Specification No. TENTATIVE Sheet 4

Toshiba Matsushita Display Technology Co.,Ltd Date: 2008 – 11- 07

Date: - -

New No. LTA057A341F-14

Old No.

←# Special ←& Addition ←Change

8) RECOMMENDED OPERATING CONDITIONS

Don't exceed “the recommended operation conditions” in this specification. (The LCD module should be used within

“the recommended operation conditions”.)

The performance and quality of the LCD module are warranted only when the LCD module is used within “the

recommended operation conditions”. Toshiba Matsushita Display Technology never warrants the performance and

quality of the LCD module when you use the LCD module over “the recommended operation conditions”, although

within “the absolute maximum rating”.

To use the LCD module over “the recommended operation conditions” may have bad influence on the characteristics

and reliability of the LCD module and may shorten the life of the LCD module.

Therefore, when designing the whole set, not to be over “the recommended operation conditions”, you should fully

take care of supply voltage change, characteristic of connection parts, serge of input-and-output line , and surrounding

temperature.

9) FEVER OF THE LED BACKLIGHT

LCD module’s upper and lower end portions (LED portions) get hot. The LEDs are built in the upper and lower end

portions of LCD module as backlight sources.

While LEDs are lit and immediately after turned off, the face of LCD module (display surface), top and bottom faces,

metal portions of right and left side faces, and metal portion of LED unit cover(s) on the back are hot and require

caution.

In case of touching (working on) such portion by necessity, surely disconnect the power to the LCD module

beforehand, protect hands (skin) with low thermal conductive gloves etc. or wait until the temperature of metal portion

gets as low as room temperature, and then touch (work on) the portion while being careful to prevent electrostatic

breakdown.

For Designing the System

2-1 DESIGNING ENCLOSURE

1) MOUNTING HOLES

Use all the mounting holes described in this Specification when assembling a LCD module in a set. Use screws

with a proper size described in this Specification.

∗2) TWIST/WARP

When assembling a LCD module in a set and using the set, be careful not to apply stress, such as twist or warp, on

the LCD module at designing an enclosure of the set. Twist or warp may cause LCD module failures.

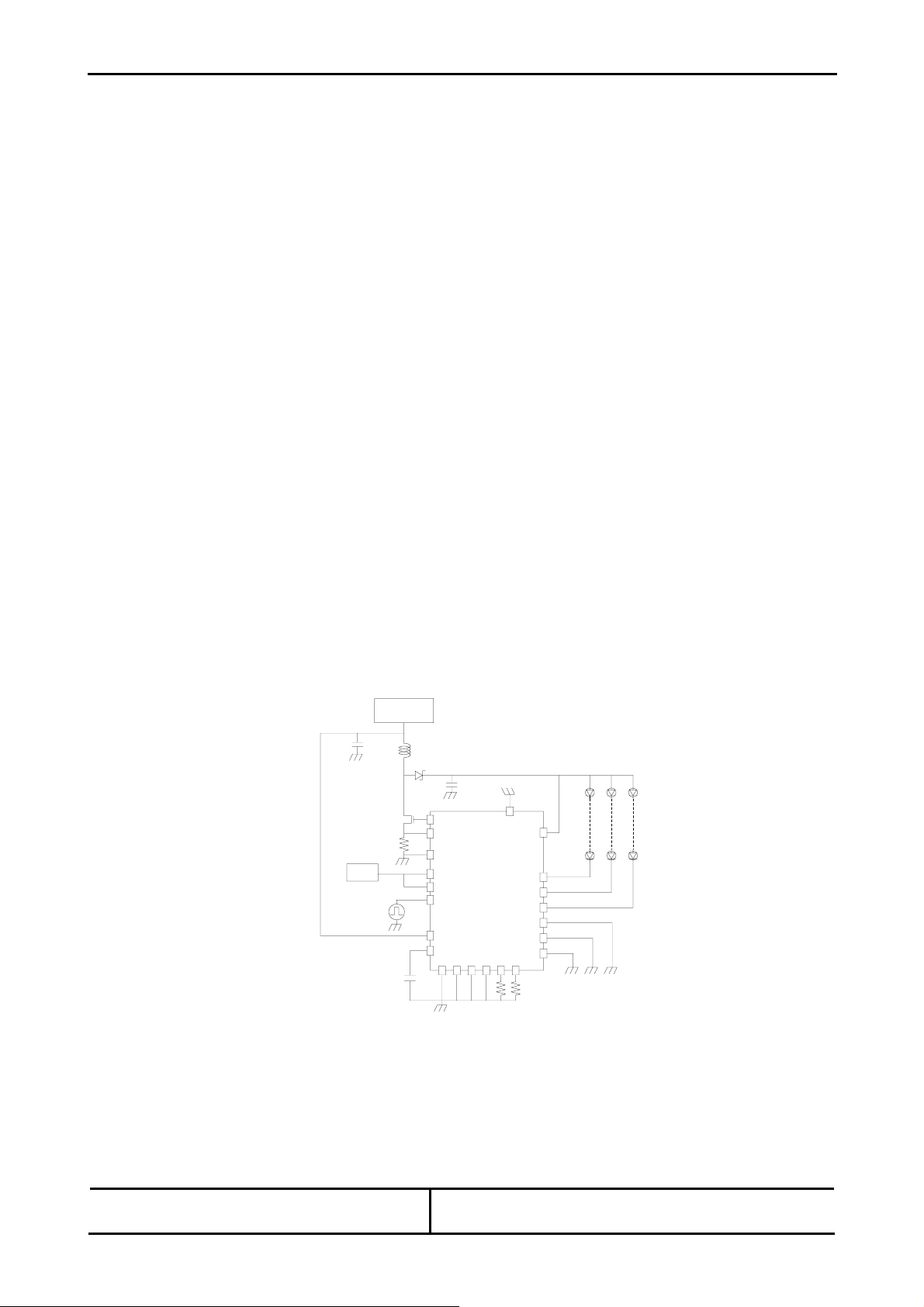

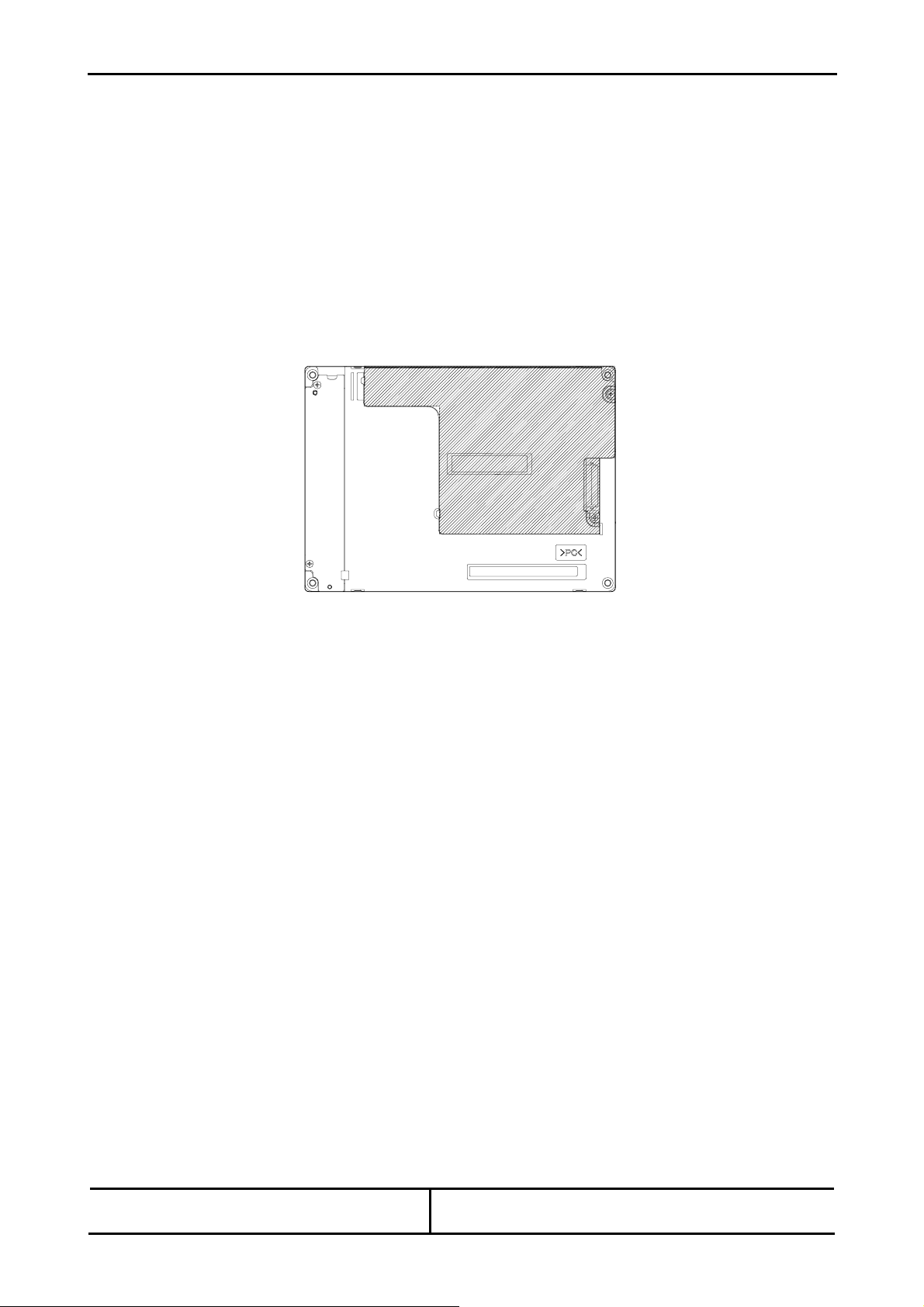

3) DESIGN ON THE REAR OF A LCD MODULE

Design a set so that the LCD module rear is not pressed by a set enclosure or a cable, etc.

Pressing the LCD module rear deforms a panel etc. and may cause ununiformity in a display. Design not to touch

the portion shown in oblique lines of the drawing below. This LCD module uses a light guide plate.

Applying stress on a light guide plate may causes white spots and black spots. Since applying stress on a circuit

board may cause damage, do not touch it.