E

PC.Board

TR623

2SAI015

Y

2SAIOISY

2eSCIBISY

2sCi8i5

Y

|

2Sci8isy

[Close

END

|

OVI

EP

reneenmamnes!

Litas

ten

ak

;

Open

END

i.

MA

R653

R66]

IOK\RE55

D6IS

[S1555

200mSec

l\OOmSec

R658

47K

D6i2

ISIS55

C6IO

1/50

lOK

R652

10

|

i

gO

a

”

(e)

R660

joomec

fe

ee

ACI2Z0/230V

|

\

,AC220V.

50Hz

1

|

te

Aeo

pTu

/\

EPO)

f

|

a

Le

ere

crerrar

ns

QOQQRO

|

50OHz

POWER

PC.Board

AC240V.SOHZ

;

ae

it

res

fone

vee

:

}

Seas

|

;

(TSO)

iS)

LA

|

PEN/CLOSE

|

/\

OPEN/CLOS

An

ON

$5

:

Oo

“sina

i

i

:

I7,3V

[T2

|

eee

g

DS

|

FY

PC.Board

SENSOR

|

emnmmmeentasneenntirns

sei,

mameoaatacastta

me

iSSaNSSA

AA

ALORA

ROTA

NAD

AARNE

ANT

cnc

hesaneainana

ie

CTIA

a

i)

-

ere

ee

_

aie

S90)

j

os

a

Po

|

adc

Lae

ss

TE,

TU.

|

ae

a

nee’;

ete,

Sama

smn

man

eens

eam

pan

dette

seascape,

tent,

aman

annie

teins

amt

i

(SIDE

VIEW)

~

OO"

a

OK

OK

OK

OK

OK

OK

OK

@R609

4.7K

rienedanaerereeenmnenunenanriinniniiestneunstnirennar

ti

@R6EO7

@R6O8

C60]

6

RO

MPD553C-315

omnia

mr

ainnnpanneninnnyneimtnentranananseint

EES

S669

ae

SPEEDS2

ease)

~

|

Muting

OFF

|O.7-V.

jMuting

OFF

]0-

lOOK

TR603,605

TREO?7,

609

R627

TR6O8,610

ZSCIBIS-

GR

1OOK

MOTOR

DRIVE

[-+~

R625

IOOK

R628

TURNTABLE

a

MCI

“CONTROL

PC.Board

—__

ee

ee

-iccsesainininanennsnarniinensrionnebenant

oor

cmnresh

nent

punceatenrt

pnt

nent

eminent

ttm

earneinacmnntminic

inant

sactrninmennacmrnenneentverinccineepebae

ene

9

eo

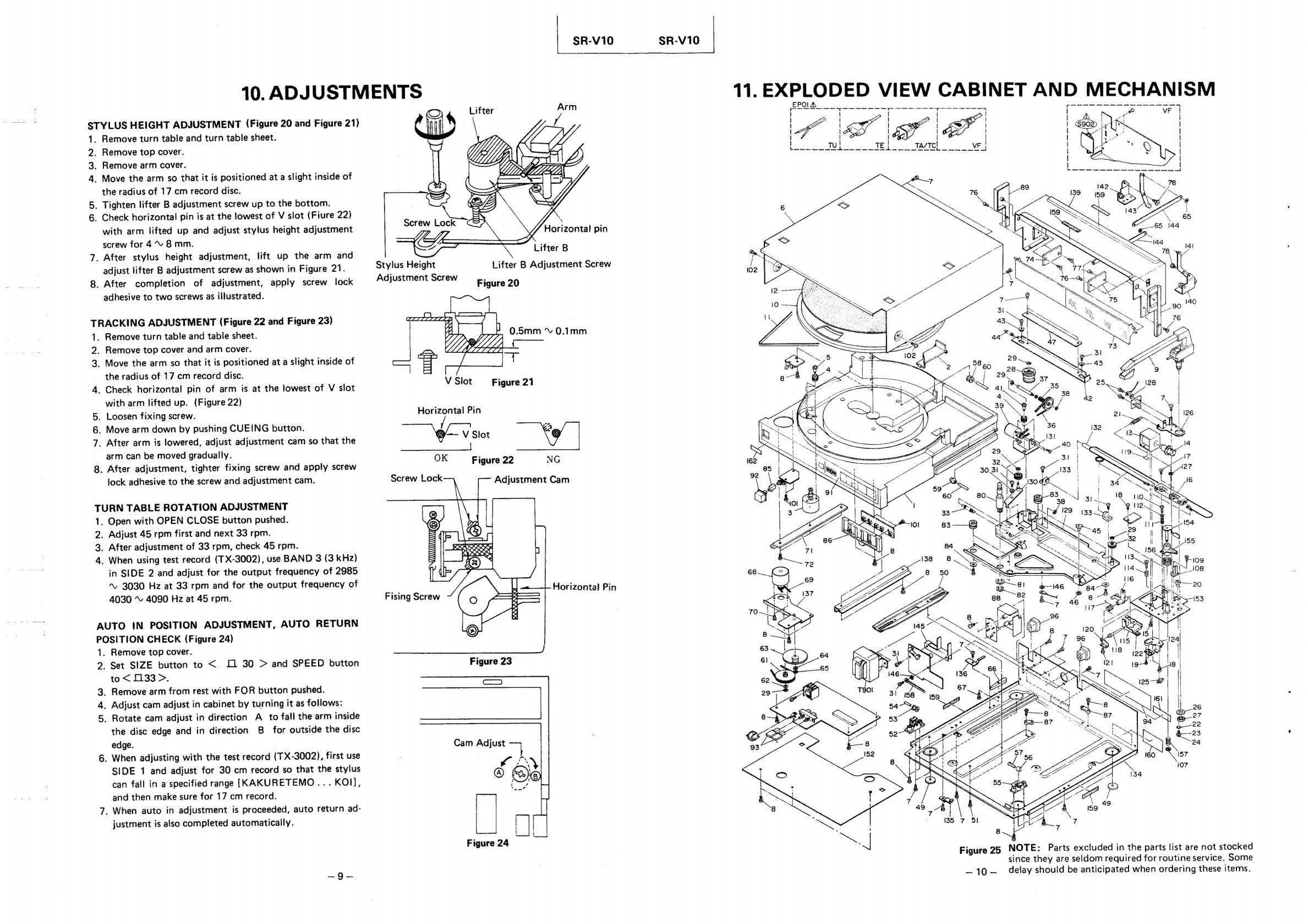

CAUTION:

The

A,

mark,

the

symbol

No.

circled

with

oval

in

the

schematic

diagram

and

the

shaded

area

in

the

parts

list

designate

components

whic

:

i

;

Paes

2

.

5

Fa

a

ree

2

Baron

3

ar?

*

goug

s

,

we

citi

god

go

a

ing

oy

re

eee

ty

64

GG

Co

ica

ed

have

special

characteristics

important

for

safety

and

should

by

replaced

only

with

types

Identical

to

those

in

the

original

circuit

or

specified

hice

Wee

RCs

eae

Zs

|

(

Fem

fy

:

ACI2Z0V

60Hz

|

Lawley

©

TA,

TC

p-l----—

=

J6Ol

REMOTE

CONTROL

JACK

uPD-553C-

315

SYNCHRO

REC

SAIOI5-GR

artnet

Toe

ot

8

9.3V

|

Biv

|

B.7V

oe

R40!

1.5K

|

ith

\

©

:

402-4,

r

j

D401

8

$x

R402

1.8K

:

2SD8soty)

vVDI221

cys

oe

R408

@

Tone

arm

Cartridge

Peewee.

“y

aera

pe

os

\

R404

5K

B

©

i

w)

a

f

IC40|

Sy

:

‘

LA5si2

1°

y

|

Ss

CIR

oxmmmna

UE

©

VE

Ee

AlSei

elecese

scat

osanegpang

eis

ar

Ome

=

|

:

L

Le

“ghost

aco

/

4

PHONO

PRC.

.Board

ott

(ecco!

ia

ed

ory,

ML

ae

OV

|

9,8V

ae

fone

EE.

TStop

|

-9-OV

|

:

:

O6VeC/

BEEE-

DRIVE

Re

are

tr

ge

res

a

ee

MOTOR

ye

ey

Teste

:

[ar

pm]

5.0.

v |

in

the

parts

list.