Contents

Safety...........................................................................3

Hauling..................................................................4

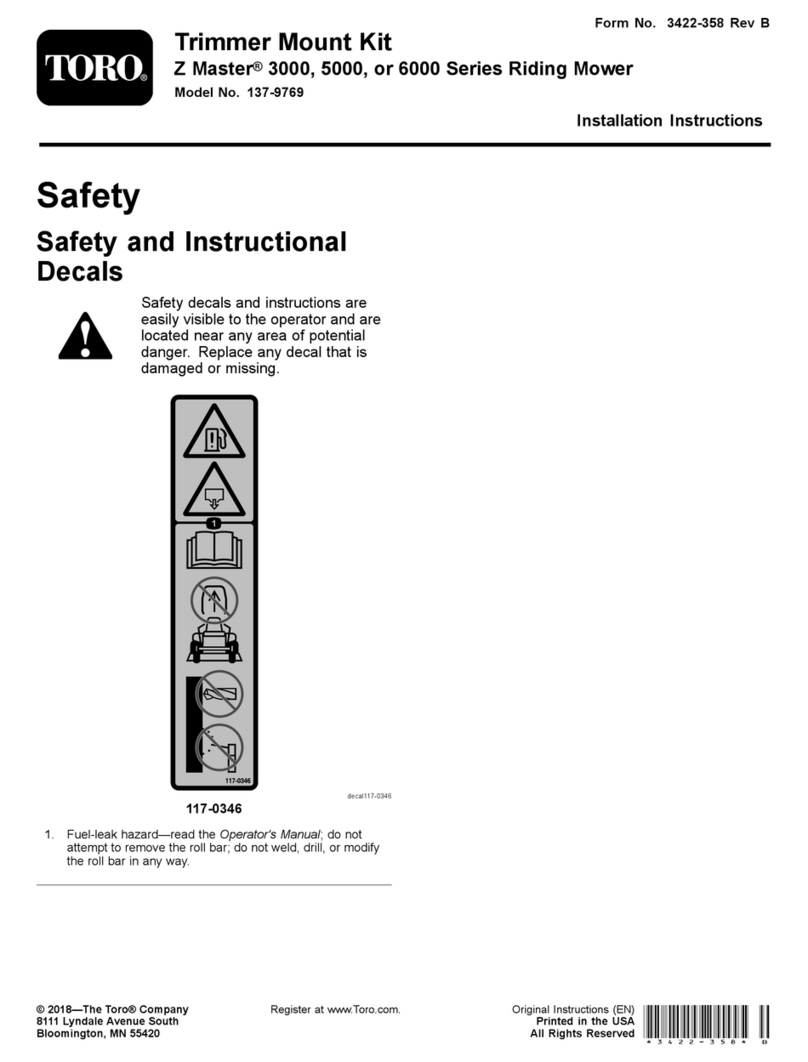

SafetyandInstructionalDecals.................................4

Setup............................................................................5

InstallingtheRoller..................................................5

InstallingtheBallStuds............................................5

InstallingtheHoopLink,OffsetLink,orChain

Link...................................................................5

RepositioningtheCounterWeights............................6

AdjustingtheCuttingUnit........................................7

ProductOverview..........................................................8

Specications.........................................................8

Attachments/Accessories.........................................8

Operation.....................................................................8

Maintenance..................................................................9

SupportingtheCuttingUnit......................................9

AdjustingtheBedknife-to-ReelContact......................9

AdjustingtheRear-RollerHeight..............................10

AdjustingtheHeightofCut.....................................11

AdjustingtheCut-OffBar.......................................12

ServicingtheBedbar...............................................12

BedknifeSpecications...........................................14

BacklappingtheCuttingUnit...................................14

Safety

ThismachinehasbeendesignedinaccordancewithENISO

5395:2013andANSIB71.1-2012.

Hazardcontrolandaccidentpreventionaredependent

upontheawareness,concern,andpropertraining

ofthepersonnelinvolvedintheoperation,transport,

maintenance,andstorageofthemachine.Improper

useormaintenanceofthemachinecanresultininjury

ordeath.Toreducethepotentialforinjuryordeath,

complywiththefollowingsafetyinstructions.

•Read,understand,andfollowallinstructionsinthe

traction-unitandcutting-unitoperator’smanualsbefore

operatingthemachine.

•Neverallowchildrentooperatethemachine.Donot

allowadultstooperatethemachinewithoutproper

instruction.Onlytrainedoperatorswhohavereadthis

manualshouldoperatethemachine.

•Neveroperatethemachinewhenundertheinuenceof

drugsoralcohol.

•Keepallshieldsandsafetydevicesinplace.Ifashield,

safetydeviceordecalisillegibleordamaged,repairor

replaceitbeforecommencingoperation.Alsotighten

anyloosenuts,bolts,andscrewstoensurecuttingunitis

insafeoperatingcondition.

•Wearappropriateclothingincludingsubstantial,

slip-resistantfootwear,safetyglasses,andhearing

protection.Tiebacklonghair.Donotwearjewelry.

•Removealldebrisorotherobjectsthatthecutting-unit

bladesmightpickupandthrow .Keepallbystandersaway

fromtheworkingarea.

•Ifthecuttingbladesstrikeasolidobjectortheunit

vibratesabnormally,stopandshuttheengineoff.Check

thecuttingunitfordamagedparts.Repairanydamage

beforestartingthecuttingunit.

•Lowerthecuttingunitstothegroundandremovethekey

fromtheignitionswitchwheneveryouleavethemachine.

•Ensurethatthemachineisinsafeoperatingconditionby

keepingnuts,bolts,andscrewstight.

•Removethekeyfromignitionswitchtopreventaccidental

startingoftheenginewhenservicing,adjusting,orstoring

themachine.

•Performonlythosemaintenanceinstructionsdescribed

inthismanual.Ifthemachineneedsmajorrepairsoryou

needassistance,contactanAuthorizedToroDistributor.

•Toensureoptimumperformanceandcontinuedsafety

certicationofthemachine,useonlygenuineToro

replacementpartsandaccessories.Replacementparts

andaccessoriesmadebyothermanufacturerscouldbe

dangerous,andsuchusecouldvoidtheproductwarranty.

3