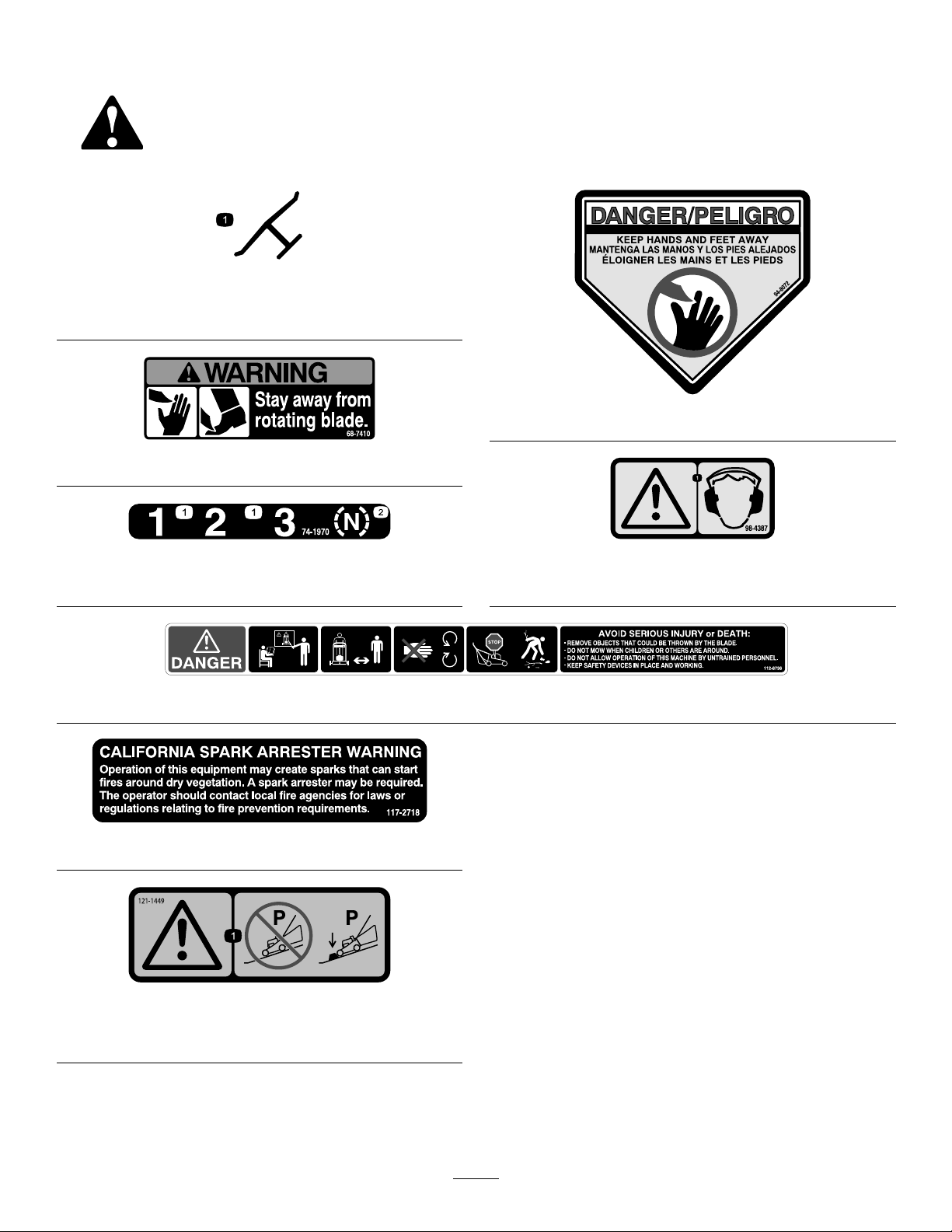

Safety

ThislawnmowermeetstheCPSCbladesafety

requirementsforwalk-behindrotarylawnmowers

andtheB71.4specicationsoftheAmericanNational

StandardsInstituteineffectatthetimeofproduction.

Improperlyusingormaintainingthislawnmowercan

resultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructions.

Torodesignedandtestedthislawnmowertoofferreasonably

safeservice;however,failuretocomplywiththefollowing

instructionsmayresultinpersonalinjury.

WARNING

Engineexhaustcontainscarbonmonoxide,an

odorless,deadlypoisonthatcankillyou.

Donotruntheengineindoorsorinanenclosed

area.

Toensuremaximumsafety,bestperformance,and

togainknowledgeoftheproduct,itisessentialthat

youandanyotheroperatorofthelawnmowerread

andunderstandthecontentsofthismanualbeforethe

engineiseverstarted.Payparticularattentiontothe

safetyalertsymbol(Figure2)whichmeansCaution,

Warning,orDanger—“personalsafetyinstruction.”

Readandunderstandtheinstructionbecauseithasto

dowithsafety.Failuretocomplywiththeinstruction

mayresultinpersonalinjury.

GeneralLawnMowerSafety

Thislawnmoweriscapableofamputatinghandsandfeetand

ofthrowingobjects.Failuretoobservethefollowingsafety

instructionscouldresultinseriousinjuryordeath.

ThefollowinginstructionsarefromtheANSI/OPEI

B71.4–2004standard.

Training

•ReadtheOperator’sManualandothertrainingmaterial.

•Iftheoperator(s)ormechanic(s)cannotreadEnglishitis

theowner’sresponsibilitytoexplainthismaterialtothem.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateorservice

theequipment.Localregulationsmayrestricttheageof

theoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtothemselves,other

peopleorproperty.

Preparation

•Evaluatetheterraintodeterminewhataccessoriesand

attachmentsareneededtoproperlyandsafelyperform

thejob.

•Onlyuseaccessoriesandattachmentsapprovedbythe

manufacturer.

•Wearappropriateclothing,includingsafetyglassesand

hearingprotection.Longhair,looseclothingorjewelry

maygettangledinmovingparts.

•Inspecttheareawheretheequipmentistobeusedand

removeallobjectssuchasrocks,toysandwirewhichcan

bethrownbythemachine.

•Useextracarewhenhandlinggasolineandotherfuels.

–Theyareammableandvaporsareexplosive.

–Useonlyanapprovedcontainer.

–Neverremovegascaporaddfuelwhenengineis

running.

–Donotsmoke.

–Neverrefuelordrainthemachineindoors.

•Checkthatoperator’spresencecontrols,safetyswitches

andshieldsareattachedandfunctioningproperly.Donot

operateunlesstheyarefunctioningproperly.

Operation

•Neverrunanengineinanenclosedarea.

•Onlyoperateingoodlight,keepingawayfromholesand

hiddenhazards.

•Besurealldrivesareinneutralbeforestartingengine.

•Besureofyourfootingwhileusingpedestriancontrolled

equipment,especiallywhenbackingup.

•Walk,don’trun.

•Neveroperateonwetgrass.Reducedfootingcouldcause

slipping.

•Slowdownanduseextracareonhillsides.Besureto

travelsidetosideonhillsides.

•Usecautionwhileoperatingneardrop-offs.

•Slowdownandusecautionwhenmakingturnsandwhen

changingdirectionsonslopes.

•Neverraisedeckwiththebladesrunning.

•Donotchangetheenginegovernorsettingoroverspeed

theengine.

•Stopequipmentandinspectbladesafterstrikingobjects

orifanabnormalvibrationoccurs.Makenecessary

repairsbeforeresumingoperations.

•Keephandsandfeetawayfromthecuttingunits.

•Lookbehindanddownbeforebackinguptobesureof

aclearpath.

4