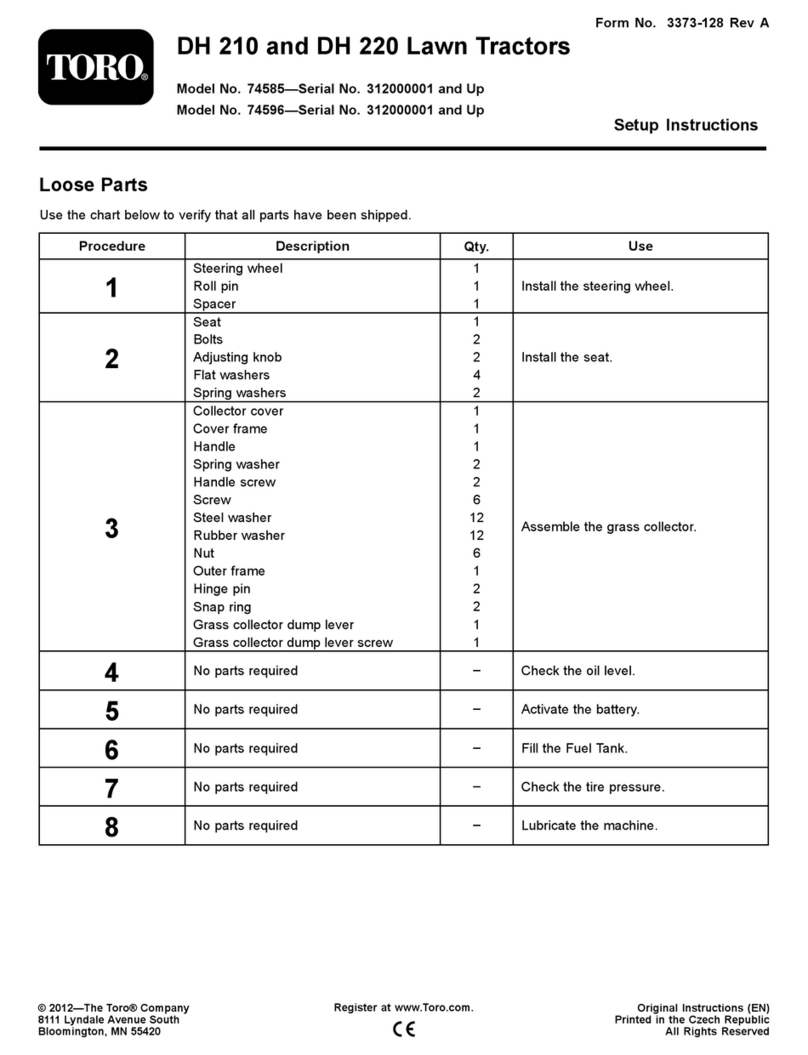

Contents

Safety.......................................................................3

GeneralSafety...................................................3

CuttingUnitSafety..............................................3

SafetyandInstructionalDecals..........................4

Setup........................................................................8

1PreparingtheMachine.....................................8

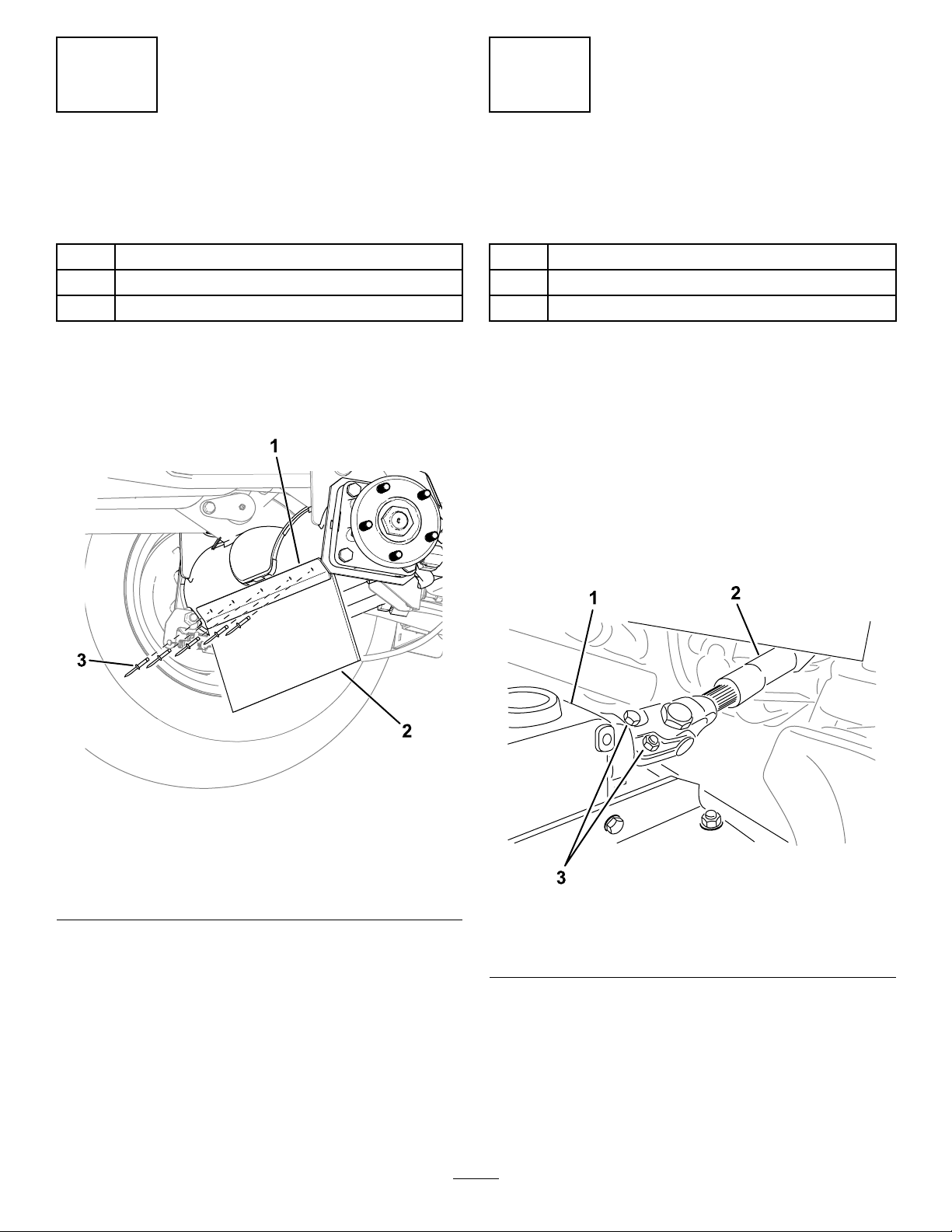

2InstallingtheCEKit..........................................8

3InstallingtheDebrisGuardtotheFront

Axle.................................................................8

4InstallingtheCuttingUnittotheTraction

Unit.................................................................9

5InstallingthePTOCover................................10

6LevelingtheCuttingUnit................................10

7GreasingtheCuttingUnit................................11

ProductOverview....................................................11

Specications...................................................11

Attachments/Accessories..................................11

Operation................................................................12

AdjustingtheHeightofCut...............................12

AdjustingtheCutting-UnitPitch........................13

AdjustingtheAnti-ScalpRollers........................14

AdjustingtheSkid.............................................14

CorrectingaCuttingUnitMismatch...................14

OperatingTips.................................................15

Maintenance...........................................................16

RecommendedMaintenanceSchedule(s)...........16

DailyMaintenanceChecklist.............................16

GreasingtheBearingsandBushings................17

CheckingtheLubricantintheGearbox..............17

CheckingtheTorqueofthePTO

Driveshaft-to-GearboxFasteners..................17

RemovingtheCuttingUnitfromtheTraction

Unit...............................................................18

ServicingtheBushingsintheCastor

Arms.............................................................19

ServicingtheCastorWheelsand

Bearings........................................................19

ServicingtheCuttingBlades.............................19

CheckingandCorrectingMismatchof

Blades...........................................................21

ReplacingtheDriveBelt...................................22

CleaningUndertheCuttingUnit........................22

Storage...................................................................23

Safety

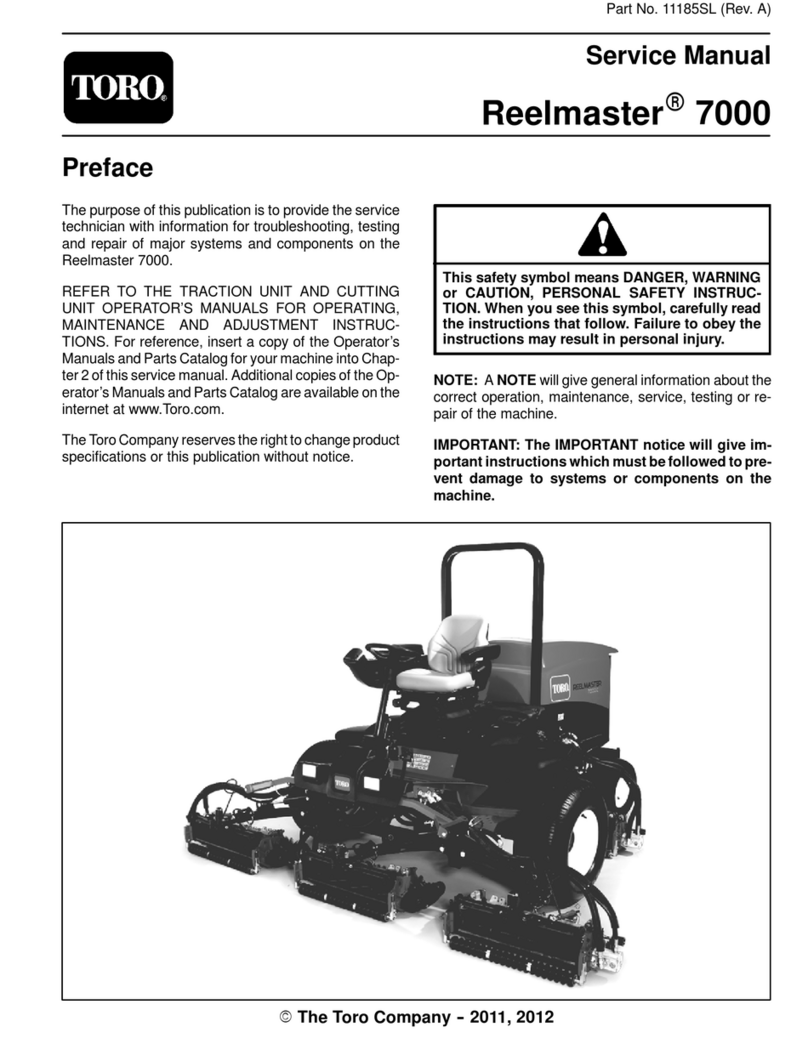

Thismachinehasbeendesignedinaccordancewith

ENISO5395(whenequippedwiththeCEKit)and

ANSIB71.4-2017.

GeneralSafety

Thisproductiscapableofamputatinghandsand

feetandofthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriouspersonalinjury

•Readandunderstandthecontentsofthis

Operator’sManualbeforestartingthemachine.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Donotputyourhandsorfeetnearmoving

componentsofthemachine.

•Donotoperatethemachinewithoutallguards

andothersafetyprotectivedevicesinplaceand

functioningproperlyonthemachine.

•Keepclearofanydischargeopening.

•Keepbystandersandchildrenoutoftheoperating

area.Neverallowchildrentooperatethemachine.

•Beforeyouleavetheoperator’sposition,dothe

following:

–Parkthemachineonalevelsurface.

–Lowerthecuttingunit(s).

–Disengagethedrives.

–Engagetheparkingbrake(ifequipped).

–Shutofftheengineandremovethekey.

–Waitforallmovementtostop.

Improperlyusingormaintainingthismachinecan

resultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalways

payattentiontothesafety-alertsymbol,which

meansCaution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

CuttingUnitSafety

•Thecuttingunitisonlyacompletemachinewhen

installedonatractionunit.Readthetraction

unitOperator’sManualcarefullyforcomplete

instructionsonthesafeuseofthemachine.

•Stopthemachine,removethekey,andwaitfor

allmovingpartstostopbeforeinspectingthe

attachmentafterstrikinganobjectorifthereis

anabnormalvibrationinthemachine.Makeall

necessaryrepairsbeforeresumingoperation.

3