WARNING

CALIFORNIA

Proposition65Warning

ThisproductcontainsachemicalorchemicalsknowntotheStateofCalifornia

tocausecancer,birthdefects,orreproductiveharm.

ThisproductcomplieswithallrelevantEuropeandirectives,fordetailspleaseseetheseparateproductspecic

DeclarationofConformity(DOC)sheet.

ElectromagneticCompatibility

Domestic:ThisdevicecomplieswithFCCRulesPart15.

Operationissubjecttothefollowingtwoconditions:(1)This

devicemaynotcauseharmfulinterferenceand(2)thisdevice

mustacceptanyinterferencethatmaybereceived,including

interferencethatmaycauseundesirableoperation.

Thisequipmentgeneratesandusesradiofrequencyenergyand

ifnotinstalledandusedproperly,instrictaccordancewiththe

manufacturer'sinstructions,maycauseinterferencetoradio

andtelevisionreception.Ithasbeentypetestedandfoundto

complywithinthelimitsofaFCCClassBcomputingdevicein

accordancewiththespecicationsinSubpartJofPart15of

FCCRules,asstatedabove.However,thereisnoguarantee

thatinterferencewillnotoccurinaparticularinstallation.If

thisequipmentdoescauseinterferencetoradioortelevision

reception,whichcanbedeterminedbyturningtheequipmentoff

andon,theuserisencouragedtotrytocorrecttheinterference

byoneormoreofthefollowingmeasures:Reorientthereceiving

antenna,relocatetheremotecontrolreceiverwithrespecttothe

radio/TVantennaorplugthecontrollerintoadifferentoutletso

thatthecontrollerandradio/TVareondifferentbranchcircuits.If

necessary,theusershouldconsultthedealeroranexperienced

radio/televisiontechnicianforadditionalsuggestions.The

usermayndthefollowingbookletpreparedbytheFederal

CommunicationsCommissionhelpful:"HowtoIdentifyand

ResolveRadio-TVInterferenceProblems".Thisbookletis

availablefromtheU.S.GovernmentPrintingOfce,Washington,

DC20402.StockNo.004-000-00345-4.

FCCID:W7OMRF24J40MDME-Base,

OA3MRF24J40MA-HandHeld

IC:7693A-24J40MDME-Base,7693A-24J40MA-HandHeld

Operationissubjecttothefollowingtwoconditions:(1)this

devicemaynotcauseinterference,and(2)thisdevicemust

acceptanyinterference,includinginterferencethatmaycause

undesiredoperationofthedevice.

JapanElectromagneticCompatibilityCertication

Handheld:

RF2CAN:

MexicoElectromagneticCompatibilityCertication

Handheld:

RF2CAN:

KoreaElectromagneticCompatibilityCertication(Decal

providedinseparatekit)

Handheld:

RF2CAN:

SingaporeElectromagneticCompatibilityCertication

Handheld:TWM240008_IDA_N4023-15

RF2CAN:TWM-240005_IDA_N4024-15

MoroccoElectromagneticCompatibilityCertication

AGREEPARL’ANRTMAROC

NUMEROd’agrement:MR14078ANRT2017

Delivred'agrement::29/05/2017

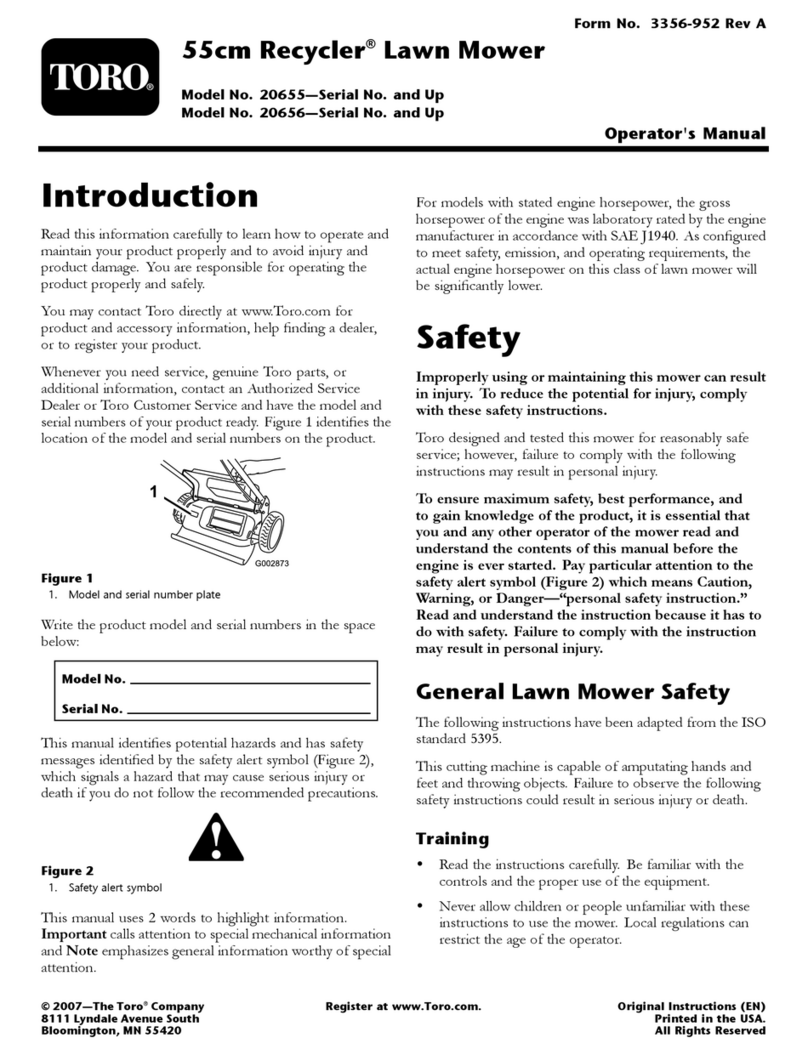

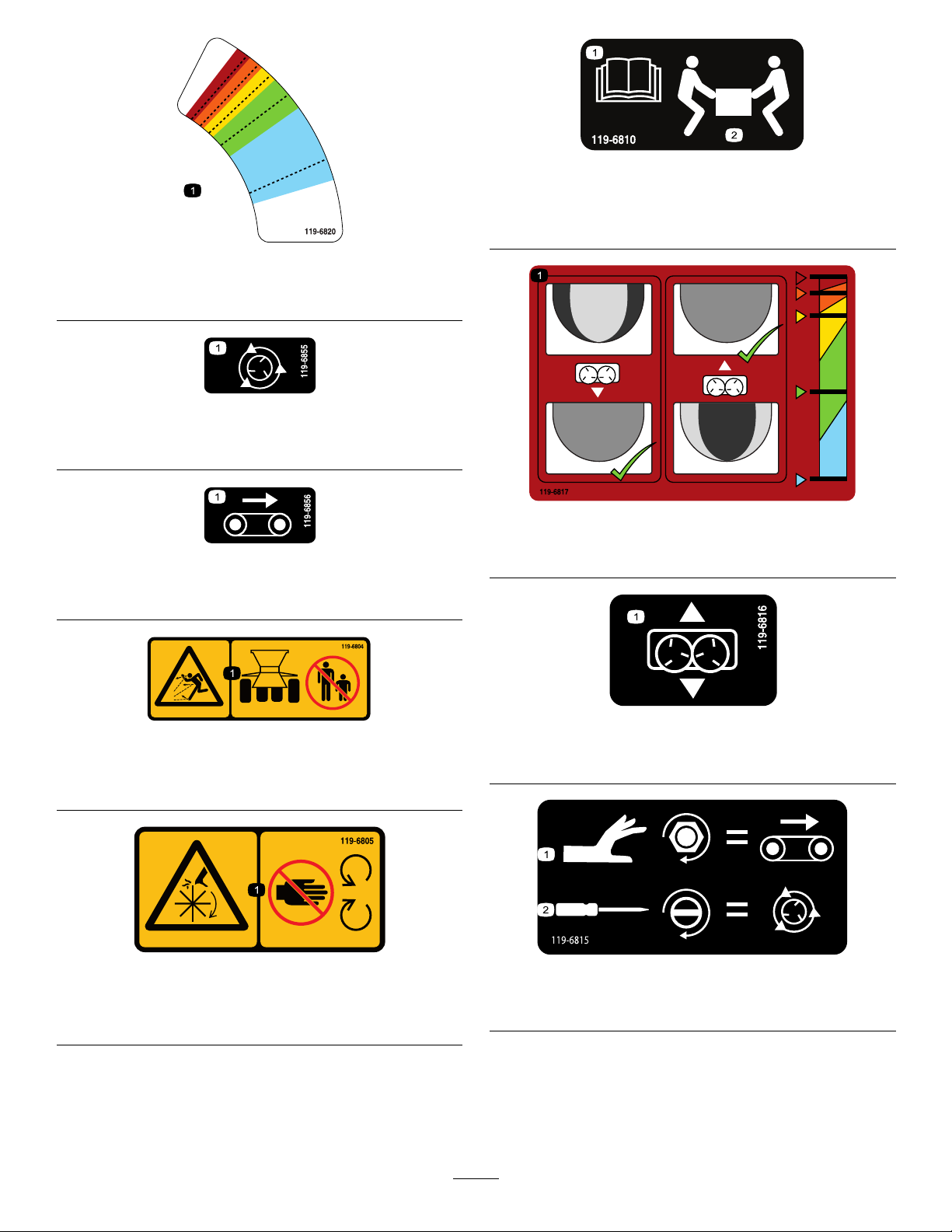

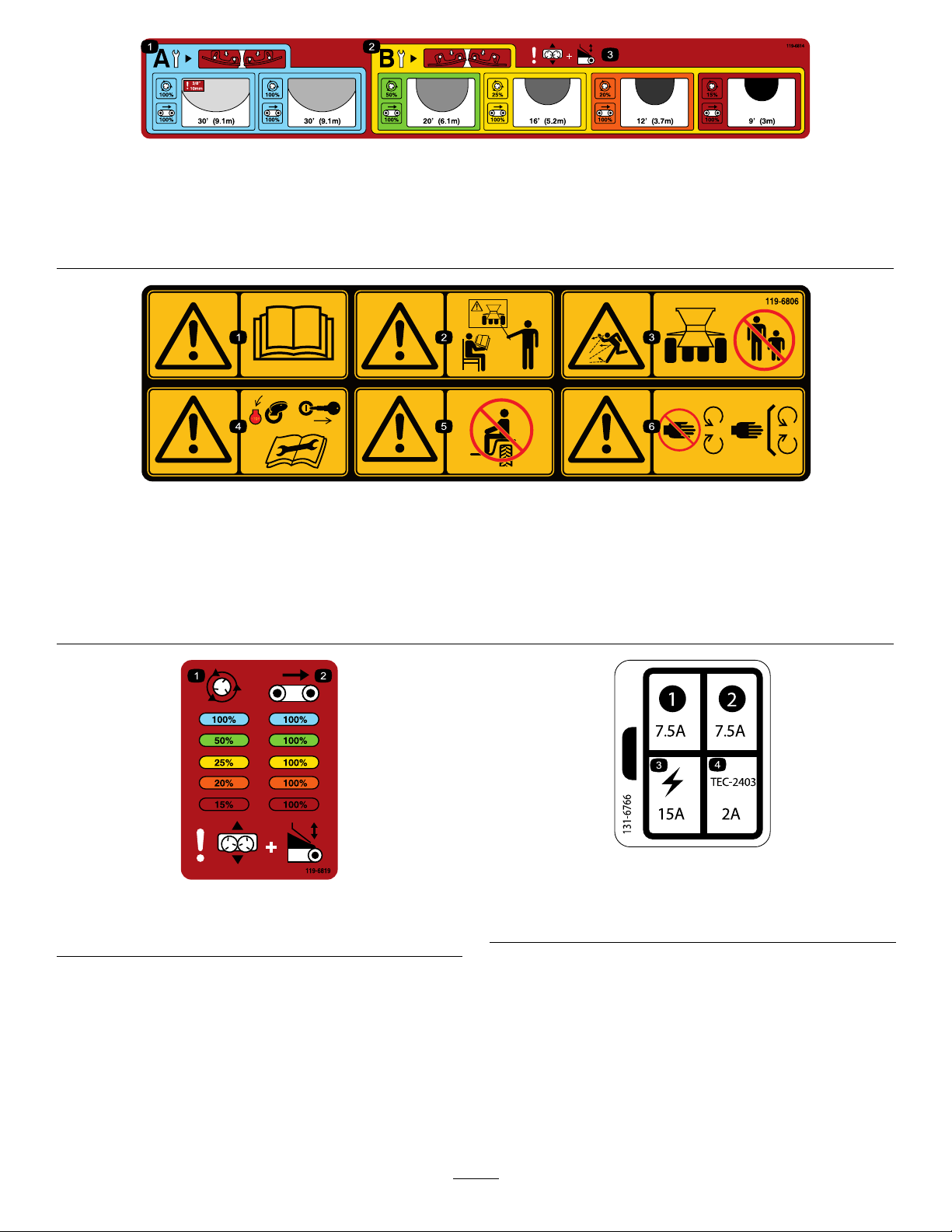

Introduction

Thismachineisintendedtobeusedbyprofessional,

hiredoperatorsincommercialapplications.Itis

designedprimarilyformeteringanddispersing

materials,underarangeofmoistureconditions,

withoutcloggingordrasticallyaffectingthedispersion.

Important:Tomaximizethesafety,performance,

andproperoperationofthismachine,carefully

readandfullyunderstandthecontentsofthis

Operator’sManual.Failingtofollowthese

operatinginstructionsortoreceiveproper

trainingmayresultininjury.Formoreinformation

onsafeoperatingpractices,includingsafetytips

andtrainingmaterials,gotowww.Toro.com.

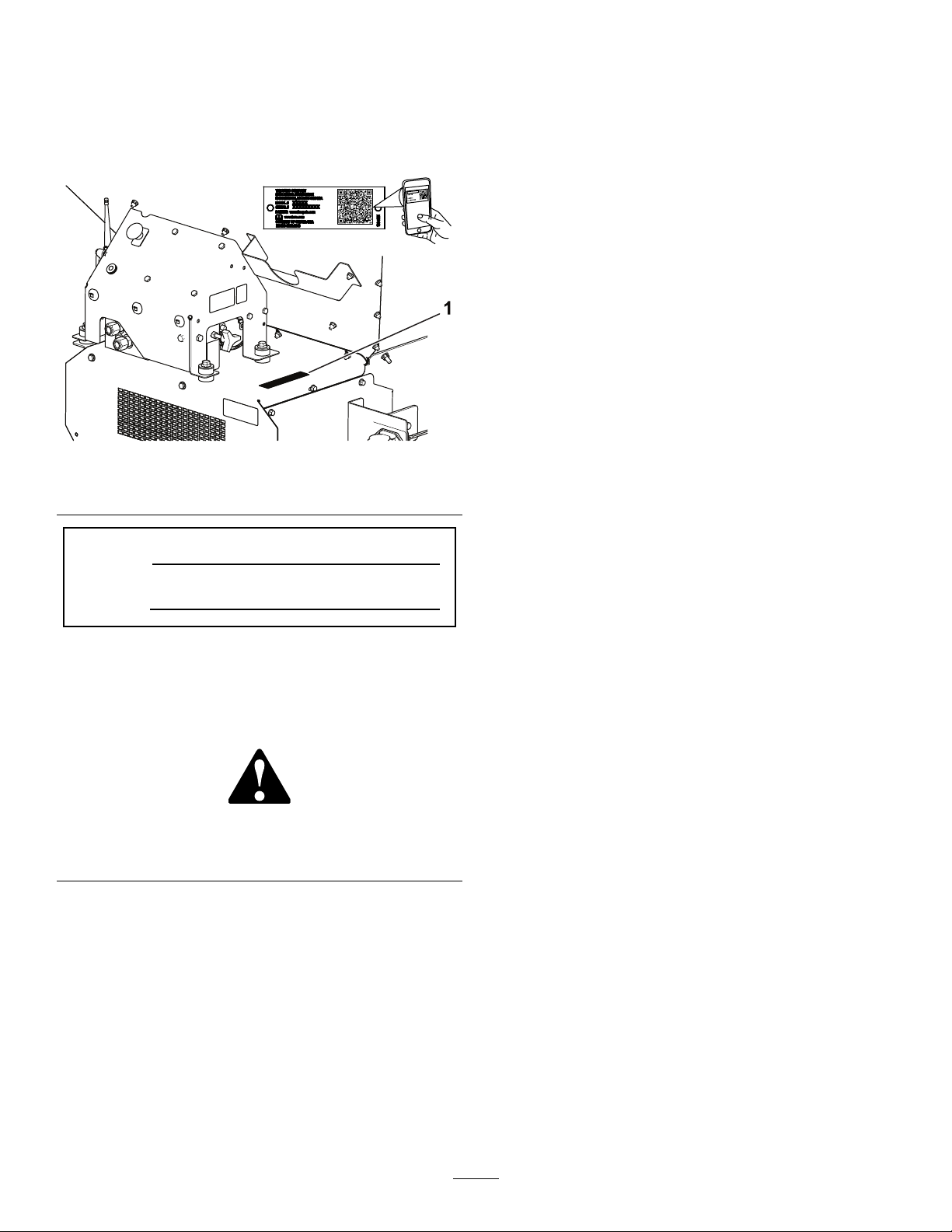

Wheneveryouneedservice,genuineT oroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

©2017—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN554202

Contactusatwww.Toro.com.

PrintedintheUSA

AllRightsReserved