5

3. If the stops on one side hit, and on the other side have

clearance, shorten the tie rod on the side that hits, and

equally lengthen the tie rod on the opposite side until

both sides have clearance.

4. Recheck the toe in.

Checking Tire Pressure

Check front and rear tire pressure. The correct front and

rear tire pressure is 20 psi (138 kPa).

Activating the Battery

Battery posts, terminals, and related accessories

contain lead and lead compounds, chemicals

known to the State of California to cause cancer

and reproductive harm. Wash hands after

handling.

Warning

Bulk electrolyte with 1.265 specific gravity must be

purchased from a local battery supply outlet.

Danger

Battery electrolyte contains sulfuric acid which is

a deadly poison and causes severe burns.

•Do not drink electrolyte and avoid contact with

skin, eyes or clothing. Wear safety glasses to

shield your eyes and robber gloves to protect

your hands.

•Fill the battery where clean water is always

available for flushing the skin.

1. Remove the battery from the tractor.

2. Clean the top of the battery with a paper towel.

Note: Never fill the battery with electrolyte while the

battery installed in the tractor. Electrolyte could be

spilled on other parts and cause corrosion.

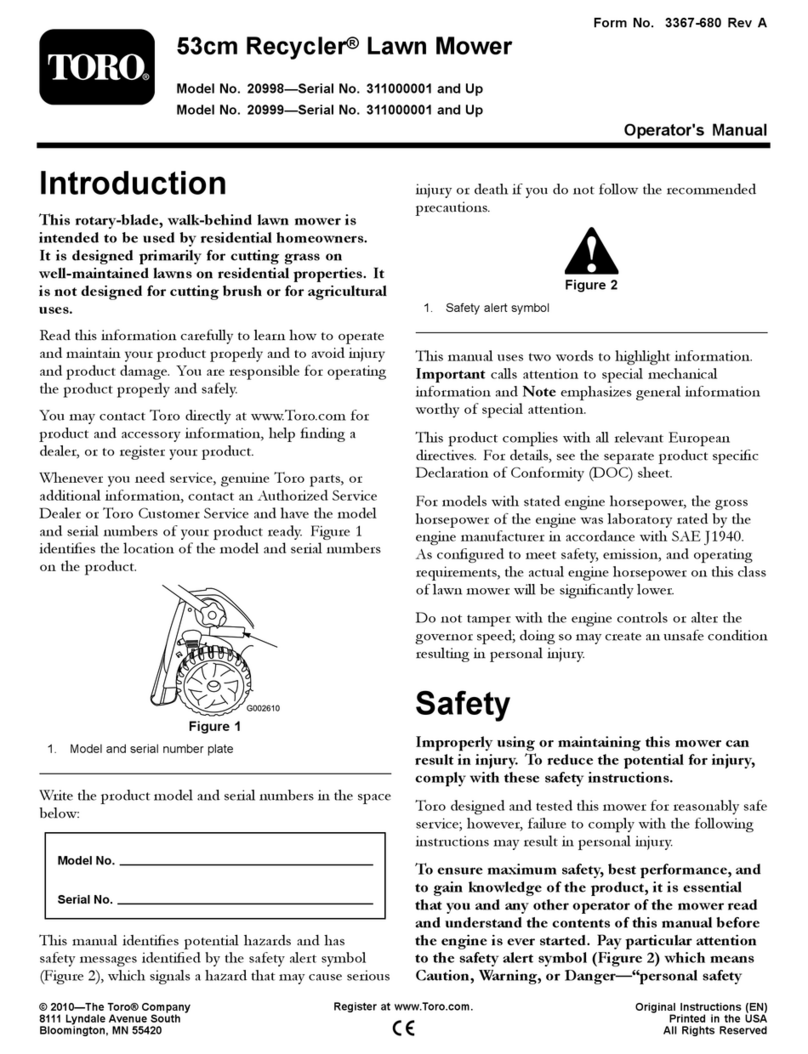

3. Remove the vent caps from the battery (Fig. 9).

4. Slowly pour electrolyte into each battery cell until the

level is up to the upper line (Fig. 9) on the battery

case.

Important Do not overfill the battery because

electrolyte (sulfuric acid) can cause severe corrosion and

damage to the chassis.

5. Wait five to ten minutes after filling the battery cells.

Add electrolyte, if necessary, until the electrolyte level

is up to the upper line (Fig. 9) on the battery case.

6. Install battery filler caps.

1

23

m-5004

Figure 9

1. Fillercaps

2. Upper line 3. Lower line

7. Charge battery for 10 to 15 minutes at 25 to 30

amps or 30 minutes at 4 to 6 amps.

Charging the battery produces gasses that can

explode.

Never smoke near the battery and keep sparks

and flames away from battery.

Warning

8. When the battery is fully charged, unplug the charger

from the electrical outlet, then disconnect the charger

leads from the battery posts (Fig. 10).

4

1

23

m-4970

Figure 10

1. Positive Battery Post

2. Negative Battery Post 3. Red (+) Charger Lead

4. Black (–) Charger Lead

9. Install the battery in the tractor and connect the battery

cables. (Refer to the Operator’s Manual – Installing

the Battery.)

Note: Do not run the tractor with the battery disconnected,

electrical damage may occur.