ALLEGEMEINE SICHERHEITSMASSNAHMEN IN BEZUG

AUF DIE WARTUNG FÜR e-STUDIO556/656/756/856/557/657/

757/857

Die Installation und die Wartung sind von einem qualifizierten Service-

Techniker durchzuführen.

1. Transport/Installation

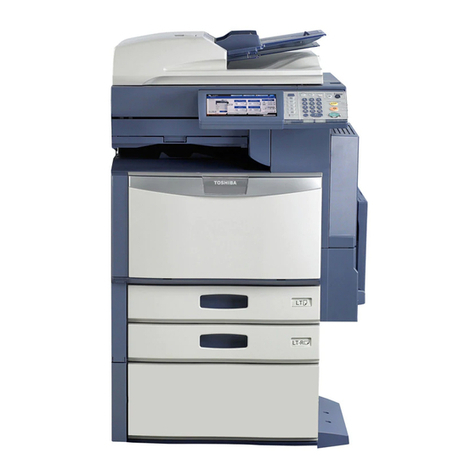

- Zum Transportieren/Installieren des Gerätes werden 4 Personen benötigt. Nur an den in der

Abbildung gezeigten Stellen tragen.

Das Gerät ist sehr schwer und wiegt etwa 203 kg (447 lb.); deshalb muss bei der Handhabung

des Geräts besonders aufgepasst werden.

- Beim Transportieren des Geräts nicht an den beweglichen Teilen oder Einheiten (z.B. das

Bedienungsfeld, die Duplexeinheit oder die automatische Dokumentenzuführung) halten.

- Eine spezielle Steckdose mit Stromversorgung von AC 110 V / 16 A, AC 115 V / 16 A, 127 V / 16

A, 220 V oder 220-240 V / 9 A als Stromquelle verwenden.

- Das Gerät ist aus Sicherheitsgründen zu erden.

- Einen geeigneten Standort für die Installation wählen. Standorte mit zuviel Hitze, hoher

Luftfeuchtigkeit, Staub, Vibrieren und direkter Sonneneinstrahlung sind zu vermeiden.

- Für ausreichende Belüftung sorgen, da das Gerät etwas Ozon abgibt.

- Um einen optimalen Kopierbetrieb zu gewährleisten, muss ein Abstand von mindestens 80 cm

links, 80 cm rechts und 10 cm dahinter eingehalten werden.

- Das Gerät ist in der Nähe der Steckdose zu installieren; diese muss leicht zu erreichen sein.

- Nach der Installation muss das Netzkabel richtig hineingesteckt und befestigt werden, damit

niemand darüber stolpern kann.

- Falls der Auspackungsstandort und der Installationsstandort des Geräts verschieden sind, die

Bildqualitätsjustierung (automatische Gammajustierung) je nach der Temperatur und

Luftfeuchtigkeit des Installationsstandorts und der Papiersorte, die verwendet wird, durchführen.

2. Allgemeine Sicherheitsmassnahmen in bezug auf die Wartung

- Während der Wartung das Gerät ausschalten und das Netzkabel herausziehen (ausser Wartung,

die bei einem eingeschalteten Gerät, durchgeführt werden muss).

- Das Netzkabel herausziehen und den Bereich um die Steckerpole und die Steckdose die

Umgebung in der Nähe von den Steckerzacken und der Steckdose wenigstens einmal im Jahr

reinigen. Wenn Staub sich in dieser Gegend ansammelt, kann dies ein Feuer verursachen.

- Wenn die Teile auseinandergenommen werden, wenn nicht anders in diesem Handbuch usw

erklärt, ist das Zusammenbauen in umgekehrter Reihenfolge durchzuführen. Aufpassen, dass

kleine Teile wie Schrauben, Dichtungsringe, Bolzen, E-Ringe, Stern-Dichtungsringe,

Kabelbäume nicht an den verkehrten Stellen eingebaut werden.

- Grundsätzlich darf das Gerät mit enfernten oder auseinandergenommenen Teilen nicht in

Betrieb genommen werden.

- Das PC-Board muss in einer Anti-elektrostatischen Hülle gelagert werden. Nur Mit einer

Manschette bei Betätigung eines Armbandes anfassen, sonst könnte es sein, dass die

integrierten Schaltkreise durch statische Elektrizität beschädigt werden.

- Setzen Sie sich während der Wartungsarbeiten nicht dem Laserstrahl aus. Dieses Gerät ist mit

einer Laserdiode ausgestattet. Es ist unbedingt zu vermeiden, direkt in den Laserstrahl zu

blicken. Keine reflektierenden Teile oder Werkzeuge, wie z. B. Schraubendreher, in den Pfad des

Laserstrahls halten. Vor den Wartungsarbeiten sämtliche reflektierenden Metallgegenstände, wie

Uhren, Ringe usw., entfernen.

- Auf keinen Fall Hochtemperaturbereiche, wie die Belichtungslampe, die Fixiereinheit, die

Heizquelle und die umliegenden Bereiche, berühren.

Vorsicht: Vor Benutzung der Manschette der Betätigung des Armbandes, das Netzkabel

des Gerätes herausziehen und prüfen, dass es in der Nähe keine geladenen

Gegenstände, die nicht isoliert sind, gibt.