3R-F330—

|

CONTENTS

1.

OPERATING

INSTRUCTIONS...............-205.

ee

err

creer

2

MOC

VOW

«a

Ss

is

ao

Sb

Se

a

ne

ae

a

ead

erat

ed

ON

eh

ae

a

ey

2

2.

DISASSEMBLY

PROCEDURE:

6.4

dc

Gree

wh

Se

RS

SO

Sr

es

Se

3

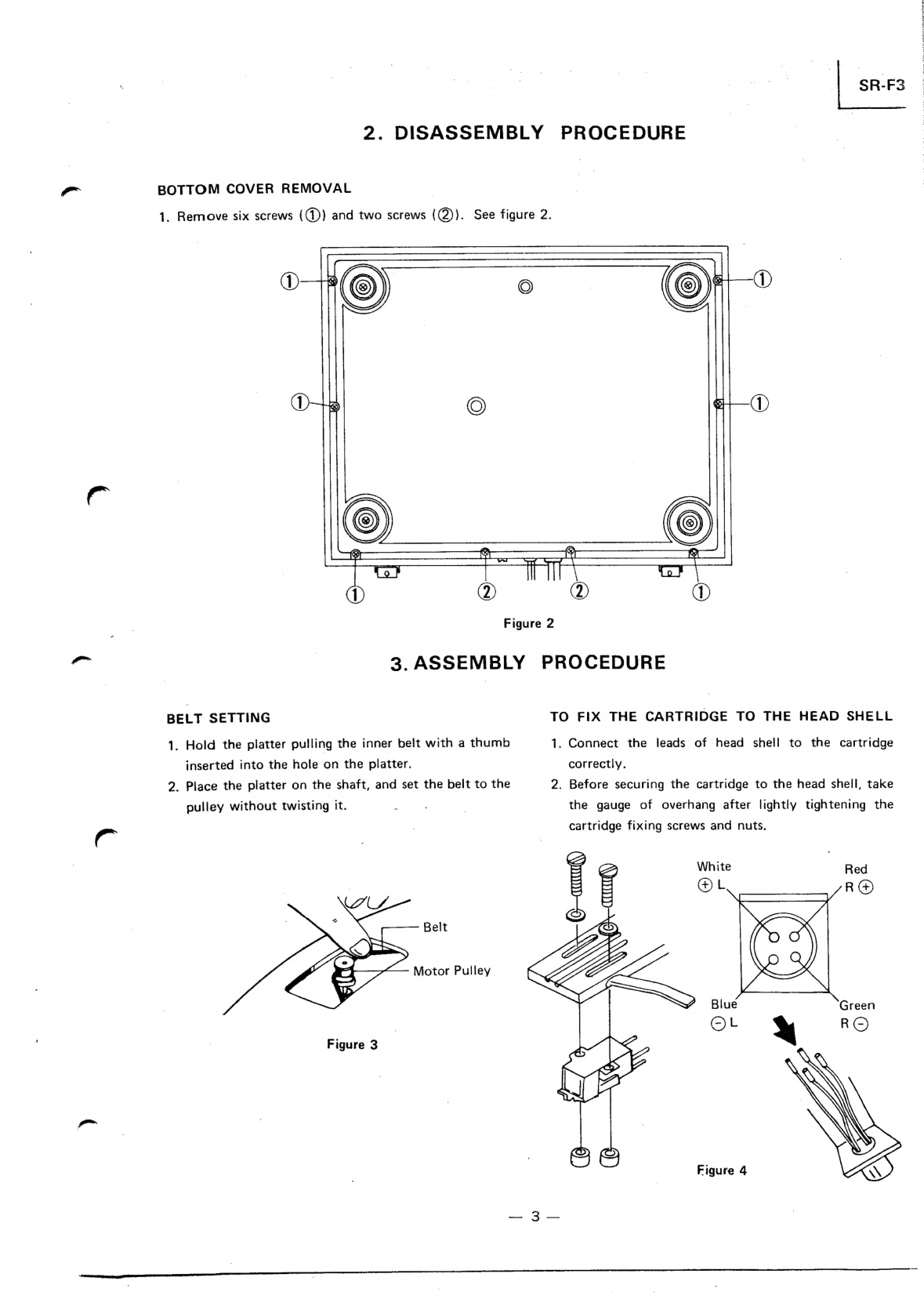

BOTTOM

COVER.

REMOVAL.

«4.605

éc8

eee

es

225

oo

eee

aR

ewe

ees

3

3.

ASSEMBLY

PROCEDURES

c55)cs

Shee

CRESS

SS

Lee

ede

ee

3

BELT

SEVIING

oie

oe

de

ce

eee

woes

Sb

be

Se

ee

ot

Se

ae

3

TO

FIX

THE

CARTRIDGE

TO

THE

HEAD

SHELL

...................

3

4.

ADIUSTMENTS:

:60c0.

eee

ik

Bie

Bh

Ge

et

OE

ee

4

and

9

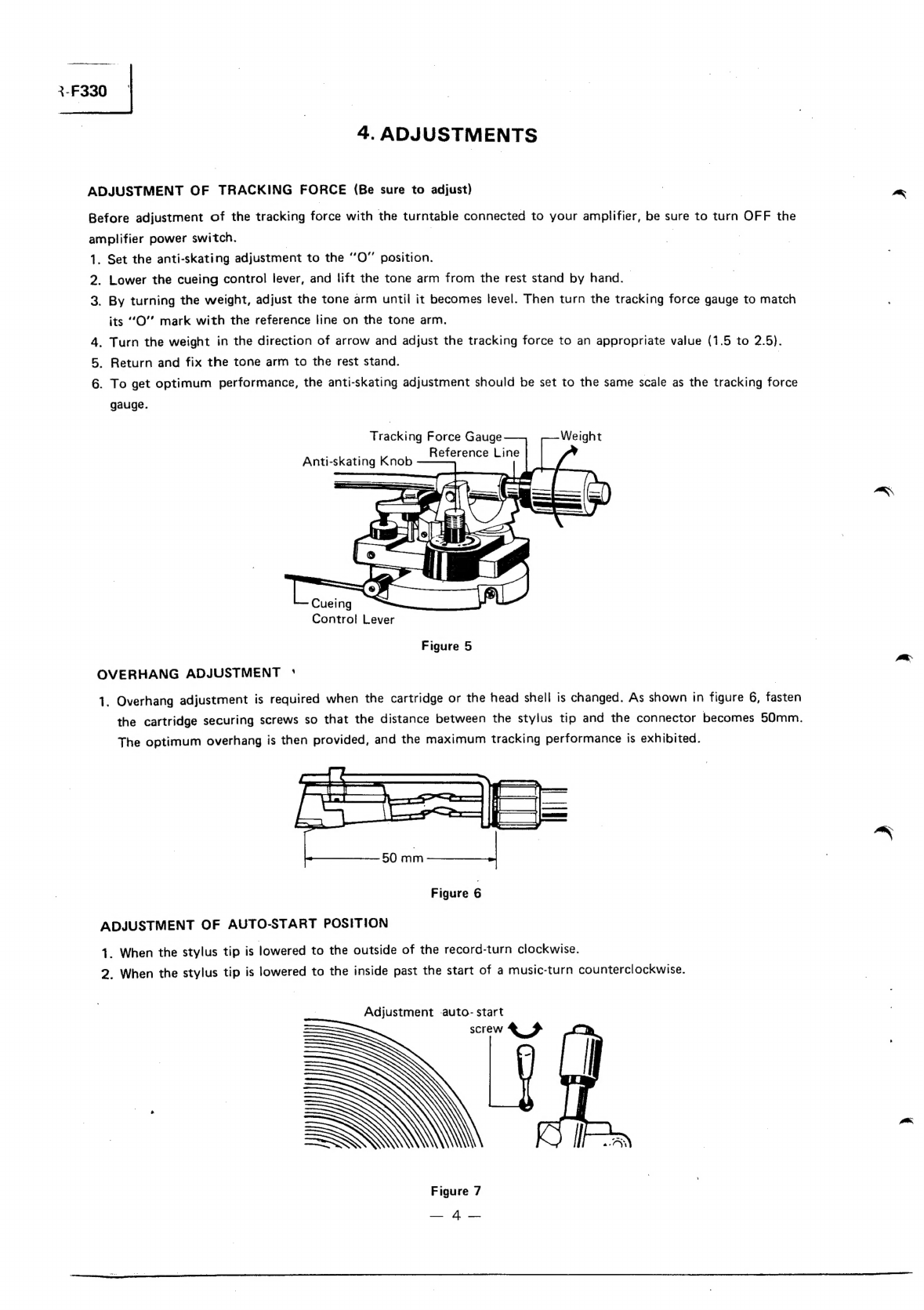

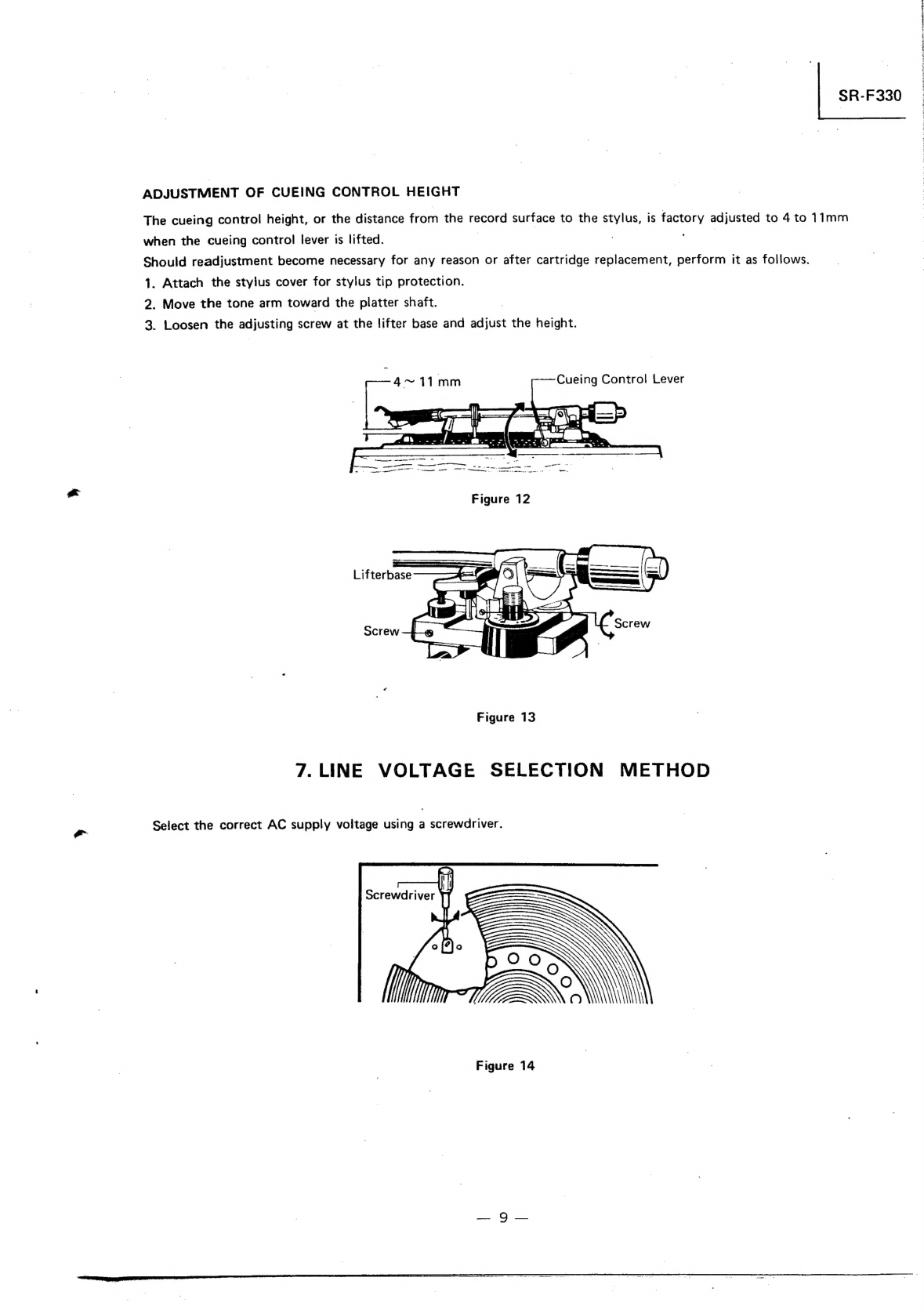

ADJUSTMENT

OF

TRACKING

FORCE

(BE

sure

to

Adjust)

.............

4

OVERHANG

ADJUSTMENT.

5:

cnet

nes

ak

eS

keh

Sie

ee

Se

we

eS

4

ADJUSTMENT

OF

AUTO-START

POSITION

.............-..--..-202-

4

ADJUSTMENT

OF

CUEING

CONTROL

HEIGHT

................-.-..

9

5.

WIRING

DIAGRAM

...........

2...

ccc

ce

ee

eee

ete

eee

5

to

7

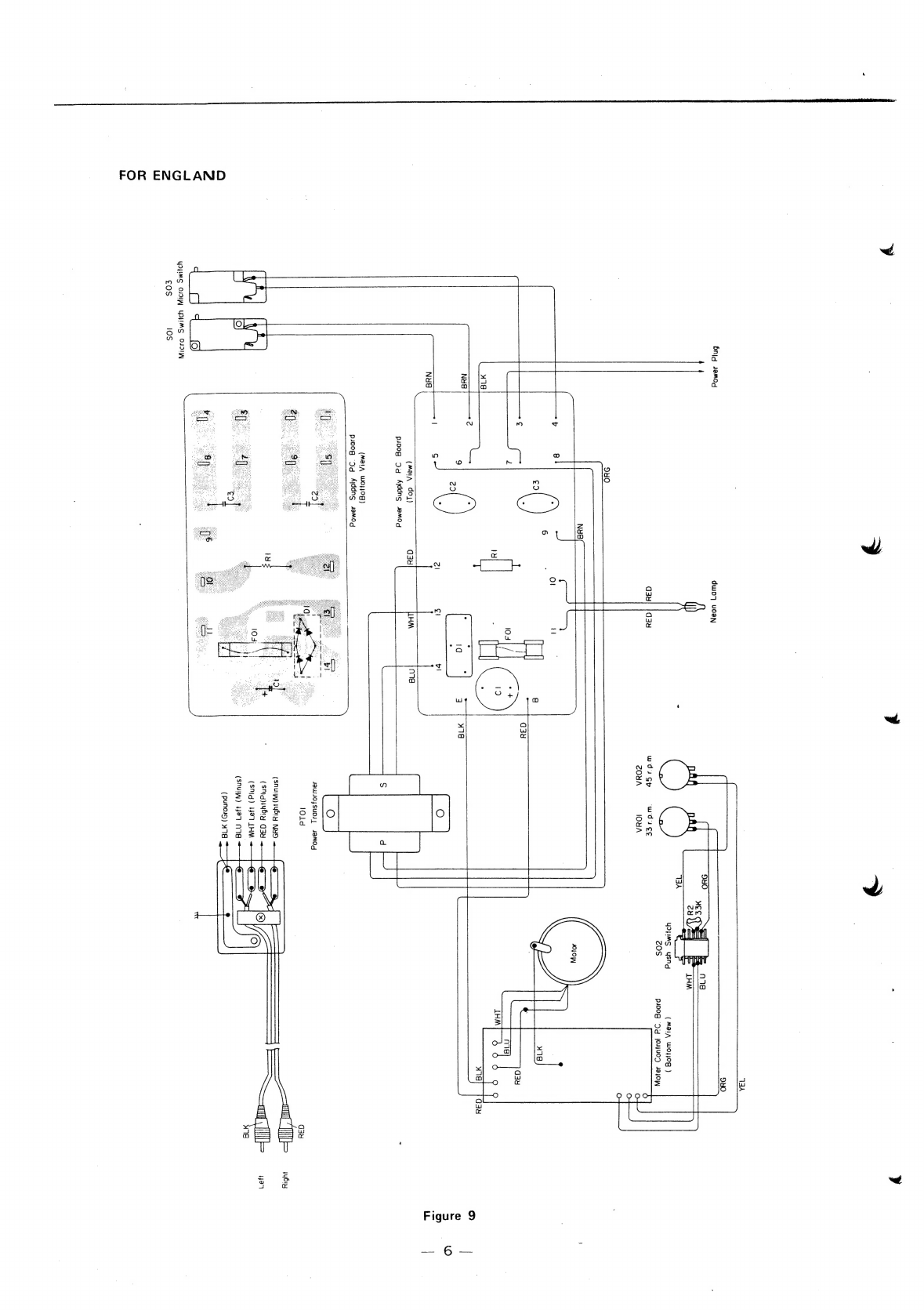

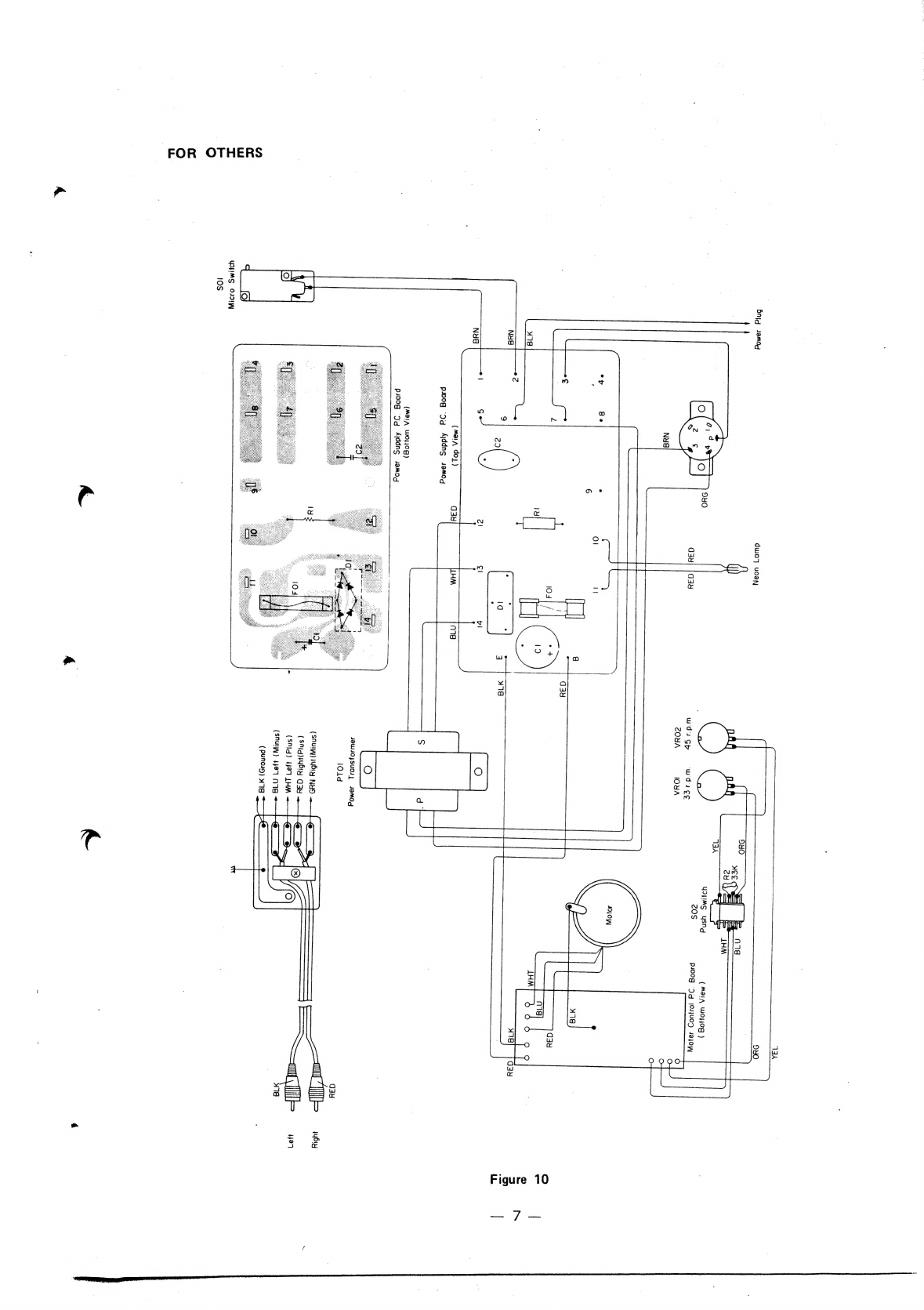

FOR

EUROPE/AUSTRALIA.

.

2.005

were

se

bee

Sh

ee

eee

oe

wee

oe

5

FOR

ENGUAND:

6

ootcstwwsc

Ache

er

bs

6

ee

ees

ee

ee

PS

6

FOR

OTHERS

oct

Giere

wwe

toed

ese

see

st

cate

ees

ee

ee

7

6.

SCHEMATIC

DIAGRAM

.......-.-.

22-2

eee

ce

tee

eee

en

ete

nee

8

7.

LINE

VOLTAGE

SELECTION

METHOD

.................2-..-2-06--

9

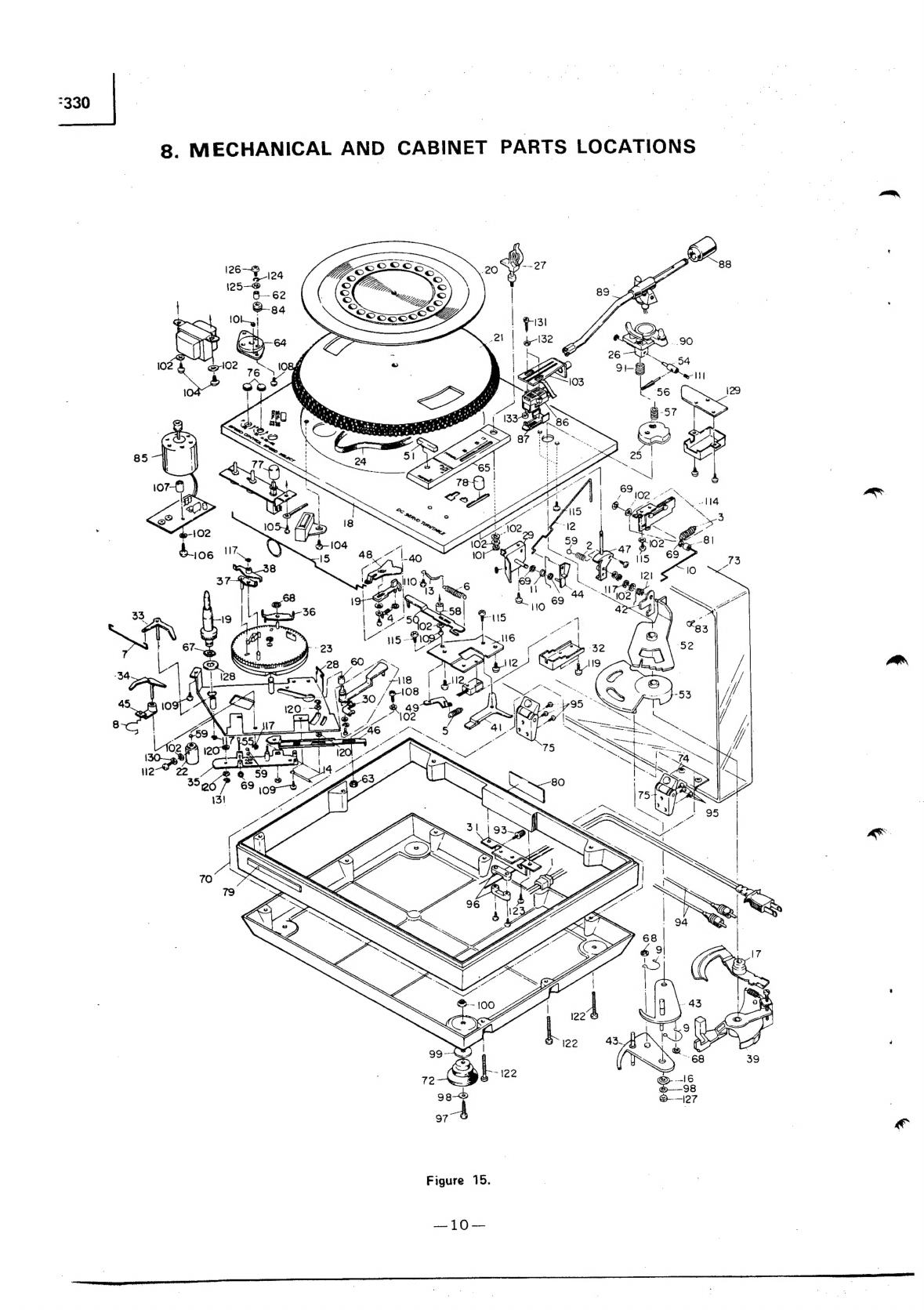

8.

MECHANICAL

AND

CABINET

PARTS

LOCATION

................-...

10

9.

PARTS

LIS!

3:4:2.60o5

2

ae

ee

oe

ees

Ee

Se

ee

11

1.

OPERATING

INSTRUCTIONS

TOP

VIEW

Weight

Platter

Sheet

Tone

Arm

Anti-skating

Platter

Cueing

Control

Lever

Shaft

Rest

Stand

Record

|

Select

Lever

Platter

Strobo

Light

Lever

(play,

cut

repeat)

Head

nae

Speed

Select

"=

65

ol

Figure

1