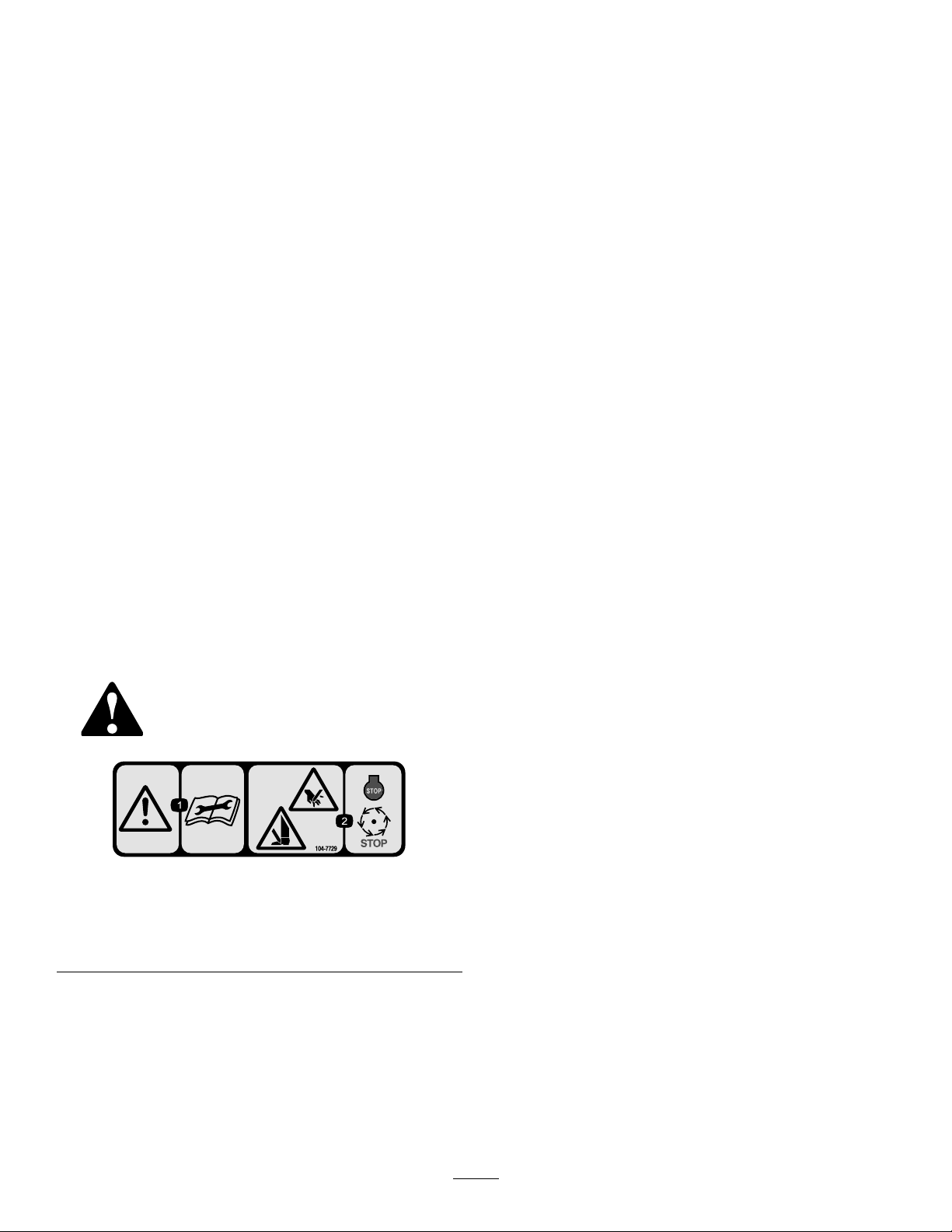

SafetyandInstructionalDecals.

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

104–7729

1.Warning—readthe

instructionsbefore

servicingorperforming

maintenance.

2.Cutting/dismemberment

hazard;handorfoot—stop

theengineandwaitfor

movingpartstostop.

3