TORQUE GUN JGUN SINGLE SPEED Series Quick start guide

3rd Edition: Oct. 2013

This manual applies to all tool part numbers in the jGun Single Speed and Dual Speed

Plus Product Families. It is recommended the manual is kept up-to-date by checking the

edion and date code at the boom of this page by ulizing the Torque Gun Company

website and downloading a copy of the most recent edion as needed.

THE TORQUE GUN COMPANY

120 Wesley Street,

Hackensack, New Jersey 07606 U.S.A.

Noce: The informaon contained in this document is subject to change without noce. The Torque

Gun Company makes no warranty of any kind with regard to this material, including but not limited

to, the implied warranes of merchantability and tness for a parcular purpose. The Torque Gun

Company shall not be liable for errors contained herein or for incidental or consequenal damages in

connecon with the furnishing, performance, or use of this material. It is further recomended that the

end-user or repair technician insure they have obtained and are familiar with the latest revision of the

manual for the equipment outlined in this document.

Restricted Rights Legend: Use and duplicaon of the informaon contained within this manual is

limited to the purchaser, end user, or licensed Torque Gun Company representave. It is recommended

that proper training for the equipment outlined in this manual be conducted by a Torque Gun Company

authorized training representave for any person who is operang or repairing the equipment outlined

in this document. Modicaon, or disclosure by any other agency or representave is strictly forbidden.

Product Modicaons: The Torque Gun Company DOES NOT ALLOW any of the products listed in this

manual to be modied by any end user without excepon. Should an applicaon require a modicaon

to the tool, or any of the standard accessories please consult with your local Torque Gun Company

representave and they will be able to obtain the assistance for any modicaon that may be required.

© Copyright The Torque Gun Company 2013: All Rights Reserved. Reproducon, adaptaon, or

translaon without prior wrien permission is prohibited, except as allowed under the copyright laws.

3rd Edion. Printed in USA. October 2013

Complies with standards publicaon BS EN 82079-1:2012

JGUN SINGLE SPEED PRODUCT FAMILY:

J-.25, J-.5, J-1, J-3, J-5, J-8

JGUN DUAL SPEED PLUS PRODUCT FAMILY:

J-A.5-AP, J-A1-AP, J-A3-AP, J-A5-AP, J-A8-AP

JGUN DSP WHEEL GUN PRODUCT FAMILY:

JGUN-A1-AP-WG, JGUN-A3-AP-WG

EN, EN-ISO, ISO Standards:

For a complete EC declaraon of conformity

or if you require any further assistance please

contact your local Torque Gun representave

or 1-888-GUN-2-GUN (1-888-486-2486) or on

the web at www.torquegun.com.

EN ISO 4414:2010

EN 61310-2:2008

EN 61310-3:2008

ISO 3744:2011

EN ISO 12100-1:2011

EN ISO 12100-2:2011

EN ISO 14121-1:2007

EN ISO 11148-6:2012

WITH THE PURCHASE OF TORQUE GUN CO. TORQUE MACHINES (PAST,

PRESENT, FUTURE) YOU HAVE OBTAINED THE LATEST TECHNOLOGY AND

LIFETIME, WORLDWIDE LOCAL SERVICE.

HELP: If you require any further assistance, please call your local Torque Gun Co. Representa-

tive or 1-888-GUN-2-GUN (1-888-48 ), on the web at torcgun.com - 24/7! It’s live!

FIND US ONLINE AT

facebook.com/torcgun twitter.com/torcgun youtube.com/torqueguncompany

FREE SERVICES

♦FREE User Safety Training upon Receipt of Merchandise

♦FREE Semi-Annual User Safety Training on Request

♦FREE Annual Safety Seminar on Appointment

♦FREE Loaner Tools in case of Product Failure within 24 Hours

♦FREE Torque/Tension Consultation/Seminar

♦FREE Half Day, First Use Supervision

♦FREE Annual Product Inspection on Request

♦FREE Product Demonstrations

♦FREE 12 Month No-Questions-Asked Warranty

♦FREE Upgrades during the Lifetime of the Tool to Enhance Safety, Durability, and Function

(Above services are NOT subject to travel expense charges)

REPAIRS

• All Repairs are Guaranteed for 6 Months

• Repairs are Subject to Labor and Part Cost, as Outlined in the Ofcial TORQUE GUN CO. Price List

• All Warranty Repairs are FREE of All Charges Including Return-Freight

• All Repairs Will be Tested and Calibrated to Ensure the Highest Quality Repairs

TOOL RENTALS

• 50% of All Paid Rentals will be Applied as a Discount Toward Any Purchase for One Year from the date of the

Rental Invoice

• 100% of all Rental Fees will be Applied if Rental is Paid in 30 days

• User Training for First Time Rentals is FREE of All Cost

• Return Freight Charges are FREE

• Rental Tools are Guaranteed to Perform and are Subject to the FREE Loaner Tool Policy of TORQUE GUN CO.

TOTAL SATISFACTION GUARANTEED 1-888-GUN-2-GUN

JGUN™ Torque Gun

OPERATIONAL MANUAL

TABLE OF CONTENTS

Warranty 6

jGun Overview 7

jGun Safety 8

Personal Protective Equipment 8

Air Supply Requirements 8

Reaction Arm or Washer 9

Key Operating Safety Points 14

jGun Setup and Use 14

Setting a Torque Value 14

Changing the Drive Direction 15

Operating the jGun 15

Loosening a Fastener 17

jGun Repair and Maintenance

Maintaining Hoses and Fittings 18

Lubricating the Air Motor 18

Calibration 18

jGun Dual Speed Plus 19

Shifting Between Modes 20

Tool Operation 20

Operation with a Socket and Reaction Arm 21

Operation with a Load Disc 21

Filter/Regulator/Lubricator (FRL) Unit Overview 22

FRL Safety 22

Personal Protective Equipment 23

Air Supply Requirements 23

FRL Setup and Use 24

Important FRL Operating Procedures 24

Emptying the Filter Reservoir 24

Adjusting Air Pressure 25

Filling the Lubricator Reservoir 27

Adjusting the Flow 28

Repair and Maintenance 28

Hoses and Fittings 28

4BREAKTHROUGH PRODUCTS FOR INDUSTRIAL BOLTING

TABLE OF CONTENTS CONT.

HYTORC Reaction Washer Overview 29

Safety 30

Personal Protective Equipment 30

HYTORC Washer Requirements 31

HYTORC Washer Setup and Use 31

Important Preparation Procedures 31

Important Installation Procedures 32

jGun Maintenance and Troubleshooting Tips 34

FIGURES

Figure 1. Reaction Arm 9

Figure 2. HYTORC Washer and Socket 9

Figure 3. Installing a Reaction Arm 10

Figure 4. Reaction Arm Installed 11

Figure 5. Tightening Reaction Arm Set Screw 11

Figure 6. Installing jGun Socket 12

Figure 7. Installing Socket Locking Pin and Retaining Ring 12

Figure 8. Placement of Reaction Arm 13

Figure 9. jGun Drive Direction Lever 15

Figure 10. jGun Operation 16

Figure 11. Using the jGun with a Reaction Washer 17

Figure 12. Dual Speed Plus jGun with Reaction Arm 19

Figure 13. High Speed Setting (Left) and Maximum Torque Setting (Right) 20

Figure 14. FRL Unit (Shown without silencer) 21

Figure 15. Emptying the FRL Filter Reservoir 25

Figure 16. Detaching FRL Reservoir 25

Figure 17. FRL Unit – Lubricator 2/3rds Full of Oil 26

Figure 18. Adjusting FRL Regulator 27

Figure 19. Adjusting FRL Oil Flow 28

Figure 20. HYTORC Washer and Socket 29

Figure 21. HYTORC Washer Socket Mounted on jGun 30

Figure 22. HYTORC Washer Installed 32

Figure 23. Aligning HYTORC Washer Socket Set Screw with Machined Recess

in jGun Splines 33

Figure 24. Tightening HYTORC Washer Set Screw 33

TABLES

Table 1: Bolt Torque Specications 14

5

BREAKTHROUGH PRODUCTS FOR INDUSTRIAL BOLTING

THE TORQUE GUN COMPANY

120 Wesley Street, Hackensack, New Jersey 07606 U.S.A.

The jGUN has a one year limited warranty. Every TORQUE GUN tool

is tested before leaving the factory and is warranted to be free from

defects in workmanship and materials. TORQUE GUN will repair or

replace, without charge, any tool which upon examination proves to be

defective in workmanship or materials for one (1) year after the date of

purchase. This warranty does not cover damage from repairs made or

attempted by other than TORQUE GUN authorized repair facilities.

The repair and replacement remedies described herein are exclusive.

In no event shall TORQUE GUN be liable for any incidental, special, or

consequential damages, including loss of prots. This warranty is

exclusive and in lieu of all other warranties or conditions, written or oral,

expressed or implied for merchantability or tness for particular use or

purpose.

This warranty gives you specic legal rights. You may also have other

rights that vary from state to state and province to province. In those

states that do not allow the exclusion of implied warranties or limitation

of incidental or consequential damages, the above limitations or

exclusions may not apply to you.

If you have questions about the warranty, contact our cus-

tomer service center at 201-828-5270.

WARRANTY

6BREAKTHROUGH PRODUCTS FOR INDUSTRIAL BOLTING

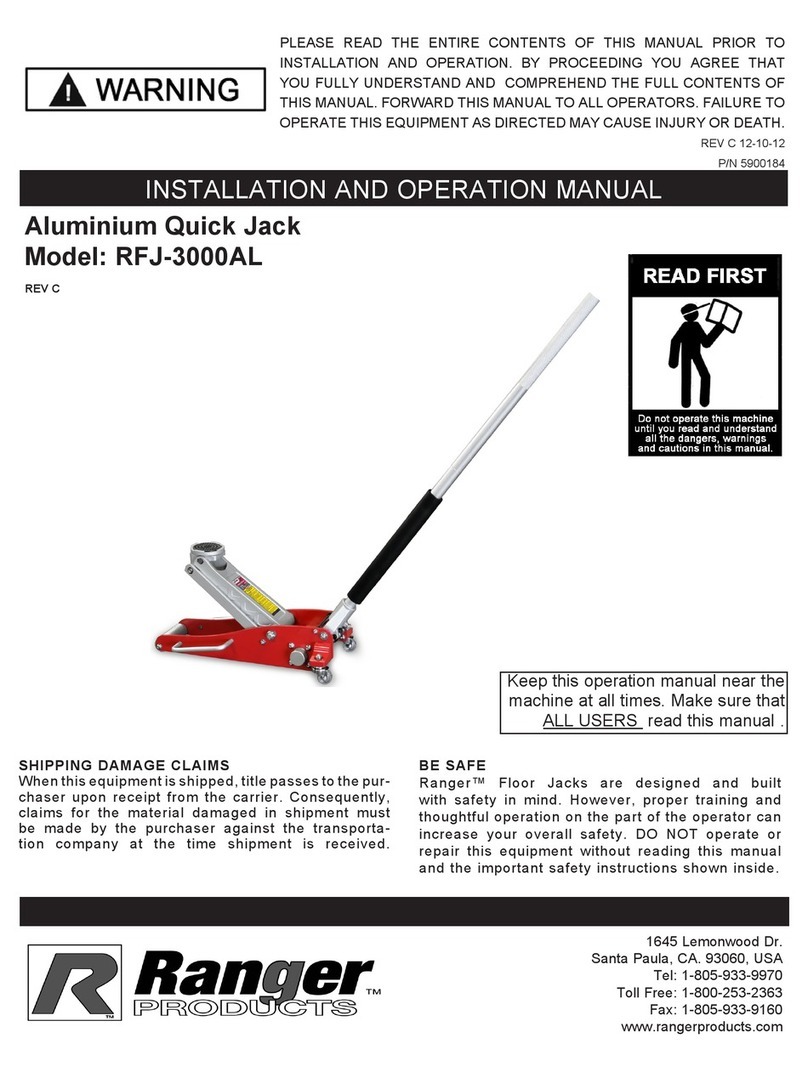

jGUN OVERVIEW

The jGun pneumatic torque wrench is designed to safely and accurately deliver up to 8,000 ft-lbs of

torque onto a fastener. This is accomplished using a patented planetary gearbox torque multiplier sys-

tem and an appropriate reaction arm or HYTORC Reaction Washer™ and HYTORC Nut™. The torque

multiplier produces torque ratios of up to 1450:1 while the reaction arm or washer is used to absorb the

high counter rotational force produced as the nal torque value is reached. At nal torque value, the jGun

safely stalls out, leaving the fastener tightened

to specication.

Unlike impact wrenches, the jGun never transmits working torque to the operator. The torque is applied

between the fastener and the reaction surface.

This manual provides information for both the standard jGun and the Dual Speed jGun.

7

BREAKTHROUGH PRODUCTS FOR INDUSTRIAL BOLTING

jGUN SAFETY

Only qualied personnel who have thoroughly read this document may operate this tool. Failure to safely

operate this tool may result in serious injury or death.

• Inspect all jGun components as they are removed from the shipping container. If damage is

found to any component, contact your shipper immediately. Do not use the tool.

• Failure to follow correct tool usage could result in personal injury, co-worker injury, and/or

damaged tools and equipment.

• Ensure your working area is clean and unobstructed before beginning work.

• jGun maintenance and repair must be performed by a qualied pneumatic technician.

• Modifying a jGun or jGun accessory is dangerous and invalidates the warranty.

• Inspect the tool before each use. Replace any obviously worn or damaged parts.

• When not in use, store the jGun and jGun accessories in the plastic storage case supplied with

the tool. Do not expose the gun to high humidity or large temperature variations.

Personal Protective Equipment

• Always wear the appropriate personal protective equipment when operating a jGun including

gloves, safety goggles, hearing protection, hard hat, and safety shoes.

Air Supply Requirements

• The air supply line must be ½-inch minimum diameter to allow adequate air ow to the jGun.

• The air supply must provide a minimum of 90 psi at 30 cfm.

• Ensure that air line ttings are tight and leak free. Do not over tighten air line ttings.

• Always use the Filter Regulator Lubricator (FRL) Unit provided with the jGun. Never use a

substitute oiler and regulator.

• Open the air supply connected to the FRL unit and run the jGun while setting the pressure on the

regulator gauge.

• Set the air pressure to the PSI needed to achieve desired torque shown on the provided

pressure/torque conversion chart, also shown in Pressure / Torque Conversion Charts.

NOTE

Set the air pressure at the FRL while the tool is running as described in FRL Setup and Use.

THE NEW PATENTED SAFETY LEVER

This patented safety mechanism drastically reduces

the chance for operator error which can lead to safety

risks.

The lever must be depressed while pulling the trigger,

thereby ensuring that the tool operator keeps hands

away from pinch points.

8BREAKTHROUGH PRODUCTS FOR INDUSTRIAL BOLTING

Reaction Arm or HYTORC Washer

Choose the correct reaction arm for the job. The jGun is shipped with a standard length reaction arm,

but your gun may have been ordered with a custom reaction arm for a specic purpose.

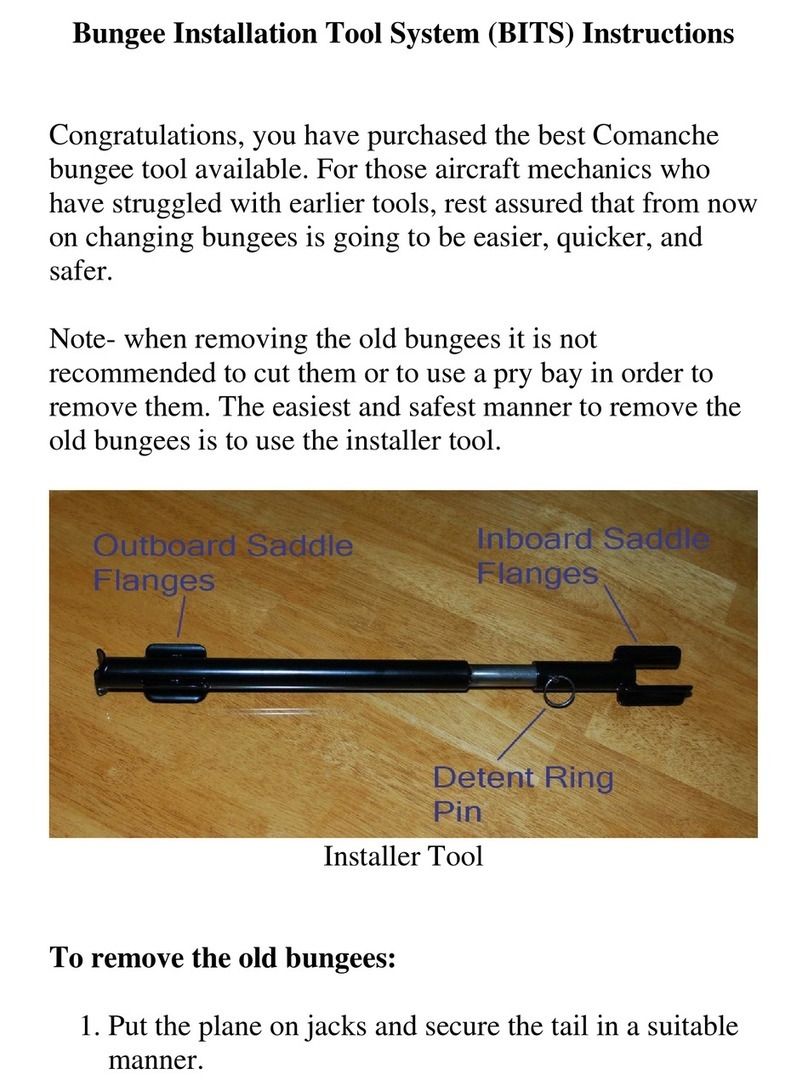

Figure 1. Reaction Arm

The HYTORC Washer system can be used for all applications instead of reaction arm.

Figure 2. HYTORC Washer and Drive

WARNING!

Never modify a reaction arm! Changes in the reaction arm may lead to personal

injury or damage to the tool.

NOTE:

Reaction arm modications result in loss of warranty for the reaction arm and the jGun. If

you need a custom reaction arm, please consult with your local Torque Gun dealer.

9

BREAKTHROUGH PRODUCTS FOR INDUSTRIAL BOLTING

Reaction Arm and Socket Installation

• Choose the correct reaction arm for the job. The jGun is shipped with a standard length reaction

arm, but your gun may have been ordered with custom-length reaction arm for a specic pur-

pose.

• If using the HYTORC Washer ™, follow installation instructions in HYTORC Washer™

Overview.

• Clean the reaction arm and jGun barrel mating surfaces before installing the reaction

arm.

• Slide the reaction arm onto the jGun barrel with the reaction arm extension facing out.

Figure 3. Installing a Reaction Arm

!! CAUTION !!

ALWAYS INSTALL THE REACTION ARM WITH THE EXTENSION

FACING AWAY FROM THE GUN.

FAILURE TO INSTALL THE REACTION ARM CORRECTLY COULD

RESULT IN THE REACTION ARM COMING IN CONTACT WITH YOUR

HAND OR OTHER ANOTHER PART OF YOUR BODY, CAUSING

PERSONAL INJURY.

10 BREAKTHROUGH PRODUCTS FOR INDUSTRIAL BOLTING

Figure 4. Reaction Arm installed

• Lock the reaction arm to the jGun by aligning the set-screw with the

hole in the splined section and then tightening the set screw rmly.

Figure 5. Tightening Reaction Arm Set Screw

• Place the appropriately sized socket onto the jGun barrel.

11

BREAKTHROUGH PRODUCTS FOR INDUSTRIAL BOLTING

Figure 6. Installing jGun Socket

• Install the socket locking pin and retaining ring.

Figure 7. Installing Socket Locking Pin and Retaining Ring

12 BREAKTHROUGH PRODUCTS FOR INDUSTRIAL BOLTING

Key Operating Safety Points

• Ensure that the reaction arm is in direct contact with an appropriate immovable object before

beginning to tighten the fastener.

Figure 8. Placement of Reaction Arm

• Using the HYTORC Washer™ eliminates external moving parts and increases worker safety.

Refer to HYTORC Reaction Washer Overview.

• Keep all body parts clear of the reaction arm and reaction arm contact point (immovable object).

• Ensure the jGun barrel is in a straight line with relation to the stud and that the socket is fully

engaged onto the fastener.

• As the tool takes up the bolt load, the jGun may shift.

!! CAUTION !!

FAILURE TO HAVE THE REACTION ARM IN DIRECT CONTACT WITH

AN APPROPRIATE IMMOVABLE OBJECT BEFORE BEGINNING TO

TIGHTEN THE FASTENER COULD RESULT IN LOSS OF CONTROL OF

THE TOOL AND PERSONAL INJURY.

!! CAUTION !!

DO NOT PLACE ANY PART OF YOUR BODY BETWEEN THE REAC-

TION ARM AND AN APPROPRIATE IMMOVABLE OBJECT AT ANY TIME

WHILE A FASTENER IS BEING IS BEING TORQUED.

PERSONAL INJURY MAY OCCUR IF ANY PORTION OF YOUR BODY

IS LOCATED BETWEEN THE REACTION ARM AND THE IMMOVABLE

OBJECT WHEN THE FASTENER IS BEING TORQUED.

13

BREAKTHROUGH PRODUCTS FOR INDUSTRIAL BOLTING

jGUN SETUP AND USE

Proper setup and use of the jGun before and during installation ensures accurate results and safe op-

eration. The FRL Unit provided with the jGun must be used with the hose provided to ensure the tool’s

durability. See the FRL Unit Overview section below for more information.

Setting a Torque Value

1. Determine the torque value for the fastener to be tightened, as shown in the Bolt Torque

Specications table below.

SAE1 SAE2

30,000PSI

ASTM 193 Grade

B7 Bolt

Gr. 7 A/F Heavy Hex

Nut Foot Pounds Estimated Load

1 inch 7/8 inch 1-7/16 inches 300 18,150 lbf

1-1/8 inches 1 inch 1-5/8 inches 425 23,690 lbf

1-1/4 inches 600 29,955 lbf

1-3/8 inches 1-1/8 inches 1-3/16 inches 700 36,990 lbf

1-1/4 inches 2 inches 800 46,776 lbf

1-1/2 inches 900 44,760 lbf

1-5/8 inches 1-3/8 inches 2-3/16 inches 1,250 53,400 lbf

1-1/2 inches 2-3/8 inches 1,500 64617 lbf

1-3/4 inches 1,600 62,400 lbf

1-7/8 inches 1,800 72,300 lbs

1-5/8 inches 2-9/16 inches 2,000 76,540 lbs

2 inches 2,200 83,100 lbs

1-3/4 inches 2-3/4 inches 2,600 89,440 lbs

2-1/4 inches 3,000 106,800 lbs

1-7/8 inches 2-15/16 inches 3,700 110,680 lbs

2-1/2 inches 2 inches 3-1/8 inches 4,000 133,200 lbs

2-3/4 inches 5,100 162,900 lbs

2-1/4 inches 3-1/2 inches 6,000 168,200 lbs

3 inches 7,000 195,300 lbs

2-1/2 inches 3-7/8 inches 8,000 213,120 lbs

3-1/4 inches 9,000 230,700 lbs

3-1/2 inches 2-3/4 inches 4-1/4 inches 10,000 268,800 lbs

3-3/4 inches 3 inches 4-5/8 inches 13,000 310,200 lbs

4 inches 14,500 354,000 lbs

3-1/4 inches 5 inches 16,500 369,120 lbs

4-1/4 inches 19,500 401,400 lbs

Table 1 - Bolt Torque Specications

The Data Above is based on bolts lubricated to manufacturer’s specifications. Due to a variation in friction, we

recommend in extreme cases to check with the bolt manufacturer, as the chart represents a guideline only.

14 BREAKTHROUGH PRODUCTS FOR INDUSTRIAL BOLTING

2. Determine the air pressure needed to achieve the desired torque by consulting the Pressure/

Torque Conversion Chart provided with each tool.

3. Open the air supply connected to the FRL unit and run the torque wrench while setting the

pressure on the gauge.

NOTE

The torque wrench must be running while the pressure is being set. When the torque

wrench is stopped, the gauge displays a slightly higher pressure than was set with the

jGun running. This is normal, proper torque is delivered under working load.

Changing the Drive Direction

1. To change the square drive direction from forward to reverse or vice versa.

2. Move the directional lever on the back cover to the left (Tighten) or right (Loosen).

Figure 9. jGun Drive Direction Lever

3. Be sure the lever is fully engaged in either direction before operating the gun.

15

BREAKTHROUGH PRODUCTS FOR INDUSTRIAL BOLTING

Operating the jGun

To operate the jGun:

1. Place the correct size impact socket on the square drive and secure it with the locking pin and ring.

2. Ensure that the square drive is fully engaged into the socket.

3. Engage the socket onto the nut.

4. Make sure the socket is fully engaged onto the nut.

5. Ensure that the reaction arm is placed rmly against a stationary surface such as an adjacent

nut, a ange, or equipment housing. (If using the HYTORC™ reaction washer in place of a

standard reaction arm ensure that it is setup according to the steps in the HYTORC Reaction

Washer Overview section.)

6. Apply momentary pressure to the torque wrench trigger to ensure proper socket engagement

and reaction arm placement.

Figure 10. jGun Operation

7. Torque the fastener by depressing the trigger until socket stops turning and air bypasses the

motor.

!! CAUTION !!

BE SURE THE REACTION ARM IS FULLY ENGAGED AND LOCATED ON

A SOLID, SECURE REACTION POINT. FOR ADDED SAFETY, REMAIN

CLEAR OF THE REAR OF THE REACTION ARM DURING OPERATION.

ALSO, WHEN INITIALLY APPLYING THE TOOL, PRESSURIZE THE

SYSTEM MOMENTARILY; IF THE TOOL TENDS TO RIDE UP OR CREEP,

STOP AND READJUST THE REACTION ARM TO A MORE SOLID AND

SECURE POSITION.

16 BREAKTHROUGH PRODUCTS FOR INDUSTRIAL BOLTING

Loosening a Fastener

1. Set the FRL Pressure to max PSI as listed on Pressure/Torque Conversion Chart.

2. Fully engage the torque wrench socket on the nut.

3. Either place the reaction arm rmly against a stationary surface or engage the HYTORC Washer

Driver over the reaction washer.

Figure 11. Using the jGun with a Reaction Washer

4. Ensure the torque wrench is set to the loosening direction.

5. Remove the fastener.

17

BREAKTHROUGH PRODUCTS FOR INDUSTRIAL BOLTING

jGUN REPAIR AND MAINTENANCE

Although the FRL Unit keeps the jGun self-maintained by continuously provided pneumatic tool oil to

the tool during operation, proper repair and preventative maintenance will ensure the full life span of

your tool.

Maintaining Hoses and Fittings

• Visually inspect air lines and air line ttings before tool use

• Replace worn or leaking air lines

• Tighten leaky ttings

Lubricating the Air Motor

To lubricate the air motor:

1. Turn the jGun upside down and disconnect the air hose at the hose coupling connection.

2. Pour approximately one ounce of air tool oil, or spray a lubricant, into the hose coupling on

the gun.

3. Reconnect the hose and operate the gun, while standing clear of the exhaust opening at the

base of the handle. Excess lubricant will release from this opening upon initial operation.

Calibration

Torque Gun provides a pressure / torque conversion chart with every tool. The stated accuracy is

+/- 5%. If you properly maintain your tool and keep it in good working condition, it will stay within

this stated accuracy. Proper maintenance procedures can be found in this jGun Operations

Manual.

If the torque required is for a critical application or if the torque output is in question, the torque

accuracy or output of a tool can and should be veried through calibration. Calibration is available

by Torque Gun Company for a minimal fee.

For the latest torque conversion charts please visit our website: www.torquegun.com/charts.

!! CAUTION !!

LOOSE FITTINGS CAN BE POTENTIALLY DANGEROUS WHEN PRES-

SURIZED. OVER TIGHTENING FITTINGS CAN CAUSE PERMANENT

THREAD FAILURE.

LOOSE FITTINGS OR OVER TIGHTENED FITTINGS CAN CAUSE PER-

SONAL INJURY AND TOOL DAMAGE.

ENSURE THAT AIR LINE FITTINGS ARE TIGHT, BUT NOT OVERLY TIGHT.

18 BREAKTHROUGH PRODUCTS FOR INDUSTRIAL BOLTING

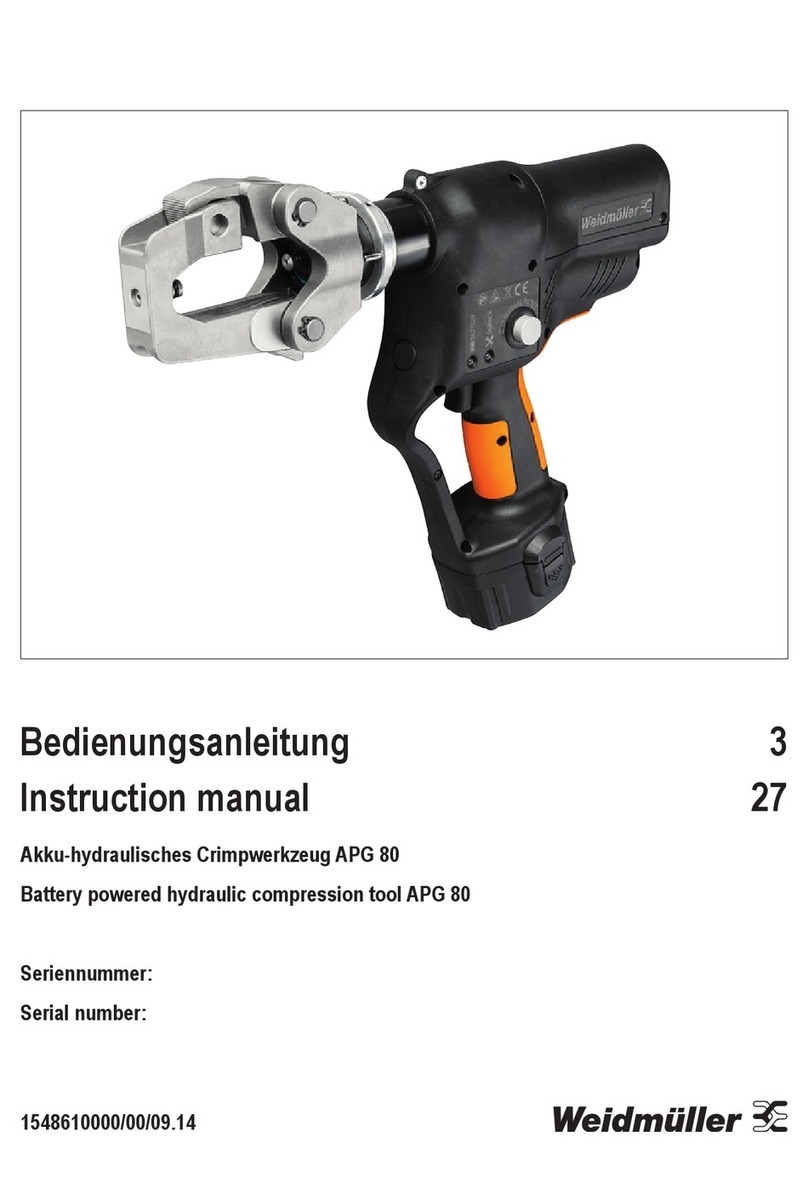

DUAL SPEED PLUS jGUN

The Dual Speed Plus jGun is another innovation of our pneumatic torque wrenches. It gives a user the

ability to select between 2 speeds; high speed or maximum torque. Physically, the Dual Speed Plus gun

is identical to the Dual Speed jGun, with the exception of the clutch wheel located on the barrel of the

gun which guides the shifting mechanism through a twisting action rather than the push and pull of the

standard Dual Speed jGun.

Figure 12. Dual Speed Plus jGun with Reaction Arm

19

BREAKTHROUGH PRODUCTS FOR INDUSTRIAL BOLTING

Shifting Between Modes

The Dual Speed Plus gun has two settings: High Speed and Maximum Torque.

Figure 13. High Speed Setting (Left) and Maximum Torque Setting (Right)

High Speed Setting (NEW STYLE SHIFTER COLLAR)

• To shift into high speed mode, push shifter collar down towards the nose of the gun and turn

counter-clockwise

Maximum Torque Setting (NEW STYLE SHIFTER COLLAR)

• To return to Torque mode, simply turn the shifter collar clockwise

Tool Operation

Before operating the tool, be sure to follow the safety precautions listed in the jGun Safety section

on page 8.

!! CAUTION !!

KEEP LOOSE CLOTHING OR JEWELRY AWAY FROM THE TOOL AS

LOOSE ITEMS MAY INTERFERE WITH TOOL WHILE IT IS IN MOTION

AND POSSIBLY CAUSE INJURY. USE CAUTION AS REACTION ARM

WILL ROTATE WITH GEAR BOX HOUSING UNTIL IN FIXED POSITION.

NOTE

NEVER SWITCH GUN MODES ON THE FLY. When shifting between High

Speed and Maximum Torque modes, make sure the tool is stopped and

fully engaged in either the forward or backward position. To ensure the

shifter is fully engaged in “torque” the red line should be visible and when

fully engaged in “run down” the blue line should be visible. If neither

colored line is visible then the shifter is NOT fully engaged and the

tool is NOT yet ready for use. You may need to jog the gun by gently

pulling the trigger to disengage the clutch. Failure to fully engage tool

may affect the operation of the tool and ultimately result in loss of control

and/or damage to the tool.

20 BREAKTHROUGH PRODUCTS FOR INDUSTRIAL BOLTING

This manual suits for next models

13

Table of contents

Popular Tools manuals by other brands

Chicago Pneumatic

Chicago Pneumatic CP 0017 SVR Safety and operating instructions

MATE

MATE TRUMPF ROLLERBALL DEBURR Use and maintenance instructions

Staubli

Staubli 16BL-MP Series Assembly instructions

Max

Max Twintier RB611T Instruction manual and safety instructions

BGS technic

BGS technic 70954 instruction manual

Rockler

Rockler 57484 instructions