4

Step 6 — Install Indoor Ductwork System — To

maximize airflow in the ductwork system, all ducts should be

kept short and have as few bends or elbows as possible. Forty-

five degree elbows are preferred to 90 degree elbows. Use tees

instead of 90 degree elbows whenever possible.

All duct joints must be fastened with screws or duct sealant

and wrapped with a quality duct tape to prevent leakage.

Aluminum foil duct tape is recommended. Galvanized ducting

from the HRV to the living areas in the house is recommended

whenever possible, although flexible duct can be used in

moderation when necessary.

SUPPLY AIR DUCTING — In homes without a forced air

furnace, fresh air should be supplied to all high-usage rooms

including bedrooms and living areas. Air should be supplied

from high wall or ceiling locations. Grilles that diffuse the air

comfortably are recommended. To avoid possible noise transfer

through the ductwork system, a short length (approximately

12 in.) of nonmetallic flexible insulated duct should be connect-

ed between the HRV and the supply/exhaust ductwork system.

The main supply and return lines to and from the HRV must

be 6 in. minimum. Branch lines to the individual rooms may

be as small as 4 in., but 5 in. lines are preferred. If floor

installation is the only option available, then special care

should be taken in locating grilles. Installation areas, such as

under baseboard heaters, will help to temper the air. In homes

with a forced air furnace, it may be advisable to connect the

HRV to the furnace ductwork (direct connection).

Building Codes and Combustion Appliance Installation

Codes do not allow location of return air grilles or any opening

such as a breathing tee in an enclosed room with spillage

susceptible combustion appliances.

The fresh air inlet from the HRV must be a minimum

distance of 3 ft from the furnace return drop to ensure proper

air mixing and temperature at the furnace core.

Direct Connection — A direct connection requires that the

furnace fan run continuously. See Fig. 13. The fan may be

inter-linked electrically (low voltage) with the HRV accessory

control contacts for intermittent demand.

To hard duct the supply air directly into the cold air return of

the furnace, remember to check the airflow balance of the HRV

with the furnace fan both on and off to determine that it does

not imbalance the HRV more than 10%. Make sure that the

minimum distance from the supply air of the HRV to the

furnace is followed. Refer to the local and National Building

and Heating Codes for any variations in these notes.

EXHAUST AIR DUCTING — The stale air exhaust system

is used to draw air from the points in the house where the worst

air quality problems occur. It is recommended that return air

ducts be installed in the bathroom, kitchen, and laundry room.

Additional return air ducts from strategic locations (i.e., green-

house, atrium, swimming pool, sauna, etc.) may be installed.

The furnace return duct may be also used.

In this method, the exhaust air is not ducted back from

bathrooms, kitchens, etc. to the HRV with dedicated lines.

This method has become popular and provides good

ventilation when installed in accordance with the instructions.

The furnace blower must be running when the HRV is operat-

ing for this method to be effective.

INSTALL DUCTING — To install indoor ductwork, perform

the following:

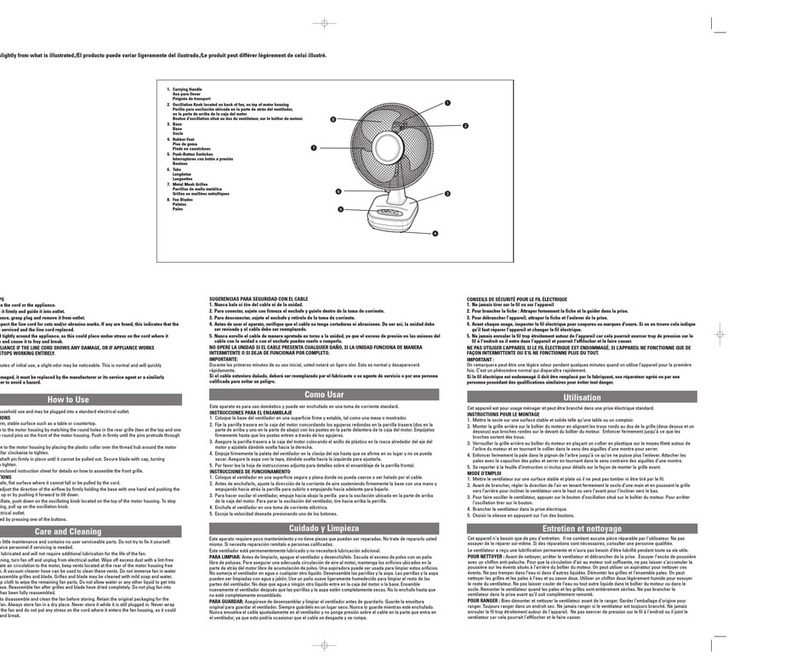

1. Begin with the duct collar on the HRV marked Exhaust

Air In. Slide a short piece (12-in.) of flexible duct over

the duct collar. Using duct tape, tape the flexible duct

to the collar.

2. Run the flexible ducting to the main rigid duct trunk

line, which connects to the remainder of the ducts

going to and from rooms in the house. Repeat the steps

for the Supply Air Out on the side of the HRV.

3. Working from a closet, attic or inside joist wall, run the

length of ducting required for the proper grille location

and cut a hole in the wall.

4. Fasten the mounting collar (field-supplied) to the duct-

ing and fasten the collar to the wall or ceiling with

screws.

5. The field supplied grille may be adjustable. It is rec-

ommended that the grilles be completely opened at

first and then adjusted later as needed.

6. Push the grille into the mounting collar or directly into

installed elbow.

Fig. 11 — Seal Hoods

Fig. 12 — Outdoor Ducting Installation

FROM HRV

Fig. 13 — Direct Duct Connection