1

Table of Contents

Manual Structure

Purpose of this manual ............................................................................................... 5

Contents...................................................................................................................... 5

Relative manual.......................................................................................................... 6

1. Installation

1-1. Operating Conditions................................................................................... 1-1

1-2. Power Supply ...............................................................................................1-1

1-2-1. Voltage and Power Requirements ..............................................1-1

1-2-2. Power Cord .................................................................................1-1

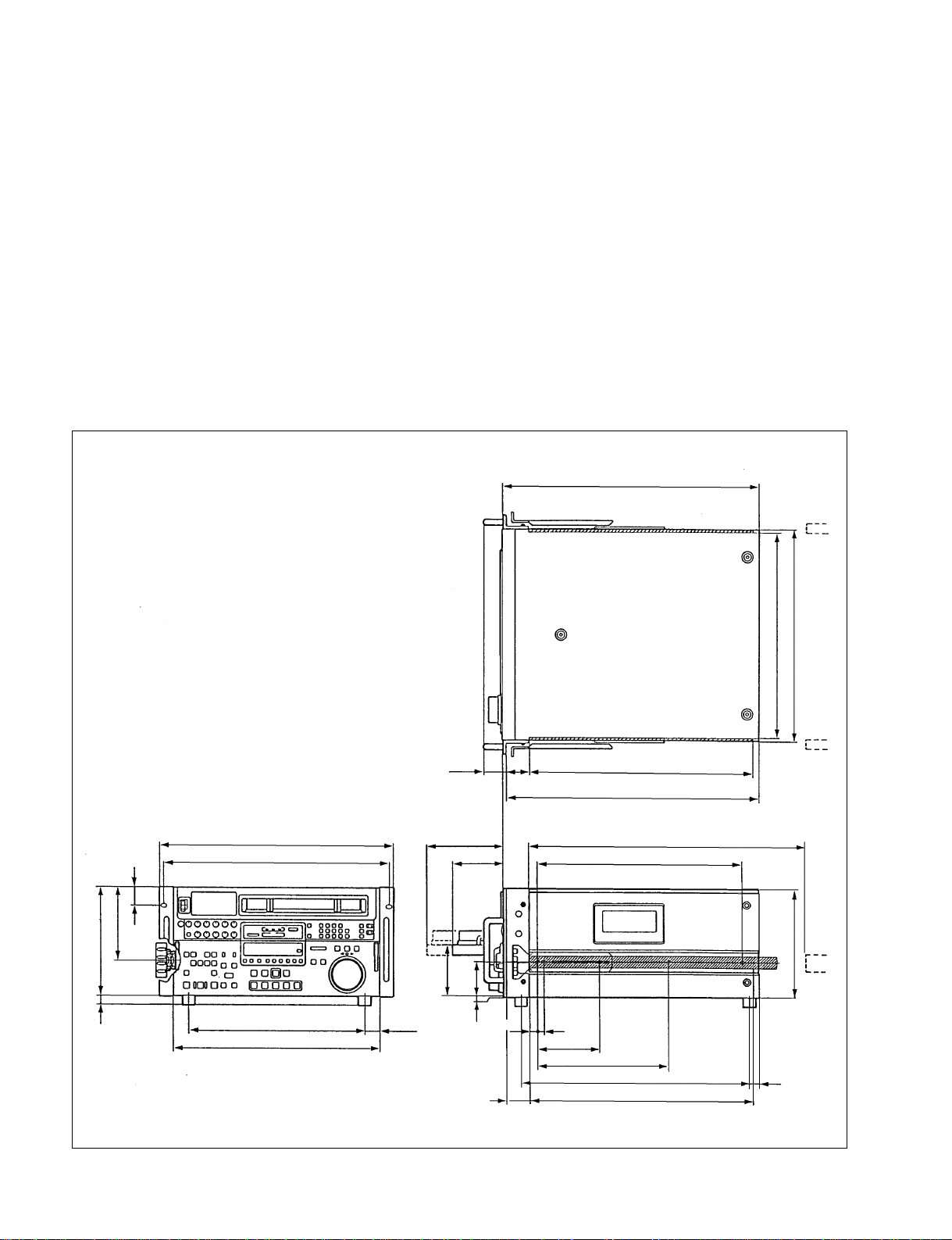

1-3. Installation Space .........................................................................................1-2

1-4. Supplied Accessories and Packing Materials List.......................................1-3

1-5. Rack Mounting.............................................................................................1-4

1-6. Matching Connectors ................................................................................... 1-6

1-7. Signal Outputs..............................................................................................1-7

1-8. Switch/Shorting Land Settings on the Boards............................................. 1-9

1-9. Search Dial Mode Switching .....................................................................1-14

1-10. Installation of BKDW-510/511 .................................................................1-16

1-11. Setup Menu ................................................................................................1-19

1-11-1. Setup Menu Items .....................................................................1-22

1-11-2. Details of the Setup Menu ........................................................1-23

1-11-3. Setting Check Sheet ..................................................................1-28

2. Service Overview

2-1. Notes on Power Supply Block.....................................................................2-1

2-1-1. Warning on Primary Circuit and Electric Shock........................ 2-1

2-1-2. Notes on Resetting the Circuit Breaker ...................................... 2-1

2-2. Removal/Installation of Cabinet..................................................................2-1

2-2-1. Cabinet Removal/Installation .....................................................2-1

2-2-2. Removal/Installation of Plate MD ..............................................2-3

2-2-3. Connector Panel Removal/Installation ....................................... 2-4

2-2-4. Power Supply Panel Removal/Installation .................................2-4

2-3. Cassette Compartment Removal/Installation ..............................................2-5

2-4. Locations of Main Part ................................................................................2-7

2-4-1. Printed Circuit Board Locations ................................................. 2-7

2-4-2. Main Mechanical Part Locations ..............................................2-11

2-4-3. Function and Location of Sensors ............................................2-12

2-5. LED Indicator Infomation on Boards........................................................2-14

2-6. How to Pull out/Push in the Lower Control Panel ....................................2-16